Serial and parallel connection of sockets: loop and star

The performance of routine household duties is greatly facilitated by numerous technical devices and equipment.“Tireless workers” illuminate the premises, wash, whip, bake, and wash dishes for us. However, simply buying them is not enough; the equipment needs to be connected correctly, you must agree.

Remember how many negative emotions are caused by a triggered machine that disconnects the line due to overload at an extremely inopportune moment. A damaged boiler, computer, or refrigerator brings quite a bit of pleasure. But the listed troubles can be trivially prevented and eliminated altogether, with which we are happy to help.

To do this, you just need to find out how parallel and serial connection of sockets for home appliances is made, in which cases the “loop” and “star” circuits are used. Our proposed article will introduce you to this very useful information.

The content of the article:

Ways to connect sockets

Today, connecting sockets is carried out in two ways: in the first, a separate electrical wiring line is installed for each point, in the second, several points are connected to one branch at once.

The type of sockets installed is closely related to the type of wiring: whether single-phase sockets are used, equipped with or without grounding, or three-phase devices are installed to power devices that operate on a 380-volt network.

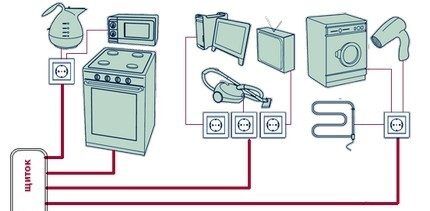

The vast majority of technical devices that need to be connected to the power supply are located or confined to the kitchen and bathroom:

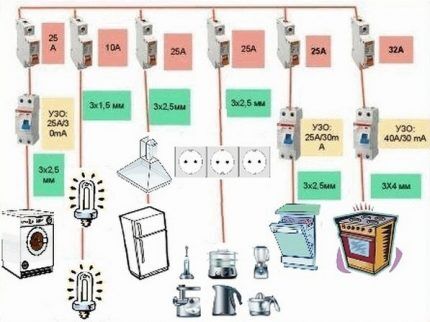

Sockets for powerful consumers, for example, electric ovens or boilers, are connected with a separate line. Whenever possible, use whole pieces of cable during installation, devoid of any connections. Electrical lines are laid separately from the shield to each point, which somewhat resembles the rays emanating from a star.

If it is necessary to connect each such consumer, the powered point must withstand a rated current of 16 - 32A. The current at the input is designed for a current with the same indicator. circuit breaker.

A daisy chain connection is chosen if it is necessary to power the electrical outlets of one group. These groups are formed in accordance with the location of appliances around the house.

The method involves connecting all elements to a common power supply line.

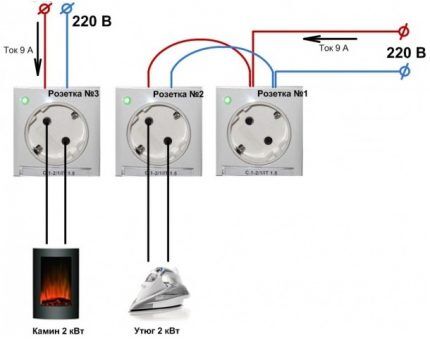

To reduce the risk of damaging several points at once, experts recommend including no more than two or three outlets in one system. This point is clearly stated in SP 31-110-2003: it is allowed to connect up to three additional electrical receivers with a cable.

The only condition is that the total current load does not exceed twice the operating rated current of the first (head) electrical receiver.

But, in any case, the circuit created in this way is designed for a load whose total value does not exceed 16A. If operating conditions are not observed, there is a high probability of emergency situations.

When connecting sockets, it is not at all necessary to use a pure type of wiring. With the right approach, they can be combined, for example, bringing the power cable to distribution box. And after it, direct one cable in the form of a loop, and lead the other separately to the power supply point of powerful equipment in the house.

The number of supply lines laid from the panel depends on how many electrical wiring routes are supposed to be laid.

Regardless of the type of method chosen, electrical wiring can be done in one of two options:

- open - involves laying wires on the wall surface;

- closed - involves hollowing out channels for laying power lines in concrete and brick walls, selecting a channel in wood for laying a cable pulled into a corrugated pipe.

