Adjusting the pumping station: rules and algorithm for setting up the operation of the equipment

For a stable supply of water with the required pressure values, it is not enough to simply buy a pumping station.The equipment still needs to be configured, launched and properly operated. Admit it, not all of us are familiar with the intricacies of settings. But the prospect of damaging devices through incorrect actions is not very attractive, don’t you agree?

We are ready to share with you valuable information about how the pumping station is adjusted. Our article provides techniques and rules for eliminating operational problems associated with insufficient pressure.

You will learn about the causes of pressure drop and become familiar with methods for eliminating them. Graphic and photo applications will explain how to properly configure pumping equipment.

The content of the article:

Features of the pumping station design

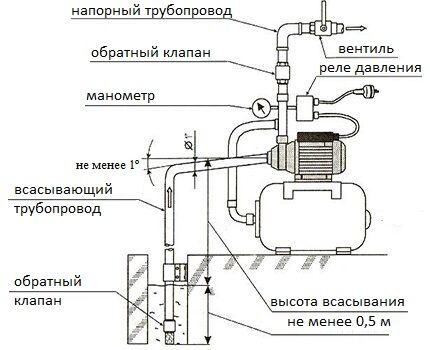

A ready-made pumping station, equipped by the manufacturer, is a mechanism for forced water supply. Its operation scheme is extremely simple.

The pump pumps water into an elastic container located inside a hydraulic accumulator, also called a hydraulic tank. When filled with water, it stretches and puts pressure on the part of the hydraulic tank that is filled with air or gas. The pressure, reaching a certain level, causes the pump to turn off.

During water intake, the pressure in the system drops, and at a certain moment, when the values set by the owner are reached, the pump starts working again. A relay is responsible for turning the device off and on; the pressure level is controlled using a pressure gauge.

Learn more about the principle of operation, varieties and installation diagrams proven in practice. pumping station The article we recommend will familiarize you with it.

Causes of hardware problems

Statistics of malfunctions in the operation of household pumping stations indicate that most often problems arise due to a violation of the integrity of the membrane hydraulic accumulator, pipeline, water or air leaks, as well as due to various contaminants in the system.

The need to intervene in its work may arise for many reasons:

- Sand and various substances dissolved in water can cause corrosion, lead to malfunctions and reduce equipment performance. To prevent clogging of the device, it is necessary to use filters that purify the water.

- A decrease in air pressure in the station causes frequent operation of the pump and its premature wear. It is recommended to measure the air pressure from time to time and adjust it if necessary.

- The lack of tightness of the joints of the suction pipeline is the reason that the engine runs without turning off, but cannot pump liquid.

- Incorrect adjustment of the pressure of the pumping station can also cause inconvenience and even breakdowns in the system.

To extend the life of the station, it is recommended to carry out periodic inspections.Any adjustment work must begin by disconnecting from the power supply and draining the water.

Correction of errors in operation

Before proceeding with more serious intervention in the operation of the equipment, it is necessary to take the simplest measures - clean the filters, eliminate leaks. If they do not produce results, then proceed to further steps, trying to identify the root cause.

The next thing you need to do is adjust the pressure in the accumulator tank and adjust the pressure switch.

Below are the most common malfunctions in the operation of a household pumping station, which the user can try to solve on their own. For more serious problems, you must contact the service center.

Violation of operating rules

If the station operates continuously without turning off, the likely cause is incorrect relay adjustment - the shutdown pressure is set to high. It also happens that the engine is running, but the station does not pump water.

The reason may lie in the following:

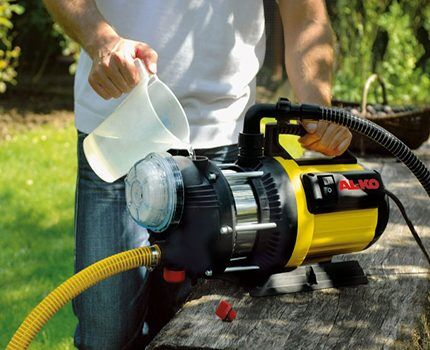

- When first started, the pump was not filled with water. It is necessary to correct the situation by pouring water through a special funnel.

- The integrity of the pipeline is compromised or an air lock has formed in the pipe or in the suction valve. To detect a specific cause, it is necessary to make sure that: the intake valve and all connections are tight, there are no bends, narrowings, or hydraulic locks along the entire length of the suction pipe.All faults are eliminated and damaged areas are replaced if necessary.

- The equipment operates without access to water (dry). It is necessary to check why it is not there or identify and eliminate other reasons.

- The pipeline is clogged - it is necessary to clean the system of contaminants.

