How to build a comfortable metal gazebo with your own hands: ideas, step-by-step instructions, photos

Building a small metal gazebo according to your own design is the best option for a suburban area.For a country house building, the main requirement is a convenient design and a reliable roof over your head.

The content of the article:

Which metal to choose for the construction of a gazebo

There are no restrictions on the material, because this is a place for a summer residence, active recreation, and not an exhibition piece. But building a gazebo from scrap metal will not be very correct. Main metal for the structure:

- professional pipe, square and rectangular section;

- round pipe (water pipe) with a diameter of 50 mm;

- steel corners 50x50 mm;

- galvanized corrugated sheets or metal tiles.

The last point concerns the fencing of the gazebo and roofing. According to the project, the roof will consist of 6 sectors, the roof covering will be made of metal. Therefore, you will additionally have to look for additional elements in order to close the joints between the sectors and the hexagonal nozzle on the “top” of the gazebo.

Preparatory work

The first step is to choose a place to build a gazebo. The site for installing the frame should be as dry as possible. It is best if the soil is dense, heavy, with a large content of crushed stone. The construction scheme allows you to install a metal gazebo both on a foundation and without it. But in any case, to prevent the metal from rusting, it is necessary to avoid any flooding of the base of the gazebo.

Selection of material and quantity

To build a metal gazebo with your own hands, you will need several types of pipes:

- For the main posts, you can use two-inch round pipe. The thickness of the metal walls is greater than that of a square profile, so the rigidity of the supports will be higher. You will need six blanks of 230 cm, one - 260 cm.

- Supports for benches are also made of metal; you will need 6 round pieces with a diameter of 50-52 mm and a length of 70-72 mm.

- The gazebo will have a table on a central support. You can cut it yourself from any round pipe with a diameter greater than 60 mm. The main thing is that the metal is rust-free. The length of the workpiece is 120 cm.

- The cross for attaching the table top can be made of metal or timber. A 30x30 mm metal corner is best suited. For the cross you will need 180 cm, for the metal edging for the tabletop - another 240 cm.

The gazebo fencing is also made of metal; it is better to use a 30x15 mm corrugated pipe. Since the fence is welded in three rows, and the length of one section is 141 cm, 26 m of profile will be required. To cover the fence you will need to purchase 9 m2 sheet metal. It will take approximately 15 m to cover the roof2 metal In addition, you will need 8 pieces (1.5 m each) of ridge strips made of galvanized or painted metal.

To fill the supports you will need cement, sand, gravel, and a resin composition. For arranging a table top with benches, a 150 mm wide board is used; it will require at least 25 m.

Interesting: Do-it-yourself gazebo with a pitched roof.

Tools

This project does not require large tools. The scope of work depends on whether a reinforced foundation will be used or not. To build a gazebo without a foundation it will be enough:

- welding inverter with a set of 2-3 mm electrodes;

- grinder with cutting discs for metal;

- garden auger with auger diameter up to 200 mm;

- shovel, 4 kg sledgehammer with rubber spacer;

- construction plumb line;

- manual rammer made of metal;

- screwdriver or drill with a set of drills;

- metal hacksaw and wood saw;

- tool for cutting sheet metal.

In addition, you will need a set of self-tapping screws and 4 1000 ml cans of paint. To mix concrete, you will need to rent a 40-liter container, a water tank, and a metal can for heating the resin composition.

Also, for work you will need to stock up on a bayonet shovel, a wheelbarrow or a bag for collecting cut soil. Everything cut from the surface of the soil must be taken out with your own hands outside the area allocated for the gazebo.

Step-by-step construction of a metal gazebo

The construction process can be divided into three stages. At the first stage, work is carried out on the ground with the pouring of cement-sand mortar. In order for the gazebo to have the correct geometry, it is necessary to wait a couple of days for the poured concrete to set.

At the second stage, it will be necessary to weld and assemble all the metal parts. Make a finished frame, process and paint the metal before laying the roof. The third stage is laying the roof, decorative finishing.

