Catalytic gas heater: varieties, recommendations for selection + review of the best brands

With the cold weather approaching, have you thought about buying a device for heating a room with minimal fuel consumption? You've heard that a catalytic gas heater is compact and quite efficient, but, unlike most gas appliances, it is absolutely safe. Is this really true? Agree, buying an expensive “pig in a poke” is not in your plans.

We will help you understand this type of heaters - in our publication we will talk about the design features and operating principles of catalytic devices. Let's look at how they provide high thermal efficiency and provide recommendations for choosing the appropriate model. We will also pay attention to the best manufacturers who have received the largest number of positive reviews from customers.

The content of the article:

The design and principle of operation of such heaters

Catalytic heaters can warm up an apartment before centralized heating is turned on, heat a small country house for the weekend, help keep the garage from freezing, and solve a number of other space heating issues.Most models are very compact: they can be easily taken to the dacha or on a hike, always staying warm even outside the house.

But the purchase of such a heater should be approached with special care, after first understanding the design features and operating principles of the devices.

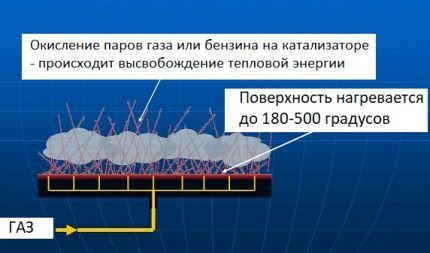

A catalytic heater produces heat by oxidation of the fuel mixture, entering the catalyst - the catalytic plate.

Due to the absence of direct flame, combustion products harmful to health are not formed during its operation. Fuel consumption is minimal.

Standard designs consist of:

- control panels;

- catalyst;

- steel body;

- mixing chamber;

- diffuser

Some models are equipped with special tubular electric heaters that serve as an additional heat source.

The main working part on which the operation of such heating devices is based is catalyst plate. It is made of fiberglass mesh coated with a layer of palladium or platinum.

Additional structural elements may include a built-in ignition device, thermostat, and automatic shutdown.

The operating principle of a catalytic heater is fundamentally different from those on which other gas appliances operate. In standard schemes, thermal energy is released after the ignition of the fuel entering the burner.

The room heating system with a catalytic device looks different:

- When turned on, the surface of the catalyst gradually warms up and reaches a temperature of 200-500 °C, depending on the selected mode.

- At the same time, the air-fuel liquid is heated in the mixing chamber.

- Liquefied gas vapors enter the hot catalytic panel.

- Under the influence of a catalyst, a chemical reaction is triggered, ensuring flameless combustion.

Despite their compact size, the devices produce a fairly impressive amount of heat, which is enough to heat a large area.

Most often, the devices are used to heat small construction sites, garages, country houses, outbuildings, tents, greenhouses, and temporary huts. It is not recommended to use them for constant heating of residential premises, except during construction or renovation, when the main heating system has not yet been connected.

Main types of designs

By connection type There are designs that are connected to a cylinder with a propane-butane mixture or to a centralized gas main. What is it used for? gas hose.

Catalytic heater models vary in type of construction. The most common option is a monolithic design, in which a container intended for liquefied gas is placed inside the housing. The volume of such a cylinder is no more than 27 cubic meters.

In the second possible modification there is no housing: only a plate impregnated with catalysts. Such heaters are very compact, they can be taken with you on hiking trips and trips to heat vehicles or tents.

Some units come with special CO2 sensors, controlling the gas level in the room. If the values increase to critical levels, an automatic system is activated, instantly turning off the fuel supply.

The device can be conventional or infrared. IN infrared gas catalytic heaters A ceramic panel is used. They are also equipped with a reflector located on the inner surface. It provides a targeted local effect and allows you to quickly reach a comfortable thermal range.

Devices with an infrared emitter heat surrounding objects without spending extra energy on heating the air. However, it is not recommended to heat small rooms with them, especially those with an area of less than 10 m². Due to their high performance, they can be used outdoors to effectively heat summer verandas and other open spaces.

We wrote about the types of infrared emitters and the rules for choosing the best option In this article.

