Bypass in the heating system: why is it needed + how to install it

All its key elements are installed through the bypass in the heating system of a modern house. This simple engineering solution facilitates the maintenance and repair of equipment connected to the main line.It also increases the efficiency and economy of heating, which is not bad at all, isn’t it?

Do you want to add a bypass to your heating system, but don’t know how to do it correctly? We will help you cope with the task - the article discusses the purpose of this element of the heating system and the key points of its installation.

Visual photos and accessible recommendations will help even a beginner cope with installing a bypass on his own. In addition, videos have been selected demonstrating the step-by-step process of assembling the bypass section.

The content of the article:

What is a bypass?

A bypass, or bypass bypass, is a pipeline that serves to organize the flow of coolant bypassing a certain section of the heating main, or parallel to it.

Most often, some equipment is installed in this area. One end of the bypass pipe is connected to the inlet pipe, the other to the outlet pipe.

Shut-off valves are installed between the bypass and the inlet of the device being rounded. It allows you to completely redirect the flow of water along an alternative path, or regulate the amount of liquid entering the device.

To make it possible to completely turn off the equipment, install a tap on the outlet pipe - between the outlet of the device and the bypass.

Types of heating system bypasses

Shut-off valves are installed not only on the inlet and outlet pipes, but also on the bypass itself.

Depending on the type of device used, there are three types of bypass pipes:

- unregulated;

- with manual control;

- automatic.

Each type has its own design and application features.

Type #1 - non-adjustable bypass pipe

An uncontrolled bypass in a heating system is a regular bypass pipe without any additional equipment.

The lumen of the pipe is constantly open and the movement of liquid through it occurs in an uncontrolled mode. The main application of such bypasses is when connecting radiators.

When designing a heating system, it should be taken into account that the liquid will pass along the path with the least hydraulic resistance.

Therefore, the diameter of the flow area of an unregulated bypass installed vertically must be smaller than the diameter of the flow area of the main line. Otherwise, under the influence of gravity coolant moving in the system will go to a nearby bypass.

In horizontal heating wiring other laws apply. A hot medium tends to rise upward because it has a lower specific gravity.

Therefore, the bypass of the lower wiring is usually made equal to the main line, and the pipe going to the radiator is smaller.

Type #2 - manually controlled bypass

A bypass with a ball valve installed is called a manual bypass. A valve of this type is most suitable for a bypass, since when open it does not reduce the internal clearance of the pipeline.

Consequently, it does not create additional hydraulic resistance to fluid movement.

The use of a shut-off device allows you to regulate the amount of liquid passing through the bypass. If the valve is closed completely, the entire flow will follow the main path.

It should be taken into account that the working elements of ball valves tend to stick to each other if the device is not in use. Therefore, such a tap should be turned periodically, even if this is not necessary.

Scope of application for manually adjustable bypasses in heating systems: connecting radiators single-pipe line and piping of hydraulic pumps.

Type #3 - automatic bypass option

An automatic bypass is installed in the pump piping of the gravity heating system. The coolant in such a line can circulate around the circuit without a pumping unit.

An electric blower is installed in the system to increase the speed of fluid movement, which contributes to less heat loss, uniform heating of the premises, and increased system efficiency.

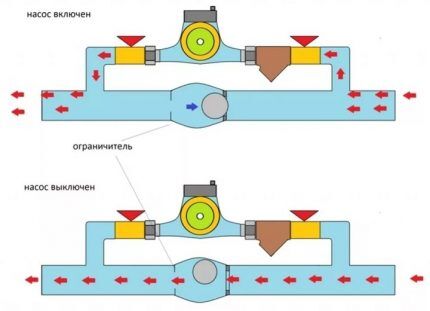

Redirection of fluid flow in a pump system with automatic bypass occurs without human intervention.When the pump is running, the coolant flows through the unit, and the bypass is closed.

If the pump stops due to a breakdown or power outage, the coolant flows through the bypass. The immobilized impeller of the unit limits or completely blocks the flow.

There are two types of automatic bypasses:

- valve;

- injection.

In the first case, a check ball valve is installed in the bypass pipe, which creates the least hydraulic resistance and practically does not interfere with the direct movement of liquid in gravity mode.