Another nuance is to install a stationary grill inside the gazebo or make it portable. The easiest way is to assemble a small roasting pan made of metal, buy or weld it from stainless steel.

Foundation: yes or no

Most metal gazebos are placed on a foundation. This is the right decision, since any welded metal structure with a roof and a closed fence has a high windage capacity. Strong gusts of wind, soil heaving, and thermal stress lead to cracks appearing in welding seams.Over time, the metal at the welding site “bounces off” from the base.

The only way to prevent the destruction of metal at the seams is to install the gazebo on the foundation or use additional reinforcement in the form of struts and struts made of iron. The first is more labor-intensive and expensive. The second often spoils the appearance of the gazebo. He doesn't have step-by-step instructions, you have to figure everything out on the go. Instead of a neat, openwork metal structure, the result is a building that looks like scaffolding.

The foundation must be used for wooden gazebos, buildings made of aluminum profiles, and polypropylene pipes. In the first case, you simply need to raise the wooden frame above the ground, otherwise the gazebo will rot from moisture. The second case is that a concrete or brick base gives the structure greater rigidity and the ability to withstand strong gusts of wind.

For metal frames, it is not necessary to use a single foundation if the soil has a high density and there is no surface or groundwater. Heaving of soil masses is practically zero.

But in any case, for the racks and supports of the gazebo, it will be necessary to make individual reinforcement of the base using local concreting. You can’t just put an iron gazebo on the ground.

For you: We build a modern gazebo with a barbecue for the dacha with our own hands.

Gazebo project

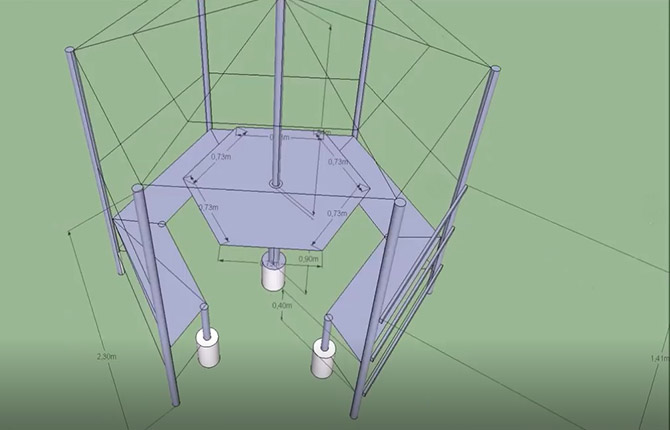

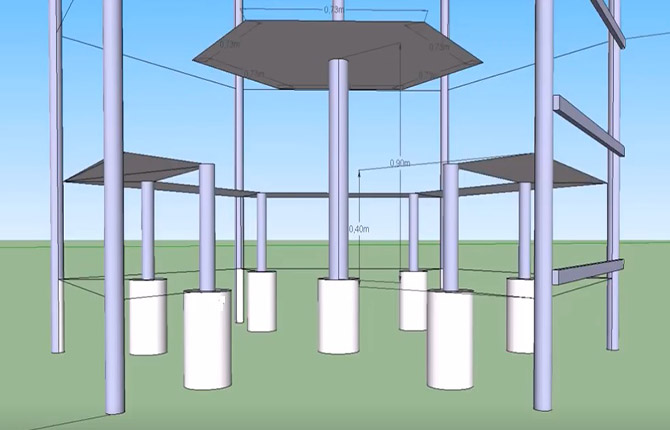

The building is a foundationless covered metal structure with a hexagon-shaped base. The nominal diameter of the base is 280 cm, the height of the gazebo is 200-260 cm. As can be seen from the drawing diagram, the metal roof rests on 7 pillars. There are six around the perimeter of the hexagon, one post in the center of the gazebo, it goes through the support and table top.

The gazebo fencing is made of corrugated sheets, but you can use any thin profiled sheet. There are benches around the perimeter inside.

Installation of vertical supports

First of all, you need to mark the site. The upper part of the fertile layer is cut off with a shovel to a depth of approximately 10 cm. The surface must be slightly moistened and thoroughly compacted with a hand tamper.

