Cable channel for electrical wiring: types of structures and their classification

The main purpose of cable channels is to protect wiring from mechanical damage and protect against fire in the event of a malfunction in the electrical network.At first glance, determining the required type of cable support systems should not cause difficulties. But when choosing, you can get confused from the widest range. Do you agree?

We will tell you how to correctly select a cable channel for electrical wiring, taking into account the complexity of the wiring diagram and operating conditions. The article we presented describes in detail the most popular varieties and provides their technical characteristics. Using our tips, you can't go wrong in finding the best option.

The content of the article:

How to choose a cable channel for wiring installation?

Even an insignificant, at first glance, characteristic of the electrical box can be a key factor in choosing the required option.

So, what properties can be considered when purchasing a product:

- Material. Pay attention to safety, durability, level of protection in case of possible fire.

- Construction type. Cable channels for electrical wiring can be produced in the form of smooth or corrugated pipes, tracks, trays, etc.

- Specifics of application. The characteristics of systems used for industrial premises, private homes or equipment may differ significantly.

For example, to the fire safety of the cable box used for installation electrical wiring in wooden houses, more stringent requirements are imposed, and static structures are not suitable for wiring used in moving mechanisms.

In addition, pay attention to color. This factor is relevant in the case of open wiring, in which the elements of the cable channel are visible and must meet aesthetic requirements.

Materials for cable support systems

All materials used in the manufacture of electrical boxes meet the basic requirements for safety, strength and aesthetics. But differences still exist, and they have different effects on the quality and operational properties of cable channels and their cost.

Plastic electrical boxes

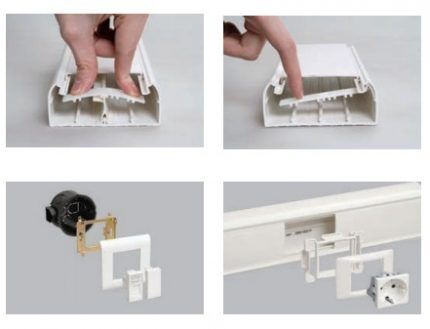

Plastic products are designed for laying open-type electrical lines, both low-current and power. Can be used for installation of electrical wiring in residential, office, industrial buildings, and administrative institutions.

They are made from PVC-based compositions with special additives that provide the products with plasticity and resistance to various negative factors - the effects of aggressive chemicals and ultraviolet radiation.

PVC products can be used in the temperature range from -32 °C to +90 °C and installed in temperatures from -15 °C to +60 °C.

Electrical boxes made of plastic are not subject to corrosion, are easy to install and have a simple fastening system. They are in a low price category, which is why they have earned the greatest popularity. The shape can be rectangular (most common), triangular, flat, or with a circular cross-section.

The material from which the cable channel is made is self-extinguishing.In the event of a short circuit, using an electrical box can reduce the likelihood of fire to a minimum.

Aluminum and galvanized steel products

Aluminum cable support systems provide protection against electromagnetic interference. Used for open wiring in premises for various purposes - in medical institutions, industrial enterprises, offices.

They are made from anodized aluminum. The material helps ensure stable operation of telecommunications systems - it prevents interference, protecting against electromagnetic influence.

In addition, it is resistant to ultraviolet radiation and high temperatures. Accessories for aluminum boxes are made of painted ABS plastic or polycarbonate.

Aluminum products have a strength of up to 20 J and a long service life. This is a particularly important quality for floor and industrial electrical boxes.

Electrical wiring with lines laid in aluminum cable ducts is carried out in the following order:

To ensure that no problems arise during the construction of the cable channel for wiring, all parts should be purchased with the same logo. Products from different manufacturers may have millimeter deviations. However, because of them, the assembled system may look sloppy and will not provide sufficient protection from external influences.

Types of cable channels: classification

Various types of cable channels intended for laying electrical wiring are usually classified based on their design features. They, in turn, depend on the location and operating conditions.

Main electrical channels

To protect the electrical network during the construction and reconstruction of buildings for various purposes, main cable channels are used. They are distinguished by a wide range of standard sizes and can be used as electrical installation lines.

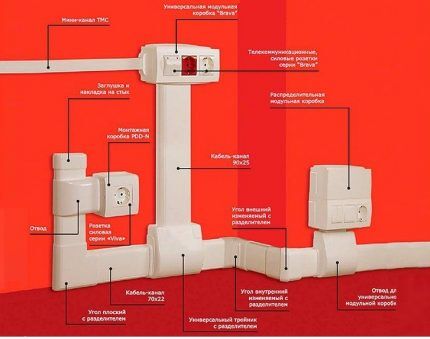

In the latter case, they are complemented by a wide range overhead electrical installation products different manufacturers. Standard sizes allow you to carry out projects of any complexity.

