How to make a 3 by 4 gazebo with your own hands: drawing, dimensions, markings

The first thing that comes to mind when choosing a place to relax is the location and size of the site.There is usually enough space at the dacha, and everything is clear with the size; the best option would be a 3 by 4 gazebo with a gable roof, preferably in a corner of the site that is sheltered from the wind.

The content of the article:

Construction on your own

Of course, a 3 by 4 gazebo or canopy can be purchased ready-made or as a kit of parts. All that is required for construction is to bring a disassembled building, make a 3x4 or even larger foundation, and assemble the gazebo according to the instructions.

But there is one circumstance - high-quality 3x4 buildings are quite expensive. Affordable, usually of low quality, you have to change a lot of things. Therefore, it is easier and cheaper to make a 3 by 4 gazebo with your own hands.

The plan is something like this:

- the foundation is mounted on block supports;

- vertical racks are installed;

- the top trim is performed;

- logs and sheathing are installed;

- the roof is laid.

If necessary, jibs are installed on racks under the ceiling. For example, if the 3x4 gazebo turned out to be too high. The last stage is decorative finishing, varnishing, painting.

But first you need to select the material and mark it. To build a gazebo made of 3x4 wood, 100x100 mm timber will be used. The material will need to be cleaned and sanded in advance.

There is no point in pre-cutting the base of a 3x4 gazebo to size; you can easily make a mistake. Therefore, the lower trim will be assembled sequentially from blanks, cutting the timber, as they say, in place.

Marking

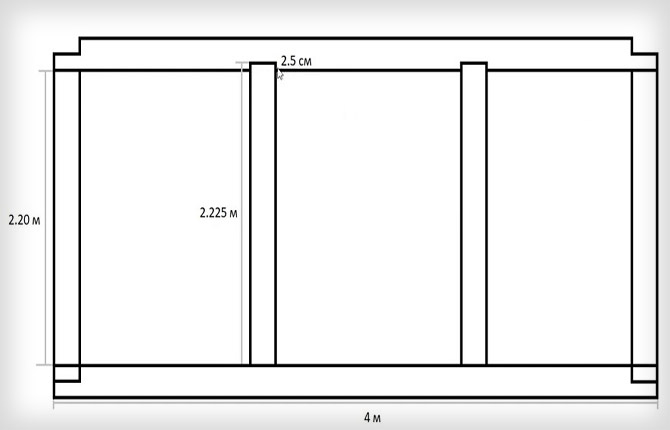

The classic columnar version will be used as the basis. The size of the gazebo is 3x4, with a ceiling frame height of 2.5 m.Thanks to the gable roof, the box is balanced and there will be no lateral forces. Therefore, it will be enough to simply correctly lay the support blocks in the holes and level them.

If it was planned to make a gazebo of the same size, 3x4, but with a pitched roof, then instead of blocks it would be necessary to cast pile supports into the ground.

The first step is to prepare the area for the gazebo - mow the grass, clean the surface, remove debris. Next, you need to mark the outline of the future upper trim. For now, it is enough to measure a 3x4 contour using pins driven into the ground and a fishing line (painting cord) stretched between them.

The next step is to place 12 PBS blocks on the ground in three rows. First in the corners, then lay the remaining eight, four pieces in each row.

Next, four blanks for the future lower trim are laid out on the blocks. They will also be 3x4. Now you need to do the following:

- Using a tape measure, measure the length of both diagonals. The position of the beam must be adjusted so that the diagonals are the same in length;

- Having fixed the beams, you need to adjust the position of the corner and row blocks. It is necessary that all wooden blanks rest on the middle part of the PBS blocks.

- Now you need to mark the position of the support blocks on the ground and proceed to arranging the foundation for the 3x4 gazebo.

Foundation

The construction of the foundation for a 3x4 building begins with digging holes for each block separately. It is rare that you can find a relatively flat horizontal platform for a 3x4 gazebo. Most areas have a slope between 3-10O.

Therefore, simply digging a hole of the required depth and installing a block will not work.Moreover, the pillars should rest on a cushion of compacted sand or a cement-sand mixture if the soil under the foundation of the 3x4 gazebo turned out to be very soft (chernozem).

You have to proceed as follows:

- cords are pulled;

- the block is removed;

- A hole is dug and wet sand or cement mortar is placed at the bottom.

