Do-it-yourself 3 by 3 gazebo: drawings, diagrams, step-by-step instructions

It is difficult to imagine a country plot or home without a cozy gazebo.A home craftsman with certain skills, tools and desire can create a wonderful relaxation area, a place to communicate with family and friends. For a small family, a 3 by 3 gazebo, created by yourself, is suitable.

The content of the article:

Preparatory stage of construction

The decision to build a 3 by 3 gazebo entails a number of sequential actions. First of all, this is the choice of location for the structure. It is necessary to take into account the wind rose with the prevailing directions, the position of the building relative to parts of the world.

It is more practical to orient the entrance to the 3 by 3 gazebo to the south, southeast. It is most convenient to place the building on a level area. Or do it on a small hill to protect it from precipitation and excess moisture.

The utilitarian component of the project is important:

- Placing it directly next to the house preserves the possibility of connecting communications and increases the local area, which will certainly affect comfort.

- Removing to the depths of the garden or plot will promote privacy, tranquility, and tranquility.

- The nature of the construction is year-round closed, or simple, open summer, which will require a minimum of materials and financial costs.

- The selection of any terrain for constructing a 3 by 3 gazebo should take into account the panorama opening from this place.

- The gazebo must please with an elegant and pleasant appearance.

The site designated for construction is cleared of debris and foreign objects. If necessary, interfering trees or branches are cut off.Communication paths are being laid.

Implementation options

The site has been selected and prepared. The next stage of construction preparation begins - what to use to build a 3 by 3 gazebo.

The simplest and most feasible option even for an inexperienced home hacker is a portable, lightweight structure made from collapsible elements. Available, practical, inexpensive. The disadvantage is seasonality and the need for storage space. Operational weakness - connections and parts become loose over time, wear out, and gradually fail.

A 3 by 3 brick gazebo is a solid structure that can easily be used as a summer kitchen, or install a barbecue or fireplace. Disadvantages include high cost and significant difficulties to build with your own hands.

An alternative to brick can be polycarbonate. Modern, lightweight, durable material. Effortlessly combined in any form with stone, wood, even improvised means. Spectacular art design combined with forged metal. The negative point is that when it rains, there is a lot of noise inside the room. Polycarbonate is also widely used in closed ground structures. Therefore, a 3 by 3 gazebo provides a steam room and the effect of being in a greenhouse.

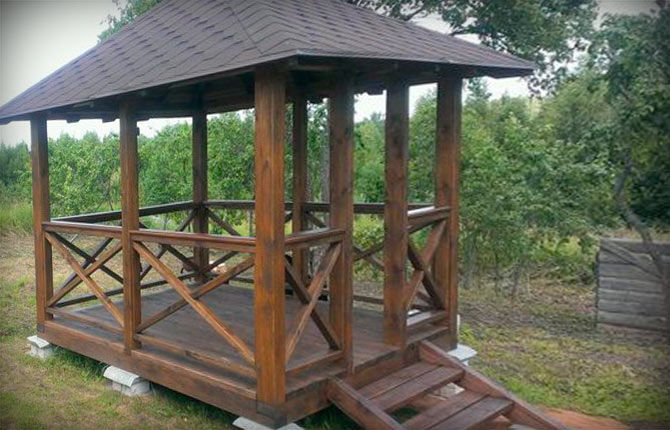

Wood is the most important raw material for construction. Low volumetric weight with high strength, softness and ease of processing, outstanding decorative capabilities. Without exaggeration, the dacha will be decorated with a masterpiece created with your own hands from this resource.

Drawings and diagrams

The site has been prepared, the dimensions of the building have been verified, and the material for the structure has been selected. The next step is drawing up a preliminary design.It reflects the configuration of the future 3 by 3 gazebo, the location of the leading parts, the design concept, and design elements. Photos of completed projects, built pavilions, and wooden gazebos will help.

