Purpose of 40 mm polypropylene pipe - advantages and disadvantages

Polypropylene pipe 40 mm is used for arranging engineering communications for various purposes - from water supply to heating system, pipeline in boiler room. This became possible due to the increased strength of the product, ease of installation, and service life of up to 50 years. With its help, you can lay both a new pipeline and replace the old one (or sections thereof).

Features and Benefits

If compare with metal-plastic analogue, the polypropylene product has increased strength, which expands its scope of application. Installation is carried out welded method - using permanent fittings, which ensures the tightness of the joints and the system as a whole. There will be no need to additionally use sealants and materials impregnated with sealing compounds.

Polypropylene pipes 40 mm are used:

- in heating systems;

- for installation of boilers;

- in hot and cold water supply pipelines;

- for arranging a riser in a multi-storey building;

- in water distribution utilities;

- for connecting the pipeline and radiator;

- to connect with metal-plastic pipes.

Since the product has increased strength, it can be mounted in 2 ways - open and closed. It is important to consider that if you plan to lay a heating system or a pipeline for water supply, then ordinary polymer pipes will not be suitable. You need to choose products marked PP type 3 or PP TYP3.

Polypropylene pipes 40 mm are made of a polymer that does not release toxic substances into the environment that is supplied through them, therefore they are safe for humans. They can be used to install a water supply system to supply drinking water to the house.

Advantages:

- ease of installation;

- ease;

- increased strength;

- low price;

- do not harm human health;

- the smooth inner surface of the walls eliminates the possibility of deposits accumulating;

- products are not subject to deformation during use.

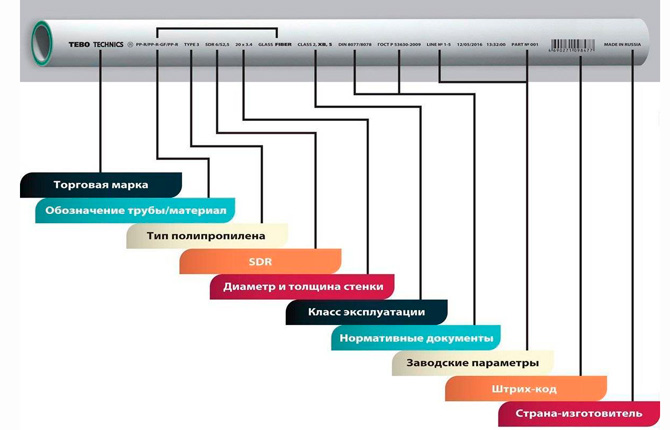

What does the marking mean?

A 40 mm polypropylene pipe for heating or plumbing is marked. Based on the numbers indicated on the wall, you can determine the type of product, the material from which it is made, important specifications.

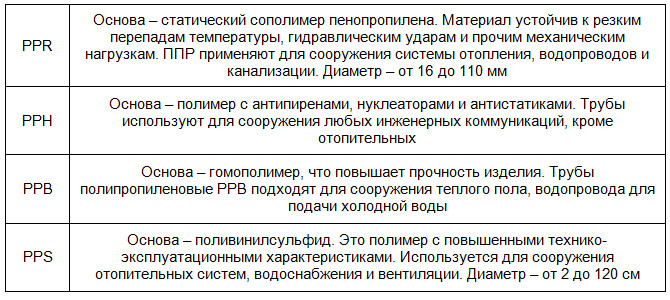

Types and brief description in the table.