It happens that the station switches on and off very often. Most likely this is due to a damaged membrane (then it is necessary to replace it), or there is no pressure required for operation. In the latter case, it is necessary to measure the presence of air and check the tank for cracks and damage.

Less likely, but it may happen that it is open and locked check valve due to debris or foreign objects. In such a situation, you will have to disassemble the pipeline in the area of possible blockage and fix the problem.

Problems with the engine

The motor of the household station does not work and does not make noise, possibly for the following reasons:

- The equipment is disconnected from power or there is no voltage in the network. You need to check the connection diagram.

- The fuse has blown. In this case, you need to replace the element.

- If you cannot turn the fan impeller, it means it is jammed. We need to find out why.

- Relay damaged. You should try to adjust it or, if that fails, replace it with a new one.

Problems with the engine most often force the user to use the services of a service center.

Problems with water pressure in the system

Insufficient water pressure in the system can be explained by several reasons:

- The water or air pressure in the system is set to an unacceptably low value. Then you need to configure the relay operation in accordance with the recommended parameters.

- Pipeline or pump impeller is blocked. Cleaning the elements of the pumping station from contaminants may help solve the problem.

- Air enters the pipeline. Checking the pipeline elements and their connections for leaks can confirm or refute this version.

Poor water supply can also be caused by the fact that air is drawn in due to loose connections in the water pipes or the water level has dropped so much that when it is drawn in, air is pumped into the system.

Inspection of the storage tank

When starting work on adjusting the equipment, disconnect the system from the network and close the pressure valve on the water intake side. Unscrew the tap and drain the water, and drain the remainder through the pressure hose, disconnecting it from membrane tank. First, check the air pressure in the accumulator tank.

The role of the accumulator in the operation of the system

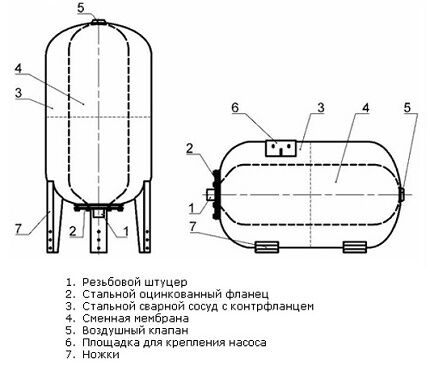

The membrane tank of a pumping station is, in fact, a metal container with a rubber bulb located inside, which is designed to collect water.

Air is pumped into the free space between the rubber bulb and the walls of the tank. In some models of hydraulic accumulators, the tank is divided in half by a membrane, which divides the container into two compartments - for water and air.

The more water enters the device, the more it compresses the air, increasing its pressure, which tends to push the water out of the container. This allows you to maintain a stable water pressure even when the pump is inactive.

The hydraulic accumulator requires regular maintenance, removing air from the bulb, which enters it along with water in the form of small bubbles and gradually accumulates there, reducing the useful volume.

For this purpose, a special valve is provided on top of large tanks. With small containers you have to make some tricks to remove the air: turn off the power to the system and drain and fill the tank several times.

Air pressure control

Although the manufacturer adjusts all elements of the pumping station at the production stage, it is necessary to double-check the pressure even in new equipment, since at the time of sale it may decrease slightly. A device that is in use is inspected up to twice a year.

For measurements, use the most accurate pressure gauge possible, because even a small error of 0.5 bar can affect the operation of the equipment. If it is possible to use a car pressure gauge, with a scale, with the smallest graduation, this will provide more reliable results.

The air pressure in the membrane tank must correspond to 0.9 times the switching pressure of the pumping station (set using a relay). For tanks with different volumes, the indicator can range from one to two bar. Adjustment is carried out through the nipple, pumping or bleeding excess air.

For normal operation, the station is equipped with mandatory control and regulatory devices:

The less air is pumped into the system, the more water it can accumulate. The water pressure will be strong when the tank is full, and weaken more and more as water is drawn.

If such differences are comfortable for the consumer, then the pressure can be left at the lowest acceptable level, but not less than 1 bar.A smaller value may result in the water-filled bulb rubbing against the walls of the tank and causing damage.

To install in water supply system strong water pressure, it is necessary to fix the air pressure within about 1.5 bar. Thus, the pressure difference between a full and empty tank will be less noticeable, ensuring an even and strong flow of water.

