Inspection well for sewerage: construction of a well in storm and wastewater systems

An extensive sewer network consisting of pipelines is located underground.I would like its important components to be accessible for maintenance, don’t I? For these purposes, you have decided to equip such an element of the system as a sewer inspection well, but you don’t know where to start?

We will try to help - this material discusses in detail the structure of this type of structure, important nuances that should be taken into account when assembling it yourself. There are also instructions for doing it yourself, in which step-by-step photos of the work process are selected for clarity.

To make it easier for a beginner in this business to understand the topic of constructing a well to control the sewer network, we have added videos on the installation of inspection wells from various materials.

The content of the article:

Purpose of underground inspection chambers

The sewer circuit is designed for the prompt drainage of domestic wastewater, rain and melt water into specially designated settling tanks, sewer wells or collectors. Inspection wells are installed in the most critical sections of the sewer network.

For the equipment of a straight line 10 m long, the construction of an additional camera is irrational, while on a 100-meter section with intersection nodes, forced turns and level differences, control points are simply necessary.

They make it possible to easily check the functions of a pipeline located at a depth of 2 m and below, and in case of breakdown, to quickly repair it. In a specially equipped chamber, all shut-off and control valves are visible, so replacing worn parts with new ones is not difficult.

An accident in a section of the underground network that is not equipped with an inspection well is eliminated by excavating the soil (including the use of heavy construction equipment). It is more difficult, longer and more expensive.

Inspection cameras also help pinpoint the location of the leak.

Humanity has been constructing inspection underground chambers for hundreds of years - from the time when the first communication systems for moving water appeared.

During this period, rules for the construction of special facilities arose, which are currently set out in documents such as SNiP and GOST.

For example, clause 2.04.03-85 (SNiP) called “Sewerage. External networks and structures”, reveals the rules for the construction of inspection wells. The article contains information about where it is necessary to arrange these objects and how to select the correct sizes.

Accepted standards help combine different networks into one seamless structure and simplify installation.

Types of sewer wells

Varieties of inspection wells are distinguished based on two factors:

- main function and installation location;

- manufacturing material.

According to the first factor, there are linear, nodal, rotary and differential types. They apply equally to both domestic and industrial communication systems.

This means that any of the named types, if necessary, for example, due to the long length of the sewer pipeline, can be install on your site.

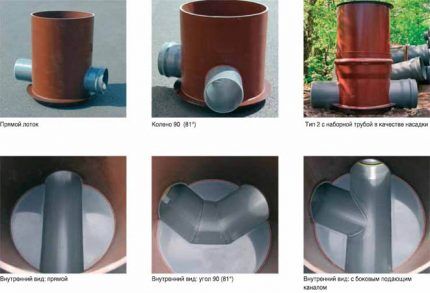

Linear ones are installed on a straight pipeline. They are equipped with one pair of pipes or outlets, which are located opposite each other.

Such wells are necessary even if there are no prerequisites for an emergency, but the section is considered quite long (according to SNiP - from 35 m to 300 m).

Rotary types, as the name implies, are mounted on pipelines that turn to the side.The general rule applies: the angle of rotation should not exceed 90º, that is, it should not be sharp.

The pipes (holes) are not located on the same line, but in places depending on the angle of rotation, but at the same level in height.

Nodal models are installed at the intersections of two or more pipelines, as well as where the central line has branches.

Wells differ in design by the presence of additional pipes (holes). As a rule, all inputs/outputs are on the same level.

The differential pipes serve to increase or decrease the flow, so the pipes are located at different levels: the inlet pipe is usually higher, closer to the neck, the outlet pipe is at the bottom. The construction of differential wells is also used when it is necessary to reduce the speed of wastewater transportation.

Despite the functional and structural differences, all types of wells are very similar. They are made from various materials.

Initially, stone and brick were considered the best, but now there are practically no stone structures left. They were replaced by practical and easier to install concrete analogues.

