Do-it-yourself electrical wiring: how to do electrical work correctly

You have to deal with replacing a switch or connecting an outlet quite often in everyday life, so everyone should have at least minimal skills in servicing the home electrical system.

We will try to figure out how to install electrical wiring with our own hands, focusing on the PUE standards and observing safety precautions. Also in this article we will look at the features of drawing up a project, the rules for introducing electricity into the house and the subtleties of reliable connection of wires.

The content of the article:

- What is required for home wiring?

- Recommendations for drawing up a wiring diagram

- Is power consumption important?

- Rules for introducing electricity into the house

- Rules for connecting wires

- Electrical wiring installation instructions

- Safety precautions when installing electrical wiring

- Conclusions and useful video on the topic

What is required for home wiring?

First of all, you should understand the structure of the electrical network. It consists of electrical points connected to each other and to the power line by various kinds of cables and wires, protective devices and circuit breakers, and a grounding loop.

Do not confuse wires and cables. The first are conductors for internal wiring, which can be single- or multi-core, the second are made up of several wires united by a common protective sheath.

Cables can be installed in the ground, under water, in concrete structures; They are also used to install a home electrical network if connecting powerful devices or special protection is required.

Wire strands are made of metals that conduct electricity well: copper and aluminum.

Copper is considered a more valuable material for a number of reasons:

- has a high current density;

- is characterized by wear resistance and fracture toughness;

- has less resistance to oxidation;

- does not compress like aluminum, so does not form gaps in joints.

For internal fixed wiring, it is recommended to use single-core copper wires, which are stronger and more reliable than multi-core analogues.

Types of cables and wires for electrical installation work:

- VVG (from 1.5 mm² to 10 mm²) and its analogue NYM – both are multifunctional;

- PVS – for connecting lamps;

- PV1 – for electrical panels;

- PV3(6 mm²) – for mounting the SUP.

Varieties of VVG may also be useful: VVG-P (flat), VVGng(A), VVGng(A)-LS and etc.

In addition to selecting wires or cables, it is important to understand grounding systems that ensure the safe use of electrical appliances. In a private house, installation of a grounding loop is required; in city apartments, the bathtub and household appliances are usually grounded.

There are several strict rules: for example, you cannot connect grounding wires to metal communications or carry out independent work in the electrical panel.

It is best to entrust the installation of RCDs and circuit breakers, as well as any installation work in the electrical panel, to qualified electricians with permits. They will be able to correctly determine the load and select a circuit breaker.

Recommendations for drawing up a wiring diagram

Drawing up a project for intra-apartment or intra-house wiring is a responsible and complex matter that requires qualifications. There are many principles and standards for installing wires, switches and sockets.

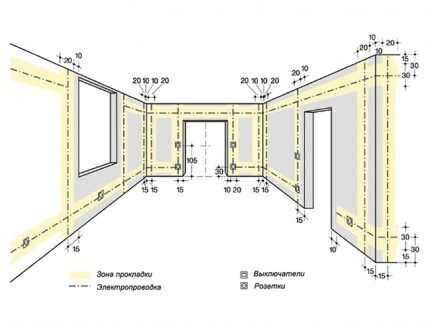

Here are just a few of them:

- It is better to divide the wiring into groups - sockets, lighting, etc., allocating separate lines for powerful electrical equipment;

- in the drawing it is necessary to indicate power points and installation locations of powerful energy consumers (oven, air conditioner, washing machine);

- location of sockets - from 0.3 m to 1 m from the floor;

- the optimal installation height for switches is 0.8-1 m from the floor;

- It’s better to have more sockets - no extension cords are required;

- a separate project - for a low-current system (to protect against interference, the wires are pulled separately from the power lines, with a distance of at least 0.5 m);

- bathroom switches lead to the corridor, etc.

It is very important to correctly lay the wiring itself - internal or external (open/closed type). We recommend that you read electrical wiring design rules in a private house.

The wiring diagram must be kept; it will definitely come in handy during repair work.

If you have doubts about your own experience or skills, it is better to contact specialists - qualified electricians. They are familiar with many small but important nuances that a simple layman cannot take into account due to his inexperience.

An experienced designer will competently draw up a wiring diagram, take into account the standards and requirements of the PUE, make calculations, select equipment of the appropriate rating and, in the end, take full responsibility. When designing and installing independently, the homeowner will have to be responsible for mistakes.

Is power consumption important?