The open version is more convenient and simpler in terms of not only installation, but also maintenance and control. But regarding the aesthetic aspect, an open wire is not always appropriate. And besides open installation method “eats up” part of the usable area: it is impossible to hang a shelf on top of the cable or move furniture close to the wall.

Inner space of the majority cable channels It has partitions between which it is convenient to place wires. The condition of the route is monitored through the upper removable part.

The closed wiring option is convenient because it eliminates the possibility of accidental damage to the cable, making it invisible to others.

But the “invisibility” of closed wiring can also play a cruel joke when trying to “hammer a nail.” Therefore, there is an unspoken rule: lay the wires in relation to the sockets strictly vertically or horizontally.

Features of installation of daisy chain connection

As already noted, the daisy chain method is used to connect sockets located in the same group, which power low-power devices, such as a computer, audio equipment...

This type of connection is more economical and technically simpler. After all, to implement it there is no need to lay a lot of cables and use additional protection. But it is worth noting that each additional point of the created chain will make it more vulnerable.

For example, we know that the rated current per outlet should not exceed 16A. If you connect such a load to one point, then nothing bad will happen. But when you turn on such a load on at least 2-3 sockets of one line, its total readings will increase, and as a result, the power cable may not withstand it.

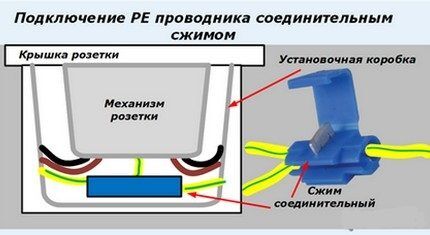

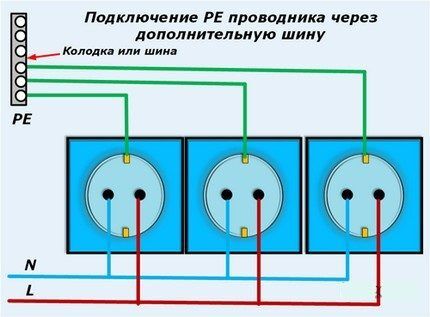

According to the PUE, during a daisy chain connection, it is not allowed to break the PE conductor of the protective grounding wire. In any case, its contour must remain unbroken.

The use of one of the technical solutions helps to reduce material costs when connecting PE conductors to sockets:

Installation using connectors

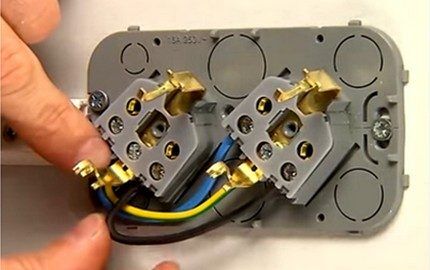

This type of connection is chosen when it is necessary to connect sockets that are located almost close to each other.

With a daisy-chain connection, the main wire supplied from the power panel goes to the seat of the multi-place socket box. From it it powers the first socket, from which, through its own contacts, power goes to the second socket, from the second to the third.

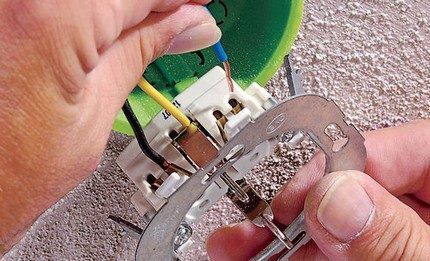

When installing with a cable, the incoming and outgoing cables are connected directly to the contact part of the device. For this reason, craftsmen recommend using models equipped with a flat spring contact.

As a last resort, samples whose contacts are made in the form of a plate pressed with a bolt are suitable. Devices in which the role of a contact is played by an ordinary bolt are not at all suitable for this purpose.

One of the mandatory operational requirements when connecting sockets with a cable is the need to reduce the contact resistance in the circuit between the contact terminals of the socket and the contacts of the electrical plug.

