Installation of a circulation pump: types, purpose and features of its installation

Ideally, the heating system should guarantee uniform heating of the room.However, it happens that, for example, in the kitchen the radiators are practically cold, in the living room there is a real sauna.

At the same time, the fuel boiler operates at its maximum capacity. Fortunately, installing a circulation pump has a positive effect on the efficiency of the fuel system.

Next, we will talk about the intricacies of choosing pumps, understand their types and design features, and also highlight the advantages and disadvantages of the equipment.

The content of the article:

When is a circulation pump needed?

When problems arise with the uniform distribution of heat in the house, one of two options is used to solve them: replacing pipes or installing additional equipment. New pipes of a larger diameter than the previous ones allow the heat distribution to be balanced.

This option is effective and practical. However, replacing pipes is not only time-consuming, but also expensive.

The second solution is to add a circulation pump to the heating system. It allows you to balance the temperature in rooms throughout the building. It also prevents the formation of air bubbles that hinder the flow of water. And the cost of a circulation pump is several times lower than the cost of pipes, their delivery and installation.

The device is also easy to install.Therefore, owners of private houses are inclined to install a circulation pump.

Planning for home heating includes not only boiler power calculation, selection of radiator locations, but also analysis of coolant movement. Of course, a large living space is an opportunity for a comfortable life for more than one person. But the coolant circulation speed decreases. Therefore, a pump is installed that makes the water circulate faster.

Purpose of circulation equipment

In a closed heating system, the boiler heats the water. However coolant circulates through the battery pipes at a low speed, so it returns to the boiler at a low temperature. The heating device operates at its maximum capacity, which reduces its useful life.

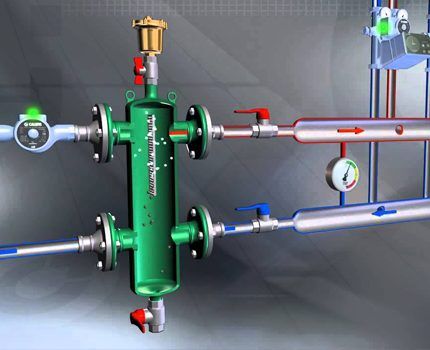

The purpose of the circulation pump is to overcome hydraulic resistance and ensure the flow of water in structurally complex, extended circuits. Including a pump in the circuit will help create uniform heating and an acceptable temperature in living quarters, allowing the boiler to operate at average power.

Also, in the case of using a pump, there is no need to arrange pipeline slopes towards the boiler and it becomes possible to significantly reduce the diameter of the pipes used in the assembly. The difference between the temperature of the water that enters and leaves the boiler is only a few degrees.

Design and types of pumps

Circulation pumps are not particularly complex in design. Therefore, they are easy to repair.

The main elements of the equipment are the housing, the impeller and the electric motor. The blades rotate, resulting in centrifugal force. As a result, areas with different pressure levels are formed.

Circular pumps are divided into:

- "wet";

- "dry".

The rotor type makes the difference. The tightness of the housing is ensured by a special metal cup, which is located between the stator and the rotor.

Placing the rotor in a coolant environment guarantees a constant decrease in its temperature and lubrication of structural elements. Also, the sounds of the pump are practically inaudible, since they are absorbed by water. Because of this, this type is used in private homes.

However, the efficiency of “wet” pumps is 50%. This is explained by the inability to seal the rotor with a large diameter. Therefore, the equipment is not used when increased productivity is required, for example, with an extended pipeline.

As for the “dry” rotor, its working part does not come into contact with water. The latter's impact is blocked by protective rings. This design is smaller in size. And the power is 1.5 times greater - 80%.

There are the following types of devices with a “dry” rotor:

- Centrifugal, in which the motor is flanged.The housing is fixed to the foundation slab using a special fastener.

- Large centrifugal devices with coupling connection and motor. If their water inlet and outlet points are located on the same axis, then they are called direct-flow.

To select the optimal circulation pump, you need to analyze many parameters. The most important of which are area of use, performance, cost and noise.

We also recommend that you familiarize yourself with the top ten circulation pumps for heating. More details - go to link.