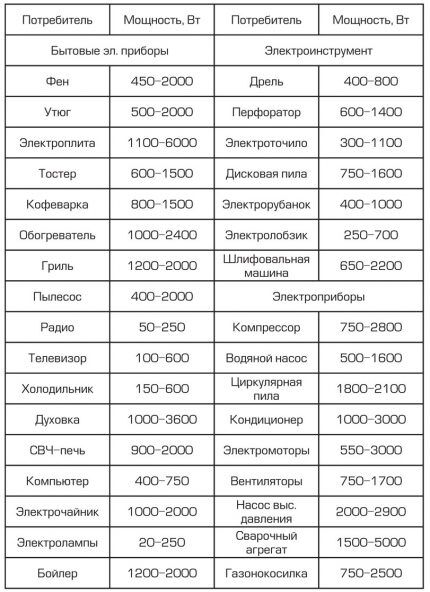

In addition to design, it is necessary to take into account such a point as power consumption in the house.

In a multi-storey apartment building, they are usually standardized, but in a separate cottage, before approving the documents, you will need to know exactly what allocated power to request from the electricity supplier.

It is a mistake to assume that the total power consumption is the sum of the individual powers.The simultaneous inclusion of all devices in the network actually does not occur, therefore, in calculations it is necessary to use such a value as the simultaneity coefficient.

For sockets, it is a maximum of 0.2, that is, no more than 20% of power points are usually used at the same time.

Rules for introducing electricity into the house

For private households, such an issue as introducing electricity into the house is important. Usually it is carried out using a self-supporting SIP wire.

If the power line support is located less than 25 m from the house, additional poles for support will not be required.

Input requirements:

- when the wire length is more than 25 m, additional supports are required (you can install a shield on the pole closest to the house, and bury the ground loop in the ground nearby);

- the height of the wire stretched between the supports is at least 2 m above the ground;

- if the wire crosses building structures, it is mounted in a protective pipe;

- the minimum distance from the ground for the building connection point is 2.75 m;

- if the wire from the control panel to the house is planned to be laid underground, then it must be placed in a protective sheath and then in a ditch at least 0.7 m deep.

It is clear that when choosing an underground installation, the entry directly into the building must be provided during the construction process.

Rules for connecting wires

A practical point is connecting the wires. It is carried out either through distribution/installation boxes or directly, using terminals or twisting.

Hiding junction boxes under plaster or wallpaper is risky - for repairs you will have to remove the lining. In this regard, some electricians implement another method of connecting wires - with mounting boxes for sockets and switches.

The advantage of this method is free access to the connection points, the disadvantage is the increased cable consumption.

Heat shrinkage is used to connect wires in the socket line; for installation of a lighting network - Wago terminals with a spring mechanism.

In addition, many people use terminal blocks, crimping and traditional soldering.

Let's consider the procedure for crimping with sleeves:

This is one of the simplest and most effective ways to install wires yourself, which requires pressing pliers, sized sleeves, a torch and heat-shrinkable material.

We have a detailed analysis of how to connect wires reviewed here.

Electrical wiring installation instructions

Let's consider one of the options in which you can do most of the electrical work yourself. For the most complex issues, you will have to contact specialists, but you can drill channels for wiring or connect sockets with switches yourself.

Stage #1 - marking electrical wiring

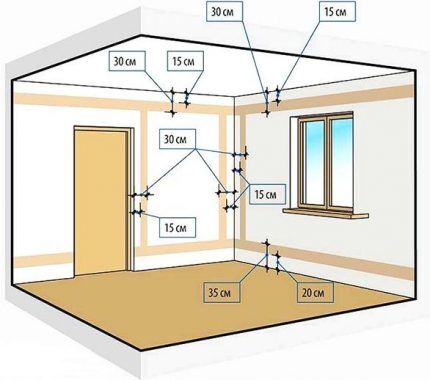

The project has already been drawn up, now using a stepladder, a level (laser or bubble), a construction tape measure, a marker, we make markings - we draw horizontal and vertical lines directly on the plaster/concrete slab where the electric mains will be laid.

You need to start by knocking out a horizontal level, which is called the “finished floor level” - that is, the floor with the finishing floor covering. It is from this that the distance to sockets and switches is measured.

The power line is laid approximately 0.3 m from the ceiling; a low-current line can be located half a meter lower. It is not recommended to plan installation near jambs.

We make sure to mark the installation locations of powerful electrical appliances (preferably with the main characteristics), the width of the grooves, and equip passage points through building structures.

