How to make a reliable barbecue cauldron from brick: step-by-step construction instructions, materials, nuances

The traditional metal barbecue cauldron has long been equal in popularity to the steel barbecues, braziers and shish kebab grills that are familiar to everyone. Most of these structures are built from sheet steel, sometimes from cast iron.

The content of the article:

Design examples

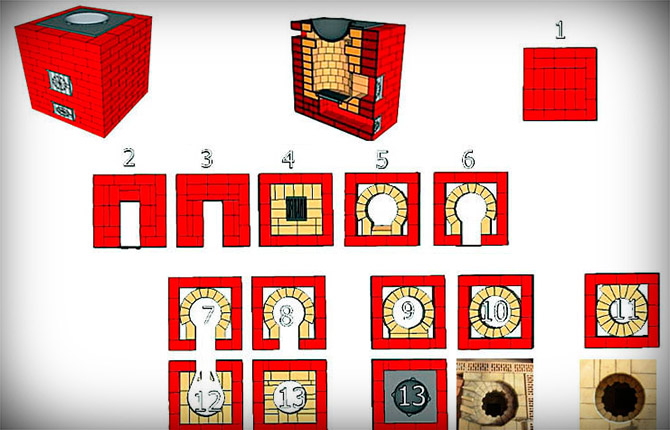

There are several ways to build a brick grill with a stove under a cauldron. They are all different, in each case the master tried to make the stove the most convenient, safe and easy to use.

It is clear that this is a temporary scheme, it is unsafe to use such a barbecue-cauldron, so you need to make a full-fledged masonry for installing a cauldron with a firebox and vent.

The weight of such a stove is no more than 300 kg, so a barbecue cauldron can even be made on a wooden floor, for example on a terrace or in a gazebo. The only drawback of the scheme is the absence of a chimney. Combustion products and flue gases will be removed only due to the natural breeze blowing over the grill of the cauldron.

In practice, “cube” barbecues are built only for small rooms where there is a built-in chimney. For open areas and extensions, a more rational solution would be to make a barbecue with a stove for a cauldron.

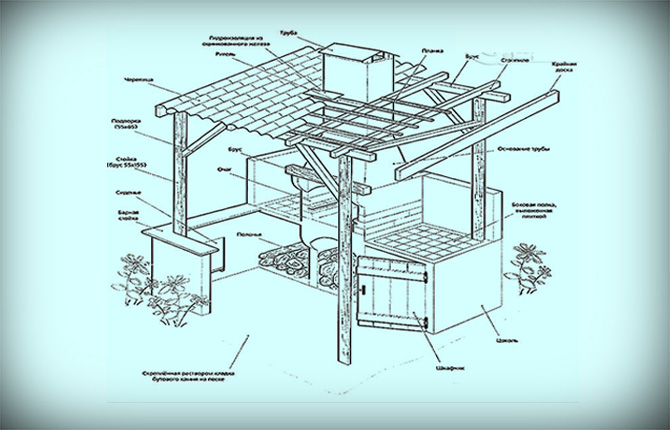

The chimney is made with an exhaust hood to prevent the accumulation of flue gases under the canopy.

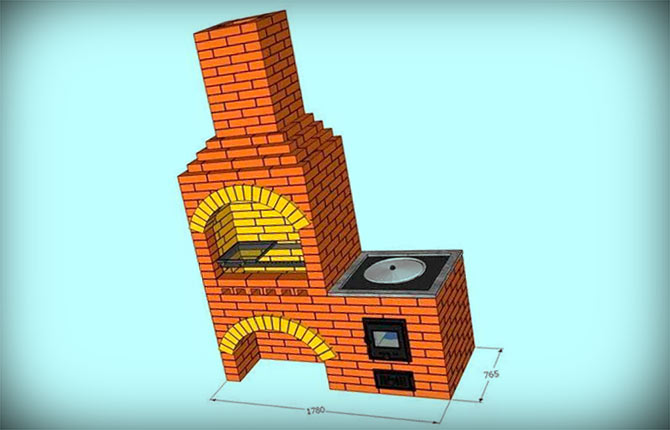

This decision is not accidental; the stove and cauldron must be connected in height to the hob or barbecue. The problem is that the round bottom of the cauldron serves as the arch of the firebox. This form is not very suitable for normal burning of wood, so the combustion process is helped by a nearby stove or barbecue, no matter what.

Therefore, if you need a project to make a barbecue cauldron with your own hands, then you can choose the option presented below as a prototype. At the same time, you can make step-by-step instructions with your own hands, and the order of the masonry and the main dimensions can be calculated in a special program on a computer.