When the pump is turned on, the flow rate increases. The coolant from the outlet pipe enters the main line and diverges in both directions.

Further along the contour it moves unhindered, and when moving in the opposite direction it encounters check valve.

Since the hydraulic pressure on the side of the outlet pipe is higher than on the side of the inlet pipe, the ball is pressed tightly against the valve seat and completely blocks the lumen of the pipeline.

The disadvantage of the valve bypass is its sensitivity to water purity. The ingress of contaminants - scale flakes, rust, scale - leads to its failure.

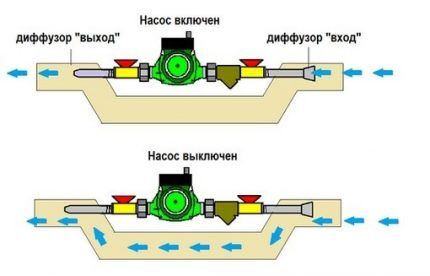

The injection bypass operates on the principle of a hydraulic elevator. A pump unit located on a pipeline of a smaller diameter is welded into the main line of a large diameter. In this case, the inlet and outlet pipes have a continuation inside the main pipeline.

When the pump is turned on, part of the flow enters the diffuser of the inlet pipe, passes through the unit and is accelerated.

The outlet pipe has a slight narrowing and is a nozzle through which liquid under pressure is ejected into the main line at high speed.

Behind the cut of the outlet pipe (along the direction of movement of the coolant in the main line), a vacuum area is created. Due to this, liquid is drawn from the bypass. The jet escaping under pressure carries the environment with it, transferring kinetic energy to it.

Thus, the entire flow accelerates further along the highway. This directed movement of the liquid eliminates the occurrence of reverse flow.

If the pump is not running, the coolant calmly passes through the bypass in natural circulation mode.

[caption id="attachment_13222" align="alignnone" width="430"]

Purpose of the bypass pipeline

The main purpose of the bypass section is to maintain circulation in the heating main in the event of a breakdown of the connected unit or a power outage.

Any device connected via a bypass can be disconnected from the hydraulic line by simply closing two valves - at the inlet and outlet. After this, the entire coolant flow will go through the bypass pipe.

A device disconnected from the mains can be easily repaired or scheduled maintenance performed. You can completely disconnect it and replace it with a new one.In this case, there is no need to stop the system and drain all the coolant.

In an individual heating system, a bypass is used in the following cases:

- Inserting radiators into a single-pipe main;

- Harness [link_webnavoz]circulation pump;

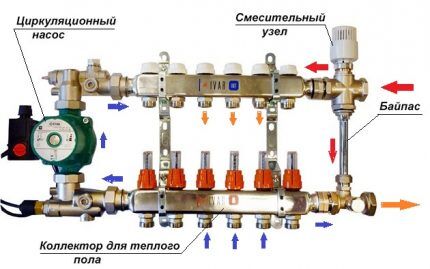

- Connection distribution manifold when installing water heated floors;

- Organization of a small circulation circuit when using a solid fuel boiler.

Depending on the location of application, the bypass connection has its own characteristics.

Situation #1 - for a heating radiator

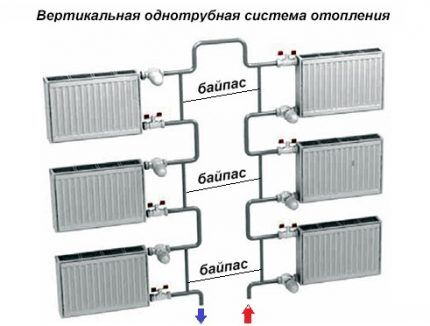

Radiators are connected via bypass only in single pipe system.

For two-pipe system And collector wiring cutting in bypass pipes does not make sense. The heating batteries in them are connected in parallel and each one receives water of the same temperature directly from the supply line.

The failure of one of the heating circuits, if there are shut-off valves, does not affect the performance of the rest of the system.

In a single-pipe system, due to the sequential connection of heat-transfer elements, the water is cooled as it passes through the circuit. The higher the heat transfer of the battery, the colder the liquid at the outlet will be.