The system includes 2-meter-long boxes and various accessories that are used for connecting channels on straight planes, at external and internal corners, and for T-shaped connections.

Cable channel systems that are planned to be used as electrical installations are supplemented distribution boxes, support frames for installing sockets, switches, etc.

Skirting and floor cable channels

Floor cable ducts are used in rooms with a large area, as well as where wiring runs under the floor. They help in organizing a functional workplace.

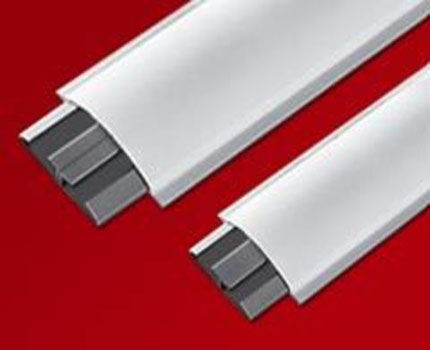

Floor structures have a streamlined shape and are characterized by high compressive strength. To connect electrical installation products, columns and tower modules are used, which can be expanded and installed one on top of the other.

Floor structures are subject to special strength requirements. The manufacturer achieves increased resistance to mechanical loads by using more durable materials, such as aluminum.

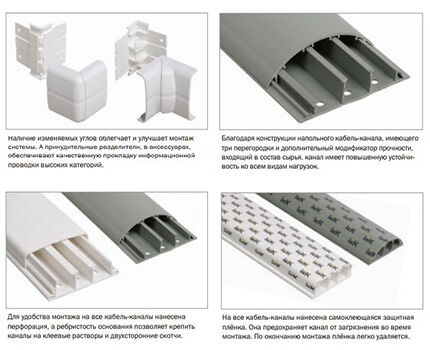

The design of plastic products is strengthened with the help of partitions, which simultaneously serve as forced separators for different types of wiring.

Skirting channels are used as baseboards and are installed around the entire perimeter of the room. To branch a floor or wall channel from a baseboard channel, special adapters are used, which can simultaneously serve as a distribution box.

Accessories and additional functions

For ease of installation and improved appearance, manufacturers are constantly working to improve cable channels. Sockets and switches can be installed above boxes or in the box itself.

Multimodular boxes and support frames allow you to install several electrical installation products side by side. Built-in separators in boxes and accessories prevent cable bending at turns and allow you to create two independent channels - for power and telecommunication wiring.

Some models of electrical boxes have a double lock, with which the lid is more tightly connected to the box. This allows installation on the ceiling, as well as laying the cable more tightly inside the channel, and placing a corrugated pipe next to it.

A box with a tight lid uses up to 100% of the usable space, while systems with a single lock can be filled to no more than 70%.Variable external and internal corner connectors make it possible to change the degree of angle; they are available for all standard sizes of boxes.

To hide the gap between the box and the wall and prevent dust from accumulating in the channel itself, a soft seal is used, which the manufacturer attaches to the base of the box and accessories.

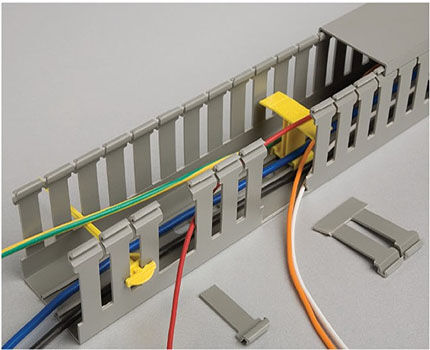

Plastic perforated box

The purpose of the perforated box is installation in electrical distribution cabinets. It is well ventilated, lightweight, and allows for neat and aesthetic wiring. Inexpensive design is often used where the appearance of the product does not matter.

The channels have teeth that can be removed at the desired location if necessary, for example, when inserting a wire into a branch, socket or switch. The perforation pitch is designed to coincide with the pitch of the contact clamps of the modular equipment.

Flexible cable support systems

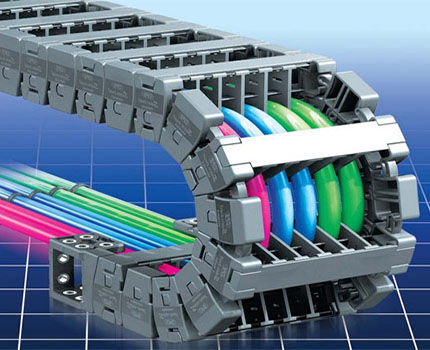

Flexible cable channels can be produced in the form of chains - multi-sectional structures that bend in one plane along the entire length. The individual elements of the track are connected to each other by a hinged coupling. They are made of aluminum, plastic, nylon, steel and can differ in height, length and pitch.

