The principle of operation of a geyser: features of the design and operation of a gas water heater

If there is no hot water in your house or your hot water is constantly turned off, then life becomes completely uncomfortable.But this is not a reason to refuse a warm shower on a cool autumn evening, don’t you agree? This problem can be solved by installing a geyser, as many users do. But how does such a miniature water heater work and can it cope with its task?

We will talk about all this in detail in our publication - here we consider the principle of operation of a gas water heater and the diagram of its design. Attention is also focused on the main equipment malfunctions and ways to cope with them. The presented material is supplemented with visual illustrations, diagrams and videos.

The content of the article:

General structure of a household water heater

The geyser is instantaneous water heater. This means that water passes through it and heats up as it goes. But, before moving on to an analysis of how a household gas water heater works, let us recall that its installation and replacement are associated with a centralized gas supply system.

Therefore, you must submit documents to the gas service of your region along with the appropriate application. ABOUT norms and necessary documents You can read it in our other articles, but now let’s move on to the device.

Different models of geysers differ from each other, but the general structure of a household geyser looks something like this:

- Gas-burner.

- Igniter/ignition system.

- Exhaust hood and connection to the chimney.

- Chimney pipe.

- The combustion chamber.

- Fan (on some models).

- Heat exchanger.

- Gas supply pipe.

- Water node.

- Connections for water supply.

- Pipe for hot water outlet.

- Front panel with controller.

The central element of the column is gas-burner, in which gas combustion is maintained, which helps heat the water. The burner is installed in a housing; hot combustion products are collected in it, the purpose of which is to heat water.

Frame made of metal and completely covers the front and sides of the speaker. It is important that the material of the housing conducts heat well, because the quality of heating depends on the transmission of heat.

On top of the device is hood And chimney, through which combustion products leave the column and the room. Their design depends on whether the column is open or closed, which will be shown below.

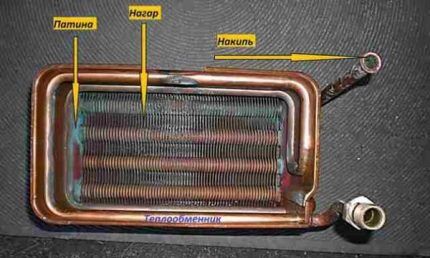

The pipes meander like a coil inside the body, water passes through them under natural pressure and is warmed by hot gases. This whole pipe system is called heat exchanger. At the bottom there are two pipes: on the right - for receiving cold water from the pipeline, on the left side hot water flows out.

Between the water supply network and the gas water heater is often installed filter, which regulates water hardness. Without a filter, the column may become covered with scale at high water temperatures. When entering the column, water passes through water node, which serves as a kind of “connection” between the water flow and the gas flow. We'll talk about this connection a little further.

Using another tube, which is also located below, the column is connected to the gas main.

There is also the front panel with control unit. It is equipped with regulators to control gas and water consumption. Depending on the model, these can be either simple knobs that need to be turned, or liquid crystal displays, where you can see many characteristics of the column, or even the nature of its malfunction if the column does not work.

How does a geyser work?

Let's get acquainted with the principle of operation of a gas water heater in the form of a simple algorithm:

- when water flows through the water assembly, the membrane tenses and moves the rod connected to the gas valve upward;

- then the valve opens the gas supply to the main burner;

- the gas is ignited from an electrode or igniter, burns and heats the water that flows through the heat exchanger pipes;

- the heated water flow is supplied to the tap through the left pipe;

- gas combustion products are removed through a chimney or hood - there is a fundamental difference between open and closed type columns, which will be discussed in detail below.

At the same time, the power of the flame and the power of water flow through the column can be adjusted using the controls on the front panel.

Now let’s take a closer look at how the burner is ignited and how the already mentioned water unit is connected to this.

Gas ignition method

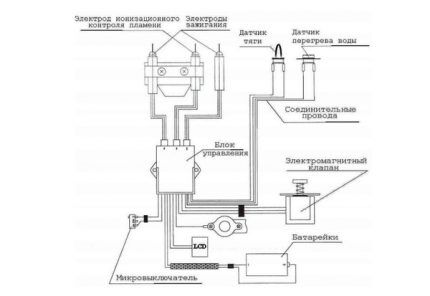

In general, geysers are based on three methods of igniting gas.As can be seen in the diagram, in all three cases the signal to ignite the main burner is the reaction of the water unit (frog).

Here are three ignition methods:

- using a piezoelectric element;

- from batteries;

- from the rotation of the hydraulic turbine.