If bypasses are not provided in a single-pipe distribution, then the first radiator will take the maximum amount of heat and will be too hot, and slightly warm water will flow through the last one.

The connection of the supply and return by a jumper near each battery divides the flow into two parts. One goes to the radiator and releases thermal energy.

The second, maintaining the temperature, flows along the circuit and connects at the outlet with the flow from the heating battery. In this way, it is possible to deliver a sufficient amount of thermal energy even to the last radiators in the chain.

Situation #2 - when connecting a pump

Connecting a circulation pump through a bypass only makes sense in a system adapted for gravity flow of water.

An accelerating manifold must be installed, the required slopes and sufficient pipe diameters must be observed. A circulation pump is installed in such a line to increase its efficiency.

If the heating system was initially designed as forced, then if the power goes out or the pump breaks down, it will not be able to function in any case.

The coolant will not circulate without a distillation unit. Therefore, in such a line the pump is installed without a bypass - in a straight line.

A feature of connecting the pump through a bypass is the possibility of a counterflow appearing in the bypass and the formation of a closed circulation loop in the bypass-pump circle.

Therefore, a shut-off valve - a ball valve or check valve - must be installed in the bypass pipe.

When the pump is running, such equipment completely blocks the lumen of the bypass pipe (valve - automatically, tap - manually).If the pump stops, the bypass opens and convection movement of the coolant occurs.

The exception is the injection bypass, the design and operating principle of which eliminates the reverse movement of liquid.

Situation #3 - when installing water heated floors

The bypass line when connecting underfloor heating is part of the mixing unit. Therefore, it is used constantly, and without it, underfloor heating will not function normally.

The water in the supply line can reach 80 °C, and in the heated floor circuit it should not exceed 45 °C. To prepare the coolant, a mixing unit with a three-way valve is used, which allows only the required amount of hot water to pass through.

The rest of the flow goes through the bypass, mixes with the cooled water leaving the collector and goes further along the main line to the boiler.

Situation #4 - in a main line with a solid fuel boiler

Using a bypass in the piping of a solid fuel boiler, a small coolant circulation circuit is formed. The bypass is connected to the supply pipeline with the maximum heated coolant on one side, and to a three-way valve installed on the return line on the other.

The valve mixes the cooled water coming from the heat transfer circuits with the hot coolant from the bypass.A liquid whose temperature is not lower than 50 °C is passed to the boiler.

Such piping is necessary when using a solid fuel boiler, since when cold water enters the boiler, condensation forms on the steel walls of the firebox. This leads to corrosion and rapid failure of the heating unit.

Through the bypass bypass section, hot water enters the mixing valve to heat the liquid coming from the system to a temperature that prevents the formation of condensation and corrosion on the walls of the boiler

Situation #5 - when installing bypass pipes

Installing different types of bypass in a heating system has its own characteristics.

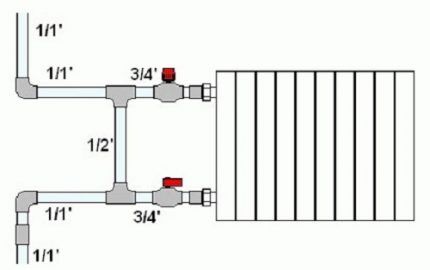

When connecting radiators:

- The diameter of the bypass pipe is selected one size smaller than the main pipeline;

- The jumper should be installed as close to the radiator as possible;

- It is prohibited to place the tap on the bypass in apartment buildings.

Installation of a radiator bypass can be carried out both when installing a new heating system, and when upgrading an existing one. For this purpose, pipes of appropriate diameters, two tees and shut-off valves are prepared.

One of the device options is installed at the inlet pipe:

- ball valve, which does not create resistance and allows the entire passing flow to pass through;

- valve – for manual adjustment of coolant volume;

- combination of ball valve and automatic thermostat – the amount of water passing to the radiator is regulated without human intervention.

A ball or shut-off valve is installed on the outlet pipe.

The elements are connected to each other by welding or threading.In any case, it is necessary to ensure complete tightness of the joints, carry out a test after assembly and exclude leaks.

