What is the difference between parquet and laminate: detailed comparative analysis, pros and cons

Choosing the right flooring material has never been easy, even if you have certain preferences. Most often, the floor covering is seen to be wooden or made of a material resembling the properties of natural wood. What to lay, parquet boards or laminate flooring, and what is the difference between parquet and laminate? There are many nuances, and you can get confused.

The content of the article:

What is the difference between parquet boards and laminate

In fact, these are 2 different types of flooring, only externally similar in design. The main difference between parquet and laminate is the manufacturing method. Different technologies and materials used. Although after laying it on the floor it can be difficult to determine the difference between parquet and laminate, there are differences, and significant ones at that.

Laminate is pressed cellulose fibers. Parquet differs in that the upper front part is always made of natural wood.

Differences:

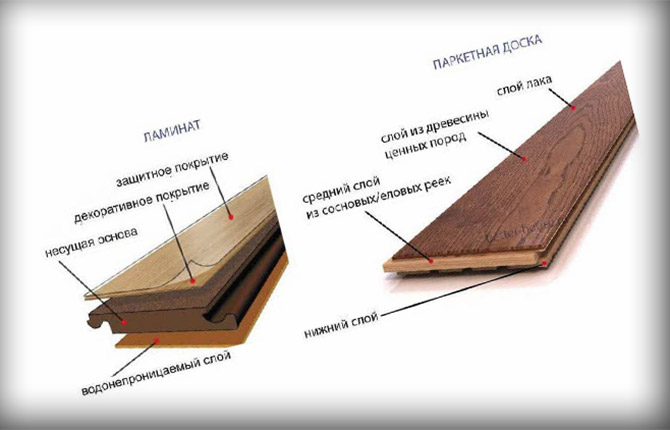

- Parquet boards can be made of several layers, but there are options when the parquet (planks) is cut from one solid wood. Laminate always has a multi-layer structure.

- Lamellas (laminated boards) can reach 6 m in length, up to 40 cm in width, parquet is produced in planks from 70 mm to 180 mm, maximum 250 cm in length. If these are square panels, then 40x40 cm or 60x60 cm.

- The top layer of parquet is always wood, most often glued veneer 2.5-5 mm thick.For laminate, it is a thick polyester or polyurethane film glued to a base of pressed cellulose fibers;

- Parquet boards are very thick; thinner than 13 mm is practically never found, usually 25 mm. Laminate can be up to 12 mm.

In inexpensive brands of laminate, the base can be fiberboard, in cheap brands it can be chipboard. For expensive laminates, a special base is made of pressed fibers impregnated with a silicone binder. As a result, the material acquires increased flexibility, does not absorb water, and most importantly, the locks are highly durable.

Inexpensive brands of parquet (rustic or country class) are oak veneer glued to heat-treated pine. High-quality parquet (Select class is cut from individual sections of logs) is almost always piece-made, with individual adjustment of the boards according to fiber colors and sizes. It can be made of oak, beech, but more valuable species can also be used - wenge, African oak, cork.

The only thing that both floor coverings have in common is the installation method. Necessarily on a substrate, the floor covering can be glued to the floor or assembled using end locks of a special design.

There is also a difference between parquet and laminate in terms of service life. If we compare in terms of durability, the leader will be parquet flooring. Piece or stacked parquet (laid from planks 40x250x18mm) is durable and resistant to wear. It can last up to 40 years. Good quality laminate will last 12-15 years.

Pros and cons of laminate

The material is simple and light. Sometimes laminate is mistakenly classified as office flooring, but this is not entirely true.It can be found everywhere, it is affordable, and thanks to the huge selection of colors, the popularity of the material is enormous. The only place where laminate floors are not installed is in shopping centers.

Another significant advantage of laminate is that the material forgives minor flaws during installation. This means that you can lay the flooring yourself without compromising quality.

There are two important disadvantages: laminate floors are not highly resistant to spilled water. Getting wet often causes the entire coating to be replaced. Laminate flooring can be repaired only in small areas by replacing 1-2 lamellas.

The second disadvantage is the creaking that appears if the lamellas were laid on an incorrectly cut substrate. Dealing with creaking floors is difficult. Typically, squeaking means that the locks are not working to secure the floor covering. It won’t take long for the tongue-and-groove connection to break.

Laminate flooring is easier to replace or maintain. If necessary, the floor can be disassembled and tried to dry. But such a solution is only possible for high-quality waterproof slats. Cheap brands, as a rule, are not durable.