Precast concrete factories produce standard parts, from which individual chambers are assembled during installation: simply install individual elements on top of each other, then seal the seams.

A modern analogue of concrete wells are polymer models, which are corrugated containers and are particularly durable and airtight.

Location depending on destination

According to SNiP standards, there are points for mandatory installation of inspection cameras:

- in places of turns and slopes, when changing the direction of the linear pipeline;

- in places where additional branches are connected to the central line;

- in areas where pipe diameters are changed.

The entrances of private sewer networks to the central system (or collector) are also equipped with inspection cameras.

The diameter of the pipes directly depends on the length of the linear section. For example, a pipeline up to 35 m long consists of elements with a diameter of 150 mm, a hundred-meter section consists of pipes with a diameter of 700 to 900 mm, the maximum possible 300-meter line consists of pipes whose diameter can be more than 2 m.

The relationship is inverse, that is, if the diameter of the pipeline is 150 mm, then after 35 meters it is necessary to install a well.

The most difficult area is selected and an inspection camera is installed. Most often this is the place where an additional sleeve is inserted, for example, coming from a bathhouse.

Manholes for private use may differ from industrial analogues in size or number of pipes, but there is no fundamental difference.

Features of various types of designs

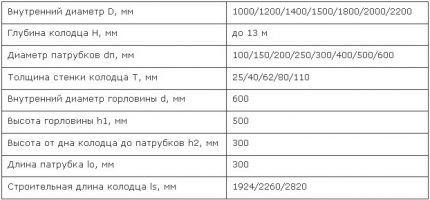

Requirements for reinforced concrete prefabricated structures are set out in regulatory documents GOST 2080-90, where the technical requirements for products are described in detail, their characteristics, markings are given, and links to related GOST articles are provided.

The advantages of prefabricated structures over monolithic ones lie in the installation possibilities. Reinforced concrete parts are heavy, so they have to be transported and installed using special equipment. It is much more convenient to ensure the delivery of individual parts than the entire structure in finished form.

During installation, additional measures are sometimes required - for example, installing a waterproof lock. By assembling the structure in parts, it is much easier to carry out specific excavation work.

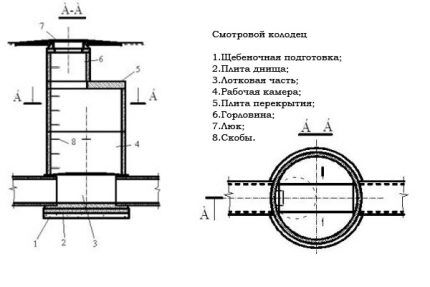

So, the lower part of the structure is a durable concrete slab, which is placed on a pre-prepared foundation. To give the structure stability and at the same time ensure the outflow of groundwater, crushed stone is poured into the pit before installation. The bottom slab is laid strictly horizontally on a crushed stone base.

The lower part is called the tray part; it is equipped with holes or pipes for installing the pipeline. The location of the inlet holes depends on the purpose of the well. Let's assume that in linear structures they are on opposite sides, in rotary ones - depending on the angle of rotation.

The main working chamber is larger in size than the others - it is into it that you should go down to check the shut-off valves, tightness of connections or wear of parts.For ease of descent, one wall is equipped with a ladder made of metal brackets.

The top of the working chamber is covered by a floor slab, to which another element is attached - the neck. It is narrower in diameter than the main part.

Neck covers himself with a hatch, which performs two functions - it protects the well from the penetration of unwanted guests and protects from street debris and precipitation. To make it more difficult to get into the chamber, the hatch is made of heavy material - cast iron.

When installing inspection cameras in a suburban area, it is not necessary to use cast iron parts. Nowadays many types are produced polymer caps, more comfortable and aesthetically attractive.

Requirements for the design of polymer products are set out in GOST-R No. 0260760. One of the common manufacturing materials is polyethylene. The reliability of the design is ensured by the production technology - the extrusion welding method.

The products are resistant to chemicals present in the soil and are wear-resistant, environmentally friendly and airtight.