Tracks are used to prevent mechanical damage to power and signal cables and their entry into moving parts of mechanisms. They also protect from dust and dirt, and serve to lay wiring and cables to the required distance.

Cable tracks can be open or closed. Closed cable channels for electrical wiring are used if it is necessary to provide high-quality protection against dust and foreign objects entering the channel. Open energy chains are installed in cases where it is necessary to give preference to lightness and simplicity of installation.

One of the flexible systems is also a cable channel with a three-dimensional circular rotation function. Such channels are used to create robots and robotic mechanisms. Their design consists of individual elements, each of which, if the need arises, can be added or removed.

Pipes for laying wiring

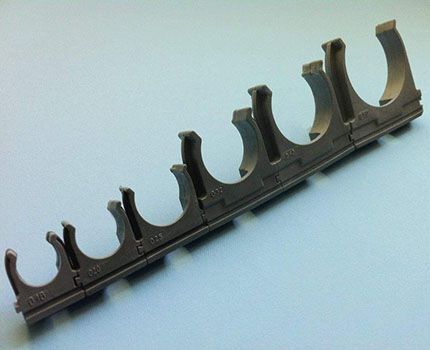

For laying electrical wires, both ordinary PVC pipes and products created specifically for electrical networks are used. When choosing a rigid or flexible pipe, they take into account where the cable will be laid, its operating conditions, the need for protection from ultraviolet rays, and aesthetic preferences.

Smooth PVC pipes

PVC pipes are used for installation of open wiring indoors or outdoors. They protect wiring from damage, contact with moisture, and are used to increase fire safety. With the help of pipes used as cable channels for electrical wiring, the most difficult installation tasks are solved.

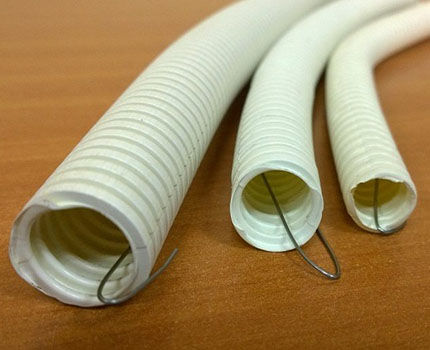

Corrugated and reinforced pipes

Like other cable support systems, electrical corrugated pipes designed to protect against fire, moisture and dust, and mechanical damage to wiring.

Due to their flexibility, they are easy to install and do not require the use of additional accessories. Used for laying hidden wiring for power and low-current lines.

PVC-reinforced pipe is used for laying power lines and information cables of hidden and open types. Can be used in the construction of communications inside the building and outside. Compared to conventional corrugated pipe, reinforced pipe is stronger and provides better protection from dust and moisture.

It is made of a reinforcing spiral made of impact-resistant PVC, and a connecting plastic PVC covering the spiral. Since reinforced pipe can withstand dynamic loads, it is often used in mechanical engineering.

For quick and convenient connection of a rigid smooth pipe and a flexible reinforced PVC pipe, various couplings are available. They can be used for straight-line connection, connection in different planes and at different angles. Thanks to couplings, you can easily connect one pipe to another, to a box, or connect pipes of different diameters.

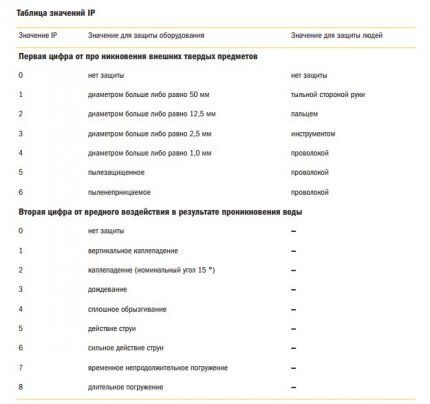

The conditions for using different types of accessories may differ: some are used indoors, protected from moisture, others can be installed outdoors, in damp and dusty areas, and have protection against moisture penetration during temporary immersion in water or strong exposure to a jet of water.

The process of installing electrical wiring in a corrugated pipe, produced specifically to protect power lines, is carried out as follows:

Having completed pulling the electrical cable through the corrugated pipe, we proceed to install the wiring:

Metal sleeve for cable protection

The metal leak-proof hose is made from galvanized steel tape. Used to protect wiring from kinks and mechanical damage, and protects against fire. Serves as a screen against electromagnetic interference.

