Laying sewer pipes in the ground: technological rules and nuances

The construction of communications brings real comfort to country life, but their open location does not have the best effect on the aesthetic component of the site.It is a completely different matter if the sewer pipeline is buried in the ground: it is not visible, the pipeline does not interfere with movement.

However, for the underground installation of the system, compliance with rules and regulations is necessary. They should be studied, don’t you agree?

The fundamental laws and subtle nuances according to which sewer pipes are laid in the ground are presented on our website. Based on the information we offer, you will build a trouble-free external sewer system.

A pipeline constructed in accordance with our advice will work perfectly at any time of the year. The article presented to your attention scrupulously describes the technology for constructing the underground part of the sewer system.

The material describes the nuances of design and installation details. Recommendations are given on the implementation of preventive measures and compliance with sewerage operating rules. To make it easier to understand, the information is supplemented with photo images and video instructions.

The content of the article:

Features of autonomous sewerage

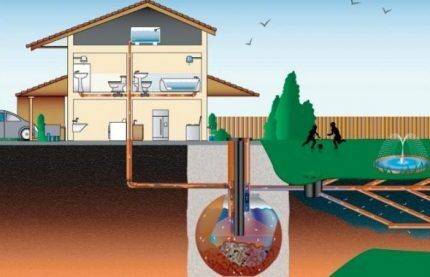

Today, almost every household has the necessary set of amenities for a comfortable stay: washbasin, sink, toilet, shower or full bath, washing machine and other amenities of civilization. Many houses are equipped with not one, but several bathrooms and bathrooms.

This entire facility, when fully operational, produces a large amount of waste and wastewater per day.According to standards, the amount of liquid waste per person per day is from 5.4 to 9.5 liters, which must be discharged somewhere.

Therefore, the drainage system is an obligatory part of the engineering communications of an individual house. It consists of internal sewerage, discharge from a residential building and an external sewer network laid on the site.

Many owners of private houses, paying special attention to the intra-house system, for some reason do not always properly approach the arrangement of external networks.

Indeed, the process of laying a pipeline seems simple; it is enough to dig a trench, connect the pipes to each other, the intra-house system and the collector, and then cover everything with earth.

But this is only at first glance. In fact, in this, as in any other work, there are many nuances that must be taken into account. Failure to comply with technological standards and improper installation of the pipeline may in the future lead to siltation and other significant problems.

The drainage system must ensure the removal of all wastewater, eliminate the possibility of flooding of the building in the event of emergency situations, and ensure the treatment of wastewater when discharged into a reservoir.

When arranging the system, it is necessary to take into account such parameters as the material of manufacture and the diameter of the pipes, the type of soil in the area, the depth of laying sewer pipes, and a certain slope angle.

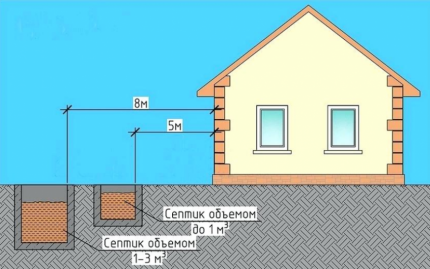

Autonomous sewerage systems for private households can be carried out in the form of separate or joint drainage and treatment. In the first case, two separate pipelines are made for wastewater from washbasins, bathtubs and sinks and for fecal matter from the toilet.

In the second case, all liquid and solid waste are combined into one common stream and entered into a septic tank, where they undergo a cleaning process, and then removed.

Selection of pipes for the device

Previously, when laying sewers, only metal pipes were used: cast iron or steel. Indeed, these materials are like no other suitable for laying in the ground. They are strong, durable, low cost, and easy to install.

However, along with advantages, metal structures also have significant disadvantages. The disadvantage of steel lines is the possibility of corrosion, and cast iron pipes – heavy weight.

A certain difficulty is present in sealing the joints of a cast iron pipe, as well as its internal surface, which, due to the characteristics of the material, will never be perfectly smooth. The latter characteristic affects the speed and quality of movement of waste inside it; over time, blockages can form in the pipe.

Asbestos-cement pipes can be used for sewer installation. They have a smooth surface, which eliminates the possibility of blockages, are simply connected using special couplings, and their weight is significantly less than that of metal structures.

