Technical characteristics of polypropylene pipes - what to look for when choosing?

Thermoplastic pipes, especially the pressure type, have practically replaced metal pipelines.And the point here is not only the low price of plastic and the simplicity of the installation process. Thermoplastic pipes comply with the requirements of GOSTs and SNiPs for pipeline structures, as well as operating conditions.

The content of the article:

General information

The category of thermoplastic pipes includes all types of plastic pipes. These are polypropylene, polyethylene (including cross-linked), polyvinyl chloride and polybutene. All products are manufactured in accordance with GOST. Its number is 521343-2003. The technical characteristics of the materials are also indicated here.

Types of material

In the above legislative document, polypropylene pipes are presented in three positions with different technical characteristics:

- Polypropylene homopolymer marked PP-H or PP of the first type, PP-G.

- Polypropylene block copolymer – PP-B. Russian marking is PP of the second type or PP-B.

- Polypropylene random copolymer – PP-R. The Russian marking is PP of the third type or PP-R.

The latter material is considered a breakthrough in the creation of pipelines for various purposes. Therefore, PP-R is used more often than others in the production of polypropylene pipes.

All polypropylene structures with a diameter of up to 180 mm are produced in coils. Above this size - in straight sections.

Special properties of polypropylene pipes

Advantages of this material:

- increased strength, the ability to withstand high pressure of the medium that moves along the highway;

- polypropylene is environmentally friendly - when heated and at high humidity it does not emit toxic substances;

- has a low thermal conductivity coefficient, which is important when it comes to propylene pipes for hot water;

- service life – at least 50 years;

- low specific gravity, which simplifies unloading and loading, transportation, moving, storing and connecting sections to each other.

Scope of pipe rolling

The list of applications where polypropylene pipes are used is wide. This includes almost all types of human activity, including the domestic sector, industry and agriculture. Eg;

- water supply: cold and hot;

- heating system, including heated floors;

- ventilation;

- drainage;

- irrigation systems;

- pipelines with aggressive media;

- pipelines pumping air under pressure.

Rated temperature and area of application

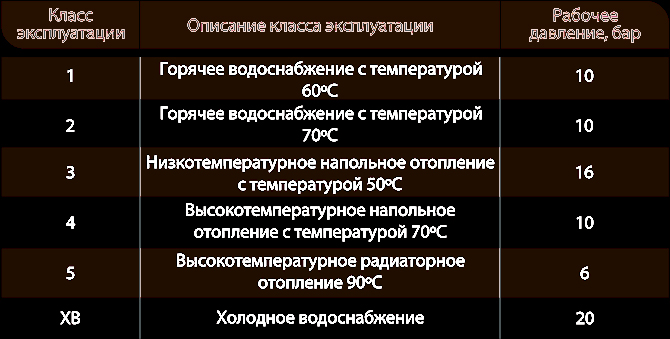

The technical characteristics of polypropylene pipes include a reliability indicator that depends on the temperature of the medium flowing inside the pipeline. According to this characteristic, pipes are divided into five classes. And all the above-mentioned types, and these are PP-H, PP-R, PP-B, are included in them.

They can withstand temperatures up to +80°C, depending on whether they belong to a particular class.

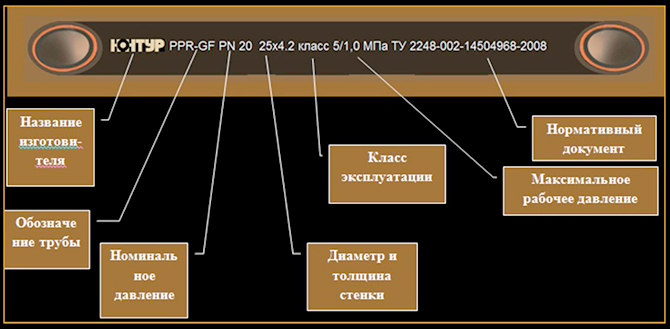

This technical characteristic is indicated in the marking of a polypropylene pipe - the class of the product is written on the wall. It will be written - class 5, as shown in the picture below.

According to GOST, the service life of a polypropylene pipeline is determined by the total operating time at high temperatures. Where the maximum value is 50 years.

Some manufacturers We try to use the latest technologies that allow us to produce material with higher temperature parameters. There are no restrictions in this regard. But the marking will still indicate “class 5” as the maximum technical characteristic according to GOST.