Ignition using piezoelectric element - This is manual ignition, and requires a button on the front panel. Pressing the button causes the piezoelectric element to close, which ignites the igniter. He, in turn, ignites the main burner after a signal from the rod, which moves the water membrane with active water pressure.

The igniter continues to burn with a small flame until it is turned off manually. This leads to increased gas consumption and increased scale formation in the pipes. One of the gas instantaneous water heaters with manual ignition is Bosch Therm 4000 O W 10-2 P.

Some models of geysers operate on batteries. Wherein arson occurs from an electric spark after the rod signal. Thus, instead of an igniter, there are electrodes that directly ignite the main gas burner.

But batteries need to be changed on average once every 10 months, and with constant use — once every 2 months to avoid unforeseen circumstances. One such battery powered speaker is Zanussi G.W.H. 10 Fonte Glass La Spezia.

Sometimes ignition occurs from rotation hydraulic turbines (with water flow). Ignition also occurs from an electric spark, but there is no need to change the batteries, because the turbine itself generates electricity as water flows.

But for the hydraulic turbine to operate, high pressure in the pipes is required, at least 0.3 bar. Not every home has this pressure. In Russia and other CIS countries, it is not recommended to buy such speakers due to unstable water pressure. An example of such a model is a geyser Bosch Therm 6000 O WRD 15-2 G, which is noticeably more expensive than the two above models.

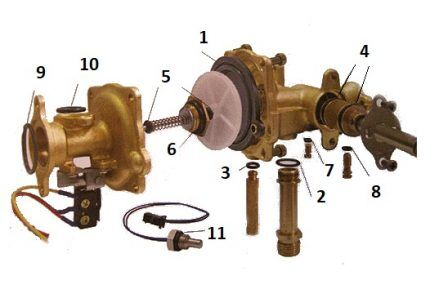

Column water unit design

The design of the water unit is of particular interest. Its structure can be seen in the diagram below, the labels for the details are below the diagram. The remaining designated elements are used for fastenings.

The main working parts are stock And diaphragm, under the influence of which it moves when water flow begins in the lower part. The rod opens the valve and allows gas to flow into the burner, which is then ignited.

Another work item - PVC ball, serving as a fuse. It cuts off the gas flow during sudden pressure changes in water pipes - hydraulic shocks, which we will also talk about later.

Combustion chamber type

Based on the design of the combustion chambers, there are two types of geysers: open and closed.

Speakers with open combustion chamber have open air access to the burner, and combustion products go into the hood.

Such models are simpler than turbocharged, which will be discussed below, their operation is almost silent and in most cases they do not require electricity. However, due to the open connection between the combustion chamber and the room, air pollution in the room is possible if the hood is not working properly.

Speakers with closed combustion chamber are turbocharged. The combustion chamber in them is sealed, in addition to the channels for air injection and exhaust. It is pumped there by a fan through coaxial pipes and goes out into the street through the chimney, along with the combustion products.

Such columns are usually fully automated, they do not have manual controls, and the traction and temperature sensors in them are more sensitive. These speakers are “modern” and safer.

The illustrations above showed a gas water heater with a closed combustion chamber. For comparison, in the following illustration you can see the arrangement of two types of speakers side by side. You will find many similar elements in them, but the principle of removing combustion products is noticeably different.

Main characteristics of the speakers

Now let's talk about the practical aspects of using the speaker. One of the main characteristics is performance. It directly correlates with power, which is indicated in kW and shows the volume of water heated per minute by 25 °C.

The characteristics are usually indicated in the device passport. A regular water heater heats 10-20 liters of water per minute at 25 °C, although this value can vary significantly.

Another characteristic of modern speakers — power modulation. It shows how the power of the column can change depending on the flow of water and is measured as a percentage of the initial power.

For modulation, the columns are equipped with special fittings with a membrane, which changes the gas supply to the burner depending on the flow. Modulation in the range of 40-100% of the device power is considered normal.

Safety sensors and their meaning

A geyser can be dangerous, because it is connected simultaneously to water and gas mains, each of which individually can pose a threat.

If there are problems with the gas or water supply, security sensors turn off the operation of the column, and special valves will shut off the supply of water or gas.

Typically, geysers can withstand voltages of up to 10-12 bar, which is 20-50 times higher than normal pressure in pipes. Such sharp jumps are possible with so-called hydraulic shocks.

