Repairing a pumping station with your own hands: typical faults and how to fix them

Unfortunately, even the most reliable pumping equipment can fail.Among the malfunctions are serious breakdowns and banal wear of rubbing parts or seals. Fixing the simplest problems can be done by a home handyman, but you must admit that even basic repair operations need to be known how to carry out them correctly.

We are happy to help you master the difficult work of a household appliance repairman. The article presented to your attention describes in detail all the typical types of breakdowns of pumping units. Effective methods for eliminating malfunctions in water supply installations are presented.

Those who want to repair the pumping station with their own hands will find answers to all the questions that arise in such cases. Useful information is supported by step-by-step photo instructions, diagrams and videos.

The content of the article:

Design and operating features

Using a pumping station, you can solve several problems related to water supply:

- organize the automatic supply of water from the source to the water supply system of the house;

- adjust the water pressure in the water supply system, bringing it to an acceptable level;

- protect the water supply system from water hammer;

- create some water reserve in case of problems with water supply.

Can be purchased pumping station in a ready-made form, which will make its installation a little easier, or assemble it yourself, selecting individual elements depending on your own situation.

For example, if a deep well is used as a water source, it makes sense to replace the surface pump with a suitable submersible model.

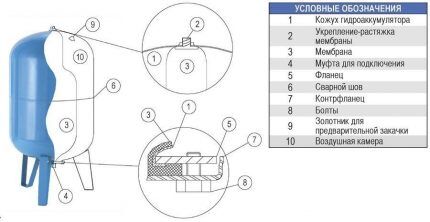

Understanding principles of operation of the pumping station will help you understand the features of repairing this device. Its important part is the hydraulic tank - a container with a built-in rubber liner. Using a pump, water flows into the membrane part of this container. On the other side of the membrane there is air (sometimes pure nitrogen is supplied to the hydraulic tanks, but this is rare).

This combination creates a certain pressure inside the container. On one side of the tank there is a regular car nipple, through which you can bleed off excess air or pump up the missing one.

On the other side there is a pipe installed. The remaining elements of the pumping station and system are connected to it through a special fitting with five outputs: pressure gauge, pressure switch, pump hose, water pipe, etc.

[adinserter name=”mobile: Insertion in text – 2″]The hydraulic tank is connected to the water supply of the house. When the water is turned on, the tank is emptied and the pressure inside the container decreases. When it reaches the set value, the pump automatically turns on and water flows into hydraulic accumulator until it is full and the pressure value reaches the set maximum level.

Switching the pump on and off is controlled by a pressure switch. This is a small device connected to both a hydraulic accumulator and a pump. The presence of such a station has an extremely beneficial effect on both the condition of the water supply system and the operation of the pump.

The hydraulic tank serves as a buffer that protects the water supply from sudden water hammer. The pressure switch reduces the number of pump starts and stops to the required minimum, which extends the life of the equipment.

Although there is a small amount of water inside the hydraulic tank at all times, it should not be considered the main place for storing a large supply of water. The larger the volume of the hydraulic tank, the higher its price.

If you need to stock up on a significant amount of water, it is better to supplement the system with an inexpensive plastic container of a suitable volume. And a small hydraulic tank will cope quite satisfactorily with protection against water hammer.

In addition, it is important to correctly select a pumping station, focusing on the characteristics of the water source and the location of water collection points.

Example of spare parts replacement

First, let's look at an example of replacing the working rings and seals of an automatic pump. The unit operated in the format of a pumping station, pumping water from the storage tank to consumers.

After several minutes of “dry running”, which occurred due to a breakdown of the submersible pump, productivity decreased, the system turned off even with the taps open at the water collection points.

Purchasing spare parts for automatic pumps produced in the CIS countries was not difficult. In Russian monetary units, about 900 rubles were spent.

If, upon inspection of the part of the pump that has not been disassembled, pockets of rust are identified, they should be removed; everything that is accessible must be cleaned of contaminants.

If the new parts of the automatic pump are installed incorrectly, the unit will not work and will have to be redone again. Therefore, it is better to immediately carefully remember or mark the sequence of location and installation side.

