Components for polypropylene pipes - rules for selection and installation

Successful purchase polypropylene pipe blanks for the installation of a water supply system can be considered half the success. Additionally, you will need fittings, fasteners, taps and other components for polypropylene pipes. At the same time, the quality of the future water supply directly depends on the correct selection and installation of all elements.

The content of the article:

Characteristics of polypropylene pipes

For domestic plumbing and heating, two types of pipes are used - reinforced and non-reinforced. In the second case, pipe blanks are made by extruding the melt through a die die. These are ordinary monolithic pipes made of polypropylene mass with copolymer additives.

Reinforced blanks are made with a sticker of an intermediate aluminum layer or welding of a sublayer with the addition of glass microfiber. This will need to be taken into account when choosing components for polypropylene heating pipes.

Polypropylene pipe blanks are marked depending on the permissible pressure of water or working fluid:

- PN10 – pressure up to 10 bar at a temperature not exceeding 45 ℃;

- PN16 – pressure up to 16 bar up to 60 ℃;

- PN20 – pressure up to 20 bar up to 80 ℃;

- PN25 – pressure up to 25 bar up to 95 ℃.

Polypropylene pipe blanks PN16-25 are available in reinforced and non-reinforced versions. PN16 with an aluminum sublayer are used in apartment heating systems with double-circuit boilers.

| PN10 | PN16 | PN20 | PN25 |

| for cold water supply | for environments with temperatures not exceeding 60 ℃ | universal, for cold water and hot water up to 80 ℃ | for heating |

| unreinforced | unreinforced | reinforced | reinforced |

| 0-45 ℃ | 0-60 ℃ | 0-80 ℃ | 0-95 ℃ |

| up to 10 at | up to 26 at | up to 20 at | up to 25 at |

Pipe blanks with the addition of fiberglass are used in:

- complete with floor-standing boilers with maximum water temperature;

- heated floor systems;

- in high pressure water pipes.

Polypropylene blanks can be made from different materials. The most affordable grade of PPH is pure polypropylene. Used to supply cold water. PPV is a complex copolymer based on polypropylene with the addition of low-density polyethylene. It has high elasticity, therefore it is used for components of cold water pipelines and heated floors.

The most common brand of PPR is a polypropylene base, into which ethylene is “sewn” in a special way during the polymerization process. Withstands constant heating up to 70℃. It is used to supply hot water and in low-temperature heating systems. The most heat-resistant material - PPs - is used for heating circuit components.

Components for assembling a water supply or heating circuit must be taken from the same brand and from the same material as the pipes. Otherwise there is a risk of damage to the solder seam. It is not advisable to solder polypropylene components of different compositions. For example, the coefficient of thermal expansion of a polypropylene pipe blank reinforced with glass fiber is 2-3 times lower than that of a conventional PPR pipe for water supply systems. Therefore, a reliable junction will not work.

Types of components

To assemble a water supply system, dozens of models of fittings and additional elements are used.

Conventionally, they can be divided into several groups according to application:

- Accessories for joining workpieces. These include couplings, fittings, adapters, triangles, simple and with a metal fitting.

- Shut-off valves, taps, filters.

- Fitting for making branches and connecting water or heat consumers.

- Elements for fastening polypropylene lines on the wall.

Within the product range of one manufacturer, all components are grouped, systematized and labeled for a specific type of polypropylene pipe. The company puts the product code on the side of the case.

In retail sales, components can be offered in groups, for example, for assembling a water supply or heating circuit. But more often you have to assemble a set of additional elements in bulk, so it is important to know every detail “in person” or at least have an idea of the structure of the components for the water supply system.

Accessories for joining polypropylene pipes

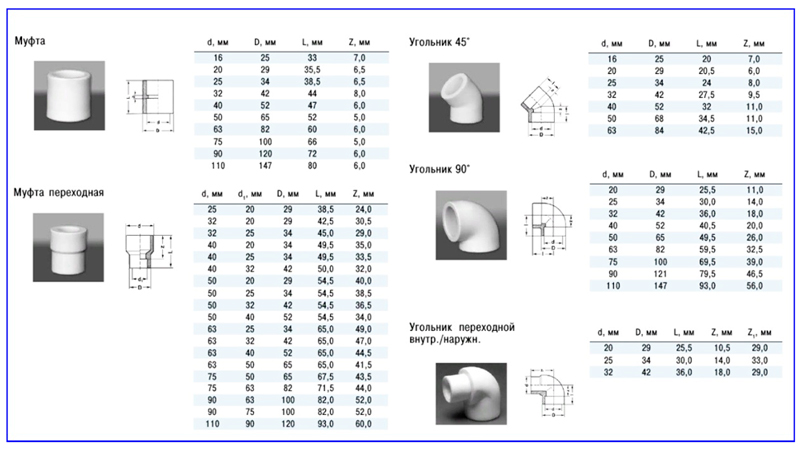

For simple joining, straight and angular couplings are used. The fitting used for welding a polypropylene pipe in one line is a cylindrical barrel with landing cavities at the inlet and outlet.