But if the pressure is lower than 0.1-0.2 bar, then the column will not be able to work. You need to carefully study the instructions and specifications before purchasing to understand whether the dispenser is optimized for low water pressure in pipes in the CIS countries and whether it will work properly. And vice versa — will it withstand sudden changes in pressure, which, alas, is also not uncommon in our conditions.

In general, a modern geyser contains many safety sensors. All of them, in case of breakdown, can be replaced.

More details about the purpose and location of the sensors are in the table below.

| Sensor name | Location and purpose of the sensor |

| Chimney draft sensor | Located in the upper part of the device, connecting the column with the chimney. Turns off the column when there is no draft in the chimney |

| Gas valve | Located in the gas supply pipe. Turns off the column when gas pressure drops |

| Ionization sensor | Located in the device camera. Turns off the device if the flame goes out while the gas is on. |

| Flame sensor | Located in the device camera. Shuts off the gas if the flame does not appear after arson |

| Relief valve | Located on the water supply pipe. Turns off the water when the pressure in the pipeline is high |

| Flow sensor | Will turn off the column if water stops flowing from the tap or if the water supply is turned off |

| temperature sensor | Located on the heat exchanger pipes. It will block the burner operation if the water is significantly overheated to avoid damage and burns (mainly triggered at +85ºС and above) |

| Low pressure sensor | Will not allow the column to turn on when the water pressure in the pipes is low. |

Basic problems and ways to fix them

Speaking about the structure and operating principles of a household geyser, as well as the sensors built into it, it is worth briefly mentioning possible failures and malfunctions.Here we will not dwell on a complete repair or replacement of the column, but will quickly go through all the elements listed in the burner description and describe their problems, as well as ways to deal with them yourself.

As already mentioned, the main element of the column — gas-burner. Often the burner goes out due to the activation of the safety sensors, which we have already discussed. Common problems that lead to this scenario — This heat exchanger contamination soot and scale.

Cause low pressure — scale formation in the heat exchanger pipes. In this case, you need to remove the heat exchanger and rinse the pipes with special liquids to remove scale.

If gas combustion does not occur completely, or the column is used for a long time, gas accumulates in the chamber. soot from the outside, which significantly reduces the thermal conductivity and quality of water heating.

To learn more about the causes of low pressure and the intricacies of cleaning, please go to this link.

If the gas valve does not open due to low pressure of the supplied water, you need to remove filter, check how clogged it is and, if necessary, rinse it. If there is insufficient water or gas pressure, you will have to contact the appropriate government service.

If water flows directly from the column, this means that the seal is broken in the pipes. It is necessary to disassemble them and replace the sealing elements. If necessary, the pipes themselves will have to be replaced.

It is worth mentioning separately water membrane malfunction. If the column is in use for a long time, the membrane of the water unit wears out and its sensitivity drops significantly. It stops responding to low water pressure, and, accordingly, does not give a signal that the burner needs to be lit. At best, it should be changed every 5-6 years.

Sometimes the problem is also in the stock, which is moved by a membrane, it can also be replaced if necessary, because there are special repair kits for this.

To better understand the design of your gas water heater model, you need to carefully study the instructions for use and the object’s passport. This will not only save your time and nerves, but will also improve your understanding of how the device works.

Conclusions and useful video on the topic

To consolidate your understanding of the structure of the gas column, you can look video review, where the arrangement of all column elements is explained in detail using a live example:

In this material we studied the structure of a household geyser and the principle of its operation. Then we looked at the operation of the main elements. And knowing the main components and elements of gas equipment, the sensors of its safety system, you can diagnose the breakdown on your own. And if the cause of the malfunction is contamination of individual structural elements, then perform personal service geyser.

Would you like to supplement the above material with useful recommendations or ask questions that we have not touched upon here? Ask for advice from our experts and other site visitors - the feedback form is located below.

There is a loud bang when igniting. Why?

Hello. Possible traction problems. How long ago did the gas workers carry out the inspection?

Change the batteries, most likely you have old batteries and there is not enough power for normal ignition, that’s why it’s banging

I had it too. The igniter is battery operated. I found the cause in the wire to the igniter. When the cover was installed, a spark hit the housing through damaged insulation (in the wrong place). The pop was due to greater gas accumulation. The solution is to wrap the area with duct tape.

Question: why doesn’t the automatic system work when the water is turned off? Gas supply continues

Change the microswitch. I felt this way because of him.

after some time of absence (closed gas and water taps), the main burner does not light up. More precisely, it lights up, but after passing water under pressure, repeatedly lighting the igniter, and other dances with a tambourine. What could be the reason?