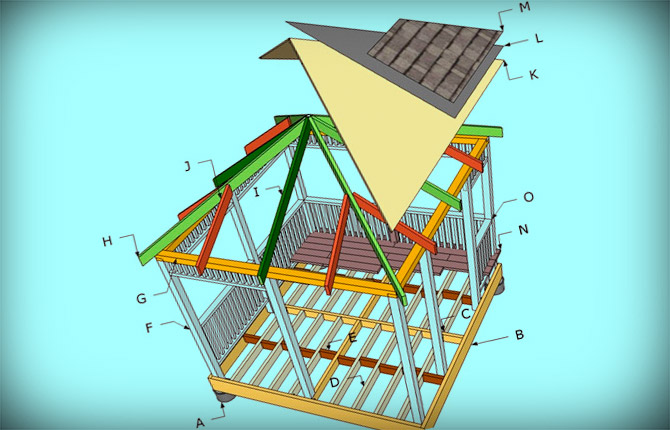

Based on the sketch drawing, a detailed drawing is prepared. The nature of the foundation, the number of supports, the configuration of parapets, and the rafter system are being studied. Drawings are made in real scale with the most detailed drawing of components and final dimensions.

Schemes of complex interfaces and parts are displayed on separate sheets. It is most convenient to use A4 paper or graph paper. If you have the skills, computer programs will help, for example, ArCon Pro, AutoCAD.

Drawings and diagrams allow you to practically see the object being constructed from all sides, calculate the dimensions, quantity of materials, and the total cost of the project.

Tools and materials

To build a 3 by 3 wooden gazebo, you need the following set of tools:

- laser or hydraulic level;

- tape measure, ruler, square, plumb line, carpenter's pencil;

- shovel, axe, hammer;

- electric drill, mixer attachment, feather drills for wood;

- circular saw with adjustable angle;

- electric planer, sandpaper;

- fitting hacksaw, jigsaw, miter box;

- screwdriver, bit set;

- electric or garden auger.

As well as a container for preparing cement mortar and concrete. You'll need a ladder clamps, clamps. You need paint brushes and protective equipment - glasses, gloves, mittens.

Approximate list of materials for construction:

- Beam 150 by 150 mm (bottom trim, corner posts).

- Beam 150 by 100 mm (posts around the perimeter, entrance opening, top trim).

- Beam 150 by 50 mm (joists, rafters).

- Boards 150 by 50 mm (flooring), boards 25 by 120 mm (roof sheathing).

- Roofing covering.

- Fire-retardant impregnation.

- Eurolining, glass, protective mesh.

- Self-tapping screws, perforated corners, anchors, plates, overlays, fittings.

- Brick, crushed stone, sand, cement.

The wood selected for construction must be dried, no more than 22% humidity is allowed, without cracks, damage, or falling knots. Defective material is indicated by blue spots - the result of steaming during improper storage, black spots - indicate fungal mold. Such raw materials cannot be used.

Step-by-step instruction

Step-by-step instructions (in this case) are the order and sequence of work to achieve the final goal - the construction and arrangement of a 3 by 3 wooden gazebo with your own hands. The instructions explain the tasks that need to be performed at a certain stage of construction and do not allow deviations from the design algorithm of actions.

Foundation

Only portable pavilions made from collapsible elements can be used without a permanent foundation. All other pavilions require at least a simple but solid base.

The weight of a 3 by 3 wooden gazebo is small, so it is not necessary and irrational to install strip or monolithic foundations. The optimal solution is columnar supports. This type of foundation is universal and suitable for any type of gazebo, except heavy brick ones.

Procedure:

- A diagram is taken and a site for construction is marked out. Wooden pegs mark the central, corner and intermediate posts.

- Holes up to 0.8 m deep are dug or drilled, depending on the density of the soil.

- A sand and crushed stone cushion is placed and compacted at the bottom of the hole.

- Formwork up to 25 cm high is made from boards or improvised materials to form parts of the support pillars protruding above the ground. The prepared cavities are reinforced, filled with concrete, and anchors are installed for mounting the lower trim.

- The above-ground part can be made of red solid burnt brick.