By the end of the marking actions, the walls, floors and ceilings in the rooms should turn into original drawings with bright and clear markings.

Stage #2 - wall slitting

Half the success of smooth gating is the correctly selected tool:

- wall chaser equipped with a vacuum cleaner;

- hammer drill (it is desirable that the impact energy is at least 15 J), drills, crowns, drills from the same manufacturer;

- grinder, discs for concrete;

- chisel;

- hammer.

Hand tools are useful in hard-to-reach areas and where pinpoint precision is needed.

Next, following the markings, we perform gating:

Without removing the tool too far, we check whether the grooves correspond to the thickness of the cable, and the cut-out socket boxes correspond to the dimensions of the mounting devices.

If everything is in order, we clean out all the recesses and niches with brushes and brushes, remove debris, wipe off dust and prime the working surface with a deep penetration compound.

Stage #3 - installation work

To install electrical wiring you will need a little more tools: stripper, pliers, wire cutters, a special knife for cutting cables, screwdrivers with dielectric handles, press pliers for enclosing wires, an indicator screwdriver, a soldering hair dryer, a tester, a screwdriver, a spatula and a container for plaster.

Then, one by one, starting from those closest to the shield, we lay the lines. When calculating the length of the wires, do not forget to take into account the 0.2 m outlets from the mounting and distribution boxes.

We place some of the wires in protective corrugated pipes, if specified in the project.We try not to twist the wires so as not to provoke internal tension.

Subsequently, they are fixed with alabaster mortar (gypsum), but not along the entire length, but pointwise. The interval of mounting fasteners is 0.5 m, but at turns and corners - 0.1 m from the bend.

To lay the cable along the ceiling, a corrugated pipe must be used, and it is attached to special clips (taking into account the subsequent installation of the suspended structure).

Stage #4 - installation of mounting boxes

The basic principles can be understood by the example of installing a single mounting box, which is performed in the following sequence:

- remove the connecting “ears” with a knife;

- We check the size correspondence;

- insert the corrugation with the wire into the designated hole on the box (cut along the perforation);

- cut off the excess corrugation, leaving a small end (1 cm);

- fix the box onto plaster: moisten the recess with water, quickly apply plaster, insert the box and hold it for a while with a straight, level object (for example, a level);

- Remove any plaster that has gotten inside the box with a damp finger.

When installing from 2 to 5 mounting boxes, a rigid frame, such as an aluminum corner, is used for strength and uniform distribution.

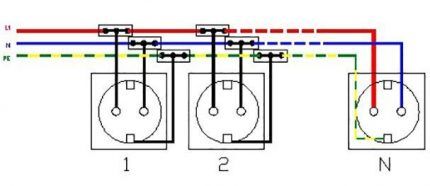

Stage #5 - connecting sockets

After installing the wires and boxes, we connect the sockets one by one. Work with switches is carried out during the installation of the lighting system.

An example of connecting a single socket without grounding:

What to do if there are 2 or more sockets? We make the connection strictly according to the following scheme:

It is recommended to exclude a daisy chain connection - from one outlet to another - due to its irrationality.

We have detailed instructions for connecting sockets in various ways. They are discussed in the following articles:

- Serial and parallel connection of sockets: loop and star

- How to connect a double socket: installing a double socket in one socket box

- Socket with a switch in one housing: how to connect a socket with a switch

Stage #6 - installation of the lighting system

Wires for the lighting system are installed before or during the installation of suspended ceilings.

You need to do the following:

- connect one-, two-, three-key switches to the power line (depending on the purpose and functions);

- if necessary, install pass-through switches;

- install lamps (spotlights, sconces, chandeliers, etc.) and connect them to switches.

To install the switch, we recommend using the circuit diagram, which is often located on the back wall, and using generally accepted wire color codes.

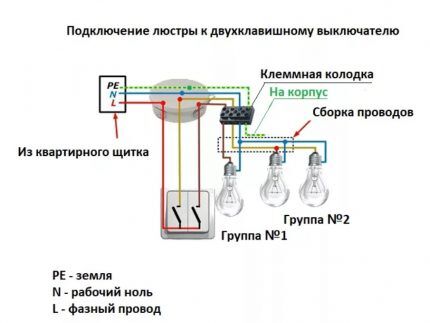

The fundamental difference between a two-key switch is that it has 3 contacts for connection, of which one is common, and the other two are separate. That is, when connecting, a two-wire wire will not work, only a three-wire one. In this case, a phase is connected to the common contact.