Conventional catalytic heaters warm the air, not the surrounding objects. Among them there are miniature portable devices and rather large installations that resemble a large boiler in appearance.

The average performance of gas heaters is about 2900 W. The power of models additionally equipped with a fan and heating element reaches 4900 W. The heating area depends on the power of the device.

Differences from gasoline and multi-fuel models

Gas appliances are the most common, but not the only type of catalytic equipment. Heating units can also operate on other types of fuel.

Depending on this criterion, three more types of devices are distinguished:

- Gasoline. Devices with a built-in fuel tank connected to a catalytic cartridge. Gasoline vapors in them enter the cartridge and undergo oxidation when interacting with the catalyst. Mobility and modest size contribute to the particular popularity of gasoline heaters among outdoor enthusiasts, hunters, and fishermen.

- On technical alcohol. Designs with a special internal compartment into which a container with alcohol or dry fuel is placed. They are presented in small-sized models weighing no more than 1.5-2 kg. They are used exclusively in field conditions: they heat tents, dry clothes, and heat food and drink.

- Multi-fuel. Universal heaters that work with any available type of fuel, both gaseous and liquid.They are characterized by rather limited power - 500-1200 W.

Apart from external characteristics, there are no significant differences between gas, gasoline and multi-fuel catalytic heaters. They all work on the principle of catalytic combustion and have a similar internal structure.

Gas appliances are easier to maintain, have high performance, and are designed for a wide range of applications.

Gasoline devices are a little more difficult to operate. To ensure efficient and uninterrupted operation, you need to fill them with gasoline of the highest purity.

Pros and cons of catalytic devices

Like any type of equipment, catalytic heaters have a number of advantages and disadvantages that must be taken into account when choosing.

The devices have many positive aspects:

- compactness and light weight – the dimensions and convenient design of most models make it easy to move and install devices; portable options can easily fit into the trunk of a car or a small travel bag;

- environmental friendliness – due to the fact that the heaters do not emit harmful combustion products and unpleasant odors, a healthy microclimate is maintained in the room, and the risk of carbon monoxide poisoning is completely absent;

- safety – the absence of flame during operation eliminates the possibility of fire, the device can be used without fear in a home, tent, warehouse, or industrial workshop;

- efficiency – operating at full power, the devices consume 100-300 g of fuel per hour, in many models the performance can be adjusted;

- fuel availability – the cylinder can be easily purchased or fill with gas at any gas station;

- simplicity of the device – the design is devoid of complex mechanisms, everything is arranged as simply and clearly as possible.

But there are also negative nuances. The most significant disadvantage is limited service life. Although marketers claim that the plate can work for up to 8 years, in practice, according to some users, the period does not exceed 2500 hours, which is associated with the gradual burnout of the catalyst during the heating process.

The second drawback is serious dependence on the quality of the fuel mixture. Poorly purified fuel affects heating efficiency and shortens the service life of equipment, quickly rendering it unusable.

Many consumers consider it a disadvantage high cost catalytic gas appliances. On average, a heater of this type with a power of 2900 W costs about 11,000 rubles.

Despite the safety of catalytic equipment, during use it is necessary to adhere to the operating rules recommended by the manufacturer.

We also recommend watching Tips for safe use bottled gas in the apartment.

Choosing the optimal heater

When choosing a suitable heater, you need to take into account many nuances, evaluate the convenience of the design, functionality, additional features and equipment of the model you like. Let's consider the main criteria for making the right choice.

Criterion No. 1 – place and conditions of application

The first step is to decide on the purposes for which you plan to buy a catalytic device. The optimal type of design and the set of characteristics required in this case depend on where and under what conditions the device will be used.

The main indicators should be selected taking into account the conditions of upcoming operation and the parameters of the heated object. It is necessary to take into account the expected frequency of use, heating area, and preview reviews of real customers about the model.

So, to heat rooms, it is worth buying larger heaters with sufficient power and automatic safety sensors. If the device will need to be moved frequently, it is better to choose a mobile design on wheels.

Criterion No. 2 – technical characteristics

One of the main parameters of a heater is power. To choose a device with the correct performance, you should perform preliminary calculations, consult with the seller, and carefully study the instructions. The technical documentation must indicate what area the power of a particular model is designed for.