To achieve the desired effect, the terminals are shaped to increase the area of the contacts themselves, as well as the force of their compression. Today, Scotchlok connectors are often used to install protective zeros. This type of clip connector is equipped with mortise contacts.

To use a clip connector, you should choose products that provide additional space to accommodate it.

Through the contact of the first socket, the phase wire of the power cable and the PE conductor of the loop are supplied, which goes further to the second socket.On the second contact there are neutral wires of the power cable and a cable to the second socket. The same principle is used to connect to the third and subsequent outlet, if its presence was provided for in the power wiring diagram.

According to the PUE clause 1.7.144, in order to connect the open conductive part of the device to the neutral or grounding conductor, it is necessary to make a branch in the cavity of the casings of electrical installation products intended for this purpose. These include sockets.

The main task when connecting sockets equipped with grounding is to ensure reliable connection elements along the entire line. After all, if for any reason the grounding contact burns out in the main power socket, all other participants in the circuit will lose the protective zero. Therefore, if it is necessary to branch the grounding conductor, the most reliable type of connection is used - crimping.

The method involves, in addition to the use of conventional twisting of wires, additional insulation and crimping of their ends using a sleeve. This ensures uninterrupted contact of the chain elements and its high mechanical strength.

Installing an additional junction box

This method involves installing a branch box or connecting block connected to the shield next to the socket cable. In this case, the cable is branched in the distribution box in the area before being connected to the socket box.

The connections inside the branch box leading to each outlet are most often made by welding. It is recommended that the insulated ends of all conductors be laid in junction boxes so that they do not intersect or touch each other.

In both cases, when connecting the phase and neutral wires to the sockets, a loop is formed, and a branch is formed from the PE conductor. Therefore, when wiring sockets, it is important to observe the polarity of the contacts: remove the neutral conductor from the terminal with neutral. Do the same with the phase wire.

Taking into account the number of working electrical appliances, the number of sockets in the room can reach 10 pieces. Using tees and extension cords is not always convenient, and it is also dangerous. In this case, they solve the problem by installing socket blocks instead of a single socket.

The design of the socket block, which includes up to four separate elements, is connected according to the same principle as a single socket.

When connecting blocks, the conductor cores are connected in any of the described ways. Bare areas are insulated with heat-shrinkable tubing or wrapped with insulating tape.

Specifics of parallel connection

The peculiarity of the parallel circuit for connecting sockets, otherwise called a “star”, is that each socket is connected separately to the panel.

The third quite justified name is “boxless”, because suggests the possibility of eliminating the junction box.The method is actively practiced in European countries, but in our country it is used to provide a separate line to powerful consumers, most often in combination with loop technology.

One of the options for a parallel circuit is demonstrated by a selection of photos:

The advantage of the “stars” is to ensure the maximum degree of security.A significant advantage lies in the creation of the ability to separately control large energy consumers, which is a priority for power distribution for "Smart home", For example. The disadvantage of the scheme lies in the impressive labor costs of the electrician and the almost threefold increase in cable consumption.

A parallel circuit is also used to connect three-phase power outlets that will power powerful electrical appliances. In this case, the cross-section of the conductors supplying such consumers must be at least 2.5 square meters. mm.

For greater reliability, they should have a small current reserve. This will make it possible to compensate for the actual deviation from the diameter specified by the manufacturer from their nominal value, which is often the “sin” of products presented on the modern market. In addition, such a solution will ensure the ability of equipment to operate in overload mode.

This installation method is advantageous in that the performance of each individual point does not affect the functioning of the remaining participants in the chain. For household appliances, this scheme is considered the most stable and safe.

A three-phase outlet equipped with grounding is connected using separate four-wire wiring. The cable, including three phases, grounding and neutral, goes directly from the switchboard.

The purpose of the wire is most easily determined by the color of the insulation:

- “phase” - wires with a white tint;

- “zero” - the insulation is painted blue;

- “grounding” is a yellow-green braid.

Grounding is essentially a protective zero.In order for it to remain so, it is necessary to ensure its reliable and constant connection throughout the entire line.

