Toilet flush mechanism: device, principle of operation, overview of various designs

Without a toilet in the bathroom, it’s hard to call a cottage or apartment comfortable.Agree, this statement is difficult to refute. There are a huge number of models of this plumbing fixture. But they do not differ in the particular complexity of their internal structure; the principle of operation is the same for all modifications.

If there is a breakdown with the water supply, then the flush mechanism for the toilet will most likely have to be repaired - it is the drainage system that most often fails in this plumbing fixture. We are ready to help you quickly deal with this problem.

In this material, we have collected and summarized information about the main types of toilet tanks, breakdowns that may occur, and ways to eliminate them. For clarity, the materials are accompanied by thematic photos and videos.

The content of the article:

Design and types of toilet cisterns

The flush cistern is an integral and one of the main elements of the toilet. This is a container with two or three technological holes for supplying/draining water and a lid.

First, water is drawn into this reservoir, and then, at the press of a button, it is discharged into the toilet bowl to flush the sewage down the drain.

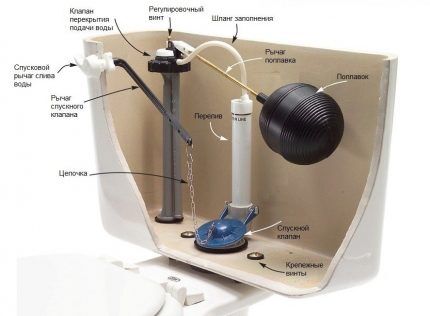

There is nothing particularly interesting or complicated in the design of the toilet flush cistern. There are only a couple of mechanisms inside.

One ensures the supply and shut-off of the supplied water at the moment when it fills the container to the required level, and the second is designed to directly drain the accumulated moisture into the bowl.

Based on the material used, flush tanks are divided into three types:

- Ceramic (faience) - reliable and cheap classics.

- Metal - not very aesthetically pleasing in appearance, but a durable option.

- Plastic (made of polyethylene) – blocks that are light in weight and installation.

According to the method of fastening and location they are:

- low-lying – installed directly on the toilet bowl;

- high-ranking – hung on the wall or located inside it in the installation block.

Separate toilets, in which the tank is separated from the bowl, have a drain pipe for overflowing water. And the higher their storage tank is suspended, the more powerful the water pressure it produces.

Their only drawback is the not very presentable appearance of the tank, located high above the floor. Therefore, most often in domestic toilets you can see models of toilets with tanks placed directly on the edge of the bowl. They are more compact and aesthetically pleasing.

Water supply options

The internal mechanism for supplying water to the toilet flush cistern includes:

- tap (float valve);

- plastic float;

- levers.

Water is supplied to the storage tank through a hole in its body on the right, left or bottom. With the side method, the float is attached to the end of a horizontal lever, which is connected to the valve of the ball valve.

And in the bottom version, the float is connected to a vertical rod located in the supply pipe.

The basic principle of operation of the mechanism for supplying water to the toilet flush cistern is extremely simple. As a result of the emptying of the storage tank, the float, which floats on the water thanks to the air inside, drops following a decrease in the liquid level.

Once at the bottom, it opens the fitting valve on the water supply, and as the tank fills, it rises again and shuts off the water supply.

Everything in the operation of this mechanism is based on the laws of physics. There are no electronics in its design, which significantly reduces the risk of breakdown. It is possible that there is too little or too much water in the toilet tank.

Then the float only needs to be adjusted so that the filling of the tank corresponds to the required parameters. But if the levers are broken, then the float system will have to be changed.

Types of drain mechanisms

If you need to flush unnecessary things from the toilet, we simply press the button on the tank. Everything else happens by itself. The water release mechanism inside is activated, opening the drain valve.

As a result, the water flow rushes into the bowl and washes everything into the sewer system.

The drainage device is activated by:

- by pressing a button;

- pressing the lever;

- pulling the chain (string).

Tanks are available in different shapes and designs. However, most of them are standardized for a volume of 6 or 4 liters and have standard hole sizes for drain valves.

There are a huge number of water drainage mechanisms themselves, different in design. But if the one in the tank breaks, it can be replaced with a new one without any problems.

Our other article contains information about the design of a drainage device - cistern fittings.