All polypropylene pipes from the classification can be used on pipelines with cold water, the pressure of which should not exceed 1 MPa.

Details

Let's move on to the technical specifications. One thing was mentioned above - temperature. But there is something equally important – pressure.

Characteristics of physical properties

Polypropylene has a low density - 0.91 kg/cm². But at the same time, this material is very durable, hence the high wear resistance. A smooth surface (external and internal) determines the quality of a plastic product. For example, the same GOST says:

- Surfaces (external and internal) should be as smooth as possible. Slight waviness is allowed - this also applies to longitudinal stripes. The main thing is that the wall thickness of the polypropylene pipe does not exceed or is not less than permissible sizes.

- During the production process, bubbles, pores, cracks and foreign inclusions should not appear on the surface. This also applies to the ends.

- The color should be uniform. It is indicated on the certificate.

Additional technical characteristics related to operating temperature:

- at a temperature of +140°C polypropylene begins to soften;

- at +170°C it melts;

- withstands the temperature of the pumped medium – up to +90°C.

Polypropylene pipes must be tested. To do this, water is driven inside them at temperatures up to +110°C.

Types of reinforcement

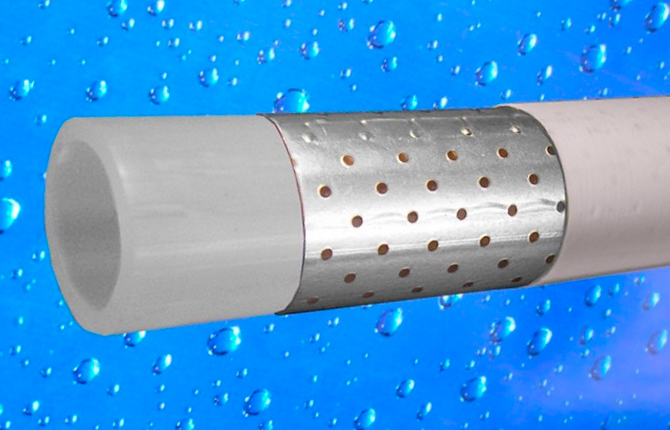

Polypropylene pipes, like many other plastic pipes, have a drawback.When hot water passes through them, they undergo a longitudinal expansion equal to 15 mm/m. Experts quickly solved this problem by placing the product inside the wall reinforcing frame.

There are four reinforcement technologies:

- A solid sheet of aluminum is used. It can be laid in one of three parts of the wall: closer to the outer surface, closer to the inner, in the middle.

- The same aluminum sheet is used, only with perforation. Its strength is lower, so the laying is carried out closer to the outer surface.

- Fiberglass. During the production of polyethylene pipes, it is placed in the middle of the wall.

- Material consisting of fiberglass and polypropylene.

The last two positions are better than the first two. It's all about the aluminum itself. Under the influence of salts present in hot water, it begins to succumb to corrosion - the quality of the pipe joints decreases. After all, when joining, the ends of the pipes are cleaned down to the reinforcing frame. And even with high-quality soldering, capillaries remain through which water reaches the reinforced frame.

Reinforcement reduces linear expansion by five times.

Technical characteristics of pipes by pressure

The second important characteristic after temperature is pressure. It directly depends on the wall thickness. The larger the latter, the greater the pressure the polypropylene pipe can withstand. This technical characteristic is also indicated in the marking, and it is denoted by two Latin letters - “PN”.

Today, manufacturers offer four positions on this technical characteristic:

- Used in water mains through which cold water moves. Designation – PN10. The pipeline can withstand 1.0 MPa or 10 atm.

- A second class product can withstand 1.6 MPa.Such pipes are usually installed in low-temperature heating systems, such as heated floors, where the coolant temperature does not exceed +60°C. Designation – PN16. They are also used in some hot water systems.

- PN20. Withstand pressure up to 2.0 MPa. Installed in radiator-type heating networks, where the coolant temperature reaches +95°C. In industry, these pipes are used when it is necessary to assemble a scheme for moving hot water from the boiler room to the point of entry into the technological process.

- PN25. Not used in everyday life, only in industrial facilities. Withstands loads up to 2.5 MPa and temperatures up to +110°C.

Characteristics by color

The color of the PP pipe does not affect the technical characteristics of the product. But manufacturers specially paint their products with the expectation that this will help them to be selected correctly, taking into account the scope of application.

