An example of calculating the slope of a sewer system: formulas and technological standards

The sewerage system is a network of pipelines, functional units, modules and standard components.The entire set is designed to ensure the unhindered passage of wastewater. It is obvious that spontaneous movement of household wastewater in pipes is possible if the slope is observed when laying them.

From the article we have proposed, you will learn how to calculate the sewer slope. After all, this is not an arbitrary value: the slope must ensure the movement of wastewater at the speed necessary for normal operation of the system. We will tell you how a parameter important for sewage is determined.

The content of the article:

Sewer network design: rules and regulations

The installation of domestic and any other sewage system is quite clearly explained by SNiP. Moreover, the explanations contained in the documents are norms and rules that professional builders strictly observe.

Do-it-yourself household construction, of course, is difficult to equate with professional activity. But this moment does not relieve the home master of installation obligations. Therefore, every builder is recommended to know how sewerage calculations are carried out.

It would seem, why go into all the subtleties of calculations? Will anything really change dramatically in the sewerage system if the slope of the pipes is made a little less or a little more than the existing SNiP parameters?

So, the practice of operating communications shows: even small deviations of slope values from established standards can disrupt the normal operation of the sewerage system.

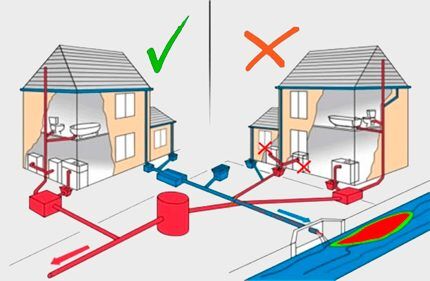

For example, the owner of a private house makes the sewer system with his own hands and does not know the calculation method. He takes and lays the slope of the pipelines “by eye”. As a result, the slope of the domestic sewer gets less than the standard figures.

The speed of movement of the household-fecal environment decreases, first minor congestions form, then massive ones that are difficult to break through. Finally, the line is completely clogged, and the task of global cleansing comes up on the agenda. And such operation of the system, with insufficient pipe slope, promises an enviable consistency of congestion and unpleasant odors.

Another point: an unprofessional craftsman installs a sewer system at a slope that exceeds the standard figures. An increased slope of sewerage pipelines increases the speed of the liquid medium, but this creates the so-called “separation effect”.

Liquid flowing above the self-cleaning speed is separated from the solid mass, which remains on the walls of the pipes.Over time, the residual masses build up, and the same result is obtained - congestion, odors, cleaning.

Correctly set slope values are the key to long and reliable operation of the system.

About the calculation of sewer networks

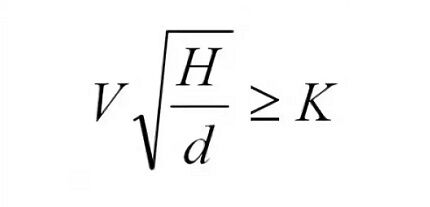

The speed of movement of the household-fecal environment, at which the self-purification effect is achieved, is mathematically calculated using the formula:

Designations:

- V – speed of movement of the liquid medium, (not less than 0.7 m/s);

- H/d – filling of the sewer pipe (at least 1/3 of the volume);

- K – resistance coefficient, depending on the pipeline material (0.5 – plastic, glass; 0.6 – others).

The practical work on the installation of domestic and industrial sewage systems allows for situations where the conditions calculated by the specified formula cannot be met due to the low flow of sewage.

In this case, it is recommended to install communications from pipes with a diameter of up to 50 mm with a slope of 3 mm per 1 meter of length. Pipelines with a diameter of 85 - 100 mm are laid subject to a slope of 2 mm per 1 meter of length. In any case, the maximum permissible value of the slope norm can be 15 mm per meter of length, but no more.

If the sewer system uses a tray mechanism for transporting wastewater, there is also a standard for this case. Thus, the filling level of trays should not exceed 0.8 times their height. The width of the sewer tray cannot be less than 200 mm.

Moreover, the width of the tray is set based on the calculation of the hydraulic properties of the system and the design features of this element.Thus, sewer trays with a height of more than 500 mm should not be less than 700 mm in width.

Trays in sewerage construction are used in the construction of storm and drainage systems. With calculation slope of drainage pipes will introduce you to the article, which we highly recommend reading.

Wastewater filled with a high content of mechanical suspensions is discharged through sewer lines made with a slope, the value of which is also determined by calculation, taking into account the provision of self-cleaning fluid speeds in the pipes.

The filling of pipelines is normalized to 1/3 of their volume. Typically, this type of wastewater refers to industrial products, where particles of metals and other solids are mechanical suspensions.

Other installation standards (rules)

The provisions of the regulatory documentation affect both the characteristics of the equipment involved in the sewer system and the nuances of the installation itself.

Closed communications equipment

For most cases of designing domestic sewer communications, the norms (rules) provide for the design of closed pipeline lines. This scheme traditionally works on the principle of movement of domestic and fecal water by gravity.