Rules for choosing circulation equipment

The “wet” type of circulation pump has a lower noise level. The opposite situation is with a “dry” rotor. In this case, noise is generated not only as a result of the operation of the pump itself, but also of the fan, which is responsible for reducing the temperature of the electric motor.

“Dry” devices are installed in industrial premises, while “wet” ones are relevant for residential premises. After all, a noise level exceeding 70 dB will have a negative impact on the psychological state of those living in the house.

In the arrangement of private houses, the priority is the “wet” version of the circulation pump. Its blades are constantly in the pumped medium, the parts will be lubricated with water and will last 5 years or more.

When connecting the device to an open heating circuit, you should pay close attention to the quality of the coolant; you should not replenish it with water containing mineral and organic inclusions.

Another criterion is the pressure indicator.So, if for optimal operation of a closed-loop system it is within 10 m, then a “wet” rotor is suitable. Enough power of 25-30 m3 at one o'clock.

When the heating system requires more pressure, then the best option is a pump with a “dry” rotor. In its design, the rotor is separated from the heating pipeline by an oil seal. This type will consume less electricity than its “wet” counterpart with the same operating efficiency.

The following formula will help you find out the required pump power:

Q=0.86*P/dt

Where:

Q – pump power, m3/hour;

P – thermal power of the heating system, kilowatt;

dt is the difference between the temperature of the water before entering the heating device and after leaving it.

Let's give a specific example. Let the area of a residential building be 200 m2. Let's pretend that two-pipe heating system. To maintain optimal temperature in winter, a thermal power of 20 kilowatts is sufficient.

The default dt is 20 degrees Celsius. This indicator is sufficient for approximate calculations at home.

As a result, we get 0.86 m3/hour. We can round to 0.9. It's better to be safe from error. And over time, the circulation pump wears out, so the power will be less.

Another equipment parameter is pressure. Every hydraulic system has resistance to water flow. This characteristic necessitates the use of the device to ensure coolant circulation in the system.

To obtain the exact value of the hydraulic resistance indicator, calculations are carried out using the following formula:

H=N*K

Where:

N – number of floors of the building (the basement is considered a floor);

K – average hydraulic costs per floor of a house.

K fluctuates in the range of 0.7-1.1 meters of water column for two-pipe heating systems. And for collector-beam, its value is in the range of 1.16-1.85.

For example, a two-story house with a basement has three levels. If the calculations are performed by a non-professional, then the maximum value from the above ranges can be taken. For a two-pipe system this is 1.1 meters. That is, we calculate K as 3 * 1.1 and get 3.3 m of water column.

In a three-story house, the total height of the heating system is 8 meters. However, according to the formula, we received only 3.3 meters of water column. This value will be sufficient, since the pump is not responsible for raising the water, but only for reducing the negative effects of system resistance.

Basic installation details

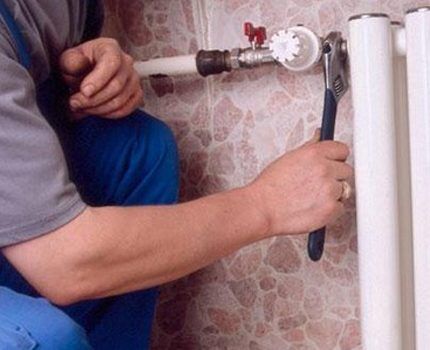

First, you need to determine the area for installing the pump in the heating network. It is important that it is in this place that it is convenient to make repairs or replace the device if such a need arises.

Previously, “wet” pumps were mounted on a return pipe through which noticeably cooled water circulated. This approach, according to reputable heating experts, increases the life of seals, bearings and rotors.

However, the structural elements of modern pumps consist of materials that are not afraid of exposure to hot water. Therefore, the device can be installed both on a pipe transporting cooled water to the boiler, and on a pipe carrying already heated water.

To normalize the pressure, the pump should be installed on the section of the pipeline supplying water to the boiler. Such a zone is located near the point where water enters the expansion tank. As a result, it will be possible to obtain a high temperature in this section of the heating system.