There are special brands of laminate with heat-resistant coating and rubberized locks. Once assembled, this material can withstand contact with spilled water for half an hour, and the polyurethane film is highly heat resistant and can easily withstand a dropped lit match or even a candle.

The wear resistance of the top coating is so great that the material can be used in crowded places, where tile or concrete floors are usually made.

Pros and cons of parquet boards

Parquet is classified as a representative type of flooring along with piece tiles made of natural stone or mosaic flooring. Just 20-25 years ago, parquet flooring could only be laid out using sawn planks measuring 50x320x22 mm.

At the same time, laying the coating was labor-intensive and required the skill and experience of a craftsman. This floor served with the appropriate level of care for 30-40 years.

Disadvantages of modern parquet boards:

- Most brands of parquet, even expensive branded ones, are machine-processed boards, glued and veneered using furniture technology. Therefore, modern parquet flooring is inexpensive and accessible to the average consumer.

- The selection of material for parquet boards is made from ordinary wood. There is no selection based on where the tree was grown, age or fiber structure. Even the Select brand is simply a high-quality solid, cut from a certain place in the trunk. Accordingly, the quality of such parquet differs from the generally accepted opinion about the strength and wear resistance of parquet flooring.

- The use of a large number of impregnations and adhesive compositions to improve the mechanical properties of parquet boards. Instead of traditional harmless wax mastics and oil polishes, paintwork materials with a complex chemical composition are used.

- In appearance, modern parquet differs little from the best brands of laminate and is even inferior in the variety of fiber patterns.

However, parquet flooring has several positive qualities that make it popular and in demand. Walking on it is much more pleasant than on laminate and especially linoleum. Parquet, even if it produces a certain amount of dust (due to wear and abrasion of wood), is harmless.Parquet flooring has a low level of electrostatics, which means dust does not stick to it like synthetic flooring.

With proper care, natural parquet lasts a long time and does not lose color or surface texture. Moreover, high-quality parquet flooring differs from synthetics in its ability to restore the color and pattern of wood fibers.

Detailed comparison

The easiest way to choose the best option is to compare both floor coverings of approximately the same class, select the points in which they differ, and determine the most important positions.

Price

Parquet will always have a higher price. Laminate production technology is much cheaper. Essentially, this is a strip of fiberboard onto which a decorative film with a fiber pattern is glued, followed by hot pressing of the film (or several layers of MDF varnish). It is not difficult to understand what is cheaper, if only because laminate can be considered an imitation of parquet boards.

Laminate production is characterized by its “omnivorous” nature. Products of different classes differ only in the thickness of the film (number of layers), the design of the joining locks and the presence of a silicone seal in the tongue-and-groove system and the back side of the base.

Making parquet boards is a complex technological process. The workpieces are sorted so that adjacent planks or glued veneer differ in color or grain pattern by no more than 1-2%.

Installation

The laminate flooring assembly system makes it possible to lay the lamellas with your own hands, without outside help. Panels of different makes and brands may differ in the design of the end locks, but almost always the procedure is the same:

- The first lamella is laid on a substrate or directly on the floor with glue applied.

- The second board is tilted at an angle (45-60O) to a horizontal surface, engage with the already laid panel and move it to a horizontal position.

- After tapping the end with a wooden hammer through the rubber spacer, you can move on to the next lamella.

Before laying laminate or parquet, the surface must be planned and leveled so that the height difference over 1 linear meter is no more than 2 mm. Then a backing made of polyethylene or pressed pine needles is laid.

Laying parquet is more complicated. Ordinary parquet boards are also laid on a substrate, but the requirements for the base are more stringent. Moreover, you need to choose the right shades, since within the same batch there may be parquet boards that differ in the saturation of the pattern. The defect can only be seen after installation.

Block parquet is the hardest to install. The dies are glued to mastic or a special viscous composition. At the end, they are scraped with a grinder and opened with varnish. This flooring is characterized by maximum durability.

Which floor is easier to disassemble?

Inexpensive laminate can be disassembled 1-2 times maximum. The process is simple, you need to proceed in the reverse order of assembly. If you try to disassemble it a third time, half of the locks will be broken. Some expensive branded brands of high-end laminate (class 33) cannot be disassembled and re-installed, but there are models of high-quality laminate flooring where the locking design allows you to open the connection and disassemble the slats.

