Engineered board or laminate: which is better to choose for floor construction

Engineered wood or laminate are two of the most popular, beautiful and versatile types of flooring.This is where their similarity ends. The difference lies in the raw materials used. There are 5 differentiating criteria that will help you make a choice.

The content of the article:

General characteristics of engineered boards

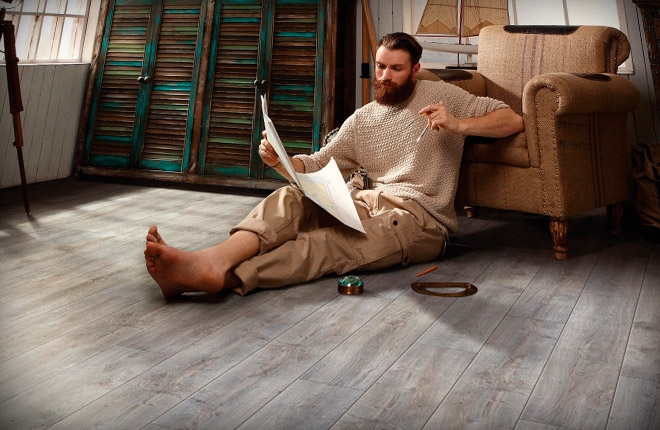

Parquet or engineered board with a lock is a multi-layer material, a kind of improved substitute for natural wood. In appearance it resembles solid wood. It surpasses it in technical characteristics. Therefore, the massive board is gradually losing its position and leaving the market.

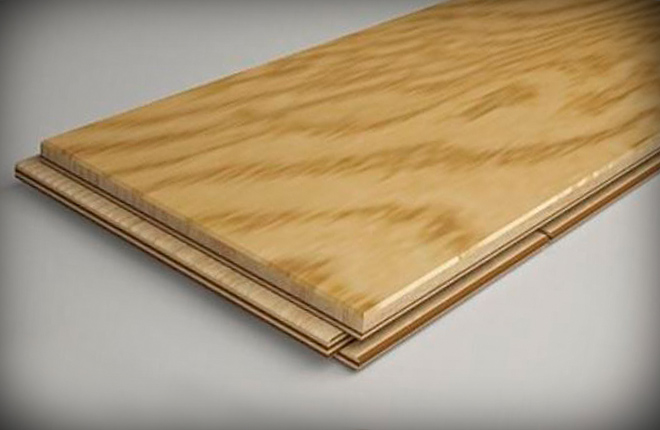

Engineered board has two layers. The lower one is a stabilizing base, occupies ¾ of the thickness. Made from high quality plywood, with internal and external cuts. These are several sheets glued together. In this case, the direction of the fibers alternates. The top ¼ is solid hardwood. This design is resistant to mechanical stress, temperature and humidity fluctuations.

This is interesting! What is the difference between parquet and laminate. Flooring and quartz vinyl tiles. What is better to choose for the floor: plywood or OSB?.

General characteristics of the laminate

The main differences from engineered boards are that laminate consists of mono-structural or dry-made fiberboards. Medium and high density fiberboard is used. Lined with a film made on the basis of thermosetting polymers.

Laminate gets its name from the word “lamination” - a method of connecting several layers. This is the lower stabilizing layer, then the main plate, equipped with an interlocking connection.The upper decorative part with a wood pattern is covered with a protective layer. Despite its appearance, laminate is classified as a synthetic floor covering.

The base is made of paper or cardboard. For strength and protection from moisture, they are impregnated with synthetic resin. The supporting structure can be made of MDF (it is light, medium density, low strength) or HDF (it is heavy and dense, more durable material). Decorative finishing - paper in a cheap laminate, natural veneer in a quality product. The coating is a film of polymer resins.

Options for comparing materials

Engineered boards are laid in exclusive and luxury interiors, as well as in rooms with increased pedestrian traffic. A large selection allows you to use different layout options. Variety of design solutions - choose the type of protective coating. Depending on the thickness, there is the possibility of local restoration and multiple grinding.

Laminate flooring can be used in any room. You should pay attention to the markings and class for rooms with high humidity, temperature, and aggressive environments. The popular material is resistant to fading and stains. Withstands long-term abrasion and stress. It does not require any processing after installation.

| Types of coating | Load-bearing base | Stabilizing layer | Decorative | Protective | Dimensions mm |

| Double-layer engineering board | High-strength birch plywood (thickness 6-16 mm) | Oak, ash, walnut (2.5-7 mm) | Varnish, mixture based on wax and oil Without coating, treatment is carried out after installation is completed | Length up to 3000 Width 300 Thickness with backing up to 30 | |

| Parquet, three-layer engineering board

| Birch plywood | Perpendicularly laid coniferous or birch boards | Cut valuable species (2-4 mm), tinted, oiled, varnished | ||

| Laminate | MDF, HDF, plastic for waterproof look | Resin impregnated cardboard | Printed paper Valuable wood veneer | Overlay – transparent, matte, glossy Texture imitating wood fibers | Length 1260-1380 Width 90-330 Thickness 6-12 |

Environmental friendliness

A high-quality floor covering should not emit harmful substances during operation. This is the essence of environmentally friendly materials. Natural raw materials means that all its components are of natural origin and do not have chemical additives.

