How to install and connect an outlet: step-by-step guide

You can solve the problem of replacing or installing an outlet on your own, without involving electricians.With some effort, you can easily refute the common belief that only specialists can perform electrical installation work.

We will tell you how to choose a socket for arranging home wiring or replacing a damaged device. The article presented for consideration describes in detail how to connect the outlet and prepare the necessary tools. Taking into account our recommendations, you will easily cope with the installation and connection of the electrical installation product.

The content of the article:

Typical types of sockets

The reasons why you need to change the outlet can be very different - from a full-scale repair to a simple breakdown. Faced with such a problem, you have to choose the right product in a store or market.

Manufacturers offer a wide variety of models in shape, color, and purpose. It is difficult for an inexperienced person to immediately decide what exactly he needs.

Sockets offered by many manufacturers differ not only in appearance, but also in the type of installation. Depending on how the wire is laid, you will need an appropriate outlet.

Based on their location relative to the wall on which the electrical outlet is installed, there are 2 types of sockets:

- built-in;

- invoices.

Built-in ones are used for installation in plasterboard walls, brick or concrete walls. The main distinguishing feature of such sockets is that their electrical parts, like the entire wire, are immersed in the wall. To do this, a special groove is cut into the wall using a hammer drill. It houses wires enclosed in a corrugated pipe.

A special recess with a diameter corresponding to the diameter of the mounting box is cut under the socket. This hole may be slightly larger, but in no case should it be made smaller. The socket box should not be subject to deformation during installation.

Built-in models are in demand among residents of megacities and other populated areas. They are popular in houses and apartments with small children. These sockets fit perfectly into the interior, thanks to the rich color palette offered by the manufacturers.

Surface-mounted sockets differ from built-in sockets in their appearance - they are located entirely outside. Their electrical mechanism is hidden only in a decorative box screwed on top of the wall. The wires also go over the wall, covered with a special cover.

Mostly overhead socket used for installation in houses with wooden walls.

Depending on the internal structure of the working mechanism, sockets are:

- with a screw clamp, when the wire inserted into the socket mechanism is fixed between plates connected by a screw. If the wire becomes flattened during use, simply tighten the screws;

- with spring terminals. Here the contact hole for the wire is expanded by pressing a special key. Over time, when the fastening weakens due to deformation of the wire, it is necessary to remove the flattened part with pliers and reconnect it.

Depending on what wiring the socket will be used for, there are two and three contact ones. Two-pin sockets are sockets without grounding. Their main advantage is lower cost.

Three-pin - with grounding. They are installed in rooms where electrical appliances that require grounding will be used - computers, washing machines and others.

Before purchasing an outlet, you need to pay attention to its back wall. It indicates what load and number of phases it is designed for. Most often, the current value corresponds to 16A and the voltage is 220 volts. However, to connect an electric stove, it is most often necessary to connect a separate line and install three-phase socket.

The time has passed when there was no special choice of sockets and you bought what was on store shelves. Now manufacturers, competing with each other, are developing various types of sockets in order to attract more customers.

For home use, you can choose the option that is most suitable for a specific room, for example, for arranging electrical points in the bathroom, in a swimming pool or in a combined bathroom, and for installation within the entrance area of a private house.

Young parents like to install sockets in which the holes are covered with special covers - protective curtains. This allows them to additionally protect their growing children who show interest in studying surrounding objects.

Also very attractive are socket models equipped with a current indicator, a timer that can be programmed as needed, or options with a plug ejector.

In the family of products for installing electrical points there is a special group - retractable sockets, the features of the device and installation of which we recommend that you familiarize yourself with.

Construction and components

To thoroughly understand how to properly install a new outlet at home, you need to study a little about its components. All sockets are sold already assembled. Therefore, when installing it, you will have to unscrew everything yourself.

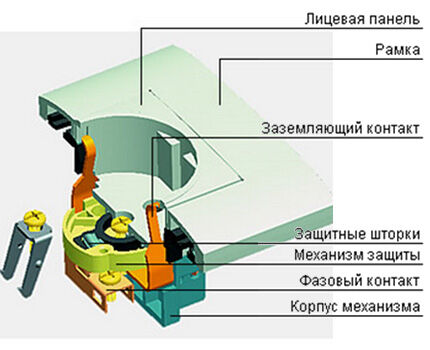

The main components of the socket are the base, the conductive part, and the decorative front panel. The base is made of ceramic or high-quality plastic. All elements are attached to it - conductive parts and the front cover.