Common problems and breakdowns

Since the pumping station consists of several components, a breakdown may be associated with one or more of them, for example:

- the pump is clogged with dirt;

- the pump motor is broken;

- the settings of the pressure switch are lost;

- the integrity of the rubber membrane in the hydraulic tank is damaged;

- there are cracks in the hydraulic tank housing, etc.

As a result, the pumping station either works unsatisfactorily or stops functioning altogether.Sometimes it’s not the station at all, but a breakdown of, say, water pipes.

To determine the cause of the problems, you should consider how the most common breakdowns occur during the operation of the equipment. For example, when figuring out why the equipment turns on but does not turn off, you need to take into account the operating features and pressure switch settings.

When troubleshooting a pumping station, you need to remember that dry running is strictly not recommended for almost all models of surface pumps. Before turning on the pump to check its operation, you should make sure that it is filled with water. If this is not the case, the device must be filled through a special filling hole.

#1: Pump works, but no water flows

If the pump turns on and you can see (hear) that it is working, but no water flows into the container, you need to figure out where exactly this water goes. The first thing to check is: check valve. If it went bad, the water simply poured back out. If there is water in the intake hose, then the check valve is not to blame; you need to look for another reason.

If the hose is empty, it should be removed and the check valve inspected. It may happen that the pumping station does not pump water at all due to simple clogging of the valve holes. It is enough to rinse the device for it to start working correctly again.

Sometimes you need to replace the spring or the entire valve.Of course, after replacing a part or repairing, you should check the operation of individual components of the pumping station, and only then carry out the final assembly and startup of the device.

If there is water in the intake hose, you need to check all joints and pipes between the pump and the tank for leaks. Perhaps the water is simply leaking through a crack or hole. The damaged pipe must be replaced, and the leaky connection must be cleaned, sealed and resealed.

There is a third reason why water does not go to the hydraulic tank: low flow rate of the water source. This happens if for some reason water does not flow into the water intake part of the well or well.

This happens, for example, as a result of silting or sanding. Or the pump for the source is chosen incorrectly; it pumps out water too quickly, and its reserves do not have time to be restored.

How to choose, install and connect correctly pumping station for water intake excavation, is set out in the article, which we recommend that you read.

The pump will most likely have to be replaced; there are special models for low-flow sources. To increase the flow rate of a well, it makes sense to pump it, i.e. wash away accumulated dirt. To flush the well, you should use a separate pump, and not the one that is equipped with the pumping station.

As an emergency measure, it is sometimes recommended to draw water from greater depths, but this recommendation should be used with caution. If the source is sandy, immersing the water intake or submersible pump too deeply can lead to contamination of the pumping equipment and its serious damage.

Another possible reason why the pump stopped pumping water is wear on the impeller. In this case, it will rotate idle. You will have to remove the pump, disassemble it, wash it, replace the impeller, and possibly the pump housing. Sometimes it's easier to install a new pump.

If the above “diagnoses” are not confirmed, it makes sense to simply check the voltage in the electrical network. If it is too low, the pump will turn on, but will not be able to supply water. It remains to establish a normal power supply so that the pumping equipment functions in the desired mode again.

#2: The device turns on, but does not work

This happens with pumps that have not been used for a long time (for example, in winter). Since the clearance between the impeller and the housing is small, these elements, being stationary, can simply “stick” to each other.

When turned on, the pump will hum normally, but the impeller will remain motionless. In such a situation, the device should be turned off immediately.

Dealing with this problem is not difficult; you just need to turn the impeller a couple of times with your hands. If, after switching on, the pump resumes operation, it means that the obstacle has been removed.

Of course, before starting operation, it wouldn’t hurt to flush a pump that hasn’t worked for some time. Sometimes the impeller has nothing to do with it, the capacitor has simply failed. The damaged element must be replaced.

#3: The pumping station operates jerkily

This behavior of equipment is most often typical for situations when problems arise with the pressure inside the hydraulic tank. First of all, you need to check the behavior of the pressure gauge. If the pump turns off as expected when water flows in, but soon there is a sharp drop in internal pressure, the problem should be looked for internally.

Most likely, the membrane in the accumulator has broken. It’s easy to verify this: if you open the nipple located on the “air” side of the container, water will flow out of it, not air.

The hydraulic tank should be dismantled, carefully disassembled, the damaged membrane should be removed and replaced with a new one, exactly the same. Trying to somehow repair a damaged liner is usually useless; it will quickly deteriorate again.