The vast majority of manufacturing companies mark the end or side surface of components with information about the class of pipe PN10-PN25, bore diameter and grade of polypropylene.

To connect pipes of different diameters, to switch from polypropylene to a steel pipe or a metal union nut, components of a more complex shape are used. Depending on the mounting method, such a coupling may have internal or external metal threads.

In addition to straight fittings, corner polypropylene couplings are used - they are used to rotate the pipeline by 45 and 90 degrees.

These components can also be made for welding two workpieces of different diameters, and have metal elements with external or internal threads.

For the final assembly of a polypropylene water supply, components are used that provide service functions:

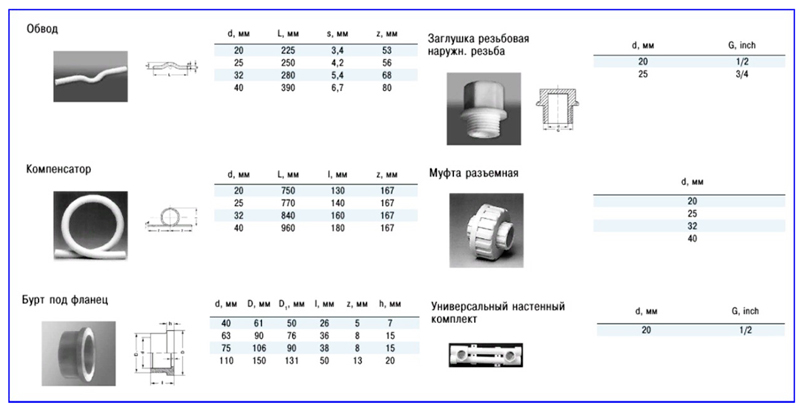

- contours if several pipes intersect in the same plane. Usually they are installed at the final stage of assembly, when it becomes possible to measure the radius of the rounding of one section over another;

- compensators made of polypropylene pipe. This pipe ring is used to compensate for the thermal expansion of polypropylene when heated;

- plugs and adapter collars from the pipe to the flange connection.

Accessories for branching pipes, bends for connecting flexible hoses

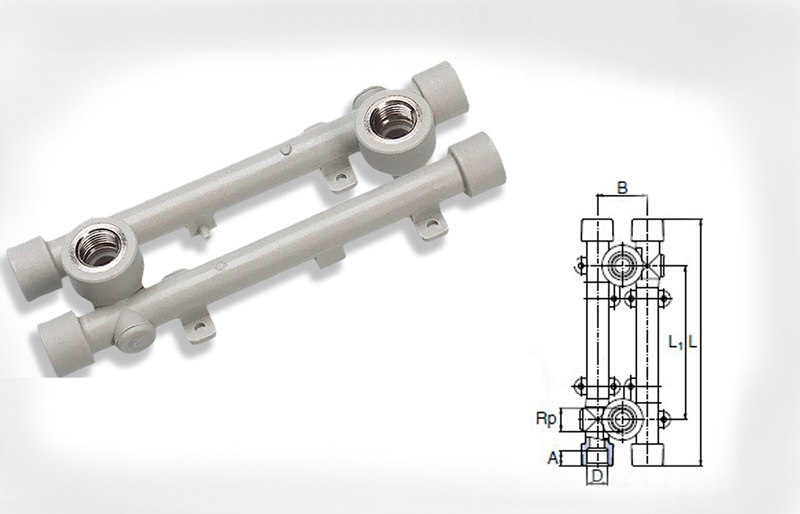

The pipe system is not necessarily built in the form of one broken or straight line. For complex water supply systems or, more often, for heating, several outlets have to be made. For example, to connect several heating radiators to the supply line. The problem of branching water pipes or heating pipes can be solved using components of complex shapes.

For example, when laying pipes horizontally, it is necessary to make a vertical water drainage above or below the main level, or branch from vertical sections of the water supply system. In this case, you can use polypropylene tees to branch the pipe at right angles to the inlet-outlet line.

They are also called reduction ones. All three holes are located in the same plane or in two at once.