The simplest type of drain siphon is a “pear”, shaped like a rubber plunger. Under the weight of water, it is pressed tightly against the drain hole and blocks it.

And when you press the lever, the “pear” rises due to mechanical force and releases water into the toilet bowl.

Then, as the tank fills, it becomes heavier and lowers back onto the seat, again closing the drain hole.

In the event of a breakdown of the water supply device, an overflow is provided in the design of the flush mechanism of the toilet tank. When a certain level is exceeded, the water will flow into this tube and go straight through the bowl into the sewer.

The most common failures of the cistern are discussed in our article: Do-it-yourself toilet cistern repair

Everything is designed in such a way that, by definition, it cannot spill out of the tank. If triggered, such a transfusion will lead to an increase in the readings of the cold water meter, but will avoid a flood.

Structurally, the flush of water in the toilet itself can be horizontal or circular. The first classic option involves supplying water in a continuous stream from one side of the bowl, and the second - forming jets in a circular pattern from its rim.

The horizontal descent is cheaper to implement, but is uneconomical and washes sanitaryware worse. The circular analogue is better in all operational parameters.

However, with a high degree of water hardness, its small holes may become clogged, which will lead to a decrease in the number of jets.

Operating principle of dual-mode drain

Modern models of flush cisterns are equipped with a double flush button. This is a tribute to the fashion for saving water.

Such devices are designed for two operating modes:

- standard – to dump the entire tank into the bowl (4 or 6 liters);

- half – to pour out only part of the volume (2 or 3 liters).

Such a system is more economical in terms of water consumption. But it is also more capricious in terms of setup and repair. The number of internal elements in it is increased, which means the risk of failure of this device increases.

In addition to the dual option, the button for the dual-mode drain mechanism can be one. In this case, the volume of water released depends on the force of human pressure on the lever.

While the button is pressed, the drain hole remains open, and when released it returns up and at the same time the drain is blocked.

Selection and repair of tank mechanisms

When choosing a toilet tank, you have to make a compromise between the price of the flush device and its quality. A structure made of metal elements is more durable, but also more expensive than one made entirely of plastic.

The water supply from below is less noisy than the side one, but you will have to overpay a lot for it. The side-mounted mechanism is simpler in design and cheaper.

The float is made in the form of a hollow sealed cylinder or an inverted glass. The first option is more reliable, but if holes appear in the plastic walls, you can forget about tightness. Water seeping through the holes will inevitably lead to failure of the float.

The principle of its operation is based on the presence of air inside. If punctures appear in the plastic, it must be replaced immediately.

A problem with drain leakage may be due to contamination of the drain valve. It’s just that dirt in the form of rust from old pipes or silt has accumulated between the rubber element and the seat.

In this case, you won’t have to change anything; just remove the cover, lift the cuff and clean everything under it with a rag. But if the rubber is worn out or aged, then it will definitely need to be replaced.

You may also be interested in information on how to replace gasket between the tank and the toilet, discussed in our article.

Before installing the valve inside the tank, it must be secured to the bowl. The design and layout of the toilet cistern are such that after installing the internal mechanisms, it will be problematic to reach the tightening bolts.

First, you should install and fasten the ceramic tank on the edge of the toilet bowl, and only then install all the devices for supplying/discharging water in it.

Repair of the float valve is carried out in the following order:

Adjusting the water level

If water is supplied from the side, then the maximum level in the tank is regulated by changing the length of the spoke. It is at its end that the float is attached. In old and many new models, the role of this lever is performed by a thick brass wire.

You just need to bend it in the middle so that the float moves down or up. The higher it ends up being, the larger the volume of the tank will be filled.

However, now metal is increasingly being replaced with plastic. But it will not be possible to bend the plastic elements at the desired angle; they may simply break.

In this design, the float must be moved along the axis of the plastic pin, thereby increasing or decreasing the lever arm. The farther the float device is from the valve, the more water will flow into the tank.

The float arm in toilet models with bottom water supply is located vertically. Here the water level is much easier to regulate.

The float element simply needs to be moved up/down and fixed at the desired height with the clamps or nuts provided for this purpose.

The main problem when making adjustments is not changing the position of the float, but the need to remove the toilet tank lid. A drain button is attached to it, which in many models is rigidly connected to the drain mechanism.