The sequence of work to replace the hydraulic tank membrane is demonstrated in the photo selection:

There are other reasons for a pumping station to operate jerkily. If the liner is not damaged, then air will escape through the nipple. In this case, you need to check its pressure. If it is noticeably lower than 1.5-1.8 atm recommended by the manufacturer, you just need to pump up some air with a suitable pump.

However, first it is better to find out where exactly the air goes.It is likely that there is a crack in the hydraulic tank housing caused by corrosion, mechanical damage or similar reasons.

It is necessary to seal the air leak or replace the hydraulic tank. Finally, you should make sure that the pressure switch is functioning correctly. If this is not the case, the relay must be reconfigured or replaced.

It happens that the pressure switch is simply clogged, especially if for some reason water with a large amount of contaminants entered the station. Clogging of the relay is also observed when salts are deposited if the water has increased hardness. The relay needs to be removed and the inlet hole inspected. After washing and removing contaminants, the device usually works correctly.

If the relay needs to be replaced, you should consider purchasing a more modern model of this device. Such devices are adjusted using arrows and screws, rather than springs, as in models like RDM-5. If you believe the reviews, setting up such a relay is much simpler, and the cost is quite reasonable.

#4: The unit does not respond to shutdown

This picture is typical for situations when pressure switch settings got lost, so the pumping station does not pump water with the required pressure. The cause is not always a broken pressure switch.

It happens that wear on the pump impeller does not allow the required operating pressure to be provided. In this case, you need to slightly tighten the large spring on the pressure switch in the direction marked “-”.

As a result, the upper pressure settings will be slightly reduced and the pump will begin to turn off. The relay adjustment should be done very carefully so as not to completely change the settings and damage the device. In addition, you need to think about repairing the pump to restore its working life, or replacing it with a new device. Incorrect operation of one element can cause an imbalance in the entire system.

#5: Water flows unevenly

It happens that the pump hums and works stably, but the water comes in uneven portions, sometimes it is there, sometimes it isn’t. Most likely, not only water, but also air somehow gets into the pipeline.

It is necessary to check whether the water intake equipment is at the correct depth and whether the water level at the source has changed. By adjusting the position of the water intake hose, the problem can usually be solved.

#6: Pumping equipment does not turn on

If the pump stops turning on, it means either the device is broken or it is not receiving power. First, you should check the device with a tester and inspect the contacts of the pressure switch. It often happens that they need cleaning. It is quite possible that after cleaning the contacts the pump will turn on without problems.

It is much worse if the pump breaks down due to the motor winding burning out. If this is indeed the case, you can smell the characteristic smell of burnt rubber. The motor, of course, can be rewinded, but only an experienced electrician can perform this operation correctly.

It is better to order electric motor rewinding from specialists at specialized industrial enterprises.In most cases, it is easier to replace the engine with a new one than to rewind it.

Recommendations for installation and operation

To reduce the number of problems in the operation of the pumping station, it is important to correctly install the equipment, as well as follow the recommendations for the operation and maintenance of the device. Necessary adjust the pumping station in accordance with the technical characteristics of the source and the required water pressure.

Standards pressure in the water supply system a private house and ways to achieve the required pressure parameters are given in our proposed article. We recommend that you read the useful material.

Here are some important points:

- To prevent vacuum compression of the water supply line, it is recommended to use either metal pipes, or sufficiently rigid PVC pipes, or a vacuum-reinforced hose.

- All hoses and pipes should be installed straight, avoiding deformation and twisting.

- All connections must be sealed and sealed, and their condition must be checked regularly during preventive inspections.

- Do not neglect installing a check valve on the water supply hose.

- The pump should be protected from contamination using a filter.

- The depth of immersion of the hose leading to the pump must exactly correspond to the recommendations of specialists.

- The pumping station should be installed on a level and solid base, using rubber gaskets to dampen the effects of vibration during pump operation.

- To prevent the pump from operating without water, it is necessary to install a special circuit breaker.

- In the room where the pumping station is installed, the correct temperature (5-40 degrees) and humidity (no more than 80%) should be maintained.

It is recommended to check the condition of the pumping station at least once every three months. Separately, you should check the readings and settings of the pressure switch.