But they also have a significant disadvantage - they are very fragile, which complicates their transportation and installation. Ceramic pipes have the same fragility.

Reinforced concrete structures have many advantages: they have exceptional strength, water resistance, and frost resistance. It is possible to make large-diameter pipes from reinforced concrete, which is impossible to do from other materials.

But laying such pipes is a big problem - due to their heavy weight, it is necessary to use special equipment, which is not always advisable in an individual household.

Today, when installing private sewer systems, polymer pipes are most often used, which, despite their strength, are lightweight, which allows them to be installed by one person. They are very simple and easy to connect, resulting in excellent tightness.

There are three types of polymer pipes - polypropylene, PVC or HDPE (low density polyethylene). PVC structures, in addition to the above advantages, are also resistant to UV radiation and have slight changes in parameters due to temperature changes.

However sewer PVC pipeline does not withstand very low and very high temperatures, and can also be deformed under mechanical loads.

During its operation, the sewer system is subject to dynamic loads that can best withstand corrugated pipes. Even if it freezes, the integrity of the line will not be compromised, but deformation of its walls may occur.

The diameter of the pipes is selected based on the amount of plumbing equipment installed in the house. So, for a country cottage with two toilets, pipes with a cross-section of 110 mm will be sufficient.

If the house building has three or more bathrooms, it is necessary to use a pipeline with a diameter of 160 mm.

Rules and limits for system depth

Some people mistakenly believe that the deeper the sewer is located, the more efficient it will work. However, it is not. This will not improve the performance of the system; the only thing that will increase is the cost of installing it.

In addition, maintenance of the sewer network will become more difficult. And the biggest disaster can happen if, as a result of heaving or erosion of the soil, the pipes cannot withstand its pressure and burst.

When laying sewer pipes, it is necessary to adhere to the norms and rules set out in SNIP 2.04.03-85. An important parameter that must be taken into account when installing a pipeline is its depth in the ground.

Despite the fact that the regulatory act does not provide clear parameters for the depth of pipes, the document indicates which criteria are decisive when laying a sewer line.

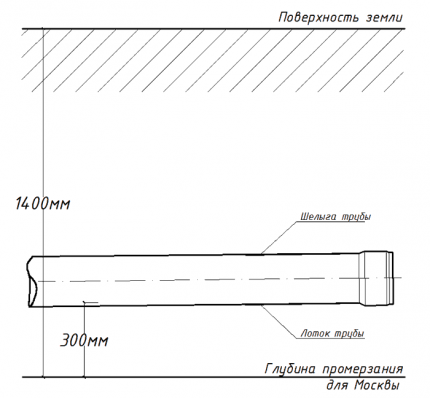

According to SNiP, it is necessary to be guided by the climatic conditions characteristic of the region, in particular the level of soil freezing, and the experience of operating sewer networks that has developed in the area.

If there is no information about the operation of the sewer system, then the minimum depth of the pipeline should be 30-50 cm above the freezing level.

In this case, there must be a distance of at least 70 cm from the surface of the earth to the top of the pipe. If the pipeline passes under a concrete platform or in places where vehicles move, the minimum recommended depth of the pipeline should be increased to 0.9-1 m.

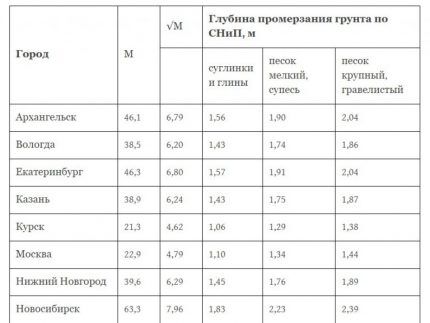

In addition, when arranging an external network, it is necessary to take into account the material of the pipes and the composition of the soil, since the freezing depth of different types of soil is not the same.

Clay and loamy soils in the same area freeze less than fine sand and sandy loam. Coarse and gravelly sand have the highest level of freezing.

Insulation of sewer pipeline

The efficiency and durability of external sewerage largely depends on properly performed insulation. This is especially important in northern regions and when pipes are laid above the freezing level. To understand how important insulation is, you need to imagine how the system works in the cold season.