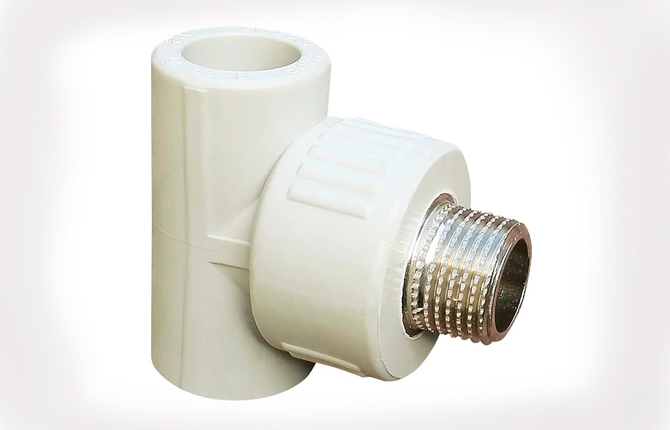

The outlet outlet can have an internal or external thread, which is convenient if you want to connect the circuit to a metal pipe.

Tees can be transitional with holes for pipes of different diameters.

Fittings with a threaded fitting are also used to connect flexible connections for faucets, waste tanks or boilers.

For bathtub or shower faucets, components known as a water outlet are more often used. This may be an angle with a threaded fitting.

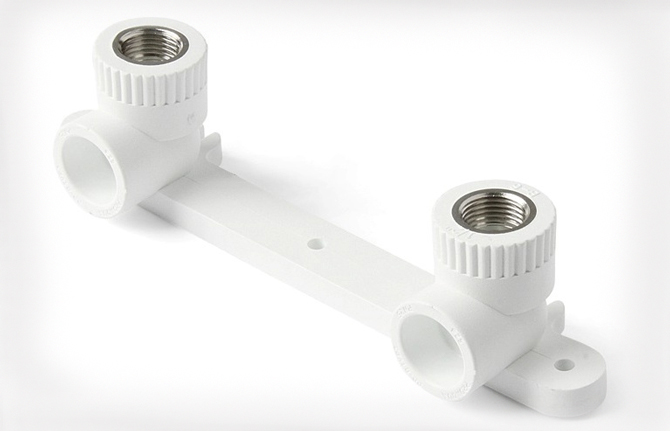

Or a more complex version of the components - a double strip with fastening for embedding into the bathroom wall.

For the kitchen, you can use a universal wall kit.

Taps and fittings for polypropylene water pipes

In addition to couplings and adapters, pipeline structures use components such as taps and valves. For cold water, you can install a full-flow faucet for soldering with pipes.

In heating circuits, a polypropylene pipe is connected to radiators using an adapter valve for soldering and fitting.

When choosing components for a heating system or plumbing, purchase a coarse filter.

Typically, models with a metal plug are used, but there are also options with polypropylene. Plastic components are used for low pressure lines, no more than 1.5 bar.

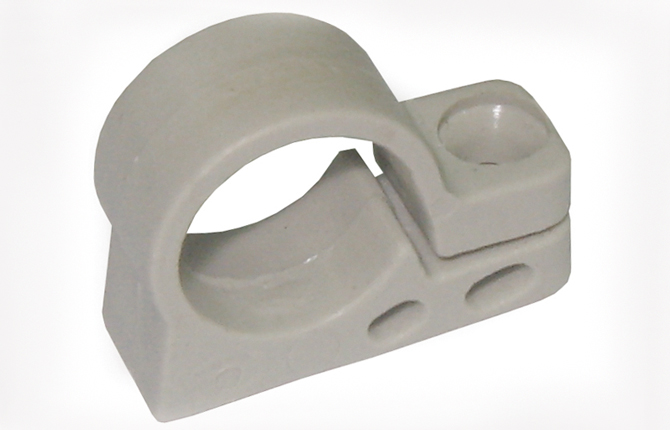

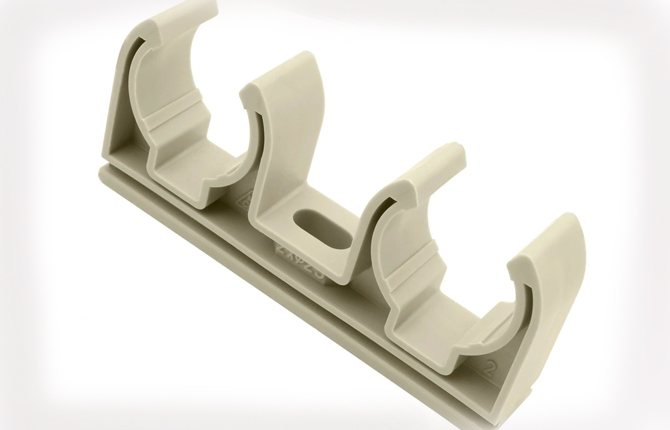

Pipe fasteners

Selection of components used for fixing polypropylene lines on walls, small.

There are two types of fasteners used for home plumbing:

- polypropylene clips;

- beaver type clamps.

Both versions of components are attached to the wall with a self-tapping screw and plug.

The fastening of polypropylene pipes must be sliding - rigid pinching is not allowed.Otherwise, when the line heats up, the fasteners of any component may break.

The clips are placed along the laying line of the polypropylene pipe.