Another important preventative step is to bleed the air that is released from the water and fills part of the volume of the liner in the hydraulic tank. On large containers there is a separate tap for this. To remove unnecessary air from the membrane of a small tank, you will have to fill it several times in a row and completely drain the water.

Conclusions and useful video on the topic

Interesting practical experience in repairing the Pedrollo pumping station:

This video clearly demonstrates the disassembly of the station pump and the process of replacing the seal:

However, before performing this procedure, experienced craftsmen recommend inspecting the shaft located underneath. If the metal is excessively worn, the new seal will quickly deteriorate. It is necessary to either restore the shaft (if possible) or completely replace the engine.

As you can see, a number of problems with the pumping station can be fixed on your own. If complex breakdowns occur, you will have to contact specialists. With proper care, the number of breakdowns can be significantly reduced.

If, while reading the material presented, you have any questions or want to share your own experience in restoring the functionality of the pumping station, please post comments.

Didn't help much. My pump has died. Worked great, properly. The second one has already... been taken as a reserve backup. All of a sudden he started punching 220 to the body. I even got an electric shock a couple of times. At the same time, it works itself. There is no burning smell, but the socket is burnt. Help me please.

Just throw it away and everything will be fine.

Turn over the 220V connection plug, i.e. you change the phase with zero, you can check it with a phase indicator, they are sold in electrical goods, they cost pennies. The pump housing must be grounded. The reason may be that the engine is damp, disassemble it and dry it in the oven at 120 degrees.

Seal the pressure switch. It breaks due to condensation.

Hello, I read it with my husband, but we couldn’t understand the reason. The station turns on as usual, but the water from the tap flows in a thin stream. The pressure gauge shows normal pressure. What could be the reason?

Did you pour water into the engine to turn it on and use it? And how far is it from your water intake?

If the pressure gauge shows normal pressure in the water supply system, but there is little pressure coming from the tap, then the problem is with the mixer itself. First of all, you need to unscrew the mesh filter on the gander and clear it of any blockages. If this does not help, then you will have to “dig” deeper, as they say. You need to remove the lever from the faucet, remove the cartridge (you may need pliers). Next, clean the holes from blockages and deposits that form over the years in any case. You may need to replace the cartridge itself on the faucet, which costs about 3-5 dollars.

The pump is installed indoors underground. After a strong squally downpour it stopped working. Apparently, water got on it through a poorly closed hatch. The lights are on, except for one orange one. When disconnected from the network and plugged back in, the orange lamp lights up and the pump turns on. After a few seconds it turns off. However, water still does not flow into the house. I keep pressing the Restart button, there is still no water. While I pointed a heat gun at the pump. I hope it dries out and works. Are there any specialists here? What do you think?

If water gets into the pump, then you will need a full range of procedures for drying its elements, as well as cleaning it from oxidation. Options with drying using a heat gun will not give the desired effect, since oxidation must be removed manually. Judging by your description, I concluded that you have a surface pump installed.

It will be necessary to test the equipment for current faults.Next is disassembling into individual elements, cleaning each individually, plus drying and eliminating oxidation.

If you do not have experience in such matters, then it is better to entrust the repair to a qualified specialist. And for the future, I advise you to install the pump in a place where it will be protected from water and moisture.

Hello, for some reason my nipple is tight, I can’t pump air. How to change it, who knows?

Try to just turn it out, damn it.

The station worked, then went silent... no water flows during operation. The engine turns on periodically, but there is no water. Could this be due to the water level in the well? Thank you.

Hello. The symptoms are not entirely clear from your question. It worked, and then went silent, but it turns on, but there is no water... When you turn on the network, does the station make noise or not? And what does it mean that it turns on periodically? How often?

To answer the last question, yes, the station may not pump water due to the water level in the well when the well is drained for some reason. But the problem may also be in the pump, supply hose, filter clogging, destruction of well walls, silting of the well bottom, blockages, and so on. A diagnosis or more complete information about symptoms is needed.