Using a relay to regulate pressure

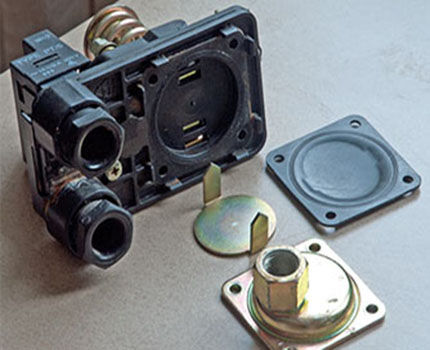

Responsible for system automation pressure switch - a device that controls the pumping station, performing the function of turning the device on and off. It also protects the system from creating excessive pressure.

#1: How the pressure sensor works

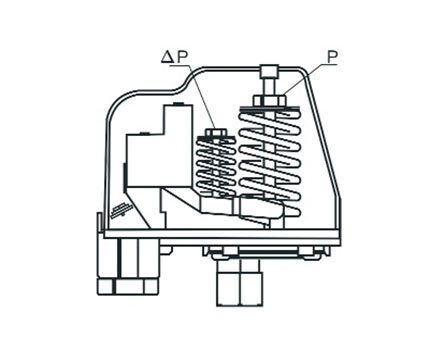

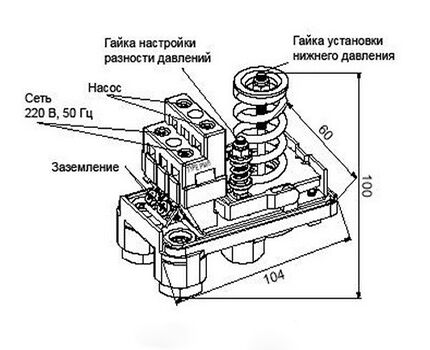

The main element of the relay is a group of contacts, which is fixed to a metal base and is responsible for turning the device on and off.

Nearby there are two springs of different sizes to regulate the pressure inside the system. A membrane cover is attached to the metal base below, under which the membrane itself and a metal piston are located. Everything is covered with a plastic cap on top.

During the operation of the operating device, several stages can be distinguished:

- When you turn on the tap, water flows to the plumbing point for some time from the filled tank. In this case, the pressure present in the system gradually begins to drop, and the membrane stops pressing on the piston. The contacts close and the pump turns on.

- The pump works by pumping water to the consumer, and when all taps are turned off, it fills the water tank.

- As the accumulator tank gradually fills, the pressure increases, and it begins to act on the membrane, which presses on the piston. As a result, the contacts open and the pump stops working.

The frequency of switching on the station, water pressure and even the service life of the equipment depend on how the relay is configured. If the parameters are incorrectly set, the pump will not work at all or will work continuously.

#2: Adjustment and calculation of the required pressure

The new device already has factory relay settings, but it is still better to check them further. When starting to set up, you need to find out the values recommended by the manufacturer for setting the permissible pressure threshold (for closing and opening contacts).

When breakdown of the pumping station, due to incorrect adjustment, the manufacturer has every right to refuse its warranty obligations.

The manufacturer calculates the permissible pressure when turning the device on and off, taking into account the expected operating conditions. They are taken into account in the development of operating parameters for different models of pumping stations.

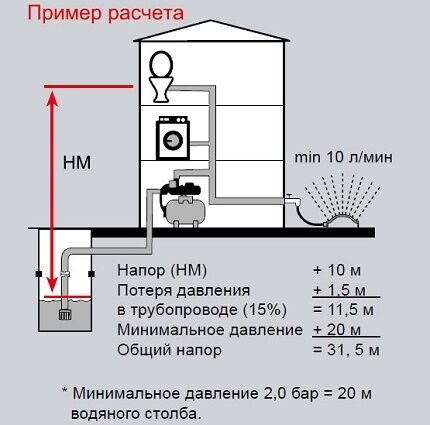

The inclusion value is equal to the sum:

- The required pressure at the highest point of the water supply system where water is drawn;

- Differences between the height of the highest water withdrawal point and the pump;

- Losses in the water pressure pipeline.

The shutdown indicator is calculated as follows: add one bar to the shutdown pressure and subtract one and a half bars. In this case, the shutdown pressure must not be allowed to exceed the maximum permissible pressure that occurs at the outlet of the pipeline from the pump.

#3: Set Recommended Settings

Before changing settings, you must record the previous values using a pressure gauge. After turning on the pump, record the pressure values at the time of turning off and turning on. This will help determine in which direction to adjust - down or up.

Further actions are in the following order:

- Disconnect the station from power, drain the water and open the relay cover with a wrench.

- The pump activation pressure is adjusted by rotating the nut that holds the large spring (P). By twisting it clockwise, the spring is compressed and the required switching pressure is set. In different device models, permissible values can range from 1.1 to 2.2 bar.