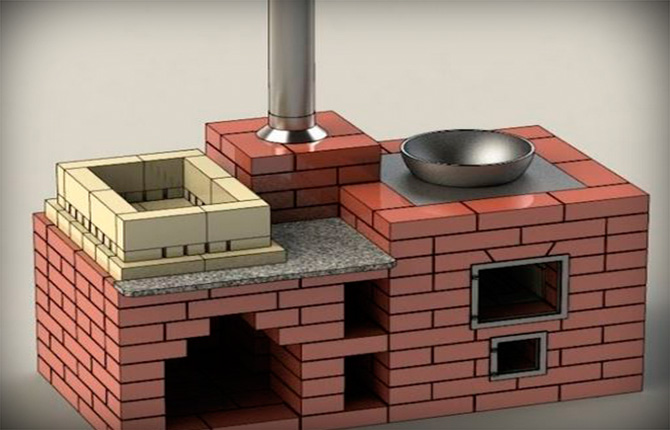

A mandatory attribute of a barbecue with a stove is a large cast-iron stove; it is installed under a cauldron, because it is impossible to embed dishes into brickwork due to the different thermal expansion of cast iron and stove bricks.

In addition to the stove itself, you will need to decorate and decorate the building.For example, make a small canopy or gazebo, as in the drawing.

We read: How to make a smokehouse cabinet with your own hands

Construction stages

First of all, you need to do the project correctly. Finnish or Swedish brick stoves are very popular.

The second step is to create an action plan:

- Choose the right place. It is better to make a barbecue in the backyard, since any firebox produces smoke and odors, so you need to take into account the direction of the wind.

- Make a foundation. Even if it is a light, simple barbecue and a 5-liter cauldron, you still need to make a base, since the structure has a rather high chimney made of brick.

- Select and purchase materials, rent tools.

- Lay out the stove body, make brick lining, install the stove and cauldron.

- Make a chimney, its height will be at least 3 m.

After laying out the stove, installing the chimney, installing grates, a stove for the cauldron, and a grill grate, the masonry will dry out for some time. Only after a week will it be possible to do the first drying: burn the paper and splinter in the firebox under the cauldron.

How to choose the right place?

It is best to make a brick stove on the windward side of the gazebo or any other place to relax. For example, make a stove with a barbecue adjacent to the podium in front of the pool or on the open terrace.

The firebox with barbecue and cauldron produces quite a lot of heat, so this is a good option for relaxing in the evening or in cold weather. Thanks to the high chimney, there will be no problems with smoke; if you make a screen for the stove, you can generally warm up by the barbecue, like by a fireplace.

Another requirement is that the location must be suitable for the characteristics of the soil and rainwater runoff. That is, you can make additional reinforcement, a drainage gutter to divert water flows, but it is much easier to choose a site on a hill.

Preparation of materials and tools

There is nothing unusual in the construction of a stove for a cauldron. The outer building is made of ordinary brick, the internal bulkheads must be made of stove stone. It is better to shield the walls in contact with the firebox with basalt felt.

List of main materials:

- clay ceramic brick - 200-250 pieces, plus fireproof 30 pieces;

- concrete M150 - 200 l, or 3 bags of ShPTs 300 cement plus sand 1.5 m3;

- dry masonry mixture for laying fireplaces 2 bags;

- two sets: one double door for the combustion chamber under the cauldron (for the firebox and ash pan) and one for the ash pan under the grill;

- basalt felt - 4 sheets 25 mm thick;

- cast iron stove for cauldron, grill grate;

- cast iron chimney valve;

- chimney cap;

- a plate of pressed vermiculite fiber with a thickness of at least 15 mm;

- two grates 300x170 mm - for a cauldron and a grill, respectively;

- soft steel wire 3 mm.

The tools you will need are a trowel, a grinder with cutting discs, a mason's hammer, a building level, paint cords, a shovel, a container for mixing concrete for the foundation, a small 7-8 liter bucket for a set of masonry mortar.

Separately, you need to buy reinforcement for the foundation, as well as a fine mesh for reinforcing the top layer of the concrete foundation. You will also need boards and a sheet of polyethylene film 1.5 x 2.5 m.

The cookware should be cast iron, namely a cauldron, and not an aluminum or steel cauldron. During the selection process, you will need to measure how tightly the cauldron fits on the cast iron plate stand.

In addition to the cauldron, you will need to buy a Chinese cast-iron frying pan with a concave bottom for the stove. Such dishes serve as a lid on the stove so that the bricks and coals in the firebox do not cool down while the cauldron is away. This frying pan is also very convenient for heating vegetables and meat cooked on the grill.

You will need: DIY gas grill

How to choose a brick

For masonry you will need fireclay and ordinary brick of the M150 brand, but of very good quality. You can come across a lot of recommendations that a stove only needs special stove bricks with a high alumina content, but this is not necessary.

In fact, solid molding bricks made from good quality clay are suitable for the outer walls of the barbecue. The main thing is the structure; the brick must be dense, heavy, without cracks or colored spots, evenly colored, with a relatively small number of pores.

Modern brick is made by plastic molding and semi-dry pressing. The first one turns out to be heavy, cold, but strong enough not to crack from the heat of the coals in the grill or in the firebox under the cauldron.

Dry-pressed bricks are usually facing or “warm” grades; they are unsuitable for laying furnace walls.

In addition to clay bricks, for the barbecue cauldron you will need fireclay, about 20-30 pieces. From it you will need to fold a pallet in the grill, as well as a firebox for the cauldron. Also, part of the fireclay will be used to lay out the outlet from the chambers into the chimney pipe.