- During the work, the square perimeter and level marks are constantly monitored.

All further work is carried out after the concrete solution has hardened. The necessary waterproofing in the form of bitumen or rubber-bitumen mastic is applied to the upper horizontal part of the support column and covered with one or two sheets of roofing felt.

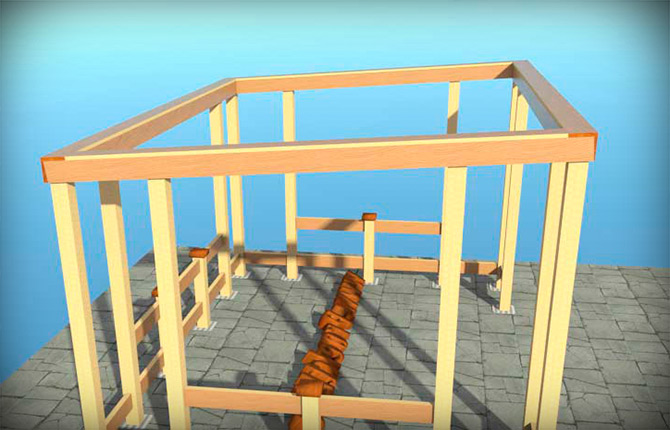

Bottom harness

This part is designed to evenly distribute the load and serves as the foundation of the entire structure. The timber, treated with a protective compound and prepared in accordance with the dimensions, is laid on the foundation. Installation is carried out by sawing “half a tree”. Holes for anchors are drilled.

A protective, usually bitumen, composition is applied to the joints. The assembly is tightened with nuts and washers placed under them. Metal parts must be painted or galvanized. In addition to the perimeter beam, another one is installed - the central one. In this case, it is necessary to control right angles and diagonals.

Frame and top trim

The frame is formed from corner and intermediate posts of the same height installed on the lower frame. For a pitched roof, the minimum height of the front pillars is 230 cm, the rear pillars – 200 cm to maintain the slope. They are leveled and fixed with temporary jibs made from scrap material and wooden slats.

Final fastening is carried out using dowels, screws, and mounting angles. The height is set aside, approximately 1 m around the perimeter. The corners are installed and a horizontal beam is attached to them. It will connect the frame and at the same time act as a railing. For greater rigidity, the structure is complemented by diagonal jibs. In this case, the walls are covered. As a rule, this is the lower part - to the level of the railing. The upper space remains open.

The upper harness is assembled in the same way as the lower one. It completes the connection of the frame beams and serves as a support for the roof. To reduce time and facilitate the process, the upper circuit is assembled together with the lower circuit, and at the right time it is lifted and mounted on top. In this case, the master will need assistants.

Floor

Immediately after the bottom trim, you can begin laying the floor. Then there will be no need to go around the vertical posts, the board will be compressed more tightly by the wedges. In addition, it is more convenient to assemble the frame on a boardwalk.

The construction of the floor begins with securing the joists. They are installed in the perimeter of the lower trim, without protruding beyond its level. The main trick to laying is to correctly orient the starting board. If this succeeds, the progress of the work will be rapid, without the otherwise necessary dismantling.

The boards, adjusted to size, are laid on the strapping and joists, assembled “into a tongue” or “in a quarter”, and fixed with galvanized self-tapping screws. A tongue and groove board is more expensive, but the tongue-and-groove joint is smooth and strong.

A quarter board is cheaper and easier to work with. It fits overlapping and even end-to-end. However, the lamellas do not fit tightly enough, which may affect the quality of the coating. An important factor is the aeration of the space under the floor.If necessary, drainage and ventilation holes should be provided.

Roof

The simplest roof is a pitched roof, easily erected with a minimum of material. But a 3 by 3 gazebo with such a roof looks unattractive, reminiscent of an outbuilding. Among the disadvantages are instability in relation to snow loads, the need for high-quality waterproofing due to the small slope angle. The gable roof is used mainly for rectangular gazebos.