Good afternoon. After 2 years of using the pumping station, Belamus noticed that the water from the tap gradually began to “spit” after a short break in operation, even overnight, a lot of air accumulated that the station stopped turning off until the tap was opened and the water and air were not allowed to escape. After this, the water began to flow without air, the station gained pressure.Before this everything was great. Now, after a slight stagnation, depending on time, the water comes with air. I checked the membrane, it turned out to be full of holes because water was leaking through the nipple, I changed it, but it didn’t solve the problem. Tell me, what could it be? All connections seem to be fine, maybe a check valve? The pressure doesn't seem to drop on its own. On the pump, under the release bolt (where the water is poured), the only thing that is broken is the thread under the bolt, which was repaired with cold welding, I would blame it on this, but that’s how everything worked before. I do not know what to do. Thanks in advance for the advice.

Help me please! The Unipump hydraulic station does not pump water, the check valve holds water, the pressure in the accumulator is 1.5. The impeller rotates, but the pressure is 0.

Tell me, please, the pump is working normally, but some kind of shavings are coming out of the tap or something. At first I thought it was sand, but no. What could it be? The end of the impeller?

If the pump is working properly and there are no malfunctions in your water supply, then there are no obvious reasons for concern. The so-called chips can be ordinary particles of sand and other elements that rise from the well due to the operation of the pump. To fix this problem, you need to install a line filter. And it wouldn’t be a bad idea to take a photo of the very “shavings” that are bothering you, in order to say exactly what it is. If you still suspect wear on the impeller, then you can remove the pump from the well and check its elements for the presence or absence of damage, and at the same time carry out preventive work.

What malfunctions can occur when the station operates for a long time without water? My pumping station has stopped pumping water...

Most likely, the problem is a malfunction of the check valve, but if you have not used it, then I recommend installing this simple device.

The principle of operation is quite simple: the check valve is immersed in water, after which the hose is filled with water and then connected to the pump. After this, the pump starts. The check valve prevents the pump from becoming airy, as a result of which it may actually stop pumping water. If the pump runs “idle” (it can do this for quite a long time), this will accelerate wear.

I will attach an installation diagram and a photo of the check valve itself, which could be causing the problem.

Good afternoon, the situation is as follows: now the pump is constantly on and makes noise, but the noise is much quieter than it was before when turned on to increase the pressure. Now when it is turned on the pressure gauge shows about 5 atm. — it still doesn’t turn off, when I turn it off by disconnecting it from the network, the pressure immediately drops to about 3 atm, and when I turn it on again, the pump makes noise again and raises the pressure back to 5 atm!

Hello! Can you give me some advice? The essence of the problem is this: yesterday our power was turned off, I started the generator, and after that the pump does not work at all!

Perhaps the problem is that there was a short circuit or power surge, which actually caused these problems. This does not mean that the pump has burned out, most likely it is a fuse, for example.If the pump was connected to the network and you started the generator, then it is quite possible that the fuse or starting device was blown.

It would be great if you could indicate the make and model of the pump so that I can give more accurate advice. In any case, you will have to take a multimeter and “ring” to determine the part that has failed.

Here are other common reasons:

— Burnt contacts on the pressure switch

— The hole for supplying water pressure to the membrane is clogged (I attach a photo);

— There is no voltage on the motor or the motor is faulty (will have to be completely replaced).

Hello! Tell me who can. Pumping station AUPS 126. If left for several days without turning on, the impeller “sticks.” And it doesn’t want to spin without external help.

Hello. In your case, you need to replace the impeller; perhaps simple cleaning will help. Most often, the impeller does not start without external help for these two reasons: blockage or deformation. The design of the AUPS 126 pumping station itself is not complicated, so replacing the impeller will not be a problem.

Good day. Station without a tank. I have such a problem. After draining the water, the station does not turn on; you need to unplug the socket and put the leaking water back into the socket. What can you do?

Hello, in order to pour water further away, I pressed the outlet of the hose, but the water pressure dropped. Can you tell me why this happens? Thank you.

I'm looking for a power supply circuit for the NSS-600/36 pumping station.

Alas, I only found operating instructions. By the way, you can write to the service centers using the contacts listed there, where they can help you. I've done this more than once when I couldn't find a power supply diagram for a pumping station that needed to be repaired.

Often, official SOs will accommodate you and provide documentation. If you succeed, then post it here, it will also be useful to someone later.

Lu-yu-di! Who knows if it is possible to install a pressure switch of another brand on the Speroni CAM 10025 pumping station?