Advice! Fire bricks are usually of good quality, but it doesn't hurt to check. You can lightly hit the surface with a small hammer, the sound should be clear, metallic. Color - from gray-yellow to straw yellow.

Therefore, before purchasing fireclay, you need to draw a brick laying diagram. It’s better to make your own instructions for assembling the combustion chamber for the cauldron and separately for the barbecue.

Preparation of the solution

The simplest solution is to buy ready-made masonry mixture for fireplaces. This is a dry batch based on purified clay, a small addition of sand, lime and fireclay powder. There is a risk of buying a fake; there are many of them on the market. But if you are not greedy, then it is quite possible to buy a dry mixture for stoves for ordinary and fireclay bricks.

The outer walls of the firebox for the cauldron, the walls and the entire part of the barbecue are laid out from stove bricks, so you can make the batch yourself. For external masonry under the cauldron and barbecue, a mixture of 20% cement, 15% each of fatty clay, lime, 40% clean washed sand is used, the rest is fireclay powder. Add 2 buckets of water per 10 liters of dry mixture.Mix the solution in small portions, because it sets quickly.

The hot part inside the furnace is laid out with a solution of cement (10%), clay (25%), fireclay (the remaining 65%). On it you can lay out the walls and the transition from the firebox under the cauldron to the chimney. On clay with chamotte, but without cement, you can lay out a shelf under the grill.

The firebox for the cauldron and the tray under the barbecue are laid out from refractory bricks. For it you need to make a separate solution - cement-chamotte. That is, instead of ordinary quartz sand, fireclay sand and lime (5%) are added to the batch.

It is very difficult to mix by hand; usually it is mixed with a concrete mixer. But its volume for a cauldron and barbecue is small, so you can try to knead it manually. The shelf life of the batch is 40-50 minutes.

Foundation preparation

You don’t have to make a concrete slab for a stove with a cauldron and a barbecue if you abandon the brick chimney and use a modern sandwich pipe.

If the cauldron-barbecue project includes a brick pipe, then you will have to fill the foundation according to all the rules:

- Stage one - you need to dig a rectangular pit. Depth - 35-40 cm, width and length are selected according to the size of the stove, so that from the cauldron-barbecue to a circle you get a blind area 30-50 cm wide. Formwork from boards is sewn onto the walls. It is necessary that the foundation is at least 10-15 cm above the ground level.

- A mixture of sand and gravel is placed on the bottom in a layer of 10-15 cm, compacted, and covered with plastic film. A reinforcing mesh is made on top of wooden choppers. The formwork is poured with concrete and covered with fireclay sand, consumption is approximately 2 l/m2.

Laying a brick barbecue

After three to four days, you can remove the formwork from the foundation. Laying the body of the stove under the grill and cauldron can begin no earlier than a week later. The layout scheme is quite simple - the first and second rows lay out the base for the firebox of the cauldron and the grill pan, as well as the central part of the stove.

On the third row, a metal sheet is laid out to form a firebox (cauldron). It will be used to lay out the fireclay vault over the ash pit.

Next, you will need to cut out the sides to install the door on the combustion chamber and the ash pan. But first, the walls of the oven under the cauldron are covered with basalt felt. The internal walls are laid out from fireclay, and the bottom part will need to be cut with a grinder to the size of the grate.

A similar operation is performed in a chamber under the barbecue. Here the temperature is lower, so if necessary, you can do without basalt thermal insulation. Instead of fireclay bricks, heat-resistant cement-fireclay tiles are laid, three pieces per wall.

At the final stage, you need to cut out the vermiculite thermal insulation lining. The sheet is strong enough to make a large hole for a cast iron stove and cauldron. The stove and lining are not placed above the firebox, but are shifted towards the chimney.That is, the cauldron will be heated by the flow of hot gases more evenly than if a place was made directly above the flame in the combustion chamber.

The last stage is installing the door into the brick walls under the cauldron. The double block is fixed with wire and sealed with a heat-resistant mass of vermiculite and aluminous cement.

The most difficult part of the stove - the pipe - can be made with metal formwork. This is a small box without a bottom, which is moved upward as the bricks are laid out. It is not difficult to make; the internal size of the box is chosen exactly according to the dimensions of the masonry.

Results

Making a barbecue cauldron from brick is quite possible for those who have at least a little experience in building wood-burning stoves. The construction principle is no different from conventional cooking, fireplace or bath products. Most instructions describe in detail the principle of choosing a brick, how to make a mortar and perform masonry. All you need is practice and the desire to build a real cauldron-barbecue with a brick chimney.

Did you manage to build a brick grill-cauldron according to our instructions? Were there any difficulties during the work process? Write comments, share the article on social networks and bookmark it.

That's right, the chamber under the cauldron should be small, but the walls are very thick. You light the stove and heat it at maximum for an hour, then put the cauldron with all the entrails and fill it with water. While it’s warming up, you scoop out the ashes and throw in a couple of oak logs. Then it’s a stove with a cauldron. And everything else, it’s so, not serious.

The stove is great.