To connect the wires and connect to the outlet, first of all, shorten their ends. Using side cutters will allow you to complete the job as accurately as possible. The end of each wire is stripped of 15-20 mm of outer insulation using a sharp knife.

The wires are connected in the following sequence:

- Remove the plastic protective cover from the socket.

- The clamping screws are unscrewed by 5-6 mm. The same manipulations are done with the screw and on the ground terminal.

- The stripped ends of the wires are inserted one by one into the box, taking into account the position of the input terminals, and placed in the appropriate sockets.

- The sockets with laid wires are tightly tightened with screws.

- The socket box with the connected wires is inserted into the wall niche and secured with side clamps.

To obtain a more reliable assembly, some craftsmen roll the exposed ends of the wires into a loop or ring so that their diameter matches the size of the screw legs.

After this, each screw is unscrewed in turn, a wire ring is wrapped around its base and tightened tightly.

At connecting socket blocks all benefits of the scheme are retained. The only thing is that the connection process takes a little more time and effort.

Increased costs are not an argument for those who prioritize safety. If you look at the situation more globally, then sometimes it is better to immediately invest more money and effort by arranging an autonomous power line for the outlet.Then you won’t have to think every time about whether it is possible to use a point to connect this or that electrical appliance.

Conclusions and useful video on the topic

Video #1. Guidelines for using the loop method:

Video #2. A detailed introduction to one of the safe options for connecting sockets:

Given that the amount of electricity spent on household needs is only increasing every year, and therefore the requirements for the reliability of sockets will certainly increase, a parallel wiring diagram should still be preferred. Especially when it comes to serious energy consumers.

To power lamps, electric alarm clocks and similar devices, a cable connection option is suitable.

Do you have any questions about the topic of the article, have you found any shortcomings in the information presented, do you want to share your experience in independent electrical installation? Please write a comment in the block below.

In the parallel circuit in the figure, use 25A circuit breakers for a wire with a cross-section of 2.5. Although in the text you speak correctly about the use of 16A machines. I think it’s worth correcting, otherwise it’s misleading.

Andrey, have you tried reading? We are talking about the use of machines with at least 16 A, and not the specific use of 16 amperes. Simply ripped off from the installation manual, which talks about connecting socket groups through breakers from 16 A.

Protect sockets with an atomizer no more than (!) 16A. And then, if the wire is 2.5 sq. mm.

There are also 10 A sockets, and then you need to install an appropriate circuit breaker under them.

Euro sockets are not designed for currents higher than 16A, and if you choose a machine that is not suitable for the current, you can safely burn the socket, and the cable will remain intact.

So even when throwing a cable of at least 3*10 to the socket, set the machine no higher than 16A, if you don’t want to connect a heater, kettle and hairdryer through a tee, go to the store for a new socket or run for a fire extinguisher.

The machine protects the weakest link in the chain from the panel to the socket, inclusive, from overload.

So if the “economical” builders laid a 1.5 kW.mm wire, then install a circuit breaker of no more than 10A, and if 3 * 4, then there is either one 16A in the panel, or 32A in the panel and at the other end there is a mini panel and several from it lines to sockets, each with a machine is not the same 16 (for example, a separate panel for kitchen sockets).

Recently I decided to eliminate the shortcomings of the electricians who in the distant past connected the sockets in my apartment, and installed several more sockets. As for me, the simplest, and quite reliable way is to connect the socket in an overhead frame. The main thing is to insulate the wires and place the heat-shrinkable tube carefully, without catching the wiring in the wall when attaching it. And the pipe itself should look appropriate and aesthetically pleasing in the room.

Well, once again I am convinced that it is better to entrust the installation of sockets to a professional electrician. It’s clear that we all know how to repair wiring, but it’s with the calculations that problems arise. You just need to take into account that now the number of devices and their power have increased significantly. That is why it is advisable to completely replace the wiring along with electrical installation points in all old houses. By the way, I personally prefer external wiring precisely because of the ease of control and repair.

Igor, I don’t agree with you. The power is constantly decreasing: compare a tube TV and an LCD, an incandescent lamp and an LED. And so almost everywhere.