In this case, you have to adjust the height of the pillow by removing sand or mortar with your hands. Next, you need to place the block in the hole, carefully tap it along the edges with a wooden hammer to level it in height (along the cord), and the supporting surface is also in the horizontal plane.

If the blocks are placed only on sand, then you can get by with just a sand cushion. For massive arbors measuring 3x4, you will need to lay a piece of geotextile under the block, then a mixture of sand and fine gravel, and only then a small amount of cement-sand mortar is thrown in.

Each pillar is made up of two blocks 19 cm high. All supports must consist of two PBS.

If, due to the slope of the site, one block is enough for the foundation on one side of the gazebo, and two PBS are required on the opposite side, then you will need to level the 3x4 foundation in height, changing the depth of the hole, or pre-plan the area horizontally - cut off part of the surface layer of soil. A 3x4 area can be cleaned with a shovel in 4-5 hours of work.

Bottom harness

After the supports have frozen, the lower chord blanks are returned to their place. At the same time, they once again check the diagonals and the 3x4 dimensions of the future gazebo frame.

The next step is to assemble the connections at the corners. One of the beams is sawn down “in half”. The thickness of the tenon is measured and the end of the second beam is sawed along it. That is, they begin to build a 3x4 harness from a general outline.

Now the joints need to be secured to supports and painted. Initially, you will need to drill through holes in the connection, as well as in the post. This is necessary to install the stud. You will need to lay a piece of glass roofing felt at an angle, and treat the joint itself with drying oil or protective impregnation.

Since the size of the gazebo is 3x4, a central beam is used in the lower frame. It is also cut into the contour with a preliminary cut with a half-size end. In this case, the thickness of both parts is carefully checked. After installing the jumper in the frame of the gazebo, the beam should not protrude above the surface of the contour.

Pillars

Almost the entire frame of the 3x4 gazebo is assembled from the same type of material - 100x100 mm timber. This makes it possible to use the material more rationally. For example, for the pillars of the gazebo, the remains of the blanks cut when arranging the lower 3x4 m frame will be used.

The pillars or vertical supports are pieces of timber 225 cm long with a notch at the top. The blanks are pre-treated with a varnish coating and dried. A total of 10 posts are required for a 3x4 gazebo.

Each such support post is placed above the foundation block and aligned vertically along two planes.

The pole is attached to the bottom frame of the gazebo using two steel angles.

To prevent the pillars from falling before the upper part of the gazebo is assembled, the vertical posts are reinforced with padded struts.

Four corner posts are clearly not enough for a 3x4 gazebo. They will still hold up a simple roof or roofing laid on the ceiling, but in general the rigidity of the building is not enough. Therefore, on the long sides of the gazebo you need to install two more intermediate vertical supports, as in the drawing.

They will be 2.5 cm higher than the corner posts. That is, when installing the top trim, you will need to make a cut in the timber for joining with the intermediate posts.

Therefore, before installing all the racks, you need to measure and cut each longitudinal beam of the upper frame of the gazebo by 2.5 cm. At the same time, try it on so that the grooves coincide in size with the heads of the intermediate supports.

Upper harness

The construction of the upper contour of the gazebo begins with the installation of the longest beams with cuts for two additional pillars. In order not to complicate the assembly of the 3x4 gazebo, intermediate supports have not yet been installed. They will be mounted on the lower and upper trim a little later, after leveling the upper purlins.

Before laying, the longest part of the upper contour is sawn down at the ends “in half a tree” and laid on corner posts.

Before final fastening, long beams must be checked for level. If you do not check, there is a risk that the 3x4 roof may end up with a slight slope to the side.

Now you will need to lay the short beams of the top frame of the gazebo with the joining along the sawed-off parts at the corners.

At the cut points, holes are drilled for fasteners and carpentry self-tapping bolts with a hex head are screwed in.

