How a pressure switch works for a pumping station + rules and features of its adjustment

Imagine that to get water at your dacha you can simply open the tap.That there is no need to fill containers with buckets for basic hygiene procedures, cooking, and cleaning. To do this, you just need to install pumping equipment with a pressure sensor, but first you need to understand its structure, don’t you agree?

Our article will introduce you in fine detail to the pressure switch for the pumping station. You will learn how the device works, how it activates and stops pumping. We describe in detail the popular options for pressure sensors and how to adjust them.

The material lists technological nuances and methods for setting up the relay. The information presented is ideally complemented by useful diagrams, photos and video applications.

The content of the article:

The role of the pressure switch in the water supply system

The device, small in size, belongs to the group of automation systems servicing pumping equipment. Its functionality is only possible in conjunction with a hydraulic accumulator.

Despite its small size, the relay performs a number of important functions:

- allows all devices to function in the specified mode;

- Reacts sensitively to changes in on/off thresholds;

- activates and stops the pump when critical values are reached.

Simply put, it regulates the automatic pumping process of water in independent water supply schemes with a membrane tank.The adjustment is made during the switching of electrical circuits when two pressure parameters are reached in the system, accepted as the upper and lower limits.

Buying pumping station, you receive a set of equipment, part of which is a pressure switch. Externally, models of different brands and series are similar, but may differ in shape, size, body color, setting method and location.

When assembling automation yourself, you need to study the characteristics of the devices and choose the most suitable ones for a particular system.

The devices are adapted for convenient installation and maintenance of the pumping station. Most often they are secured with a fitting at the inlet hydraulic accumulator, but can also be mounted in the pipe of the cold water system in close proximity to the device.

Design and principle of operation

The pressure control relay has a simple dismountable design, thanks to which the user can independently adjust the operation of the accumulator, narrow or expand the parameters.

The internal parts are housed in a durable plastic case that resembles an irregularly shaped box. It has a smooth surface and only 3 external working elements: two coupling clamps for electrical cables coming from the network and the pump, and a ¼, ½, 1 inch metal pipe for connecting to the system. The thread on the pipe can be either external or internal.

Inside there is a base to which the working elements are attached: large and small springs with adjusting nuts, contacts for connection, a membrane and a plate that changes its position depending on the increase/decrease in pressure parameters in the system.

The contacts of two electrical circuits, closed when the maximum pressure parameters are reached, are located under the springs, which are fixed to a metal plate. When the pressure increases, the membrane of the hydraulic tank is deformed, the pressure inside the bulb increases, and the mass of water presses on the plate. That, in turn, begins to act on a large spring.

When compressed, the spring is activated and opens the contact that supplies voltage to the motor. As a result, the pumping station is switched off. With a decrease in pressure (usually in the range of 1.4 - 1.6 bar), the plate returns to its original position and the contacts close again - the motor begins to work and pump water.

When purchasing a new pumping station, it is recommended to test the equipment to ensure that all components are working properly. Checking the performance of the relay occurs in the sequence outlined below. As an example, the Haitun PC-19 model.

Mechanical models do not have an indication or control panel, but they can be equipped with a forced activation button. It is necessary to make it function.

Criteria for selecting a relay for a pump

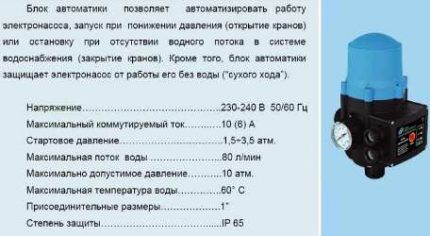

There are many universal models that are sold separately from pumping stations and can be used to assemble a system with your own hands. When purchasing a relay or automation unit, you must rely on the characteristics of the device. They can be found in the technical documentation.

It is important that the relay’s capabilities match the characteristics of the rest of the equipment.

You should start from the nominal pressure, but the upper limit of the operating pressure is also important. It is necessary to take into account electrical indicators and maximum water temperature. A mandatory parameter is the IP class, which indicates dust and moisture protection: the higher the value, the better.

Connecting thread sizes are indicated in inches: for example, ¼ inch or 1 inch. They must match the dimensions of the connection fitting. The dimensions and weight of the devices themselves are approximately the same and are secondary characteristics.

It should also be remembered that there are built-in and remote models. Most commercially available devices are universal: they can be connected directly to hydraulic tank or mounted on a pipe.

Electronic relays have the same functions as mechanical ones: they are responsible for the water supply and protect the pump mechanism from dry running. They are more capricious than simple models and are sensitive to suspended particles in the water. To protect the device, a mesh dirt filter is installed in front of its connection point.

One of the differences from the traditional model is the delay in turning off the pump. If, when the pressure increases, the mechanical device responds quickly, the electronic analogue turns off the equipment only after 10-15 seconds. This is explained by a careful attitude towards equipment: the less often the pump is turned on/off, the longer it will last.

Some switch models, as well as automation units, operate without a hydraulic accumulator, but their functionality is limited to simpler use. Suppose they are great for watering the garden or pumping liquid from one reservoir to another, but are not used in the home water supply system.

At the same time, the technical characteristics of the devices are the same as those of traditional relays: factory setting is 1.5 atm, shutdown threshold is 3 atm, maximum value is 10 atm.

Reasons for customization

The dismountable design of the device and the setup instructions were not invented in vain.Factory parameters rarely meet the requirements of the water supply system, as well as the volume of the accumulator.