The second type of components is put on the pipe in advance.

After soldering the pipes, you can select a location for installation and secure the part with a dowel.

How to choose components

The best solution when selecting parts for assembling a plumbing or heating system is to use the catalog of one manufacturer. This approach will ensure that the components match each other both in terms of material and product dimensions.

What you need to pay attention to:

- The components must be correctly selected according to the mounting dimensions. Therefore, it is necessary to draw up a diagram of the future wiring and mark the type of parts on it. It is important to correctly determine the dimensions of the components. After that you can make a list.

- For water supply and heating systems, components are made of different materials. Glass fiber reinforced polypropylene parts should only be welded to pipe blanks of the same material.

An exception may be the situation when pipe blanks with a reinforcing aluminum sublayer are used for hot water. In this case, components can be purchased in one list, for both cold and hot water.

The wall thickness of the polypropylene body of the components is much greater than that of the pipe. Therefore, there are no special problems with heat resistance.

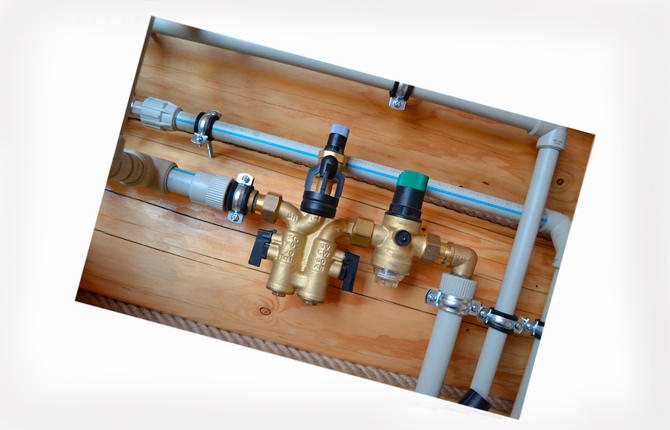

For water supply

First of all, you need to install a tap and filter on the inlet part. At the inlet in front of the water meter, a polypropylene valve-type tap with a rubber gasket and a clamping nut on the rod is mounted. This type is considered more reliable and durable.It is better not to skimp on components for the introductory part.

Tees, transition fittings, couplings are purchased according to the list. It is advisable to buy components from one manufacturer. If the water supply system requires the installation of blocking taps, for example, when connecting plumbing or a boiler, then it is better to take components made of brass and install them on polypropylene adapter couplings.

For heating system

Planning a heating circuit is no different from a similar process for a water supply system. The only difference is that development begins with choosing a location for the security group and selecting components for it.

The second feature is that the list of components for polypropylene heating pipes must include an expansion compensator. You can use a ring or a Kozlov compensator.

If desired, this type of component can be made independently.

Installation of components

Soldering of the water supply starts from the input. The heating system begins to be assembled from the security team.

When soldering components onto polypropylene workpieces, two rules must be followed:

- You can’t cut or cut anything in advance. All components are soldered to the pipe sequentially as you move along the assembly diagram.

- Complex units are assembled separately. Only after making sure that a particularly valuable type of component is soldered to the pipe blank correctly can you install the unit on the water supply.

When using good soldering iron The process of soldering parts is progressing quickly. You need to place the components to be welded on the heating nozzles, heat them for a certain time and connect them.

| Pipe diameter, mm | 20 | 25 | 32 | 40 | 50 | 63 | 75 | 90 |

| Heating time, s | 5 | 7 | 8 | 12 | 18 | 24 | 30 | 40 |

| Welding time, s | 4 | 4 | 6 | 6 | 6 | 8 | 8 | 8 |

| Cooling time, s | 120 | 120 | 220 | 240 | 250 | 360 | 360 | 360 |

If some part was soldered unsuccessfully, it is not necessary to throw it away. It is enough to cut off the outer part of the pipe blank with a hacksaw; everything inside the coupling can be cut out with a feather drill for wood.

Short-term heating does not in any way affect the characteristics of components, including taps and threaded couplings.

Selecting components for polypropylene pipes is an important process that has many nuances. You need to take everything into account - from the type of system where they will be installed, to the material and dimensions. Therefore, it is important to study the characteristics of these parts in advance and study the range of well-known companies.

Elements of connecting polypropylene pipes: video.

Did you know about all the nuances of choosing components? Write in the comments. Save the article to your bookmarks so you don’t lose useful information. Share it with your friends on social networks.

My advice, take the additional ones in one list with pipes, fasteners, and taps. Plastic, casting seams, markings - everything will be the same. If something in a branded set has been replaced with Chinese consumer goods, it will immediately become obvious. This happens, especially in construction supermarkets.

Polypropylene from different manufacturers is soldered in different times, so the table is a table, but you need to practice. Otherwise, polypropylene pipes will turn out crooked.