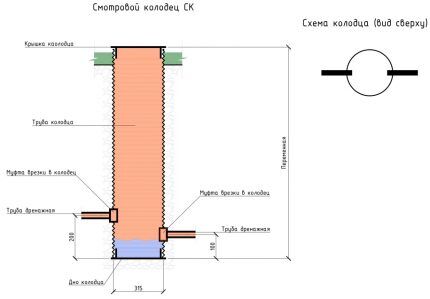

Outwardly, they resemble large capsules with a hole in the neck. Unlike concrete analogues, plastic cameras purchased and installed ready-made.

The products are adapted for quick installation and connection of pipes. Due to easy installation, many country home owners prefer plastic cameras.

Dimensions of concrete structures

A complete list of standard sizes can be found in regulatory documents, for example, in Article 2.04.03-85 SNiP. Dimensions refer to the sizes of various parts of the structure and incoming pipes, as well as the distances between them.

If the diameter of the passing pipeline is 600mm or less, the length and width concrete ring wells must correspond to 1 m.

As the diameter increases, the dimensions of the chamber increase:

- for rectangular reinforced concrete products — pipe D 700 mm = well D+400 mm;

- for round reinforced concrete products - pipe D 700 mm = well D 1250 mm, up to 1000 mm = 1500 mm, more than 1200 mm = 2000 mm.

There are types of wells that are not intended for drainage. If communications lie at a depth of 100-120 cm, and the diameter of the pipeline is 15 cm, a compact inspection chamber with a diameter of only 60 cm is suitable.

It is used for cleansing procedures. These products are often used in dachas for the installation of short-length storm drains.

The height of the working chamber is 1.8 m, however, there are models with reduced dimensions. Width - at least 1.0 m. Neck diameter - 0.7 m. The dimensions of all parts of the well must be such that a worker can easily go inside and carry out repair or cleaning procedures.

The hatch is usually located at the same level with the surface of the roadway or sidewalk, on the lawn it rises above the ground level by 5-7 cm, in an undeveloped area by 20 cm.

If necessary, install a locking device on the lid. One of the main conditions for sizing is the safe operation of manholes.

Solving installation issues

If you decide to lay a sewer network yourself, first study the SNiP standards and requirements for the installation of all elements of the system.

This also applies inspection wells for stormwater drainage. They are necessary even if the underground pipeline is laid along the perimeter of the cottage - each corner turn is equipped with an inspection chamber.

Option #1 - assembling a structure from concrete rings

The location for installation is planned at the design stage, so the preparatory work comes down to the following activities:

- precise marking of the area for digging a pit;

- clearing the area of trees, bushes and debris;

- construction of a temporary entrance for equipment (if necessary, dismantling of obstructing structures).

When the territory is cleared, we begin to dig a pit - we take out the soil to the required depth (the height of the structure + a cushion of crushed stone).

We level the bottom, fill it with a 20-cm layer of crushed stone, compact it, and, if necessary, seal it with bitumen mastic. The pit is completely ready for installation of a reinforced concrete well.

Next we proceed according to the following plan:

- We lay the base (ready-made concrete slab or homemade cushion in the form of a 10-centimeter screed made of M-50 concrete).

- We equip the tray - we form the lower part from M-100 concrete, reinforce it with a galvanized steel mesh.

- The ends of the pipes are sealed with layers of cement and bitumen.

- After 2-3 days, we treat the inside of the concrete rings with bitumen and install them on the tray part.

- We install the floor slab, the neck, and seal everything.

- We grout the joints with cement mortar and bitumen (SNiP 6.3.8 states that in the presence of groundwater, waterproofing is required 50 cm above their surface).

- We plaster the tray.

- We build a clay castle in the lower part (30 cm wide, 60 cm above D pipes).

- We check the quality of waterproofing - fill it with water and leave it for a day (we close the exits with plugs).

At one stage we connect the pipes.

After a successful check, we backfill and make a blind area in the upper part (one and a half meters along the diameter of the neck).

