Wago terminal blocks: varieties and their characteristics + subtleties of connecting wires with Wago terminal blocks

Twisting conductors is considered an outdated connection method that does not meet new electrical safety requirements; soldering and welding are labor-intensive, and crimping requires a special tool.

The easiest way to connect wires is to use Wago terminal blocks - special devices that quickly and easily provide reliable contact, and, if necessary, fixation in the right place.

Let's take a look at the types of terminal blocks and how to install them.

The content of the article:

Application Features and Benefits of WAGO

The name “Vago” has long become a household name: almost all spring, self-clamping or lever connectors for wires are called that way.

In fact, this is the name of a brand that produces a wide range of various mounting products for switching single-core and multi-core wires.

Convenient devices can be useful at any stage of electrical installation work.

Therefore, even when drawing up the project and making calculations for the estimate, it is necessary to clarify the approximate number of connecting elements required for switching wires in electrical panels, junction boxes, and electrical installation devices.

Options for using terminals:

In fact, terminal blocks can be used wherever a fast and reliable connection is required. But you need to be careful and not install non-removable products where future separation is expected, and vice versa.

Many installers have long switched to optimizing their work - and indeed, they have received only advantages from this:

- installation of electrical wiring is faster;

- installation does not require additional tools or skills;

- terminal blocks are always available for free sale;

- there are many varieties for all types of electrical work, no need to look for substitutes;

- reliable, isolated, protected contact is ensured;

- safety standards are observed.

But there are also disadvantages. The main one is the high price of the products. If you need to replace the wiring in one junction box, the material losses are not noticeable, but when you need to change the wiring in the whole house, buying connectors can cost a pretty penny.

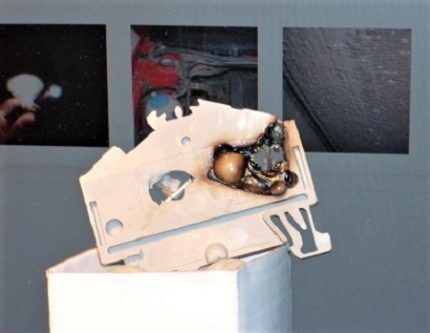

The second disadvantage is the possibility of fire or melting of products.It should be understood that original Vago brand products cannot ignite unless the installation requirements are violated.

The second cause of fires is the use of non-original products. Aliexpress sells countless inexpensive electrical products made in China. They only look like Vago terminals; in fact, they are a cheap fake.

It is clear that they are made of unreliable, fusible, fragile, and possibly dangerous materials.

Distinctive features of original Vago products:

- characteristic shade of flags (levers) or body;

- markings on the back;

- diagram and labels for wire stripping on the body;

- the contact strips inside the housing are thick;

- metal parts are not magnetic.

Accordingly, cheap analogues differ in shade and sometimes in characteristic odor. They do not have full markings and marks, and the internal strips are very thin and magnetic.

Review of popular types of terminal blocks

There are several classifications of Vago terminals. They can be grouped by size, purpose, method and place of application. But the most convenient division into categories is considered to be a combined classification, which takes into account both functionality and installation location.

Let's consider the main groups of terminal blocks used for the electrical network. We will not consider terminal blocks with a choke, a capacitor, as well as for transformers and printed circuit boards due to their rare use in domestic conditions.

Category #1 - for lighting equipment

The category includes several types of products designed for connecting spotlights, sconces, chandeliers and other lighting equipment.

Kinds:

- Series 294 and 294 Linect® are used for switching thin-core, single-core, multi-core wires without preliminary preparation. A special plate can be used to relieve tension. Maximum current – 24 A.

- Episode 272 for wires with a cross-section of 2.5 mm² is divided into insulated and compact terminals.

- Episode 293 differs in that it has a direct grounding contact and a snap-on mounting foot.

Category advantage: development Push-in CAGE CLAMP, thanks to which there is no need to put lugs on the wires or seal them before installation.

On one side there is a hole for connecting a third contact with a cross-section of 0.5-0.75 mm².

Category #2 - for electrical installation work

This is the largest and most popular group, since the universal devices presented in it can be useful at any stage of arranging an electrical network.

The basic principle of connecting conductors is the abandonment of screw contacts and the use of spring clamping mechanisms.

Kinds:

- Series 224 - a specially designed device for connecting a single-core conductor to a thin stranded one.

- Series 243 – for servicing low-voltage systems that use 1-core wires of small cross-section – 0.6-0.8 mm.

- Series 2273 – compact but powerful devices for saving space in distribution boxes.

- Series 273/773 – for 1-core conductors 2.5 mm² and 4 mm². Recognized as the best-selling in the world.

- Series 222 – universal devices for all types of conductors, withstanding even powerful currents.

- Episode 221 – an improved version of the 222 series with a transparent compact case.