Next, using a peg and a cord driven into the center of the site, you need to draw a circle with a diameter of 280 cm. Immediately sprinkle the contours of the circle with dry sand so as not to rub the markings with your feet. Points are marked for drilling holes for the main supports, and additional points for installing stands for benches, as well as a large metal pipe for the table.

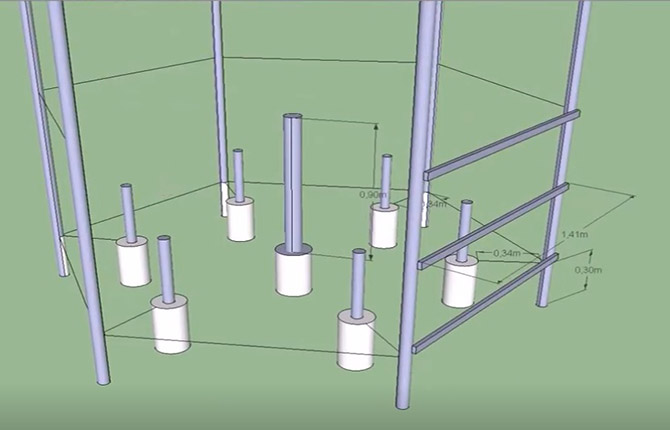

The holes are drilled using a garden drill to a depth of 50 cm. Excess soil must be removed from the site. Crushed stone is poured into the bottom. After filling, the depth of the holes should be the same, 30-32 cm. Before installing vertical metal supports, the lower end must be treated with a molten resin composition (machine oil + molten resin in equal parts). The protection must harden on the surface of the pipe.

The pipe is installed in the hole and fixed with two or three struts; wooden slats can be used. Each support is aligned vertically in two planes, after which the hole is filled with gravel.

After installing all the external supports of the gazebo, they need to be adjusted in height. To do this, several cords are pulled diagonally, then the highest pillars are brought down using gentle blows with a sledgehammer on the end. After leveling, you need to make a liquid mixture of cement and sand, pour the mixture onto the crushed stone under the pillars. In this form, the structure should stand for at least two days.

Supports for benches

The next stage of construction is to make support posts for the benches. First, we draw a line from the already concreted support to the center. Next, set aside 40 cm from the pipe and drill a hole to a depth of 40 cm with a garden drill.

At the bottom of the hole we pour a mixture of sand and gravel 10 cm thick, put a film inside and install a metal stand in it. Fill the free space around the pipe with concrete and fine gravel.

Important! Each bench stand must be treated with a resin composition, otherwise the metal parts will quickly rot.

Before the mixture hardens, the pipes must be aligned vertically. A similar method is used to install a large support for the table and the central pillar.

As soon as the concrete has set, all supports, main and additional, must be degreased and primed. You can paint the frame after completing the construction of the gazebo.

Installation of a gazebo

Before starting assembly, it is necessary to draw up a diagram and establish the sequence of assembly of individual structural elements.

Installation begins with the installation of the upper frame trim. It is necessary to cut six pieces 141 cm long from a 40x20 mm pipe, and then weld them to the ends of the supports from the inside. The installation of additional metal crossbars added rigidity to the frame of the gazebo, so you can install a roof with a fence.

Immediately after the top trim, rafters are installed. For this, you can use any metal, but a professional pipe or a 30x30 mm corner is best. Six blanks are cut with a grinder, welded to the central support and alternately to the surface of the supports. The seams will need to be immediately cleaned, degreased, and primed.

The next stage is the manufacture of the gazebo fencing.To do this, you will need to cut 15 blanks from corrugated pipe and weld them to the main supports of the gazebo. The metal at the welding points is also cleaned and primed.

If the roof covering is too thin, then an additional tier of strapping will need to be welded to the rafters. Otherwise, the roof of the gazebo will flap in strong winds.