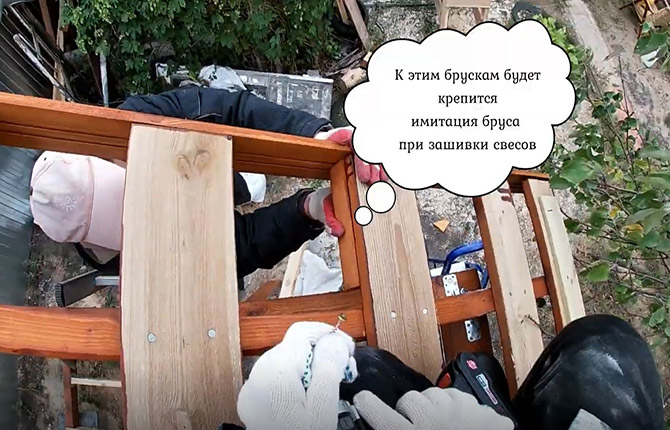

Now you can install the intermediate vertical supports of the 3x4 gazebo. Each post is inserted into a groove and attached to the beam of the top frame of the gazebo with ordinary nails. Before hammering in the fasteners, you need to drill holes in the timber so as not to split the wood.

In a similar way, short three-meter bars of the upper trim are cut and sawed. All intermediate posts are attached to the lower base of the gazebo using corners. At least two corners for each rack.

Roof

The frame for the roof of the gazebo is made according to a gable scheme.With a size of 3 by 4, the roof will require 4 pairs of rafter beams.

For a 3x4 gazebo, a fairly massive roof is selected, designed to withstand bad weather, heavy rain and wind. The rafters will be made from forty boards 150 mm wide, auxiliary parts will be cut from scrap lumber.

The length of one rafter is at least 180 cm, and of a pair - up to 3.8 m. If you take into account the dimensions of the 3x4 gazebo, then lifting and sawing down heavy rafter beams on the stairs is extremely inconvenient. Therefore, all assembly work is carried out below on the ground or on a workbench.

You will first need to make a template from two rafters and a lintel. The template made from boards is lifted onto the upper roof frame and fixed vertically from the gable side.

Next, on the lower edge of the rafters, mark the contours of the cut of the supporting surface. Since the error when assembling a roof on a 3x4 frame is quite large, another lift to the top frame will be required to make sure that the cut is done correctly.

Now, using the template, you can make a pair of rafters for the rear wall, then for the two intermediate ones.

Each pair is reinforced with a strip of spacers (nailed). In addition, along the joint line, the two parts are tightened with self-tapping screws.

On the inside, the joint is reinforced with a metal plate. On the top frame of the gazebo, each pair is attached using metal corners

In this case, for a 3x4 gazebo, the roof frame is assembled on the same rafters. There is no ridge beam as such. The lower and upper trim, vertical posts are made of fairly massive timber 100x100 mm.

The size of the entire building is small, only 3x4 m, so there is no particular need to embed an additional ridge beam.In addition, the roof of the gazebo is supposed to be made of metal tiles, so there will be no deflection or deformation of the rafter legs, even if there is a half-meter layer of snow on the roof of the gazebo.

But the use of a ridgeless roof imposes certain restrictions. For a 3x4 gazebo, the length of the overhangs should not be more than 30 cm. If you need to make a small 3x4 hut in the chalet style, you will have to make a ridge beam with supports on the ceiling.

The longitudinal rigidity of the roof frame is ensured by a fairly powerful sheathing of 150x30 mm boards. For a 3x4 m frame building, thinner slats could be used plus a ridge beam with struts. But in this case, a more reasonable solution is to strengthen the sheathing.

The scheme for laying boards on the rafters is the same, holes are drilled, and then nails are driven in.

After lathing, the overhangs (cut ends of the rafters) are hemmed with a cornice board. In this case, a screwdriver with “yellow” screws is used.

Cross railings

The fence is built from separate pieces, embedded between the vertical posts of the gazebo. In this case, for a building measuring 3x4, you will need to cut 11 pieces of “short” pieces from a forty board. The length of the blanks for the three-meter side is 85 cm, for the four-meter side - 140 cm. The latter will need to be adjusted to size, since the distance between the vertical posts on the long side may differ.

The workpieces will cut between the posts, so the length of each and the depth of the cut will need to be selected. It is optimal to make a groove on the stand up to 1 cm deep. But for arbors measuring 3x4 from 100 square meters of timber, if necessary, you can do more.

The cut joint will need to be cleaned, sanded if possible, and be sure to be opened with varnish.Before installing the railing, the end surfaces of the crossbars (as well as the grooves) are rubbed with a wax candle. This makes it easier to install the cross member into the groove. Ideally, the gazebo fence should be inserted by hand, but it can be lightly knocked down.