Products of the 221 series are especially popular in Russia. Due to their reduced size, they are often used where space is limited, for example when many connections need to be squeezed into a small junction box.

Installing the terminals is easy due to the well-thought-out design: due to the recesses on the sides, the connectors do not slip out of your hands, and the lever does not require much effort to manipulate.

Inside the plastic case there are tinned rods protected from gases. Despite the apparent fragility, the terminals can withstand heavy loads. They are capable of transmitting current up to 32 A and 450 V at a maximum temperature of +105 ° C.

Universal terminals 222 series are no less popular due to their simple design and reasonable price. Their versatility is explained by the possibility of switching conductors with a cross section of 0.08-4 mm².

The advantage of the series is the ability to make a bridge connection between two conductors of different cross-sections and types, for example, single-core and thin multi-core.

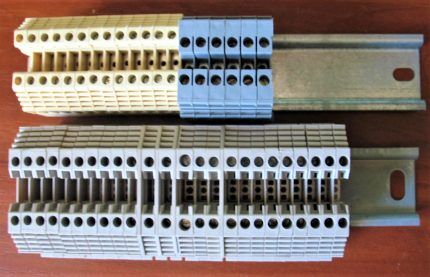

Category #3 - for installation on a base

Locking terminal blocks and modular blocks are not loose or hanging without support. They are installed on a plane - a mounting base.

Kinds:

- Series 862 – housing blocks are designed for connecting up to 4 conductors, allowing you to switch crimped, ultrasonic sealed and unprepared conductors.

- Series 260-262 serve for lateral, and 264 – for front mounting. These are modular terminals and blocks for installation on a DIN rail.

- Series 869 used for terminals up to 4 mm². They are fixed on the front side and equipped with support legs or mounting flanges.

What exactly to choose, terminals or blocks, depends on the amount of work, the number of conductors and electrical installation tasks.

Also, all pads have special holes - measurement points for testing after installation. The design is designed in such a way that it is easy to attach marking tape and indicate the purpose of each module.

Recommendations for Vago installation

There is no need to specifically learn how to use Vago terminal blocks; the installation process is quick and simple. It is much more important not to make a mistake in choosing and to ensure that the products comply with the parameters of the electrical circuits.

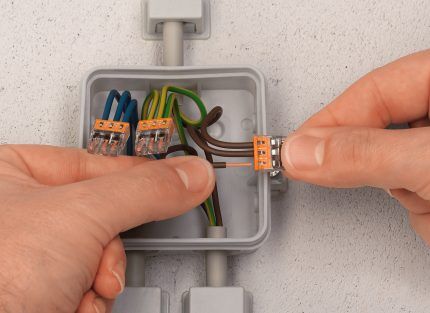

Let's look at the switching of wires using the example of transparent connecting terminals of the 773 series for 3 conductors:

- We strip the end of the wire by about 12 mm - remove the insulation.

- We insert the conductor into the socket and move it until it stops. Ideally, the end of the core without insulation should fit entirely into the housing.

- We check the reliability of the fastening by slightly pulling the wire in the opposite direction.

We also recommend reading our other material, where we told you how to choose a stripper for stripping wires. More details - go to link.

Transparent plastic makes it possible to verify whether the core is installed correctly.

There is a special hole for testing on the back of the Vaga for connecting electrical wires. Thanks to it, without opening the case, you can use an indicator screwdriver to determine the technical parameters of the circuit.

When installing removable terminals, the design of which is distinguished by the presence of a lever, it is necessary to perform a couple of additional actions:

- remove insulation;

- lift the “tongue” up;

- insert the conductor into the hole and push it all the way;

- return the lever to its place;

- visually or by slightly pulling, we check the reliability.

The 221 series terminals are the most convenient to install: the wide levers are easy to raise and lower with light finger pressure.

Usually, special marks are applied to the terminal block housings to help clean the conductors.

To ensure that the process of connecting wires goes quickly and smoothly, you need to remember a few simple rules:

Be sure to study the passport data of the terminal blocks; the range of conductor cross-sections, maximum voltage, and number of cores are always indicated there. It is also necessary to deal with labeling electrical wires by color.

Be sure to calculate the total load of all lines that the terminal connects. In order not to exceed the rated current of the product, it is advisable to select it with a small margin.

Conclusions and useful video on the topic

Installation of terminal blocks 2273:

Instructions for series 222:

Wago electrical installation products are known all over the world and do not require additional advertising.

Many electricians have already abandoned others ways to connect conductors and have long used only self-clamping terminals or lever blocks from a well-known manufacturer. This is easily explained: installing Vago is easier and faster, and communication efficiency is higher.

Have you ever used Vago terminal blocks? Please share your impressions of using them. Leave your comments in the block below. There you can ask questions about the topic of the article, and we will try to answer promptly.