In addition, the presence of an additional tier of horizontal planks makes it possible to lay OSB slabs on the roof and glue a coating of bitumen shingles. This roofing is more difficult (more expensive) to install, but the appearance of the gazebo clearly benefits. In addition, bitumen shingles dampen noise well.

A roof with a metal roofing covering has one important advantage - it is easy to build and will cost much less than other options. But during rain, the noise from drops hitting the roof will be very loud.

Healthy: How to make a gazebo from a profile pipe with your own hands.

Assembling benches and tables

For the tabletop you will need to make an additional fastening, with which it will rest on the table stand. The design consists of several sections of a 30x30 mm corner, welded in pairs with each other and the metal of the support.

In addition, from the corner you will need to weld a hexagon with a side of 73 cm. It will serve as the basis and edging when laying the tabletop boards. The entire structure will need to be primed; if the weather is dry, then the metal can be painted.

The width of the bench can be increased or decreased or, if necessary, the boards can be made removable. Everything is determined by the size of the table, as well as the amount of additional “furnishing” of the gazebo.

In the simplest version, the benches are made from magpie boards. For each segment you need to cut two boards 20 cm wide and 140 (115) cm long.The workpieces are pre-grinded to remove chips, splinters, and roughness.

To install, you will need to weld one horizontal cross member to each post. It can be made from any metal, for example, from scraps of professional pipe. But it’s best to make it from a 40x40 mm corner. Each cross member is welded to the surface of the outer post and to the head of the inner support.

But before final assembly of the gazebo, all primed parts must be painted and thoroughly dried. Any enamel can be used. It is important to choose the right time for painting. It is recommended to do it late in the morning, when the morning dew has already gone, but the parts of the gazebo have not yet warmed up enough. Otherwise, the varnish film will dry too quickly, and frozen cavities will appear on the surface - bubbles of evaporated solvent.

Also, do not paint in rainy weather, heavy fog or wind. In the first case, a thin film of water condensate forms on the metal, and the coating will quickly peel off from the surface of the pipe. When there is a lot of dust in the air, the painted surface will become rough.

Installation of barbecue

To install a brazier or barbecue, you will need to make an additional platform in front of the entrance to the gazebo. It is usually tiled or simply covered with sand and paved with natural stone.

The use of a barbecue should be considered at the stage of planning the gazebo. You need to choose a position in such a way that the wind blows mainly from the side of the building towards the grill. Then you don’t have to worry that the smoke will interfere with your rest.

Article for you: We make a gazebo from scrap materials with our own hands.

Gazebo sheathing

After painting all the metal parts, you need to wait a couple of days, and you can begin installing the roof.Blanks in the form of isosceles triangles are cut in advance. All that remains is to lift them to the rafters and fix them with screws to the crossbars. The joints between the sheets and the crown are covered with decorative overlays.

On the inside, the roof frame parts can be covered with overlays, but you don’t have to do this. Usually this is done only if the roof leaks at the joints during rain. To avoid leakage, the side edges of the triangles are folded up and sealed with a sealant for entrance doors before installation on the roof.

But sometimes it is better to immediately choose metal tiles or polycarbonate instead of corrugated sheets. A thin profiled sheet of metal is suitable for covering the gazebo fencing. The cladding is cut to size and fixed to horizontal crossbars.

All that remains is to tighten the screws with a screwdriver. To install the cladding, it is recommended to use a special model of self-tapping screw with a drill tip. You just need to remember to install plastic expansion washers under the head.

Interesting: DIY gazebos made of wood. How to make a 3 by 4 gazebo with your own hands

Results

The easiest way to build a gazebo is from metal of different types and grades. Racks made from old but still strong water supply, fencing made from corrugated sheets, frame made from angle iron and corrugated pipes. The result is a safe, comfortable place to relax with a strong roof over your head.

Tell us about your experience building gazebos. How successful was it? Also bookmark the article and share it on social networks.

It’s probably better to do it on brick supports, it’s more reliable. Just driving a pipe into the ground is somehow scary.

Not scary. If the booth stands on a layer of limestone or granite, then this will be better than any foundation. But you will have to dig up to a meter to make sure there is no quicksand.