PVC and HDPE sewer pipes for external sewerage: types, characteristics, advantages and disadvantages

When installing a drainage system, PVC sewer pipes for external sewerage, as well as HDPE pipes, are used. While largely similar in their technical and technological characteristics, these products still have a number of significant differences that affect the ease of installation and subsequent operation of the sewer system.

We will talk about the properties of polymer materials for pipe production. We'll tell you how to choose the type of pipes so that installation is less labor-intensive and faster. Taking into account our advice, you will easily select products for installing external sewer networks.

The content of the article:

General requirements for pipes for external sewerage

Since the construction of external sewerage requires a lot of effort, and its service life directly depends on the resistance of network elements to unfavorable conditions, an appropriate safety margin is included in the production of sewer pipes: greater resistance to temperature fluctuations and soil pressure.

What parameters characterize PVC and HDPE sewer pipes used for external sewerage:

- Material. For external sewerage, pipes made of durable materials are used that can withstand not only the aggressive environment of wastewater, but also temperature changes and mechanical loads. The properties of these materials are the most important criterion when choosing the type of pipes.

- Wall thickness. Taking into account the pressure exerted by the ball of soil, as well as the tendency of some types of soil to heave in winter, the thickness of the pipe wall for the external main should be 1.5 times morethan for internal.

- Design. The strength of the pipe, resistance to deformation, and method of installation of the system depend on this parameter.

- Dimensions. The diameter of the pipes and their length are calculated at the design stage of the sewer system

- Color. Pipes for outdoor use are painted orange. This makes them easier to locate during drain repairs or other excavation work and helps avoid damage.

Choosing pipes for an external sewer network is a responsible task, because installation work is expensive and labor-intensive, and the longer the pipes last, the better.

When choosing and purchasing sewer pipes It’s better not to skimp on their quality, to study the product characteristics and operating parameters.

Use of polymer pipes

Polymer pipes include products made from synthetic compounds, made of PVC and HDPE. All polymer pipes have similar properties and characteristics that attract both builders and consumers.

Significant advantages are lightness, strength, low cost. These and many other qualities have made polymer pipes popular in the construction of wastewater disposal networks.

The use of polymer pipes is especially important when installing external pipelines.

What makes polymers such a convenient material:

- Ease. Laying to a depth of 1.5 m, the large length and diameter of pipes for laying an external sewage system means that installation work is quite labor-intensive. The use of polymer elements greatly facilitates installation, reduces the cost of installation and allows you to abandon the use of special equipment and tools.

- Strength. The material can withstand heavy loads, suitable for laying pipes in the ground. It is resistant to mechanical damage and has great compressive strength.

- Surface smoothness. An important property for pipes that discharge wastewater is a smooth inner surface on which sediments do not linger.

- Anti-corrosion properties. Polymer materials do not interact at all with moisture, as well as with most chemicals.

In addition, plastic pipes normally withstand temperature fluctuations and seasonal weather changes. But it’s not worth laying PVC pipelines in the open air - ultraviolet rays have a destructive effect on them. Outdoors, pipes made of polymer materials can only serve for a long time if they are protected by a protective casing.

PVC pipes for external sewer network

PVC sewer pipes are made from polyvinyl chloride, an affordable and popular plastic that is widely used in the production of many plastic products.

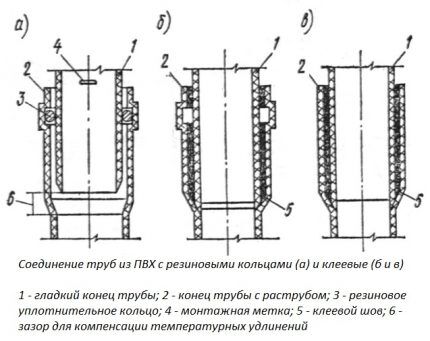

Products can be single-layer (monolithic) or three-layer, in which the intermediate layer is made of porous uPVC, and the remaining two are made of primary uPVC. They are popular in laying external sewer lines. corrugated PVC pipes, well resistant to soil pressure.

PVC pipes are used primarily for the construction and repair of non-pressure sewers with a pressure in the system of no more than 0.16 MPa, for the drainage of storm water. They are used for the removal of aggressive wastewater, liquid and gaseous media with chemical resistance in the range of 2-12 pH, temperature from 0 to +60 ° C.

When installing external sewerage PVC pipes they are lowered to a depth below freezing of the soil or thermal insulation materials are used to protect against freezing.

Covered sections of the system protect from sunlight. Long-term exposure to ultraviolet radiation on polyvinyl chloride pipes leads to photodestruction - loss of elasticity and strength.

According to the class of ring stiffness, products are marked as:

- SN2 - 2 kN/m2 — the depth of laying such pipes underground is up to 1 m;

- SN4 – 4 kN/m2 — laying depth up to 6 m;

- SN8 - 8 kN/m2 — laying depth up to 8 m.