It is easier to dismantle un-glued parquet on a backing, but re-laying the board can be difficult. Locks on parquet boards differ from laminate ones and, as a rule, are not designed for reuse.Therefore, the parquet will have to be glued to the floor a second time.

Which is more durable?

With proper care, a solid wood parquet floor can “survive” 2-3 generations of high-quality laminate flooring. Especially if it is oak or beech, wenge, ebony. Regular veneered parquet on a plywood base lasts no longer than high-quality laminate.

Parquet can be considered more durable due to strong locks, but again only with care and periodic treatment of the coating with protective mastics. If you do not take care of the parquet board, then cracks quickly appear on the end surface, which leads to the destruction of dies and panels.

Laminate is distinguished by the fact that it does not require special care - it is enough to lay the material correctly and at least once a year treat the cracks with protective waxes to prevent the accumulation of dirt and water in the locks.

Flammability

Due to the high content of pure cellulose fiber, lamellas are less resistant to open fire and hot objects. The maximum temperature is considered to be up to 120℃, after which the protective film begins to soften and swell.

With short-term contact, even with open fire, the laminate has noticeable durability. If you drop a hot iron, soldering iron or a lit candle (match) on the floor and pick up the object within a few seconds, only a dark spot will remain on the surface.

Laminate flooring burns better than plank flooring or parquet, so you can’t place a potbelly stove or apartment fireplace on the floor.

Parquet is highly resistant to heat - it does not burn, even if the process of charring the wood or plywood base has begun. But you need to take into account that all brands of parquet boards (except for piece) are impregnated with special compounds.

Therefore, when the coating burns, a huge amount of toxic gases (including carbon monoxide) are released, causing suffocation and even poisoning.

Strength

If we compare it in terms of fatigue strength, the laminate will be more durable. Due to their more elastic base, laminate panels are flexible. This means that flooring laid with slight errors and incorrectly placed furniture will result in the floor popping or squeaking. In extreme cases, a small bubble will appear, but the laminate will remain intact.

Parquet does not forgive mistakes - if the coating is “suspended” in the air, even in a small area, the result will be broken locks at the joints.

On the other hand, parquet flooring has high contact strength. On top of the covering you can install a heavy cabinet on thin legs, even a cast-iron bathtub, and the wood will withstand the pressure. Especially if it is piece parquet.

Laminate has low contact strength - incorrectly placed furniture can cause the lock to break.

Which material is more wear-resistant?

You can compare 2 types of flooring only within the same wear resistance class:

- The heaviest laminate (for cafes, minimarkets, offices) class 33 is highly wear-resistant. It is higher than that of a good panel parquet with additional surface varnishing.

- Middle class laminate, 31-32, approximately corresponds to the characteristics of high-quality parquet flooring. It is used in apartments and private houses as the main floor covering.

- Budget class parquet is superior to inexpensive laminate flooring in all respects.

It should be taken into account that the wear resistance of parquet largely depends on two factors - the nature of the wood and the care of the coating. On laminate, restoring the protective film is difficult and not always possible, while parquet can “survive” several major repairs with restoration of the appearance and texture of the surface.

This is useful! Engineered board or laminate: what is better to choose for floor construction.

Humidity resistance

For parquet, any contact with moisture is undesirable; this differs from floorboards or fiberboard. Even if the floor covering is regularly maintained, treated with mastic or wax, water spilled on the floor finds cracks and flows under the base. But this requires at least 10-15 minutes.

If the washing machine leaked, or a container of water was overturned on the parquet floor, you must immediately remove the liquid from the surface and, if possible, dry the floor. If the apartment is flooded by neighbors or the roof is leaking, then urgently dry the parquet, and most likely re-lay some part.

Conventional brands of laminate also do not tolerate contact with water well, perhaps even worse than parquet. But waterproof models of laminate flooring with rubber seals in the locks can stand in water for an hour for a new floor and 20-30 minutes for an old worn-out floor without damage.

Which is warmer

Definitely, a laminate floor will retain heat better due to the lower thermal conductivity of the material. In addition, a thick cork or coniferous substrate (8-12 mm) can be laid under the laminate. In this case, you can even walk on the floor with bare feet, even if the material is laid directly on the concrete floor slab.

Parquet is cooler; dense and heavy wood conducts heat better.A thick substrate cannot be laid under the panels.