Ceramic bases are considered more reliable, but they require particularly careful installation, because if damaged, you will have to buy a new socket.

The decorative overlay is designed to hide all working elements. It serves as a reliable insulator of the working part from external influences. Some models provide the ability to simply replace this part of the outlet.

The working part of the socket consists of spring contacts and terminals to which electrical wires are connected. One of the important contacts is the grounding one.

The conductive elements are made of brass or bronze. The latter are better, but are extremely rare. Therefore, you should choose options made from tinned brass - they are more reliable than conventional brass, are better soldered and last longer.

Standard installation steps

In order for the outlet to work for a long time and not create any problems, you need to be careful about its installation. It is important to do everything correctly and consistently, without haste.Only in this case can a good result be guaranteed.

Preparations before installation

The preparatory stage of installation begins with the purchase of the desired model and the required number of sockets. Here it is important to consider where they will be installed and select the models that are most suitable in a particular room.

Then you need to take the tools that may be useful during the installation process. This is a construction level, the socket itself, screwdrivers for tightening fasteners and screws, a construction knife or stripper for removing insulation, pliers, a special screwdriver for checking voltage, electrical tape.

If you not only need to replace an old outlet with a new one, but also install additional space for connecting electrical appliances, then an extensive set of materials and tools may come in handy.

You will need a socket box (mounting box), a puncher for making recesses for the working mechanism, attachments for a puncher of the required diameter, a ruler/tape measure, a simple pencil, and a construction plaster mixture.

Power outage is a guarantee of safety

The most important thing in any electrical work is turning off the electricity! Without this, it is unacceptable to begin installation.

Depending on what is installed in a particular apartment or house, you need to unscrew the plugs if a meter with plugs is installed or set the levers to the “off” position if there is an electrical panel with automatic switches.

Then you need to additionally make sure that the working area is truly de-energized.To do this, you need to take a pre-prepared indicator screwdriver and check for the presence of voltage in the wiring to which the outlet is to be connected.

Selecting a socket connection diagram

Having chosen the appropriate socket models and prepared the necessary tools, you have to decide how to properly connect the socket.

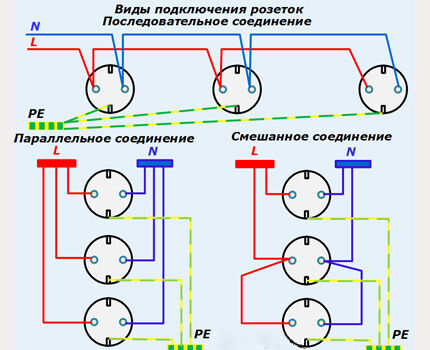

There are different socket connection diagrams to the power supply:

- sequential, when the sockets are connected one after another;

- parallel, if each outlet has its own wire from the junction box;

- mixed, the option when some sockets are connected in one way, and the rest in a different way.

It’s easy to decide on the type of connection - if the additional connection point to the electrical network will be used to operate powerful devices, you should choose a parallel circuit. For low-power electrical mechanisms, it is convenient to give preference to a sequential circuit.

Installation of mounting boxes

After making sure once again that the workspace is de-energized, you can proceed to the next installation step. If this is not a replacement for an old outlet, then you will need to note where exactly one or more additional outlets will be located. For this you will need a ruler/tape measure and a pencil.

If you have planned replace a damaged socket or remake the device, then you need to act in a different sequence, described in detail in the article we propose.

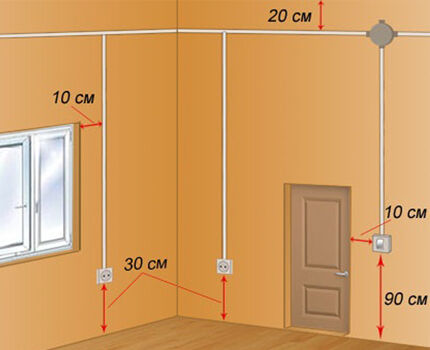

When choosing a location for the future location of sockets, you should focus on the convenience of their further use. For sockets, they try to maintain the following distances:

- from the floor - not less than 30 cm;

- from the ceiling - at least 20 cm;

- from the window - at least 10 cm;

- from the plinth under which the wire is hidden - 0 cm.