Stage #7 - electrical panel installation

To assemble an electrical panel, it is better to hire a specialist, because this is a complex job that requires experience and knowledge. The metal housing of the switchboard contains circuit breakers and RCDs, the rated powers of which can only be calculated by a professional electrician.

Not only the proper functioning of the entire electrical system, but also the safety of the apartment’s residents depends on proper assembly. Detailed instructions for assembling the electrical panel are reviewed In this article.

It is strictly prohibited to carry out electrical installation work, including preventive work, in apartment buildings with common switchboards; this is carried out by specialists from the management company. They also control the operation of metering devices.

Safety precautions when installing electrical wiring

To protect yourself and those who may happen to be nearby, the following rules must be observed during electrical installation work:

- Use only serviceable equipment – power tools, carriers, extension cords.

- Before starting work, be sure to turn off the power supply using automatic devices and RCDs. To avoid accidentally turning on the voltage on the site, you can hang a sign or warn your neighbors.

- For insurance, use testers and indicator screwdrivers.

- Make sure that the insulation on the tool handles is in order.

- Try not to work alone - you may always need help with work or medical assistance.

Separate rules apply to working with a hammer drill, wall chaser or powerful drill. In addition to protective clothing, gloves (with an insulated palm) and a mask (respirator) are required. Shoes should fit snugly and not slip.

Laying electrical wiring under the ceiling must be done only from a platform: chairs or tables are absolutely not suitable.

Every professional electrician is familiar with the rules of first aid in case of electric shock, but ordinary people, unfortunately, do not always act competently.

Ideally, in any room where electrical work is being done, you should have a fire extinguisher on hand. Dousing sparking or flaming wires with water is strictly prohibited.

Conclusions and useful video on the topic

You can learn how to properly work with tools, wires and various electrical devices, as well as plan work, by watching a useful video.

Wall chipping and ceiling installation:

Interesting theory about electrical wiring and protection:

Installation of socket block:

Electrical installation work is considered complete when the wires are connected and masked, the junction boxes are covered with covers, and the electrical panel is fully equipped. You can replace a socket or install a chandelier at any time - installation of lighting fixtures and decorative elements is most often carried out after finishing work.

But when performing any manipulations with electrical equipment, remember the most important thing - the safety of human life..

Do you have significant experience in electrical installation work and have you independently designed and installed electrical wiring in your home? If you notice errors or inaccuracies in the instructions we provided, please point them out to us by leaving a comment in the block below this article.

Or are you just learning the installation rules and want to clarify some nuances? Ask your questions - we will try to help you.

The first picture shows an incorrect connection of wires - aluminum is connected to copper by twisting. Properly, copper and aluminum are connected using either clamp connectors or a threaded clamp. Otherwise, these two metals will begin to react and oxidize and over time the contact will become floating.And with powerful consumers (a household welder) it will start to spark, and as a result, the contact will soon burn out.

Didn't you read the description under the picture? It says that you can't connect like that...

I also always connect copper and aluminum wires only through terminals to avoid unnecessary situations. A good table of power consumption of electrical appliances, I saved it for myself, I didn’t think that a vacuum cleaner consumes so much energy. Is it possible to somehow determine when installing a chandelier where the cable runs in the ceiling, so as not to get caught in it when installing the mount?

Good afternoon, Dmitry.

To answer the question, I assume that the house is brick. In these houses, floor slabs are used, where the distance between the lower plane of the slab to the cylindrical voids through which wires are laid to lamps and chandeliers is 30 millimeters (I have attached a screenshot of the cross section of the slab). This parameter helps you decide whether you need to drill through. If not, then you won’t have to buy the device.

Otherwise, purchase ADA Wall Scanner 50. The last number is the depth limit at which live wiring is detected. By the way, he also finds reinforcement. Has light and sound indication.

And one more thing - the antenna of a transistor receiver, moving in the intended area of laying the wire, also “feels” the voltage - the receiver emits a characteristic noise.

Hello.I agree with Vasily, but it’s not necessary to buy a detector for one chandelier; you just need to call any electrician (unofficially it’s many times cheaper, they don’t charge for a call) and ask him to test the wiring with his equipment.

Maybe I missed it. The question is: is it possible, if there is a 4 mm sq. wire to the hob, to connect the oven through the block with a 6 mm sq. wire? 4+ 6 mm square - is this acceptable? I have differences with my master.