Therefore, plywood subfloors are used for concrete subfloors, or, as an option, cork flooring can be installed. It is not afraid of water, and its thermal conductivity is even lower than that of laminate on the thickest backing.

Noise insulation

Parquet is definitely the most “resonant” material. In terms of sound insulation, it is inferior not only to laminate, but even to ordinary PVC tiles. If the neighbors above have laid parquet, then not only steps will be heard, but even the sound of an object falling on the parquet floor.

Cork parquet has good sound insulation, while coatings made of oak, beech, and ebony are very noisy. Sometimes, to dampen noise, the joints between the boards are treated with a silicone compound - this makes it possible to reduce the noise level by 20%.

Laminate may also not have good sound insulation, for example, if the material is glued to a concrete floor without a backing. But such schemes are used mainly in cafeterias and public institutions, where it is important to extend the service life. Oddly enough, without a soft base, laminate lasts longer.

Care

High-quality laminate requires minimal maintenance; 1-2 times a year, you need to clean the joints from accumulated dust and treat them with silicone oil to squeeze moisture out of the locks.

After 3-4 years of service, budget stamps are periodically opened with a special polyurethane varnish. This allows you to partially restore the protective film and close the joints from moisture.

After wet cleaning, the laminate flooring must be dried. If it is a warm floor, then the heating power is increased to 80% within 20-25 minutes. On ordinary floors, it is enough to open the window and door to allow a draft (even cold air) to dry the coating.

Caring for regular parquet involves treating the joints with wax mastic at least once a month. Piece parquet has increased maintenance requirements. At least once every two weeks you will need to rub the floor with mastic, and if necessary, polish the surface. This treatment guarantees reliable protection against scratches and moisture.

Once every 5 years, the surface of the piece parquet is scraped or sanded to level the surface. As the top layer of wood wears away, “paths” form on the surface; in addition, edges rise on the boards themselves, which need to be cut off.

But these requirements most often apply to old and budget brands of parquet flooring. For example, ebony or wenge floors are not scraped. It is highly resistant to abrasion, so the first repair, if necessary, can be carried out no earlier than after 15 years of operation.

Environmental friendliness of the material

Parquet is definitely considered a cleaner and safer surface. Especially if these are piece dies, and not boards glued together from several different types of wood. Parquet flooring is distinguished by the fact that the front part of the wood is practically not subjected to deep processing.

Excludes heat drying or pressure compaction. All other surfaces are treated with protective impregnations. But after assembly they remain closed and do not pose a danger to humans.

Laminate has the opposite situation. The outer layer is a polymer film and paper with applied texture and fiber colors. Both materials undergo sanitary and hygienic control, so there is nothing to fear.

Sometimes dust appears on inexpensive brands of laminate, which is thrown out through the locks from the surface of the concrete by a stream of air.

Such problems are typical for coatings laid on the cheapest polyethylene foam substrates. There is no dust formation on cork or coniferous lining materials.

Which one is better for heated floors?

The thermal conductivity of parquet is slightly higher than that of laminate. Therefore, a covering made of planks is better suited for arranging a heated floor.

In addition, the structure of the parquet floor is distinguished by a large number of tiles and joints between them. This means that, thanks to the large number of seams, the parquet flooring is more flexible and will not “bubble” when subjected to strong heating, for example, when using a cable floor heating system.

For laminate, lighter systems based on carbon graphite film are recommended.

But parquet boards have one drawback: they have a high coefficient of thermal expansion. With strong and prolonged heating, wood, even thermally stabilized and varnished, can change size and even crack. Therefore, when choosing what is best for a warm floor, you need to take into account the heating scheme.

You can only understand the difference between parquet and laminate from your own experience. The most complex and capricious character of a parquet floor. Therefore, the selection of planks, laying the material and caring for it must be approached carefully. And laminate can be considered as a temporary replacement. Although most modern laminate floors are not that different from cheap parquet.

What would you choose? Share in the comments. Save the article to your bookmarks so that useful information is always available.

My grandfather comes to me with rheumatism.He says that while I walk on the parquet at home, my feet are fine, your feet are on laminate, and after a day they already hurt. By the way, for some reason dogs don’t like laminate flooring; they try to scratch everything.

Parquet has long been obsolete. What's the point of spending crazy money, messing around with wooden blocks, if there are cool Swedish brands of laminate that are superior to parquet. Both the quality and the design, everything is there. I can even put out a cigarette on the floor, and nothing will happen to him.