Important! If the workpiece is tight, then you cannot beat it; you will need to trim the ends. If you hit it hard, you can break the fasteners or deform the racks. The 3x4 frame is not rigid enough to withstand hammer assembly.

Roof

The roof of the gazebo is covered with metal. Corrugated sheeting can be used as a roofing covering; it is easier to install and does not require calculations, preparation of sheathing, or special screws.

Metal tiles will cost twice as much. First you will need to correctly calculate the number of sheets with a width of 118-119 cm per slope. The actual dimensions of the covered surface of the 3x4 gazebo roof may differ from the calculated ones. It all depends on the length of the rafters and overhangs. In addition, in most cases, the top frame of the gazebo is slightly larger or slightly smaller than 3x4, and is also far from the ideal rectangular shape.

Therefore, each roof slope must be measured individually - in length, width and diagonally, and every meter must be checked. This is the only way to calculate the actual area of a 3x4 roof.

One sheet will be laid along the entire length: from the ridge line to the front board. Before purchasing metal tiles, you need to know the vertical pitch of the wave in advance. The step at which the screws will be screwed into the roof sheathing depends on this. It may happen that the overhang of the sheet edge will be small. Accordingly, normal water flow into the gutter will not work.

At the last stage, you will need to sew wind and ridge strips onto the roof of the gazebo. Everything is attached with self-tapping screws.The quality of a 3x4 roof will be determined by the first or second rain.

Joists and floor

First of all, you need to choose a floor layout. This can be plywood or more often OSB sheets (18 mm), sewn directly onto the beams of the lower trim. This scheme is allowed for 3x4 m floors, provided the soil is dry with a low level of soil water. For example, if the gazebo is built on sandy soil.

Often, owners backfill a 3x4 area with a mixture of sand and fine gravel. It is believed that a layer of up to 10 cm is guaranteed to block moisture evaporation.

In fact, this is not entirely true, so it is better to make a deck for black soils and loams. This means that relatively thick boards of 35-40 mm are selected for the floor, which are sewn directly onto the beams of the lower frame, without any lags.

A gap of up to 5 mm is left between the boards, thanks to which moisture easily escapes from the underground.

For a 3x4 gazebo, the distance between the beams is 90-100 cm, this is enough to hold the floorboards without sagging. The only condition for using such a scheme is the annual treatment of the boards with protective oil or varnish.

Decor and interior design

To improve the appearance, you can use lathing or make the fence completely closed from polycarbonate.

For example, if a gazebo for a summer residence is built in the garden or next to the beds, then instead of lathing, you can stretch a mesh or make a wire support for grapes and climbing plants. The sunny side can be covered with polycarbonate, there are plenty of options.

A selection for you:

- DIY 3 by 3 gazebo

- DIY gazebos made of wood

- DIY brick gazebo

- How to build a comfortable metal gazebo with your own hands

- We build a gazebo from polycarbonate with our own hands

- How to make a gazebo from a profile pipe with your own hands

- We make a gazebo from scrap materials with our own hands

- We build a modern gazebo with a barbecue for the dacha with our own hands

- How to make a beautiful gazebo from pallets

- Do-it-yourself gazebo with a pitched roof

- DIY hexagonal gazebo

Results

Building a 3 by 4 gazebo with your own hands is not as difficult as it might seem. Of course, a lot depends on the chosen material and design features. In this case, a massive beam was used, a simple insertion into half a tree, connections with nails and self-tapping screws with a minimum number of struts and jibs.

A 3x4 gazebo can be built from lighter material, but in this case the experience and skills of a professional carpenter will be required.

Tell us about your experience installing a 3x4 gazebo. How do you think the foundation and roof of a building can be made simpler? Also share the article on social networks and add it to bookmarks, this will help the development of the site.

Remove the internal pillars, install diagonal braces instead, a couple of jibs on the pillars under the top frame, and you can save the material by half. You can also use a slab on the roof; it will be cheaper to roll everything up with painted corrugated sheeting.

It turned out beautifully, now cover the table and a couple of benches with polycarbonate, well tinted. Can be converted into a summer kitchen.

Do you have a photo of the finished gazebo that was built? As far as I can see, the first photo and video at the end of the article are rather illustrative.