Engineered boards are made from natural materials. There are no harmful fumes when heated. But do not forget that plywood glue contains phenol. Therefore, environmental friendliness depends on the manufacturer. Namely, on the quality of glue, oil and paints and varnishes for processing the top layer.

Laminate is made from compressed wood waste, which is considered a natural raw material. Melamine or acrylic resin, which contains formaldehyde, is used for gluing. This substance, harmful to human health, is released when the laminate is heated above 40°. Particularly dangerous at high concentrations.

Small amounts of formaldehyde are present in natural wood. It gives it the smell of wood. According to European standards, there are the following environmental classes:

- E1 – permissible amount of formaldehyde resins no more than 0.125 mg per m3;

- E2 – from 0.125 to 1.25;

- E3 – from 1.25 to 2.87.

In Europe, the production of third class products is prohibited. The E0 class is currently at the development stage. High-quality laminate has an emission of no more than E1. Certified manufacturers move to E0 standards.

terms of Use

It is preferable to use engineered board in large rooms. She is not afraid of temperature changes. Can be laid both on a warm floor and on a closed veranda, in the corridor. The engineering board coating is not moisture resistant. Therefore, it is not suitable for the bathroom and kitchen.

In this regard, laminate is more resistant to temperature, humidity, does not ignite (symbol “B” on the packaging), and is not susceptible to fading. They are divided into classes based on their endurance level. Depending on the quality of the raw materials, it is used for home or industrial premises.

This is useful! Is it possible to lay laminate flooring on old parquet?.

Care

Engineered board requires periodic cleaning. It can be swept and vacuumed. Regular wet cleaning with a soft cloth, without forming puddles, is required. To prevent scratches and dents, walk on the floor in soft shoes or slippers.

Laminate flooring is easy to clean. In this regard, it is a leader among finishing materials. If there is no dirt or stubborn stains, it is enough to wash the floor with warm water. To maintain shine, the water should be changed more often. You can add a little 9% table vinegar. For care, do not use bleach or products containing acids and alkalis.

Durability

The service life of an engineered board lasts from 20 to 40 years. The thicker the top decorative layer, the more times the floor can be restored - scraped, impregnated with oil, varnished.

The most wear-resistant laminate of class 32. It can last from 15-20 years, if all the rules of care are followed. It usually has to be replaced after 5-8 years. It deteriorates when liquid penetrates through the joints.

Installation method

There are several ways to lay engineered wood.This is the connection of modules into a lock, installation with glue, a mixed version. There are several types of installation - figured, deck, squares, herringbone. And although the installation process is complicated, you can do it on your own.

Laminate is installed in a locking way. It can be installed on any base. The old one does not need to be removed if it does not have any changes or damage. The substrate is pre-installed.

But the most common is the direct method. Installation is carried out from the window. Laying in herringbone, stripes, and diagonally is also used.

There can be no clear answer to the question of what is better to choose for the floor - engineered wood or laminate. You need to be guided by the technical characteristics, take into account all the pros and cons of the material, relying on your financial capabilities, familiarize yourself with the manufacturers, and check the quality certificates.

This will come in handy! How to lay linoleum on old parquet. Leveling the floor with plywood on an old wooden floor.

What type of flooring do you prefer? Leave a comment, share the article on social networks, add it to bookmarks.

Why do designers criticize laminate so much? After all, if it’s an expensive laminate, will it be more stable and reliable, or am I missing something? Help me decide, because although I hear everywhere that parquet boards are better, I can’t always determine this even visually.

Because laminate is not a natural covering. Read on Wikipedia what laminate consists of. This is polyvinyl chloride + a picture of a tree, I think the desire to lay a floor for yourself will immediately disappear. Designers do not like, roughly speaking, “counterfeits”!

Do designers only choose furniture from solid wood for their clients? Are all clients rich? Some kind of stupidity, we are surrounded by substitutes and surrogates and even fakes, because we are not so rich as to buy only eco, it’s funny to deny this.

Laminate flooring is a variety of textures, colors and naturalistic patterns up to “newspaper”, “wine boxes” and “painted boards”, and does not have a noticeably repeating pattern. It is possible to diversify the design of modern premises. A high-quality one does not smell, does not scratch or crack at the joints from wet cleaning. Does not require maintenance, set it and forget it. In case of damage, one lamella can be replaced. Quiet when using the substrate. Due to the low profile height, it does not create steps at the joints, for example, with tiles. It is not afraid of warm floors and is not trampled in walk-through areas. Inexpensive installation work.