And where, excuse me, do you see a decrease? New plasma panel 52 inches/132 cm - 197 W. LED panel 52 inches/132 cm - 120 W. Color tube TV "Rubin 714" (1967) 17 inches/43 cm - 200 W. CRT TV 32 inches/81 cm - 80 W.

And let’s take into account that under the communists, the maximum that was turned on was 1 TV and 1 iron at the same time, so let’s go to the extreme - 1 soldering iron and 5 100-Watt light bulbs. Since you are giving advice, can you calculate the power consumption? And let’s take the current apartment: there’s a TV in the room, a TV in the kitchen, I won’t count the light bulbs—it’s not worth counting small change.

A man came out, turned on the kettle, turned on the microwave, and there was also a washing machine. We already get 6 kilowatts, which gives a load of 27 amperes. The old wiring to the apartment was done with 2.5 aluminum wire. Can you say offhand whether it will work or not?!

Answer to Alexander - what is the downside, we take a picture from one site, text from another, in the end, “You haven’t tried to read.”

16 ampere socket group... this is 3.5 kW (3520w) the recommended load current for an average socket, which can be bought in our store (if we take into account only imported manufacturers). Only for Russia the sockets are marked 16A, since in any case ours will plug in 9 kilowatts.And the question is, can the wiring itself withstand such power across the cable cross-section? Take a classic or Arab 32 Ampere in a meringue common in Europe 10 A and 32A (as we like to call it power) type C, D, M and G type C is designed for low power, then when type G is rated 32 A, and a cable for plugs marked AWG8.

According to our standards, this is from 8 kW, that is, about 45-50 Amperes (we do not have such a section).

Amir, it’s pointless to compare a diode lamp with an incandescent lamp, about the same as a two-burner “Vyatka” electric stove of 2 kW and a modern hob of 19-12 kW, a Soviet electric kettle of 500 watts and a modern (fast) 2 kW. All devices that have a heating element type heating element - their power has never decreased! TEN is evil!

I note that in many new houses the wiring is done exactly according to your principle. Like the power drops, the wire is 1.5 square meters throughout the apartment, and then the question is why the machines fly and the terminals burn out. There are GOST requirements - multiply by 2 and do it - this is your safety. Only here in Russia on the market you can buy an outlet for 20 rubles, while any German simply will not buy an outlet that costs less than 10 euros, simply for the reason that safety cannot be cheap.

let's take it in order

1) the socket group is designed for 16 amperes and this is really 3.6 kW. but PUE-7 clause 1.3.10-1.3.11 about permissible currents says that the permissible long-term current for one three-wire wire is 21A (operating temperature of the conductor 65-70 degrees) and do not forget about the installation of this wire (air, groove, etc. .d.) now let’s consider an average circuit breaker with VTX “C”.its conditional non-trip current according to the thermal release is 16*1.13=18.08A (i.e. it should not turn off within an hour) there is also a conditional trip current and it is equal to 16*1.45=23.2A and with such At currents, the circuit breaker must break the network in at least an hour.

2) Now let’s get to the bottom of our copper))) at 100% working we get 65-70 degrees, but there are 3 more modes of its operation:

- overload mode in which the conductor heats up to 90 degrees (not critical at all, if everything is in order with the machine, then it will not reach this temperature)

- limit mode - 160 degrees (if the machine is “kakaha” and does not want to turn off at the set time due to overload, namely the electromagnetic release) yes, there are 2 releases in the machine!

- non-ignition condition - 350 degrees (this can happen if the shield is assembled from shit and sticks and there is no hope of salvation)

Let's look at my example: a 5.5 kW instantaneous water heater through a 3x2.5 conductor was connected to a 20A circuit breaker, 16 minutes passed from the start of the flow heater to the shutdown of the machine. we check the numbers (conductor 5.5 kW * 4.4 A = 24.2 A, automatic 20 * 1.13 = 22.6) and the conductor has become warm (tactile sensations, did not measure)

conclusion: the machine saw an excess of the non-disconnection current and worked within the time set for it.

p.s. 8KW is 35.2A)))

On the one hand, of course, for safety and reliability, you can lay the entire house in a star pattern, but is this advisable? My wiring is simple - parallel connection of each room to a separate circuit breaker, and a cable inside the room. With the exception of very powerful devices, there is a separate output for them. And there haven't been any problems yet.