At some facilities (usually industrial), where wastewater is discharged without the presence of odors and dangerous fumes, it is permissible to carry out communications using gravity trays. In this case, it is necessary to equip the tray lines with a water seal device.

If we consider the system in plan, then each individual section sewer communications is mounted strictly straight. If it is necessary to change the direction of pipeline laying, standard mounting components are used (angles, crosses, tees, transitions, etc.).

It is unacceptable to change the calculated slope values of sewer pipelines on a separate section of a completed line mounted in a horizontal position.

Which pipes are suitable for the system?

In relation to sewerage networks (domestic, industrial), as well as with an emphasis on the properties of corrosion resistance and strength, various modifications of pipes are used for sewerage installation.

For communications made on the principle of gravity, the pipe materials are:

- polymer compounds;

- cast iron;

- concrete;

- glass;

- asbestos cement.

Selection criteria and rules pipes for external sewerage are given here. The information we recommend will be useful to all zealous owners of suburban areas planned for development.

For communications transporting liquids under pressure, pipes are made from the following materials:

- polymers;

- cast iron;

- asbestos cement;

- reinforced concrete.

Internal sewer lines are installed in one of two ways: open / hidden. Regardless of the installation method, polymer pipes are widely used in installation. With selection guidelines best sewer pipes The article we recommend will familiarize you with it.

Plastic sewer pipelines may be laid in the ground below the floor level of buildings. But the load on the area with such communications should be taken into account.

Plastic fittings are considered universal and can be successfully used for internal and external networks.

Features of installation of risers

Installation of risers inside residential buildings is done in channels, shafts, and boxes. Their design must comply with fire safety regulations. Shafts, boxes, channels, etc. must be equipped with removable panels.

By removing the panels, access to communications is provided.The use of removable panels made from materials that can burn is allowed if the sewer line consists of polyvinyl chloride pipes. The panels of the shafts where polyethylene pipes are laid are usually made of fireproof materials.

Open and closed lines

Installation of open sewer pipelines made of plastic is permitted inside the attic areas of residential buildings, as well as in basement areas.

The transition points of sewer risers from the living area to the attic area must be sealed with cement mortar, at least 20-30 mm thick. The same mixture is used to protect the area of the pipe 80-100 mm above the ceiling level, and before sealing with cement, a waterproofing material is applied to the surface of the pipeline.

Laying internal sewer lines is prohibited in the structure of floors, inside walls, and in the ceiling area of residential rooms. A number of buildings and premises for other purposes, where a special sanitary regime is provided, fall under the same requirements.

If it is necessary to lay a drainage pipeline from a bathtub sink or kitchen sink, this is done above the floor level using waterproofing agents, followed by lining the installation area.

It is not allowed to combine domestic and industrial sewage systems if the industrial wastewater contains toxic or flammable liquids.Sewage networks of any type, the design of which provides for the drainage of wastewater to an external sewer, should be equipped with ventilation risers.

Upper limit switches ventilation pipes must be removed through the thickness of the roof and raised to a height:

- For flat roofing coverings (at least 300 mm).

- For pitched roofing (not less than 500 mm).

The horizontal distance from the riser outlet to nearby windows and balconies of the building must be at least 4 meters.

Laying sewer pipes

Pad sewerage pipeline with slope - this is only part of the requirements for the general laying of the sewer network. You should also take into account the standards established for laying pipes, based on the risks of damage and destruction.

These standards are determined by the effect of temporary and permanent loads on communications. For example, for domestic conditions, laying sewer pipes inside buildings is carried out to a depth of at least 100 mm, if the floor surface and the upper outer wall of the sewer pipe are taken as the measurement points.

Pipelines internal domestic sewerage, mounted in places of possible mechanical influences, it is recommended to protect them by limiting direct access to them. For these purposes, protective nets, trays, channels, etc. are used.

If the pipeline is located below the level of seasonal freezing of soil layers, the technology should be used insulation of sewer pipes. Rigid polyurethane foam quite claims to be a modern insulation material. Sewer pipes are also insulated with mineral wool with preliminary waterproofing.

When the location for laying communications is a trench, after developing it with a calculated slope and before laying the pipes, it is recommended to compact the soil. Soil compaction work is carried out on the bottom of the trench along its entire length.

The soil must be compacted to a depth of at least 200-300 mm. After these measures are completed, gravel is poured into the trench with a calculated slope, or trays are laid and sewer pipes are placed in the trays.

Conclusions and useful video on the topic

Interesting and educational thoughts about the correct slope of the sewer pipe:

Organizing household wastewater is not as simple a matter as an inexperienced layman might imagine. Professionals in the field of housing and utility communications know: it is necessary to calculate the laying of sewer networks in each case of their construction, regardless of whether the installation is being carried out for a private home or an industrial system is being built.

Please write comments, ask questions, post photos in the block below. Tell us about how you laid sewer lines on your own suburban area, and whether they followed the slope specified by the standards. It is possible that your advice will be useful to site visitors.