In addition, you need to pay attention to the following characteristics:

- gas consumption – how much fuel is required for operation, is the device economical;

- dimensions – what is the width, length and height of the device, is there enough space in the room to provide free space around it (1.5 m in the front, 0.2 m in the back and sides);

- control type – mechanical or electronic;

- weight and volume of the provided cylinder – Is the device too heavy, how difficult will it be to move and install?

It is important to check the packaging and its compatibility with the equipment. The standard set includes gearbox, gas hose, sometimes a cylinder. If any of the elements do not fit with the device, you must purchase suitable adapters.

It is desirable that the heater be equipped with additional design and functionality.

The main additions and features are as follows:

- automatic power control in several modes;

- horizontal position sensor that turns off the device in case of sudden mechanical impact, distortion, or overturning;

- indoor carbon dioxide level control system;

- infrared heating;

- piezo ignition;

- electric turbofan;

- overpressure relief valve.

For greater ease of use, you should choose a device with wheels for free movement, handles, and stand legs that can be installed in different positions.

Review of the best manufacturers

An extensive range of catalytic heaters is represented by various imported and domestic brands. Let's look at several manufacturers whose products are recognized by consumers as the best in this area.

No. 1 - reliable and functional Bartolini devices

Heating equipment from the Italian brand Bartolini is most in demand on the market. The company produces quite powerful devices with a performance of 2900 to 4200 W, running on liquefied gas.

The main emphasis in production is on the independence of equipment from the availability of communications.

Heaters from an Italian manufacturer can be purchased at prices ranging from 11 to 18 thousand rubles. They are distinguished by good quality, reliability, and economical fuel consumption.

Most of them have CO2 monitoring sensors and rollover shutdown systems. The model is especially in demand among buyers Bartolini pullover k.

No. 2 - compact and economical models from Campingaz

The next most popular company is Campingaz. This French company produces efficient and safe gas heaters for residential, warehouse, commercial and industrial premises. Special attention is paid to portable equipment that ensures a comfortable stay in nature.

Brand devices provide excellent heat transfer and have European quality certificates. Their production uses new technologies for economical fuel consumption.

The average cost of products is 11 thousand rubles. The best representative of the range is considered Сampingaz cr 5000 turbo.

No. 3 - convenient and safe Kovea brand heaters

The Korean company Kovea offers customers gas heaters of various designs. Mostly these are compact, portable, low-power models that operate on the basis of infrared radiation.

The Korean manufacturer practically does not use plastic elements in the design of its devices, which further increases the safety of operation. The average price of products is 5-8 thousand rubles.

No. 4 - inexpensive and durable heaters from Argo

A budget option for a catalytic heater is offered by the domestic manufacturer Argo. The gas heat generator of this company is designed for heating industrial premises, garages, and verandas with normal air circulation. Farmers often use it in greenhouses and barns.

With not too large dimensions, the weight of the device is 6.7 kg. It does not have wheels, so it is quite difficult to move it over long distances. But for stationary use it is quite suitable. The approximate cost of the device is 2000 rubles.

Does the catalytic version of the device seem unreasonably expensive to you as a temporary heater for a summer house? We recommend checking out others gas appliances, suitable for heating temporary premises.

Conclusions and useful video on the topic

Recommendations for choosing devices, main design differences between models:

The feasibility, pros and cons of using a catalytic heater in the following video:

The process of applying a catalyst to the surface of a plate at home:

How catalytic combustion occurs is a visual experiment in the following video:

Catalytic gas heat generators are an excellent option for temporary heating of various premises, heating garages, tents, and greenhouses. They are completely safe: during their operation no harmful combustion products or unpleasant odors are emitted.

A large selection of sizes and designs makes it easy to choose a device, both for stationary use and one that you can easily take with you on the road. When choosing a catalytic heater, you need to focus on the operational characteristics of the room, individual requirements, and financial capabilities. It is also important to give preference to reliable manufacturers with a positive reputation in the market.

Do you use a gas heater with a catalytic plate and want to share your opinion about the advisability of purchasing such a device with other users? Tell us about the pros and cons identified during operation, add unique photos of your heater model in the comments block below.