No one, Maxim, is calling for powering every socket and light bulb from the apartment panel - re-read the article.

By the way, directive documents (PUE, SP) recommend separating groups of room loads, lighting and powering washing machines and electric stoves with separate lines. A screenshot of the corresponding paragraph of SP 31-110-2003 is attached.

In the figure explaining the wiring in the apartment, the ratings of automatic switches in the lighting network and sockets for household appliances with normal electricity consumption (refrigerator, portable kitchen appliances, hood, etc.) are clearly overestimated.

The power of a chandelier with 5-7 LED lamps does not exceed 50 W. Consequently, the current consumption will not exceed 0.3A even taking into account losses in control devices (the so-called electronic transformer). It is quite acceptable to install a 6A circuit breaker. And for room sockets - 10A. For kitchens - 16A. In this case, selectivity will be achieved with respect to the input circuit breaker (usually its current according to the terms of Energy Accounting is 16 - 25A).

It depends on your luck. Since diode lamps contain switching power supplies, albeit not of high power, when they are turned on, the inrush currents can be large. Sometimes the C10 machine gun can also knock out. If everything works without false positives on B6, then yes, this is preferable.

And at my dacha, “star”, I got five sockets (parallel) for one machine 🙂 They work normally, but in one socket of the machine it’s a bit difficult to fix five stranded wires with a cross-section of 2.5 🙂 I’ll probably install another one for 16A. I don’t see any point in installing any other box for connecting the wires.

Good afternoon, Vitaly. What you have “made up”, of course, is not provided for by any PUE. I decided to give you a similar, but less crazy and civilized option for connecting multiple outlets using a “wire splitter”.

Have you heard about DIN rails, N/PE busbars (this is one of the elements of the grounding/grounding network)? I attached a photo with the tires so as not to have to explain for a long time.

You can supply a power wire to such a bus “from above” from the input machine, and from “bottom” you can output the wires to your sockets. No hassle with fixing five wires in the terminals of the machine. The selectivity is no more than that of your circuit, but it will add aesthetics to the shield. Just count the wire cross-section.

I would like to see how you pushed 5 nshvi into 1 machine gun. If you haven’t finished, then I have bad news for you))))

Sorry, but can you tell me what could have happened?.. Two sockets are connected in parallel, the TV is turned on in one, we use the other as needed (iron, extra lamp).

Now we are connecting the Christmas tree garland, after repeatedly turning off the lights in the house (an ordinary apartment building), when the garland was turned on, the TV began to turn off (for a few seconds), then turned on again. Thank you in advance.

Show me a person who can plug in a computer, TV and vacuum cleaner into one socket (or block of parallel sockets)?

Well... I have a kettle, PC and TV hanging on the same extension cord. Consumption does not exceed 3 kW. Now, if you connect two kettles or a kettle and a vacuum cleaner... Then it would be bad. And so, this is most likely due to the fact that there are not many sockets in the room, which are already all on one machine.I hope to soon convert it to external wiring, with a separate socket and machine for the kettle and separately for the PC.

What method of connecting sockets is better to use if the socket group consists of 5 points for power equipment with a cable or a star?

What method of connecting sockets is better to use if the socket group will consist of 5 points for power equipment to be connected with a cable or a star?

We kindly ask everyone who wants to write to order for websites - choose a topic that is feasible for you. The author of this article, for example, would do well to write an article on the topic: “removing urinary stones and other serious contaminants from individual plumbing installation products”

The network suffers most from the load in rooms, where a heater (air conditioner), an iron and a hairdryer with a total power of 6-7 kW can be turned on simultaneously on one line. Therefore, in each room it is advisable to connect at least 2 lines and sockets in parallel, except for block ones for TV, Internet and other low-power consumers. No more than 2 sockets per line for consumers 2-2.5 kW and 1 socket for consumers over 2.5 kW.