- By turning the small nut (∆P) clockwise, you can increase the gap between the cut-out and cut-in pressure of the device, which is usually 1 bar. Thus, the shutdown pressure can be fixed at values in the range from 2.2 bar to 3.3 bar.

An important nuance is that the small spring does not regulate the shutdown threshold, as some people mistakenly understand.

It sets exactly the delta between the values of turning on the station and turning it off. That is, a completely weakened spring will not create a difference - the delta will be zero and the on and off values will be the same. But the more it is delayed, the greater the difference between them will be.

Check the correctness of the set values using a pressure gauge. If it was not possible to achieve the required values on the first try, continue the adjustment.

#4: Selecting non-standard pressure values

You can set a different pressure level in the device, different from the manufacturer’s recommendations, by adjusting the equipment to the individual needs of the user. By increasing the range when switching on and off, the station is triggered more rarely.

This makes the device last longer, but makes the water pressure uneven. By reducing the difference, a stable pressure is achieved, but this way the pump will operate more often.

Conclusions and useful video on the topic

The video will demonstrate how to adjust the pressure of the station:

Video about what to do if the station frequently triggers:

When carrying out independent adjustment of the pumping station, it is necessary to take into account that sometimes changes to factory recommendations can worsen the performance of the plumbing system. Pump, hoses, plumbing fixtures - all have pressure limits, violation of which will lead to breakdowns. Therefore, before embarking on independent actions, it is better to ask for advice from an experienced specialist.

Please leave comments in the block below. Share your personal experience in installing and operating pumping stations, as well as in tuning them. Ask questions, report shortcomings in the text, post photos related to the topic of the article.

At my dacha it often happens that the lights go out. And an old water pump is installed, which is not regulated in any way and sometimes even spits out air. I would like to know from you whether it is possible to install units so that you can regulate the pressure and connect to it a silent device with an independent supply of electricity?! It’s just that I’ve already seen such a device on TV.

Hello. Yes, there are devices whose operating principle is to use water energy, if we understand you correctly. We have sent a signal to our editor-in-chief, perhaps such an article will soon appear on the site especially for you.

Mikhail, hello. I have a pumping station installed at my dacha. Until a certain point, it worked properly, so to speak. One day, when I went home, I forgot to turn off the electricity in the bathhouse and turned off the water. In general, for about twelve hours she worked for me like this. After this I can’t set the pressure switch to turn on and off. The pressure gauge shows about 1 bar and doesn’t raise anything more. What could it be?

We have an apartment on the top floor, maybe this is due to low blood pressure. Water flows from the taps, but without much pressure if turned on at full power. I'm trying to persuade my husband to install a pumping station as booster equipment.Now I doubt that such work can be done independently, without a plumber. It’s easy to connect, but understanding all these adjustments and settings is much more difficult.

Elena, there are other devices for yours. Pressure booster pumps, fully automatic and compact.

Hello. You live in an apartment building and this is not your headache, but the management company’s. The standard water pressure in an apartment is regulated by SNiP 2.04.2-84 as amended in 2012.

According to the rules, the minimum pressure of the water column on the 1st floor is 1 bar, with each subsequent floor + 0.4 bar. If it does not meet the standard, submit a complaint to the Criminal Code in writing, have them come, measure and correct it, or write a refusal with justification, which you will appeal to the housing inspectorate.

How to drain water from a hydraulic accumulator?

Completely only through disassembly.

The method of disassembling and scooping out with a small cup, and then with a cloth. I did this recently when a rubber bulb burst.

Hello. Through the drainage system (automatic drain valve or any mechanical devices), if the tank is equipped with one. The second method is to disconnect it through the water supply pipe and drain the water directly from the pear; it is, of course, desirable that the connection be made through the “American”, this is easier to do.

How to set the upper pressure threshold? The lower one was successfully configured. Switches on at 1.5 bar. But I can’t do the top one. It pumps itself up to almost 4 bar... And the bolt on the small spring is unscrewed. Fully. But she still pumps up to 4. I need up to 3.

Hello. The thing is that the relay with which the pressure is adjusted is quite difficult to set up if you have no experience. But this shouldn't be a problem in the future.

The “P” indicator is responsible for the upper pressure threshold, you need to adjust it, do not touch the clamping nut with the “ΔP” indicator (lower threshold). Most likely the problem is an incorrect adjustment of the spring (relay). I have attached a visual photo. If something doesn’t work out for you, then attach a photo, we’ll think about it further.

Didn't find the topic. Tell me, after turning off the pump, let’s say at 3 atm., the pressure in the system gradually drops and remains at 2 atm. This is fine?