White pipes are usually purchased when it is necessary to build a water supply network. But they do not withstand low temperatures well. Therefore, they try not to lay them outside or insulate them.

Gray ones are purchased for heating systems, but they are also often used for plumbing installations. They are chemically and thermally stable and hold temperature well.

Black ones are used in the construction of drainage systems, but they are also often used in street water supply. Their peculiarity is that they withstand the negative effects of sunlight well. Therefore, they feel great when used outdoors in the open air.

Green ones are polypropylene pipes, which manufacturers recommend using to create an irrigation system. The technical characteristics of the products do not meet the requirements of GOST.But recently, manufacturers have begun to pay great attention to the technical side of things. Therefore, green polypropylene products are also recommended for the organization of water supply networks.

Famous pipe brands

Technical characteristics are the main criterion by which it is necessary choose polypropylene pipes. But the Russian building materials market is filled not only with branded products. 50% are brands unknown to anyone with incomprehensible technical characteristics. Therefore, it is important to pay attention to the manufacturer when choosing. Here is a ranking of 10 popular brands.

In tenth place is the English brand “Blue Ocean”, whose products are manufactured in China. Not the worst Chinese material - it’s not for nothing that many European countries have certified it. The catalog includes both standard polypropylene pipes and reinforced ones (fiberglass and aluminum).

Ninth place goes to the Russian brand “Pro Aqua”. These polypropylene pipes cannot compete with European analogues. But they seriously compete with Chinese and Turkish ones due to their environmental friendliness and good technical characteristics. For example, pipe products from this company can withstand short-term pressures of up to 7.0 MPa.

Eighth place was given to the Turkish company “Tebo”. And although the product belongs to the economy class category, its technical characteristics are quite good. The manufacturer offers pipes with a diameter of 20-160 mm and fitting to them. All of them are reinforced with either aluminum or fiberglass. The catalog contains classes PN10, 20 and 25.

The Turkish company “Pilza” occupies the seventh place in the ranking. Here price and technical characteristics are in an optimal ratio.

The next place (sixth) is given to a joint venture, where the participants are Russia and Italy. This is the Valtec brand. This is one of the most popular brands in Russia.

In fifth place is the Romanian brand “SupraTherm”. The brand has been known in Europe since 1990. There is still a shortage of pipes in Russia. Attractive price, plus almost German quality. Has all European certificates.

Czech polypropylene pipes of the “Wavin Ekoplastik” brand are in fourth place. Today it is the most famous brand whose catalog includes products reinforced with basalt. The quality is not inferior to German.

All three prizes are occupied by polypropylene pipes produced in Germany:

- The third place in the ranking is occupied by the company “Wefatherm”;

- second “Aquatherm”;

- the first "Banninger".

Read the article: TOP 12 best soldering irons for pipes: review, photos, pros, cons, price.

How to choose products

Many people are looking for inexpensive polypropylene pipes, but with good technical performance. And it is right. It is not difficult to find such analogues on the market today. The main thing is to choose it according to the operating conditions.

Recommendations:

- For hot water supply and heating, purchase reinforced products.

- In private homes, it is better to use products with a technical indicator of PN20. In city apartments - PN25. This is due to the fact that in the heating system of urban houses the coolant pressure is high.

- The temperature indicator in the certificates and markings of many manufacturers differs from the standard (according to GOST). This does not mean that the actual temperature value does not meet the standards.

Even high-quality products do not guarantee trouble-free operation of the pipeline if installation requirements have been violated.In this case, even increased technical characteristics will not help.

Did you know about all the nuances that you need to pay attention to when choosing pipes? Write in the comments. Save the article to bookmarks and share it on social networks.

The video will complement our article and answer the remaining questions.

Polypropylene pipes for heating - how to choose.

Sources:

- https://internet-law.ru/gosts/gost/8446

- https://iseptick.ru/truby-i-fitingi/polipropilenovye-truby/texnicheskie-xarakteristiki-polipropilenovyx-trub-vidy-markirovka-osobennosti-ekspluatacii.html

- https://vse-o-trubah.ru/tsveta-i-sfera-primeneniya-polipropilenovyh-trub.html#

- https://markakachestva.ru/best-brands/3165-10-luchshih-proizvoditelej-polipropilenovyh-trub.html