There are simple rules that will allow you to correctly install circulation equipment:

- placed below and above the pipe near the pump Ball Valves. The latter allow you to suspend the water supply, repair or replace the device;

- a filter is installed in front of the pump, which prevents dirt and other mechanical irritants from entering the device;

- An air valve is mounted on top of the bypass. It prevents the formation of air jams;

- There is an arrow on the pump body. It indicates how, in relation to the direction of water flow, the pump should be placed;

- The “wet pump” is installed in a horizontal position. If the electric motor is not completely in the water, then the device will fail faster;

- the device terminals point upward;

- all connections are protected with sealant and gaskets;

- use sockets with grounding for security.

Following these simple recommendations will allow you to install the circulation pump in the system as correctly as possible. In the future, its work will bring exceptional comfort to its owner.

It is important to remember one feature of manually operated equipment - in order to release air, you need to open the air valve for 5 minutes before each start of the pump.

While the fuel system is not filled with water and air has not been released, it is prohibited to turn on the pump. Otherwise, the device may burn out. But the automatically controlled pump releases air without human intervention.

The sequence of installing the circulation pump in the heating system is as follows:

- If the heating system is already in use, the water must be drained several times. This way they get rid of mechanical irritants.

- Bypass installation. Special taps are installed below and above the pump, which hold back water in the event of a pump breakdown and allow the device to be replaced.

- Mount the filter.

- Install a bypass pipeline line.

- Install shut-off valves to prevent free flow of water in the system.

- Install an expansion tank (relevant for an open type system).

- Install the pump in accordance with the instructions and installation rules. They are mounted horizontally, since in a vertical position it will lose a third of its performance and quickly fail.

- The joints are treated with sealant, which will have a positive effect on the operating efficiency and service life of the pump.

- Fill the fuel system with water.

The optimal number of circulation pumps is determined by the length of the pipeline. For example, if the total length of pipes is up to 80 m, then one device with average power is sufficient.

Although, it is better to install one for constant work, and install the second “in reserve”. This will allow, in the event of a breakdown of the main working device, to immediately start circulation of the coolant through the system.

If the pipeline in the heating system is extended to a distance of more than 80 m, 3-4 circulation devices or more will be required.

You can also order professional installation. The cost of specialist services is determined by the prevalence of the device model, the complexity of the bypass pipes and the number of pipeline circuits.

You can read detailed instructions on installing a circulation pump in the heating system Here.

Advantages and disadvantages of pumps

Many consumers focus exclusively on the strengths of the circulation pump. There is no doubt that this equipment brings great benefits to the home owner.

Its main advantages are as follows:

- Unpretentiousness – the device has no special requirements for the heating system. Various types of devices ensure the formation of a heating circuit of the required length.

- Optimal coolant speed. The equipment creates pressure differences and ensures better movement of water flow.

- Performance – prompt activation of the heating system. The batteries are filled with warm water in a matter of minutes.

- Convenience. The pumps are easy to install, maintain and replace.

- High efficiency. To ensure a comfortable temperature, a minimum of electricity is sufficient.

Circulation pumps not only increase the efficiency of the heating system. They are also easy to install and maintain. Also, the equipment, if installed correctly, will last for many years.

But, unfortunately, it also has several disadvantages. The main disadvantages of heating systems with pumps are as follows:

- Increased energy costs. The more powerful the device, the higher the bill.

- Device dependence on electricity.

- Additional expenses. It is impossible to install the pump without purchasing the accompanying parts.

- Installation costs. If the heating system is already operating, you cannot do without a specialist who will connect the pump in accordance with the technical requirements.

To reduce your dependence on electrical energy, you can purchase a diesel generator specifically designed for a specific pump group.

Or install the device with a slope so that the system operates on the basis of natural circulation for a short period.

The advantages of the circulation pump seem more significant than its disadvantages. As a result of using the device, the efficiency of the fuel system significantly increases. Most of the disadvantages of the unit relate to additional one-time or regular costs.

Conclusions and useful video on the topic

About the design and installation rules of the pump in the video:

Features of installing circulation equipment in a heating system are demonstrated in the video:

Having become familiar with the operating principle of circulation equipment and the main differences between wet and dry type, you can choose the most suitable option for your heating system. If you wish, you can install the pump yourself. To do this, you should follow the rules and useful recommendations for installing circulation equipment.

Do you have personal experience installing similar equipment? Please share it with our readers. Tell us about the installation nuances that you know. Leave your comments, ask questions, share your experience in the comments section.