It depends on what pressure parameters you have set on the relay. In total, I understand that the pressure drops after turning off the pump from 3 atm. yes 2 atm. There is also a question about the system itself in which the pump is used: heating, irrigation, water supply. For the first type, this is a problem that needs to be solved; for the other two, it’s natural.

There is water leaking somewhere, check the entire pipeline and check the check valve.

Maybe you can give advice on how to solve the problem.

When pressure is pumped into the system (automatic watering), the pumping station turns off when it reaches 5 Bar and turns on again after 1-2 seconds. This on/off is repeated an infinite number of times. I assume that this is due to an imbalance of air pressure in the hydraulic accumulator and water pressure in the system (automatic irrigation lines).

If you turn off the hydraulic accumulator (cut it off from the system with a tap), then the pump is turned off without comment.In a 50 liter hydraulic accumulator, the air pressure is inflated to 1.5 Bar (as recommended by the manufacturer). The pumping station (pump AL KO 6000) uses an electronic hydraulic controller (AL KO). The switching pressure is 0.8 bar, and the switching pressure is 5 bar. I tried to set the pressure in the accumulator to 0.8 bar. The problem of repeated on/off when reaching 5 Bar does not solve the problem. What do you recommend doing?

Hello. In your case, the problem is directly in the accumulator. Since, judging by the symptoms described, the problem is in the storage tank, I advise you to experiment with the pressure inside the accumulator in both directions (more/less). It may make sense to try a mechanical pressure switch instead of an electronic hydraulic controller. Calibrating the pressure readings in the pumping station itself can also help.

How to configure the pump to turn on/off if the relay is new without factory settings. The pressure in the accumulator is 1b bar. On the old relay it turned on at 0.9 and turned off at 1.5 bar. Vertical lift height 13.8 m.

Thank you for the input data on the pressure in the accumulator, on the indicators of the old relay and regarding the vertical lift height. But alas, this is not enough for accurate consultation. To give accurate advice on setting up a pressure switch, you need to know the current model, as well as which pumping station is used.

Without this data, I can offer general advice on setting up a pressure switch. Let's look at the example of a standard RD-5, where the indicators are set at 1.5 atm from the factory. on switching on (large spring) and 3 atm. to turn off (small spring).

To reduce the switching threshold, you need to twist the large spring counterclockwise. Do not forget that at the same time you need to adjust the small spring. You can view the factory settings on the manufacturer's website. But if they are knocked down, then you will have to adjust using the “scientific poke” method, as they say. Also, you must have an air pressure in the hydraulic accumulator of at least 2.5 atm in order to correctly adjust the RD.

Speroni station, I can’t configure the correct shutdown. It turns on by ear when all the water is released from the accumulator, you add so that the switching threshold occurs earlier, and it stops turning on altogether. Give advice on what to do.

Why does the description contradict the video? On and off is of great importance. And it is absolutely forbidden to make typos.

Thank you for your attentiveness, but it’s still not clear what kind of typo we are talking about? Everything is described in detail in the article. And the moments with turning the pumping station on and off are not confused.

As for the video itself, it contains practical advice, but the title of the video itself is a little inaccurate: “The pumping station often turns on and off.” However, this does not greatly affect the essence.

And the article, as well as the video, gives practical advice on eliminating the causes of frequent switching on/off of pumping equipment:

— adjustment of the expansion tank;

— membrane replacement (must be done once a year).

About setup pressure switch The answer has already been written above and this is also discussed in another video.

The pumping station turns on at 1.4 bar and turns off at 2.8.When it reaches 1.4, it turns on, works for a few seconds at 1.4, and then drops to 0.8 and operates at this pressure (that is, it does not maintain a constant pressure of 1.4 when the water is turned on). The pressure in the accumulator is 1.5. What could be the reason?

Good day. installed a new al ko pumping station. It worked fine for half a day. In the evening it didn’t turn off at all (The pressure was within the normal range, but from the sound there was a feeling that air was being sucked in. Tell me, what should I do?

A question. Towards the end of the decline in pressure in the hydraulic accumulator (about less than 2 atm), the pressure gauge needle drops abruptly and the station turns on, that is, the pressure decreases not evenly, not smoothly, but abruptly. What could it be?

Periodically the station starts up poorly. Could this be due to low voltage in the network? The voltage according to the voltage stabilizer is sometimes 230 W, sometimes 180 W. Neighbors use electric saws, the light blinks. At the station the electric engine is P = 400 W, sometimes poor starting?

Good afternoon. Our pumping station is running, pumping water and air. Turned off when the air came out. Then later all the water containers, the tap, the titanium were filled... After a while it turned on again. She worked for a long time until the air was released. And the pressure is high. New.