You can install an external one.

you can. look at the pump power and what the relay is designed for

The station works, creates pressure, but sometimes does not turn off.

Hello. If this is a question, then there is very little starting information. When did the device start to malfunction, what are the other symptoms, does it not turn off for a long time or does not turn off until it is cut off from the power circuit, how often does this happen, and so on. You provided too little information for remote diagnostics. There may be a blockage in the module, an incorrectly adjusted relay, a water leak, and so on. In general, I am in favor of adjusting the relay, but this is a preliminary “diagnosis”.

The hole on the relay is clogged, unscrew the 4 screws on the back and clean the hole, wash the cap and rubber seal, reassemble it as well - and everything will turn off. Sometimes you can’t unscrew the relay because the wires are in the way, then you can try unscrewing 4 screws on the spot. If this is not possible, then you need to disconnect the wires.

Hello! I have a Parma station, after 1 year of intensive use it stopped pumping water - it only pumps up to 2.8 ATM and longer than expected.The whole reason is in the venturi tube - a crack appeared. In any case, it’s Chinese... does anyone know where I can get it by mail?

As I understand it, the crack appeared on the tube, which is a removable part of the pump, so there is no need to worry too much. To be precise, this part is called a corner connecting hose. Sold separately, cost about 5-7 dollars, depending on length. You can order such a hose at any plumbing store; it is a popular consumable, only you need to choose the right thread and diameter.

As for Chinese production, their hoses are the same in price as those made in Italy, for example. But here you need to pay attention to the materials:

- brass nuts;

- elastomer hose;

— tube and braid material made of steel.

In terms of price/quality ratio, I can recommend the Italian-made Fado hose.

Pumping station Jumbo 60/45, manufactured in 2007. The impeller does not start. You turn on the water in the tap, the motor “moos”, but the impeller does not spin. I recently replaced the membrane, it leaked and filled with water. Lubricated the bearings. I don’t know, tell me what else can be done? Thank you.

Hello Arnold. This is a fairly common problem for pumps. Moreover, it manifests itself not only at the manufacturer pumping stations Jumbo, but also many others.

The motor is idling, the impeller does not rotate, since the problem lies in the keyed connection between it and the shaft. Often the metal breaks in this place, and the torque from the shaft is not transmitted to the impeller.

I am attaching photos for you that will help you fix the problem. In order not to change the shaft itself, you can “patch up” the groove using brass and a file. It will not be difficult to grind out a piece of brass that will “close” the defect in the keyway.

And the membrane has nothing to do with it in your case. It reacts to changes in pressure, as a result of which the pumping process starts/stops. But it does not affect the rotation of the impeller.

Hello! Need some advice. Installed a Zubr pumping station - 50 liter tank. Everything is working fine. On/off range - 1.5-3.0 atm. But there is one small problem. When reaching 3 atmospheres, the station turns off, but drops to 2.2 atm.

Then the pressure remains normal, there are no leaks, the needle does not fall. It was possible, of course, to use it that way, but the pressure drop is 0.8 atm, and that’s 5 liters of water. There was a filter in front of the pump, I thought it was taking away. I removed it, everything remained the same. I don't understand what's wrong. Maybe someone had this?

Hello, Valery. The filter in front of the pump does not affect the pressure in the system in any way, so you can put it back if you have not already done so. In general, your problem is common; it concerns not only the Zubr pumping station, but pumping equipment from any manufacturer in general.

You need to adjust the pressure in the hydraulic tank. To do this, you need to completely drain the water; using a pump, you can expel all the water through an open tap. First, do not forget to turn off the pump and shut off the water supply to hydraulic accumulator or a storage tank, if it is additionally connected to your system.

So, after you have drained all the water, use a regular car pump to increase the pressure in the tank to 1-1.5 atm. In your case. My system pressure is 4 atm, so I pumped up the pressure in the hydraulic tank to 2 atm.

Friends, tell me.. Gilex station Jumbo relay RDM5, the pump works normally, the standard pressure is 2.8-1.6 The inside of the hydraulic accumulator barrel is 1.6. But periodically the pump does not turn on, it buzzes but does not turn on for 15-20 seconds. Then it starts to work. Sometimes you hit the body of the RDM5 relay, it immediately works, I thought it was a problem with the relays, I changed two Russian ones and installed a third one made in Italy. The filling is the same and the problem also remains.