A 3 by 3 square gazebo is best suited to a hipped roof. This rafter system consists of four triangles of the same shape and size. It’s easier to completely assemble it at the bottom and then lift it up, fastening it to the top harness. The securely fixed roof is sheathed with lathing and prepared for the roof.

Roof

There are no special subtleties in the arrangement of the roof. Roofing materials differ from each other in installation technologies, but the procedure for performing the work remains common to all. First, a covering is laid on the roof and carefully secured.

At the next stage, additional elements are installed - wind strips, bumpers, ridges, valleys. Their purpose is to localize weak points through which snow, wind, and rain can penetrate. Next, if the project provides, a drainage system is attached.

Painting impregnation

Wood, as a building material, is susceptible to rotting, damage by fungi, insects, and fire. To protect against fire, fire retardants are used - aqueous solutions based on phosphates. They are applied with a paint roller, brush, or spray gun. There are universal products with fire-bioprotective properties.

Traditionally, craftsmen combine protective impregnation with painting, using the extremely popular Pinotex Ultra. Together with protection, the composition gives the treated wood a noble shade.

The entire set of wooden parts and materials must be carefully processed before constructing the gazebo. This will increase the service life of the building by many years.

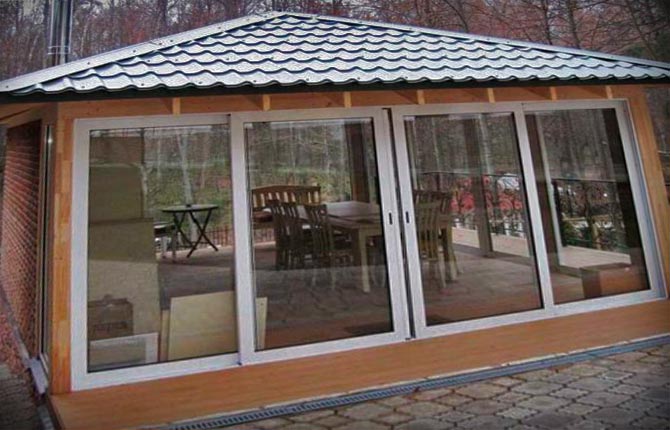

Glazing

Glazing will help protect you from wind and precipitation and make your stay in a 3 by 3 gazebo more comfortable. It will be possible to use the space not only in the off-season, but also in the winter. The following options solve this problem:

- Simple glazing using conventional joinery frames.

- Aluminum, traditional metal-plastic systems.

- All-glass, frameless glazing method. The latest trend is visually perceived as a solid glass wall.

- "Soft Window" A combination of transparent PVC film with dense colored, window-like frame and fittings for fastening.

The latter option allows you to open and close windows, and use soft glass in the doorway. The material is resistant to ultraviolet radiation and mechanical damage. A mosquito net can be easily installed in any opening. Installation and removal do not require any special effort. The right choice for a small gazebo.

Safety net

An unexpected method - continuous drapery of a 3 by 3 gazebo with a protective mesh - demonstrates:

- Lasting shading effect.

- Total protection against insects.

- The water-repellent properties of the mesh perfectly cope with bad weather.

The negative point is that the design and beauty of the gazebo is hidden by a cheap mesh.

Having a clear idea of the final result, a persistent master, even alone, is able to implement a 3 by 3 gazebo project with his own hands.If you have ever built a gazebo yourself, please share your experience. Leave a comment, repost the article on social networks, bookmark it.

A selection for you:

- How to make a 3 by 4 gazebo with your own hands

- DIY gazebos made of wood

- DIY brick gazebo

- How to build a comfortable metal gazebo with your own hands

- We build a gazebo from polycarbonate with our own hands

- How to make a gazebo from a profile pipe with your own hands

- We make a gazebo from scrap materials with our own hands

- We build a modern gazebo with a barbecue for the dacha with our own hands

- How to make a beautiful gazebo from pallets

- Do-it-yourself gazebo with a pitched roof

- DIY hexagonal gazebo