If the sockets are placed too high or low, it will be extremely impractical. About the rules for the location of sockets and switches according to European standards in detail written here.

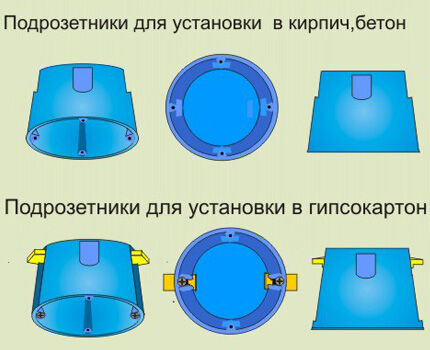

Having marked the places where the sockets are to be installed, you should make holes for mounting boxes. They, depending on the material of the walls, come in different diameters. Here you need to focus only on your own situation. The main rule is that the hole should not be smaller than the socket itself.

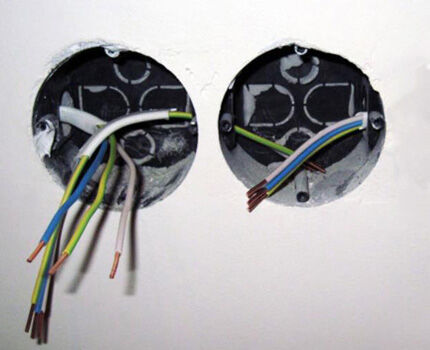

The mounting boxes themselves are made of plastic, very rarely metal. Good quality plastic, non-flammable. It provides reliable insulation of the wires that will be located in such a box. The shape of socket boxes can be round, oval and even square. Although it is most convenient to work with round plastic boxes.

The order of the installation stage of the socket box depends on the condition of the walls and the individual characteristics of the home.

The most common situations are:

- full-scale renovation of the premises. In this case, grooves are cut in the walls, a cable is laid in them that will power the sockets of the entire room, and holes are made for mounting boxes;

- the walls are already finished with a decorative coating, and the electrical cable is recessed into the wall. In such a situation, you will need to carefully use a knife to clear the already prepared holes for installing mounting boxes;

- the walls are finished, the cable is laid under the baseboard or hidden in an external insulating box. Then you need to install external sockets;

- The walls are finished, the cable is not laid. Here you have to choose the most optimal installation option.

Convenient if you only need to make a hole for an additional outlet. Decorative overlay - the front part will cover the consequences of the work.

Otherwise, if you want to avoid damaging the external finish of the walls, you will have to approach the installation process creatively. One of the options is to use the overhead installation method, when the wire is to be run over the wall, packing it, for safety reasons, in protective and decorative channel.

Another convenient option is to install the socket immediately above the baseboard, hiding the electrical wire under the baseboard. In this case, you will also have to use an overhead model.

You need to install a mounting box into the prepared hole for the socket, threading the power cable into it. This hole must be thoroughly cleaned of dust and construction debris. You can use a vacuum cleaner or brushes. The socket box is securely fixed in the cleaned hole.

To do this, the prepared gypsum mixture is applied, and the installation box with the cable threaded is immersed in the hole with the mixture. All work continues after the solution has set - this will take no more than 10 minutes.

In this way, one or more socket boxes are installed, as well as a mounting box for a double socket. If a whole row of sockets is to be installed, then the mounting boxes are installed in a row strictly horizontally or vertically - as planned by the owner of the room.

Most often this is a horizontal option. In this case, single socket boxes are placed close to each other. They are necessarily connected to each other, and their horizontalness is checked by the building level.

Connecting and checking the device

After securing the box, work begins with the power cable coming out of it. Firstly, you first need to cut off the excess piece, leaving about 7 cm from the edge of the socket box. Remove the braid from it - the top insulating layer that unites the internal wires.