We leave the upper part open by installing a locking mechanism on the hatch, or we disguise it by closing it with a decorative polymer cover.

Option #2 - installation of a plastic well

Installation of a polyethylene chamber is faster and easier.Preparatory work is carried out according to the same plan as for constructing a concrete structure.

The main thing is to comply with installation standards, which can be clarified with the manufacturer or with specialists from the company selling the product.

Stages of constructing a polymer manhole:

- Digging a pit by excavating soil to the required depth (the width should exceed the dimensions of the chamber by 20 cm in all directions).

- Arrangement of the base: filling a filter layer of crushed stone, a leveling layer of sand (15-20 cm).

- Installation of a plastic well on a prepared base.

- Connecting the sewer pipeline.

- Backfilling with interval compaction (every 3-5 cm).

Sometimes cement is added to the sand for backfilling. Compaction protects against movement in water-logged soils. Due to their lightness, some models are equipped with a loading chamber (or several chambers), into which concrete is poured during installation. A kind of anchor provides stability during the movement of groundwater.

Separately, it is worth mentioning the features of installing a polyethylene well under a sidewalk (garden path) or road (roadway). To ensure that the walls can withstand the load and not collapse, reinforced concrete slabs are installed.

Over time, when the road surface deforms, the slabs will shift, but the well will remain in its original position.

For protection, two reinforced concrete slabs will be required.In the center of the bottom plate there is a hole that exceeds the diameter of the chamber by 1.5-2 cm.

The well is lowered into the hole so that it is 9 cm higher than the bottom of the polyethylene product. The top slab resembles a regular ceiling with a hole for a hatch, which is located strictly above the stairs, that is, offset from the central axis.

Polymer wells in conjunction with plastic pipes form a reliable system, wear-resistant and environmentally friendly, capable of serving for decades.

You may also be interested in information about polymer sand wells, discussed in detail In this article.

Nuances of waterproofing work

Inspection wells are dry-type technological structures, which are most often located in wet soils.

When constructing these structures carrying out waterproofing is a mandatory measure that guarantees the safety of pipeline fittings and effective work on cleaning or flushing pipes.

Practice shows that leaks in prefabricated concrete structures most often occur not due to defective products, but due to improper processing of joints. This means that sealing seams is a serious and responsible procedure.

Three types of insulation are used as waterproofing compounds:

- bitumen-polymer;

- cement-polymer;

- polymer.

Bitumen-polymer waterproofing includes coating materials (mastics) and weld-on rolls, the gluing of which requires heating to a certain temperature. The second option is used less frequently, since special skills in using a gas burner are required.

Cement-polymer compositions are cheaper, have excellent technical characteristics and are suitable for independent use. The prepared mixture is applied with a spatula in 2-3 layers to a moistened, cleaned surface, leveled and allowed to dry.

Polymer waterproofing is elastic and durable. Mastics and rolled membranes are ideal for potentially moving structures - even with a slight displacement, the sealing of the joints will be maintained.

In addition to the walls, it is also necessary to insulate the base of the well. It is usually done at the stage of laying the concrete slab, before installing the rings. The slab is covered with a cement-polymer composition, and the lower joints are also covered with it.

Conclusions and useful video on the topic

The materials from the videos will help you correctly select and install inspection wells for sewerage.

Interesting information about polymer sand wells:

Installation of concrete rings for a drainage well:

Installation of a plastic well:

Drainage system for a summer residence:

The construction of a manhole is reminiscent of the construction of other types of sewer structures - filtration or storage. However, there are some nuances that you need to become familiar with before starting installation.

To avoid making mistakes in choosing products and installation technology, refer to regulatory documents and consult with professionals.

Do you have experience in constructing a sewer inspection well? Or do you just want to start arranging it? Perhaps you still have questions after reading the material? Ask for advice or leave your recommendations in the comments block located at the bottom of the article.

Why is a concrete tray made when using concrete rings?