A metal hose is recommended for laying electrical wiring on flammable surfaces, including wood. The maximum operating temperature at which the cable duct can be used is +100 °C.

Hanging trays for cable systems

Metal cable trays can be used for open laying of routes along building elements - ceiling, walls, floor. Their installation facilitates access to the electrical network during its maintenance and modernization.

They are used inside retail, office, industrial premises, residential buildings and outdoors. There are also tray-shaped systems made of plastic.

Rolled metal trays

For installation and protection of wiring, perforated and non-perforated trays are produced. Systems with holes promote better ventilation and prevent wires from overheating.

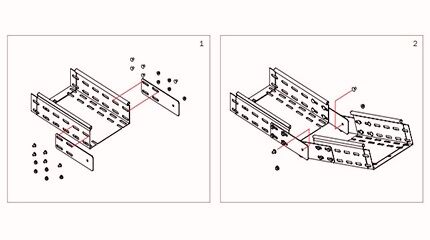

If desired, the trays are equipped with covers that are fixed with a simple press and do not require additional latches. The lid lock securely holds the tray even when mounted vertically. The trays are connected to each other using the provided female-male connectors or a connecting plate.

Wire trays for industrial power lines

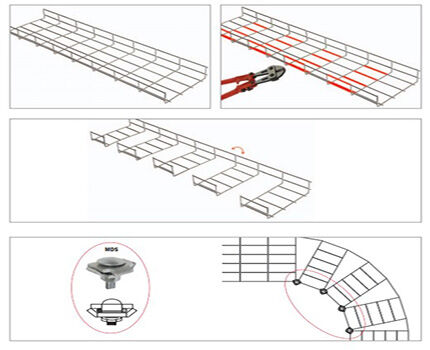

The production material, installation and principle of use of wire trays are slightly different from metal tray systems. The main difference between them is that wire structures are folded with a minimum number of accessories and contribute to greater ventilation of the cable route.

To install the trays, use a special connecting kit. It allows you to more reliably fasten the elements of the cable support system to each other. Wire suspension systems may include a cover that securely holds the wiring inside the cable channel even if the route is vertical.

The wires are laid in a box and secured clamps. Wire tray designs can be quite spacious. This characteristic is especially relevant when installing electrical networks in industrial buildings and warehouses.

Conclusions and useful video on the topic

Video #1. What types of cable channels are there:

Video #2. Installation of a plinth cable channel for electrical wiring:

Video #3. Using corrugated pipe to protect wiring:

In the case of open wiring, in which a potential ignition source remains unlocalized, the main criterion for choosing among the many types of cable channels for electrical wiring should be safety.

That is why it is necessary to carefully study the technical characteristics and operating conditions of the products. It's even better to consult a professional electrician.

Please write comments in the block below. Tell us about how you laid the wiring yourself using cable channels. Perhaps you have valuable information that is worth sharing with site visitors?

The materials from which the cable channels are made are durable and non-flammable, regardless of which option is used, be it plastic or metal. The choice is simply huge. The main thing is to decide what you need. Modern decorative cable channels will allow you to conduct external electrical wiring throughout the apartment, which will fit into any interior picture. If you want to lay a cable outdoors, you have at your disposal durable, sealed boxes and corrugations for any placement: be it underground or underwater.

I agree with the previous opinion, but I’ll just make some small amendments.Cable channels of various systems are designed for a certain power of current-carrying wires and this must be taken into account during its installation and in no way should wires with high or normal mains voltage be laid in the route intended for laying low-voltage wires and antenna cables.

Good afternoon, Artyom.

You will also have to correct your comment - structurally, cable channels limit the cross-section of the wires used. In other words, a cable, for example, with a cross-section of 3x240, cannot be installed in apartment cable channels, which are discussed in the article.

Regarding the high, low, and other voltages you mentioned, the Electrical Installation Rules do not use these categories. All electric power industry, electricians focus on the following ranges: electrical installations up to 1000 V; electrical installations over 1000 V.

Regarding laying wires of different voltages in cable channels, look at the PUE section “2.1 Electrical Wiring” (to make the search easier, I attached a screenshot).

Please note that energy workers are guided by their own Rules, while signalmen, Internet users and others are guided by their own. No one confuses their own wiring with “other people’s”.

I'm quite happy with standard plastic cable ducts. I have highways everywhere. Now there is quite a wide choice, you can take a simple white one, or you can try to match the color of the walls so that it is minimally noticeable. In cases where it is possible, I try to do without them altogether, if I can hide the cable behind furniture or under a window sill.