Inside you will find 3 wires of different colors - blue, white and yellow-green. This is the most common color composition used for markings. Instead of white there can be brown, red, black and others.

Secondly, the wires need to be freed from the individual insulating layer by carefully removing it with a stripper or knife at a distance of about 1 cm. Now we have to work on connecting them to the working mechanism sockets with grounding.

Yellow-green is the color of the grounding conductor. It must be connected to the central contact responsible for ground.

Blue or blue-white is a working zero. This wire must be connected to the extreme terminal of the working mechanism of the socket. The remaining wire, most often it will be white or beige-brown, must be connected to the second outermost contact.

Depending on the type of socket, the connection is made by pressing a special key if the mechanism uses spring terminals, or is fixed between the plates using a screw clamp.

To fix it in a screw clamp, sections of wires cleared of insulation are first bent so that it looks like a small half ring. Thanks to such preparation, it is easier to work: the wire will not slip out from under the screw during fastening. You need to bend it clockwise.

When all the contacts are connected, you need to carefully bend the wires and carefully place them together with the working mechanism of the socket inside the mounting cup. Then carefully screw the mechanism to the socket box using the screws located on its edges.

These screws will allow you to tightly fix the working part of the socket. It is important not to overtighten the fasteners so that nothing breaks.

If everything is securely and horizontally fixed, you can proceed to the final stage of electrical installation - screwing on the decorative trim. To do this, you need to tighten the central screw without overtightening it.

The outlet is now connected in compliance with all safety rules.You can tighten the plugs or turn on the levers on the panel and check its functionality. If all actions were performed consistently and correctly, then a new working outlet will be available to its owner for many years.

The need to install an additional outlet may arise completely unexpectedly - the old one will fail or new furniture will block free access to one of the existing ones.

Having information about the nuances of installing and connecting an outlet, you can easily cope with this work yourself.

How to correctly connect the socket block is described in detail. in the next article.

Conclusions and useful video on the topic

Video #1. Step-by-step guide in video format about installing the socket:

Video #2. A detailed and understandable video to help craftsmen planning to install sockets with hidden electrical wiring:

Video #3. The video is a warning against dangerous grounding methods sometimes used by DIYers. If your neighbor advised you something like this, it’s better to refuse:

Having become familiar with the main nuances and stages of installing an outlet, you can perform this type of electrical work with your own hands. Everything that seemed unfamiliar and therefore incredibly complex became clear and simple.

It is not at all necessary to call an electrician and ask him to connect an additional outlet, when you can do this work yourself, pleasantly surprising your loved ones.

Would you like to share your experience as an independent electrician? Do you want to provide information useful for home craftsmen? Please write comments in the block below, ask questions, leave photos on the topic.

When choosing an outlet, don't be greedy. Take those that not only look beautiful, but those that are also reliable. The body of the mechanism must be made of ceramics, and the contacts must be brass, the plastic must not be brittle. The socket box should also be made of high-quality, non-breakable plastic. Must sit tightly in the nest. If you move an outlet, lay the wires at right angles so that you don’t run into them yourself during the next repair.

If you are installing an outlet in a barn or garage, take “Soviet” design outlets: they are unprepossessing, but reliable.

I wandered around “Electrics”, I didn’t find an article with my problem, I’m writing here, maybe someone will help. So. I made a separate line for the water pump and water heater. I installed a 20 A switch for each device. After some time, the one on the pump began to turn off. They advised to change it to 30 A. But when replacing it, it turned out that the problem was in the switch itself - the contacts were burnt. Question: isn’t it risky to leave 30 A? After all, it gives too much margin for operation. In general, any advice on min-max A for a 1 kW pump? Thank you.

If the word “switch” means an installed machine that knocks it out of the network, then I would say that 20 A and 30 A are too much for 1 kilowatt. Moreover, if the connection was via a separate line for the pump and water heater.If the machine is connected purely to the pump, then 6-10 A will be enough. If they are both connected to the same line, then 10-16 A (depending on the power of the water heater itself).

I repeat, for 1 kW 30A the delay will be large. And one more thing, charred contacts, this is something abnormal. I would change the wire to a thicker section and check the devices for electric shock. Better yet, I would call a specialist who can already find his way around the place.