DIY heating distribution manifold: diagrams and assembly features

The defining task when designing an autonomous heating system is the uniform distribution of the coolant.This task in the heat supply system is performed by a control and regulation unit - the distribution manifold.

The uninterrupted operation and reliability of the heating circuit largely depends on the correct choice of device, high-quality installation and connection. If you want to install a heating distribution manifold with your own hands, then you need to carry out calculations and design the wiring in advance.

We will help you resolve these issues. In the article, we examined the design of the collector group, identified the pros and cons of a heating system with a comb, and described the rules for the design and installation of a distribution unit.

The material is supplemented with practical advice on selecting components, assembling and connecting the collector to the heating system.

The content of the article:

The role of the collector in heating

When arranging a water pumping unit, you must adhere to the rule: the total sum of the diameters of all branches should not be greater than the diameter of the supply main.

Let's apply this law to the heating system, but it will look like this: a boiler outlet fitting with a diameter of 1 inch is allowed for use in a double-circuit system with pipes with a diameter of ½ inch.

For a house with a small cubic capacity that is heated exclusively by radiators, this kind of system is considered productive.

In practice, a private cottage is equipped with a more modernized heating circuit, where additional circuits are installed:

- heated floor system;

- heating of several floors;

- utility rooms, etc.

When a branch is connected, the level of operating pressure in the circuits becomes insufficient for high-quality heating of all radiators, respectively, and the comfortable atmosphere will be disrupted.

In this case, a balancing unit is installed for a branched heating main using a distribution manifold. Using this method, it is possible to compensate for the cooling of the heated coolant, which is typical of traditional one- and two-pipe schemes.

By means of equipment and shut-off valves, the required coolant temperature indicators are adjusted for each of the lines.

Main characteristics of the collector system

The main difference between the collector and standard linear method of redistribution of the coolant is the division of flows into several channels independent of each other. Various modifications of collector installations can be used, differing in configuration and size range.

The design of the welded manifold is quite simple.The required number of pipes is connected to the comb, which is a round or square pipe, which, in turn, are connected to individual lines of the heating circuit. The collector installation itself is interfaced with the main pipeline.

Shut-off valves are also installed, through which the volume and temperature of the heated liquid in each of the circuits is regulated.

The positive aspects of operating a heating system based on a distribution manifold are the following:

- Centralized distribution of hydraulic circuit and temperature indicators occur evenly. The simplest model of a two- or four-circuit ring comb can balance the indicators quite effectively.

- Regulation of heating main operating modes. The process is reproduced due to the presence of special mechanisms - flow meters, mixing unit, shut-off and control valves and thermostats. However, their installation requires correct calculations.

- Ease of maintenance. The need for preventive or repair measures does not require shutting down the entire heating network. Due to the sliding pipeline fittings mounted on each individual circuit, you can easily shut off the coolant flow in the required area.

However, there are also disadvantages to such a system. First of all, pipe consumption increases. Compensation for hydraulic losses is carried out by installing a circulation pump. It must be installed on all collector groups.In addition, this solution is relevant exclusively in heating systems. closed systems.

Modifications of collector units

Before you begin assembling the collector assembly, it is necessary to determine its functional load. The equipment can be installed in several sections of the heating main. Based on this, the necessary equipment, dimensions and level of automation of the work cycle are selected.

In fact, for the full operation of such a node, two devices are needed. Using a comb, the coolant is distributed along the contours of the central supply pipeline. The return collector channel is represented by a collection mechanism and the point of departure of the cooled liquid into the boiler.

Installation of a homemade distribution group may be required when installing water-heated floors or for preparing standard heating with radiators.

Distinctive features of both options are their sizes and components:

- Boiler room. The welded manifold group is made of pipes with a diameter of up to 100 mm. A circulation pump and shut-off valves are installed on the supply side. The return ring is equipped with shut-off ball valves.

- Warm floor system. Similar equipment is present in this mixing unit. With its help, it is possible to significantly save on coolant consumption, especially if additional flow meters are installed. More information about the mixing unit in a heated floor system is written in this article.

Each of these solutions provides an individual installation scheme.Correct installation of all elements can be carried out only after detailed calculations of all operating point parameters.

There are also differences in the quantity required circulation pumps. In the boiler room, each line is equipped with this device. For heated floors, only one installation is provided.