During the passage of liquid, which always has a positive temperature, the pipe is partially filled with liquid waste. Water vapor also fills the pipe.

In winter, at subzero temperatures, the part of the pipe located closer to the surface cools, which leads to the formation of condensation, and then frost, which rushes to the center of the pipe, which often causes blockages.

It allows you to avoid the formation of frost and blockages, as well as protect the system from freezing. high-quality insulation pipelineA. It can be done using different materials that are abundantly available on the market today: foamed polyethylene, polystyrene foam, isover, thermal insulation and others.

Insulation materials can be rolled or molded. The first are wound onto the pipe while it is being laid in the basement. Thermal insulation shell made of foamed polyethylene has a similar application.

They are not used as thermal insulation for underground lines. Mostly molded insulation is used, which is made for a specific pipe diameter. Thermal insulating material of the required diameter is simply placed over the sewer pipe.

If the temperature in the region is very low, then insulation alone is unlikely to be a reliable protection of pipes from freezing. In this case, a heating cable is usually used, which is laid along the outside of the pipe inside the heat-insulating material.

At using a heating cable You need to make sure that the joints are completely sealed to prevent moisture from leaking inside.

Forming a slope for free flow

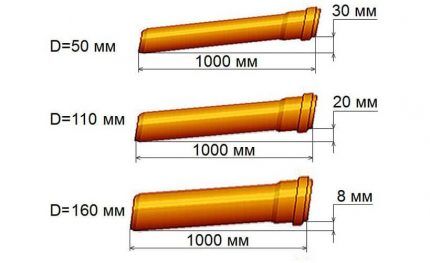

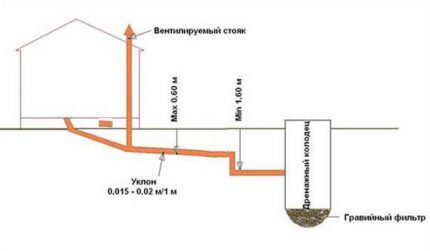

When laying the pipeline, it is necessary to provide a slope towards the septic tank. According to technological standards sewer pipe slope with a diameter of 110 mm should be 20 mm for each meter of pipeline. Pipes with a diameter of 160 mm must be laid with a slope of 8 mm per meter of laid line.

The presence of a slope is a determining parameter for the successful functioning of the system. The closer the pipeline performance is to the standard, the more efficient the sewage system will work.

A complete lack of slope, as well as excessive slope of the pipeline, will lead to siltation of the system. In the first case, waste will not be able to be transported through the pipes at the required speed, which will lead to the formation of blockages.

In the second, the liquid will move too quickly, which will ultimately reduce its transport capacity, and waste will remain in the pipe, which will also lead to blockages and further silting of the pipeline.

You can control the slope level of the entire trench using a special device - a level. If the device is not available on the farm, then the slope is checked using a building level.

Procedure:

- At the beginning and end of the pit, pins are driven in to which the cable is tied.

- A building level is applied to one end of the rope and adjustments are made to the horizon.

- The height of the trench is measured from both sides to the cable.

- Simple mathematical calculations are performed.

For example, the total length of the trench is 50 m, a pipe with a diameter of 110 mm is used. On the exit side of the house, the depth of the pit is half a meter. In this case, at the end point of the pit, its depth should be equal to one and a half meters.

Detailed technology for calculating sewer slope is described in this article.

If the site has a natural slope that exceeds the recommended standards, it is possible to lay a sewer system with several vertical transitions. In this case, on horizontal sections of the pipeline it is necessary to comply with regulatory indicators.

Another option is to lay a vertical pipe at the exit from the house to a considerable depth, and then lay a pipeline from it with the required slope. In this case, the depth of the trench will be greater than when laying using the first method.

For the same purposes, you can use a drop well, into which wastewater flows smoothly to a lower level of the pipeline.

Pipe laying work

Technologically, the process of laying sewerage is not particularly difficult. First you need to dig a trench, the depth of which corresponds to the standard indicators characteristic of the given region.

Before laying sewer pipes, sand is poured into the bottom of the ditch. The height of the sand base is 10-15 cm, so the depth of the trench should also be increased by these values.