To avoid breaking anything, this structure should be disassembled extremely carefully. First you need to carefully unscrew the clamping ring of the button. And only after this will it be possible to move the lid without fear.

Have you ever had an unfortunate toilet lid break? You can try to fix it yourself. IN this article we looked at how to do this step by step.

Almost all the working elements of the flush cistern mechanism in the toilet are now made of plastic rather than metal. Because of this, they often break.

Plumbing stores sell both ready-made drain and supply structures, as well as their individual components for repair. In some situations it is cheaper to replace only part of the device, while in others it is easier to replace the entire assembly.

You might also be interested in reading about how to properly disassemble the cisternso as not to accidentally damage anything.

Photo instructions for replacing the device

For home craftsmen who want to completely replace a damaged drainage device, the following photo instructions will help them in their work:

Replacing the drain valve will require dismantling the tank.

To prevent unnecessary contamination of the room and provide yourself with a comfortable place to work, cover the most suitable area with old newspapers or rags.

The process of replacing a drain device is simple, but it requires care and strict adherence to the sequence of steps.

Conclusions and useful video on the topic

We offer useful videos that allow you to better understand the mechanism of operation of the cistern.

Technology for repairing the toilet flush assembly:

Water does not fill into the tank - what can you do:

Ways to eliminate drain tank leaks:

The toilet flush device is not an overly abstruse or complex design. The mechanism consists of two working elements - one for supplying and controlling the water level, and the second for direct drainage into the bowl.

There are several types of these devices, each with their own pros and cons. But the essence of the work is the same in all cases. At the same time, it is not difficult to install, adjust and repair them with your own hands.

Most issues can be dealt with without calling a plumber. Problems can only be caused by installations installed in the wall - for installation and toilet installation repair It is better to involve experienced craftsmen.

Are you familiar with the drainage mechanism of various types of tanks? Or do you use a wall-hung toilet whose cistern is hidden in the wall structure? Perhaps you encountered some kind of breakdown in the drain system and fixed the problem yourself? Please share your experience with our readers by leaving your comments below this article.

It is water meters that force us to look for more reliable mechanisms for toilets.The owners learned to count money. Such a simple design of a float, tap and valve, and at the same time it eventually gives a failure that you will not immediately notice. At first the flow will be constant, but barely noticeable, drip. Then, if you do not intervene and repair it in a timely manner, the process will inevitably intensify.

I agree with Oksana, it was because of the water meter that I decided to check my toilet. And it turned out that it really was leaking. I resolved this issue myself, without the intervention of a plumber. The toilet flush device is a design that couldn’t be simpler and you can fix everything with your own hands. Therefore, I recommend that you look into your “structures” more often, especially for those who already have old toilets; they tend to leak due to the fact that the plastic from which the device itself is made is already outdated.

Thank you very much for the video. Everything is very clear. Is it possible to turn the fastener in the toilet tank, through which water flows into the toilet itself, a little? The reason for the question: the tank is narrow, and the float touches the device that supplies water.

Olga, now there are flat floats on sale with the same 6mm mounting hole. Slowly turn the old float and at the same time pull it down (do not forget to turn off the water supply valve to the tank). New float according to the same scheme, only with upward force.

Our AM toilet has an excellent mechanism. Just like a plumber installed a toilet, it’s been fine for 3 years.

VERY old Soviet toilet, 45 years old, cast iron tank under the ceiling, 1000% reliable. But... now the water is draining, flowing well, but only as long as you pull the chain.But it should be triggered by a short press, it has always been like this. Is it possible and how can I fix this? Apparently the channel is clogged causing water to pour out. Thank you.

I disassembled the toilet tank and began to run quietly. It seems to have been fixed, but I noticed something unclear - the tank filling tube is inserted into the drain tube and when water fills, it runs from below. Who knows why?

the principle of operation is all very well described, but I was interested in the question of how the drainage of water is coordinated with the supply of water from the point of view of saving water, because as water is drained from the tank, water gradually begins to flow and the newly incoming water can pour out until the outlet valve closes and a moment may come when the speed of flowing out will be equal to the speed of flowing in and the water is constantly flowing, I would like the opening of the inlet valve to occur after the closure of the outlet valve. This problem interested me, thank you for your attention.