Based on the wall thickness, there are light, medium, and heavy types of pipes with values from 2.2 to 12.3 mm. For external sewerage, PVC pipes with a wall thickness of 2.7 mm are used, their diameter varies from 110 to 630 mm.

Standard sizes of sewer pipes are lengths of 0.5 m, 1 m, 2 m, 3 m, 6 m, sometimes up to 12 m - the dimensions are indicated by the manufacturer without a socket.

The most popular sizes of polyvinyl chloride pipes are products with a diameter of 110-200 mm and hardness class SN2. In terms of price and technical indicators, they are an ideal option for construction autonomous sewerage on a suburban area.

HDPE pipe for installation of external sewer network>

HDPE pipes are made from low-density polyethylene using the continuous extrusion method. The material does not interact with acids, alkalis, organic acids and water - the higher its density, the more resistant it is to organic solvents.

The smooth inner surface of the pipes does not interfere with the free movement of wastewater containing mechanical particles and is not susceptible to silt and lime deposits.

The operating temperature range of polyethylene pipes for sewerage is from -20 to 60. HDPE pipes are used for the installation of pressure and free-pressure sewerage, drainage and storm systems.

For a short time, a polymer pipeline can withstand a temperature increase of up to 100. The pipes are installed underground or protected with insulating materials from exposure to sunlight - the material is sensitive to UV radiation and disintegrates quite quickly under its influence.

Double-layer corrugated pipes

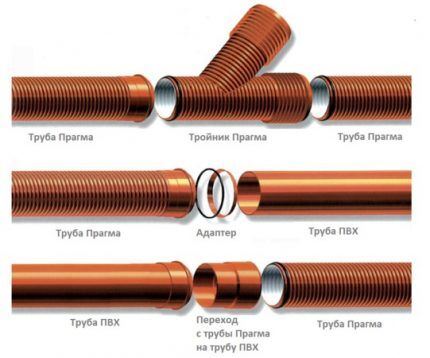

Corrugated pipes made of polymers are widely used in the construction and repair of municipal and industrial facilities. The first such options were made of PVC, but now polyethylene is used as a material that better resists the effects of aggressive wastewater and organic compounds.

Since for large-scale construction pipes with a diameter of more than 315 mm with stiffness classes SN16, SN8 are in greater demand, corrugated products are the most acceptable option when assessing the price-strength ratio.

The advantageous characteristics of corrugated pipes are achieved by using a special manufacturing method in which both walls of the pipe are produced simultaneously, connected to each other and forming a monolithic structure.

Cavities are formed between the outer wavy surface and the inner smooth one, which makes the product lighter. The corrugated outer wall provides sufficient annular rigidity and resistance to deformation.

The inner layer of the pipe has a perfectly smooth surface and does not contribute to the formation of deposits and the accumulation of silt and mechanical particles.

The polyethylene sewer pipe is designed to operate at temperatures no higher than +40°C and a short-term increase to +60°C. For external networks in which the temperature of the drained liquid does not rise above +35°C, this is quite enough.

Comparison of PVC and HDPE pipes for external sewerage

To summarize, the advantages of PVC pipes include:

- wear resistance;

- light weight;

- wide application;

- anti-corrosion properties;

- ease of installation sewer system;

- low cost.

Disadvantages of polyvinyl chloride pipes:

- cannot tolerate sub-zero temperatures;

- sensitive to shocks at subzero temperatures;

- Substances with temperatures above 45 °C cannot be transported through the pipeline.

PVC pipes are used both in laying external lines of the system and in organizing the internal part sewer system of a private house.

Pipes HDPE have the following advantages:

- material strength;

- not susceptible to corrosion;

- wear resistance, durability;

Well-founded technical and technological advantages include ease and versatility of use. The wider range of operating temperatures is very attractive.

The disadvantages of polyethylene pipes include:

- high cost compared to other types of plastic pipes;

- a more labor-intensive process of installing system elements.

The main parameters that people pay attention to when purchasing sewer pipes are the material of manufacture, design, and dimensions.

In addition to pipes for installing the external part of an autonomous sewer system, you will need plastic wells, used for organizing turning points, collectors and inspection points. Our recommended article will provide guidelines for their choice.

Conclusions and useful video on the topic

Types of pipes for external and internal sewerage:

Installation of PVC pipes when installing external sewerage:

The range of pipes used for the construction of external sewerage is quite wide, but sewerage pipes made of PVC and HDPE are most in demand due to their quality characteristics and cost.

It is impossible to unequivocally state and advise which type of pipe to choose when installing a sewer system - from polyvinyl chloride or polyethylene - since when choosing, you need to take into account the conditions in which the system will be used and the financial capabilities of the owner.

Would you like to talk about what type of pipes you chose to organize external sewerage in a suburban area? Share the reasons why you preferred your option. Please leave comments in the block below, ask questions, post photos on the topic of the article.