The width of the trench is laid approximately 40 cm larger than the diameter of the pipe used. At the points where the pipes approach the septic tank and at the exit from the house sewer system, the trench is made a little wider so that it is convenient to carry out installation work.

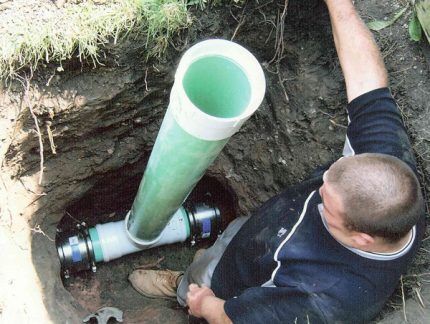

After the trench and base are prepared, it is necessary to connect the pipes together and then lay them. It is beyond the power of one person to lay long sections of the highway evenly and correctly, so it is advisable to involve several assistants in this work.

There are special rubber seals at the ends of the pipes.Before joining them to each other, silicone plumbing grease is applied around the perimeter of the pipe, which facilitates the joining process and makes the joint more reliable.

But you cannot use force here; excessive force on the pipe can damage the rubber band or tear it out of its seat, which will lead to a violation of its tightness.

Before laying the prepared pipeline, a pipe is placed at the exit from the house drainage system, which has the required angle. The other edge of the line fits into the hole in the septic tank.

If the storage well was made recently, it is advisable not to immediately seal the hole with concrete, since the pipe may burst when the septic tank shrinks.

Backfilling a sewer pipe is carried out as follows: first, sand is poured so that the pipe is completely covered with it. Then it is watered with water, and after it shrinks, another batch of sand is added. After this, the highway is completely covered with earth.

According to technical standards, rotary wells must be installed in places where the route turns, and inspection wells must be installed on straight sections of the pipeline for every 35 m. In addition, every 15 meters of the direct line an inspection or cleaning is installed.

The revision can be made from the same sewer pipe, which is installed vertically in the required sections of the pipeline using a tee. It is closed with a plug on top.Using this fairly simple device, you can quickly access a clogged section of the line.

In the most critical areas of the network it is better to install manhole.

Actions to take when the sewer freezes

If you have not insulated your sewer pipes, or have not insulated them sufficiently, and they are frozen, first of all, you need to identify the damaged section of the pipeline in order to choose a method to solve the problem. Metal pipes can be heated using a blowtorch.

If the pipeline is made of plastic, open fire cannot be used. You can pour hot water into the sewer, in which you have previously dissolved salt (2 kg per 10 liters of water). You can direct a stream of steam or hot water to the revision closest to the frozen area.

If the damaged pipe is located in the middle of the main line, you can use a steam generator to warm the soil. However, this process can take quite a long time. It is best to prevent the system from freezing, and when laying pipes, provide them with high-quality thermal insulation.

Conclusions and useful video on the topic

This video covers the process of laying external sewerage in great detail, and also provides regulatory indicators that must be adhered to during installation:

This video shows how to lay sewer pipes in the ground:

Despite its apparent simplicity, the work of laying sewer pipes requires a competent approach and knowledge of regulatory laying rules. Only if the necessary indicators are observed and the work is carried out correctly, can a truly effective and durable sewer system be installed.

Are you trying to install sewer pipes yourself? Or maybe you don’t agree with the material presented? We welcome your comments and questions - the contact form is located below.

Using my own example, when faced with the installation, or more precisely, the replacement of sewer pipes, I thoroughly learned the regulatory documents. I installed the pipes, so to speak, “by eye” according to the principle of the location of the old ones. In fact, the angle of inclination of the entire line was insufficient, which led to unpleasant consequences in the future and, ultimately, to the rework of the entire highway. Bad experience. The article revealed even more nuances. Not everything is as simple as it seems at first glance.

You need to know the standards. We also encountered this. We are building a small country house. Last summer the crew did the installation of sewer pipes and everything else for us. But in the spring we were flooded. As it turned out, the pipes were initially of poor quality, which prevented everything from being connected hermetically. According to the popular saying “the miser pays twice,” everything had to be redone.