Distribution node design

There is simply no universal scheme for a radiant heating project. Each case is individual, which is why the unit is equipped with the necessary devices privately. However, it is worth familiarizing yourself with the general recommendations and rules.

Rules for installing the comb

Installation of the collector is not possible in an apartment. However, there is an exception to the rule - in some houses, when all communications are installed, additional valves are installed, through which the heating circuits are connected. This device allows for individual wiring of the collector.

The schematic arrangement of heating should be designed in such a way that the location crane Mayevsky was on the comb. This option is considered optimal, because over time, accumulated air will need to be released from the circuits.

Features of the beam group

The radial wiring group has many nuances, but some of them are also typical for heating of other modifications.

Features of the comb system:

- The circuit package must include compensation tank, with a volume of more than 10% of the total volume of the thermal fluid.

- The optimal location of the expansion tank is on the return pipeline in front of the circulation pump, since the temperature regime is lower here.

- If a thermo-hydraulic distribution is used, the circuit is designed so that the tank is located in front of the main pump, which is responsible for the forced movement of water in the boiler piping.

- The circulation pump is installed in a strictly horizontal position. If you do not adhere to this rule, at the first air lock, the device will lose cooling and lubricant.

The distribution group can be assembled from various materials: polypropylene or metal. The selection is made based on work skills and the availability of tools for connecting parts.

The process of selecting pipes for installing a distribution group is also considered important.

The main factors taken into account when choosing contour elements:

- Purchase of pipes only in coils. Due to this, connections are not made in the wiring installed under the concrete screed.

- Heat resistance and tensile strength must be determined individually, based on the technical data of the heating system.

Due to the predictability of the operating characteristics of autonomous heating, you can use polypropylene pipes. They do not have unwanted connections and are sold in continuous 200 m lines.

The material is heat resistant and can withstand temperatures up to 95°C with a permissible burst pressure of 10 kg/1 cm2.

For a multi-story building, it is preferable to choose a corrugated pipe made of stainless steel.

This material shows excellent technical capabilities to cope with such a load:

- heated coolant up to 100 °C, which is more than enough for the heating circuit;

- pressure up to 15 atm;

- fracture pressure up to 210 kg/1 cm2.

Fittings designed for polypropylene can be plastic or made of brass. The fitting connection is equipped with a locking ring, which is threaded onto the pipeline.

An important characteristic of polypropylene pipes is the memory of mechanical processing, which results in plastic deformation of the substance.

For example, when stretching pipes with an extender and installing a fitting into the connector, after a certain time the pipe will return to its previous state and crimp the part. The contact can be secured with a locking ring.

Heating manifold calculation

Initially, to manufacture a thermohydraulic comb, you will need to calculate its main parameters - length, cross-sectional diameter of the pipes and the number of branches of the heating main. You can calculate these characteristics yourself or use special software.

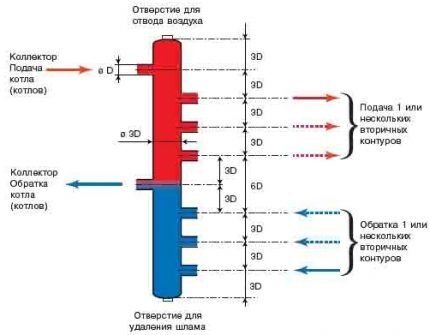

The hydraulic balance of the structure is the main condition that must be met. Applying the rule of three diameters for a hydraulic separator, it is necessary to perform the following action - sum up the cross-sectional diameter of the connected circuits.

As a result, we get an amount equal to the diameter of the main pipe connected to the supply line. Using this principle reduces the likelihood of imbalance of the entire heating system.

A special cabinet or housing is used as a place for the distribution unit. When arranging the system, it is necessary to adhere to the permissible minimum distance between two heat-conducting input and output lines - 6 diameters.

The issue of correct selection of the circulation pump performance is also relevant. To do this, it is necessary to calculate the specific rate of water consumption of the system and, based on the results, select a pump.

If the circuit is complicated by several combs, the calculation is performed for each individual circuit and in general for the entire system.

Self-assembly of equipment can be carried out using a pipe with any type of cross-section. This aspect does not affect the operation of the device and does not increase local losses. They will be compensated by the circulation pump.

Rules for selecting components

Having completed all the calculations, the next step is to select the required set of mechanisms. The simplest set consists of shut-off valves. However, with such a device it is difficult to regulate the power of individual heating lines.