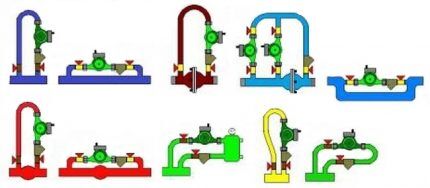

When connecting a pump, the bypass is most often part of the main line. Since it ensures the flow of coolant in natural circulation mode, its internal diameter should under no circumstances be narrowed.

The pump is installed on a bypass pipe, the diameter of which may be less than or equal to the diameter of the main line. The subtleties are correct circulation pump installation discussed in our other article.

For installation, it is easier to purchase a ready-made pump unit of the required size and configuration. This will ensure the correct position of all elements and reliable connections.

However, making your own decoupler for the pumping unit is not difficult if you follow some rules.

The pump should be oriented so that the impeller axis is horizontal and the terminal box cover is facing upward.

This ensures free access to the terminals to which the power is connected, and prevents liquid from getting on them if leaks occur.

A high-quality check valve or ball valve is installed in the bypass section to ensure complete flow through the pump and to prevent reverse movement of the liquid along the circuit.

Conclusions and useful video on the topic

Errors in installing the radiator bypass, which lead to poor heating of the heat-transfer element:

Why you can’t install a shut-off valve on the radiator bypass in an apartment building:

How to assemble a bypass pipe with a pump in such a way that it is convenient to disassemble an already installed and connected product and carry out routine maintenance of elements and repairs:

A simple engineering solution - a bypass - allows you to make the heating system more efficient and achieve a comfortable thermal regime in all rooms.

Failure of individual elements of the highway or a power outage will not cause big problems. The coolant will circulate through the main line and the house will be warm.

Have you started installing a bypass yourself and want to find out something? You can ask your questions in the comments to this article.

Or do you have a positive assembly experience? Please share it. Perhaps some of the home craftsmen will be able to avoid mistakes thanks to your recommendations.

I came across the concept of bypass both at work and at home. I have a bypass at home in every room near the heating radiator. We spotted such a system from our friends and also made it for ourselves. Now I already know from the article that we have a bypass type - manually controlled (i.e. with taps). It is very convenient and practical. If you need to change the heating battery, even during the heating season, the taps are closed and the water does not enter the battery and goes straight through.We connected the battery, opened the taps and water flowed through the battery. In addition, I also have a heated towel rail in the bathroom connected using the bypass principle.

We want to install a bypass. Our control computer refuses, citing the fact that it is “not allowed.” The batteries are connected in series from the living room to the kitchen. The radiator in the kitchen does not warm up well. Riser ts01′ to batteries 3/4. Are there any norms? documents or technical conditions to install a bypass? Single-pipe system with top supply tn. House since 1960 Thank you.

As I always say and will not stop repeating, answers from any authorities to which you apply must be demanded in writing. The answer in the form of “not allowed” verbally is more like the fact that people simply do not want to deal with solving your problem.

First of all, I recommend not to solve the problem on your own, but to involve the management company in eliminating it, since these are their responsibilities. It may be that you need to replace the pipe between these two radiators, or it may be easier to clean the pipe. Here, let the management company decide how to fix the problem; you are required to submit a written application, which will indicate the problem.

It is possible to install a bypass; this is not prohibited by regulations, but in this case it will be eliminating the symptom, and not the source of the problem itself.

The video on the bypass on the circulation pump shows how not to install the mud pan and the terminal box of the circulation pump.

Hello.I often see lately how locksmiths do it in apartment buildings; instead of a bypass, they make a straight pipe with leads to the radiator and weld a bolt into the pipe opposite the lead to the radiator. Is this correct, what consequences might there be?

Hello. Just in case, let me clarify - “bolt”, are you talking about a fitting?

I have such a problem in the house Leningrad single-pipe system at the bottom of the radiators pipe 20 metal-plastic supply 55 return 45 on the street at the heating inlet the housing and communal services mechanics made a bypass; the return does not rise above 47 degrees; there is a pump on the return 25x40, why does the return not go away and the temperature of the batteries does not increase? on the return line most of the radiators in the house how to solve the problem please tell me