Using settings, you can not only “adjust” the upper and lower limits to the optimal values, but also make the operation of the equipment more gentle - for example, reduce the number of pump starts/stops. To do this, it is enough to slightly increase the range between operating pressures - delta.

You may also encounter incorrect settings of the factory model. If the delta is incorrectly coordinated and made too small, the pump will constantly turn on and off, reacting to a minimal increase in parameters.

Recommendations for adjusting the device

By manipulating the springs, you can change the pump shutdown threshold, as well as adjust the volume of water in the accumulator tank. It is generally accepted that the larger the delta, the larger the volume of liquid in the tank. For example, with a delta of 2 atm. the tank is 50% filled with water, with a delta of 1 atm. – by 25%.

First, let's remember the general rules of adjustment:

- to increase the upper response limit, that is, increase the shutdown pressure, tighten the nut on the large spring; to reduce the “ceiling” - weaken it;

- to increase the difference between the two pressure indicators, tighten the nut on the small spring; to reduce the delta, loosen it;

- moving the nut clockwise means increasing the parameters, counter-clockwise means decreasing them;

- To set up, you need to connect a pressure gauge, which shows the initial and changed parameters;

- Before starting the adjustment, you need to clean the filters, fill the tank with water and make sure that all pumping equipment is working.

All adjustment actions are carried out only after testing the system and detecting low performance or obvious errors in operation. It also happens that the station stops working due to a blockage that has clogged the filter or one of the narrow pipes. There is another article on our website that describes the process of adjusting the pressure switch in more detail - go here linkto view the material.

Practical examples of relay configuration

Let's look at cases when turning to adjusting the pressure switch is really necessary. This usually happens when purchasing a new device or when frequent pump shutdowns occur.

You will also need to configure it if you received a used device with lost parameters.

Connecting a new device

At this stage, you should check whether the factory settings are correct and, if necessary, make some changes to the operation of the pump.

To track the progress of work, it is recommended to write down all received data on a piece of paper. In the future, you can return the initial settings or change the parameters again.

The pump stopped turning off

In this case, we forcibly turn off the pumping equipment and act in the following order:

- We turn it on and wait until the pressure reaches its maximum level - let's say 3.7 atm.

- We turn off the equipment and lower the pressure by draining water - for example, to 3.1 atm.

- Lightly tighten the nut on the small spring, increasing the differential value.

- We check how the cut-off pressure has changed and test the system.

- We configure the optimal option by tightening and loosening the nuts on both springs.

If the reason was due to incorrect initial settings, it can be solved without buying a new relay. It is recommended to regularly, once every 1-2 months, check the operation of the pressure switch and, if necessary, adjust the on/off limits.

Situations that do not require adjustment

There can be many reasons when the pump does not turn off or turn on - from a blockage in the communications to engine failure. Therefore, before you start disassembling the relay, you should make sure that the rest of the pumping station equipment is working properly.

If everything is fine with the other devices, the problem is in the automation. Let's move on to inspecting the pressure switch. We disconnect it from the fitting and wires, remove the cover and check two critical points: the thin pipe connecting to the system and the contact block.

If cleaning measures did not help, and adjusting the position of the springs was also in vain, most likely the relay is no longer suitable for further use and should be replaced with a new one.

Suppose you come across an old but working device. Its adjustment occurs in the same order as setting up a new relay. Before starting work, make sure that the device is intact, disassemble it and check that all contacts and springs are in place.

Conclusions and useful video on the topic

Practical video tips will help you better understand how to adjust a new pressure switch at a pumping station if the parameters do not suit you for some reason. You will also learn how the dry running device differs.

Recommendations for setting up automation:

Professional tips for proper adjustment:

Comparative characteristics of two types of relays:

Specialists are usually not invited to correct the operation of the pressure switch, since this is a simple procedure that takes little time. You can leave the factory settings, but even minimal adjustments will help extend the life of the pump and hydraulic tank, and also optimize the operation of the station.

Do you have personal experience in adjusting the relay for the pump and can you share good advice with visitors to our site? Please leave your comments, ask questions, and share your experience in the block below.

The pressure switch in the pumping station is one of the wearable elements. Carrying out independent diagnostics and repair operations is prohibited! However, the cause of system failures is not always a malfunction of the device. I had a case when the pump did not produce the required volume of water, the relay constantly tripped, turning off pumping. After reading a couple of articles on the Internet, I decided that the reason was the hydraulic accumulator. Having disassembled the tank, I realized that the membrane was damaged, which is why water got into the air chamber. I drained the water, changed the bulb, now everything is fine - the pump is working. True, there is still a relay in stock, purchased as a replacement, although the old one has worked for more than 5 years and continues to perform its function properly.

Let me ask, what law or other legal document prohibits the diagnosis and repair of pressure switches? As well as the storage tank, if you had carried out a complete diagnostic immediately, you would have limited yourself to replacing the rubber goods in the tank.

Where was this information when I did all this myself at my dacha) Although my son and I used some sources from the Internet, I don’t remember which ones. Everything went wrong. The relay was installed in almost a couple of hours. But nothing worked because the pressure was not taken into account, and our device did not have protection against “dry running”. Now we urgently need to take an electronic relay and install it. Tell me the price.

You left too little input data; at least you could write what pumping station you have. Look at the Danfoss relay, I bought it a few years ago for about 3000.