To solve this problem, crane axle boxes are installed on the feed comb, through which smooth adjustment is possible. Rotameters are mounted on the return manifold.

For warm water floors, the configuration scheme will be different.

For assembly you will need the following elements:

- Shut-off and control valve. Installation is carried out on connecting pipes. With the help of this fittings, the flow of coolant is completely or partially stopped. It is recommended to use automatic modification.

- Rotameters. Such elements are mounted on the return collector. They perform a similar function as the previous element, only in the return pipeline.

- Mixing unit. By mixing hot and cold water flows, the specified heating operating mode is optimized.

The manifold kit is necessarily equipped with a safety group headed by a pressure gauge, air valve, thermostat and circulation pump. It can be supplemented with servo drives, the control of which is reproduced through the control electrical unit. Thus, the operation of the system can be automated.

Subtleties of self-assembly

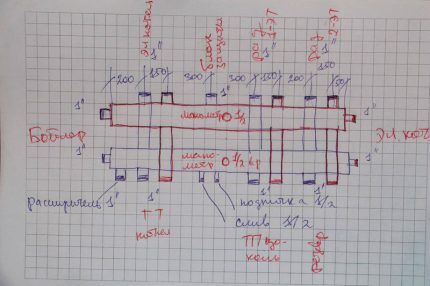

Before manufacturing the collector, it is necessary to draw up a diagram showing the location of all the elements of the assembly. It is better to choose steel pipes with a square cross-section as the manufacturing material. This type is easy to process, which significantly reduces labor costs for installing pipes.

The step-by-step process for producing a prefabricated distribution structure is as follows:

- Marking and cutting of the main body. According to the design diagram, it is necessary to mark the profile pipe.Using a gas cutter, holes are made in the marked areas.

- Preparing connections. The pipes are threaded using a die.

- Staffing. Next, the prepared pipe sections are welded to the body. Their fixation must be done by tack spot welding. Then, during the main welding, the workpieces are welded along the edges.

- Fasteners. Brackets for fastening are welded to the block.

- Cleaning and finishing. After cleaning, the body is primed and coated with heat-resistant paint for metal products. The supply and return circuits are painted in two different colors for ease of identification.

If polypropylene pipes are used for production, you should pay attention to the presence of a reinforcing layer in them. In its absence, the plastic structure may be subject to deformation due to the current temperature conditions.

For those who do not have special tools, you can assemble a comb from separate ready-made elements. It is better to select components from one company.

Installing a comb in the heating system

The primary task is to check the distribution manifold for tight connections. The installation is implemented according to the design scheme. Depending on the material used to manufacture the main unit, the connection conditions are determined.

The choice of connection technology depends entirely on the modification of the device used.

In addition to maintaining the level, during installation you must follow the following rules:

- electric and gas boilers are connected to the upper or lower pipes;

- a circulation pump is mounted at the end of the structure;

- the circuits can be connected at the top or bottom of the comb;

- indirect heating devices and boilers operating on solid fuel must be connected to the distribution group on the side;

- the entire hydraulic separation unit for the underfloor heating system is placed in a protective box - this reduces the risk of damage to the constituent elements of the collector.

At the final stage, it is necessary to carry out a control start-up of the heating in order to timely identify hidden or obvious deficiencies in the design.

Additional information on organizing a radiant heating system using a distribution comb is given in this article.

Conclusions and useful video on the topic

Detailed technical process for assembling the collector group:

Ready-made combs for arranging heated floors, which are not always equipped with the necessary functionality, are, due to their high cost, not available to the general public. Let's see how to assemble a budget version of the design with your own hands:

The distribution group can also be implemented using polypropylene pipes. You can learn how to do this from the video:

Correct selection of components and installation of the collector unit is the key to efficient and reliable operation of the heating main. Due to the minimum number of connections, the risk of leaks is minimized. An important advantage is the ability to control and configure each heating circuit.

Share with readers your experience in assembling and connecting the distribution manifold. Please leave comments on the article, ask questions and participate in discussions.The feedback form is located below.

Good and efficient heating system. After installing the collector and connecting the heated floor and radiators to it, our house became much warmer than with radiators alone. This is especially true for children's rooms and bathrooms, where enhanced insulation is needed. Accordingly, the system is designed so that the coolant is delivered to these places at the optimal temperature for heating. In addition, the collector system can be controlled by choosing the most favorable heating mode.