Hello, please tell me how to fix the problem. Pumping station Marina CAM 40/22 (operating for 3 years). Stopped pumping water. It turns on for 20 seconds and turns off, after a while it turns on again for 20 seconds. etc. The water in the station was filled, I looked at the entrance and there was also water, I pumped up the pressure with a pump. On the pressure gauge there is only an arrow at 0.2-0.3.

Vibes with red failure

Jumbo does not supply water to the accumulator. The pressure gauge is stuck at maximum. It works all the time. It comes out of the tap fine. Out of the blue. It worked fine, then I noticed that it wouldn’t turn off.

P.S. Moreover, the hydraulic accumulator is empty!

Yesterday we replaced the water filter. It stands next to the station. Today the water flows in jerks (pulsates) and the pump turns on in time with these jerks. When the tap is opened, the pump turns on

Good afternoon

Tell me about the DENZEL PS800X pumping station, due to a voltage drop the station pumped 3 atm and did not turn off, it worked for 4 hours until they noticed that the head was very hot. Turned off. After it cooled down, they turned it on. It works but doesn’t pump water, can you tell me what could be wrong? Thank you.

This is the problem...maybe someone can tell me. Marina station, at first it started only if you turned the impeller with a screwdriver, then it stopped working altogether.... It worked for 4.5 years

Good afternoon. Should there be a groove on the shaft for the retaining ring? I have not it.!

Hello, my station pumps from a bucket but does not pump from the well, the pipe length is 7 meters, maybe the impeller is worn out and cannot lift water from the depths

Hello! My station pumps from a bucket, but the pipe doesn’t want to come out of the well, the length of the pipe is 7 meters, maybe the impeller is worn out and can’t lift water from the depths?

STREAM pumping station has been in operation for 3 years. During this time, I pumped air into the hydraulic accumulator 4 or 5 times after the station began to turn on frequently. After pumping it up with a car pump, normal operation was restored. Once again, when trying to connect the pump, water flowed out of the nipple. From repair articles on the Internet I concluded that the membrane was faulty. Naturally, all the valves were closed after the power was turned off and the water was drained. When removing the lid holding the membrane, a fair amount of water spilled out, including from the removed bulb. There is also water in the tank itself up to the level of the hole.

The pear is dirty with brown sediment. I took it outside, washed it in a barrel, filled it full of water, but it didn’t flow out, as if there were no holes.

I ask for advice on what to do.

— Clean everything again, reassemble and try again.

— Buy a new bulb and connect it with it.

- Or maybe there is some other reason why water flows from the nipple, but I don’t know about it,

Can you tell me where I can buy a membrane and whether it is necessary to install additional protection against dry running on the AQUA BOOSNER pumping station?

question. The pumping station suddenly did not start. when connected, it started up, splashed out some of the pumped water into the tank when it was turned off (the day before it worked fine) and that’s it. It is installed in a well with 4 rings. in the well when the forest was dry. I opened the check valve and water came out. what is the reason

Good afternoon.

Help me figure out the cause of poor water pumping by the omnigen jy1000 pumping station.

The pumping station is already 3-4 years old.

When the tap is opened and the water is drained to the supply-return capacity, the pressure drops to 1 atm and water flows in a small stream from the watering hose.

I removed the station, connected the inlet hose to the barrel - this does not happen.

What could be the reason?

Happy New Year everyone, the hydraulic tank on the aquario is leaking, so far that’s the point, I disconnected the tank, put a plug in, everything seemed to work, but then when water is supplied, the pump supplies water in the mode of every second on and off, but if I increase the water flow (I open the second faucet), the pump is working normally... ????

The pump works, but has become very noisy. Is it the bearings or the pump itself?

Water leaves the supply hose (1-inch HDPE pipe). The check valve seems to be fine. If you turn on the consumption source at intervals of several minutes, everything is fine.If the break is 1-1.5 hours, the dry running indicator turns on. There is no water in the supply hose. Need advice on what to do.

Good afternoon. Pumping station Metabo 3500/25 Inox. The thread on the filter cover of the suction pipeline through which water is poured into the pump is torn off. 3 pieces have already torn off. What is the reason?

Workshop video? Tell your technician about mandrels and silicone grease. It's sad to watch.