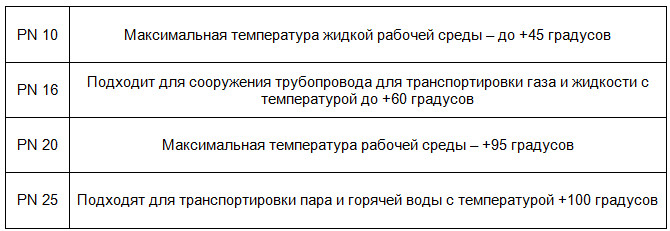

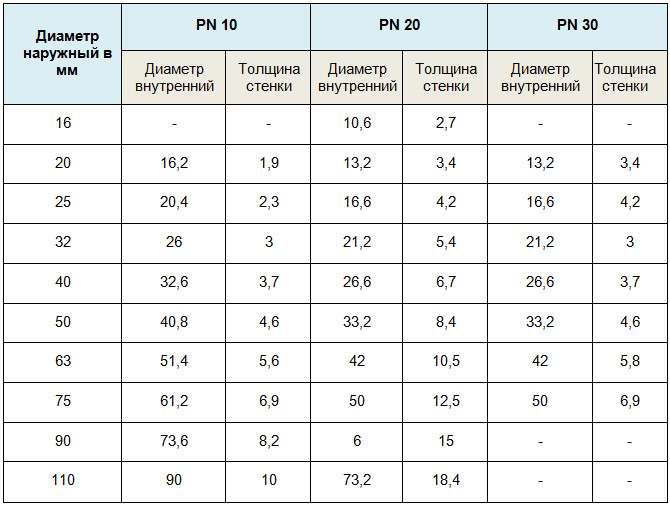

The marking also indicates the operating pressure. The classification is shown in the table.

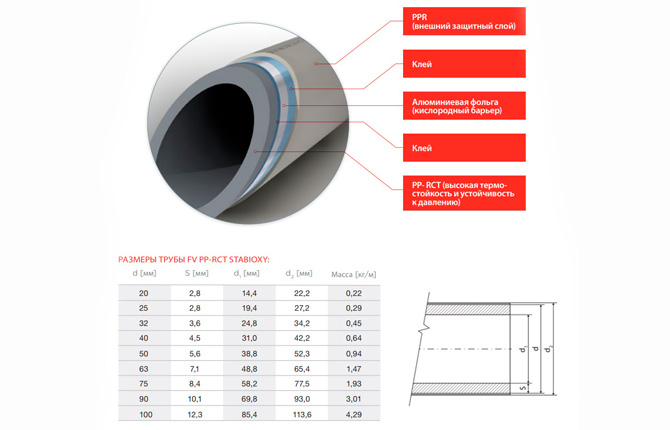

Pipes can be supplemented with a reinforcing layer at the production stage. The reinforcing material is:

- aluminum;

- perforated foil;

- fiberglass;

- fiber fiber.

Reinforced polypropylene pipe 40 mm has increased wear resistance and strength. It can be installed in a pipeline for supplying hot water or for installing a heating system.

What are the application features

Before constructing a pipeline, you need to determine the required pipe diameter. The optimal throughput is from 0.4 to 0.6 m/s. If the readings are lower, the risk of air locks increases. If it is more, the resistance to fluid flow increases, which affects energy saving.

Manufacturers produce polypropylene pipes with different diameters, which allows you to choose the one suitable for the construction of the pipeline. A product with a diameter of 40 mm of grade PN25 (PN30) and a working pressure of 2.5 atm is suitable for a heating system.

The diameters and wall thicknesses can be seen in the table below.

Recommended connection matching (specified size outer diameter of products in mm):

- 16 – it is planned to install a pair of radiators;

- 20 – installation of a group of radiators;

- 25 – it is assumed that several radiators will be installed on one wing;

- 32 – the need to connect an entire house with up to 12 radiators;

- 40 – connections for houses with more than 12 radiators.

Soldering of polypropylene pipes 40 mm is not carried out at low ambient temperatures. The minimum acceptable value is +5 degrees. You will also need a construction knife to cut products. For soldering, a special electrical apparatus is used. You will also need for installation fittings for polypropylene pipes 40 mm. They will ensure the tightness of the pipeline.

Polypropylene pipes are a modern alternative to metal counterparts. They have improved technical and operational characteristics, which allows them to be used for the construction of utilities of any type. A person who does not have special knowledge in construction and carrying out household plumbing work will be able to cope with the installation.

Do you prefer polypropylene or metal-plastic pipes? Why? Write in the comments. Save the article to bookmarks and share it on social networks.

Secrets of installing polypropylene pipes.