Cable for heating a water pipe: markings, types, manufacturers + features of choice

Nature sometimes makes its own adjustments to the well-established life of a country house.In winter, housing may be left without water supply due to freezing of pipes, even those that are underground and insulated with mineral wool.

To maintain comfort in the house during cold times, you can use a cable to heat the water pipe, then even the most severe frosts will not harm the communications. We will tell you how to choose the most suitable type of cable. The article we propose describes the types of heating systems and provides an explanation of the markings.

The content of the article:

Types of heating cables

There are heating cables resistive And self-regulating. Their main characteristic is specific heat release, expressed in the amount of heat per linear meter.

A cable may contain several components combined into a single system.

It is mounted on the communications using one of two methods - along the pipeline and by internal installation. The choice of method is influenced by specific circumstances.

Type #1 - resistive cable

The operating principle is based on the property of metals to warm up when an electric current passes through them. The metal core is heated here, and the device itself can be compared to a long boiler. A feature of such cables is a stable amount of heat generated at any outside temperature.

This is also their main drawback - the impossibility of saving electricity. Its consumption will be the same both at +1 °C and at -18 °C outside, if the system is not equipped with a thermostat and temperature sensors.

Such wires cannot be placed close to each other, and when laying, it is necessary to prevent their intersection. Otherwise - overheating and all the ensuing consequences. In turn, resistive type heating cable comes in three types - single- and double-core, as well as zonal.

Double-core ones are more expensive than single-core ones, but despite this, they are more popular. This is explained by the fact that, due to their design features, there are no difficulties when connecting.

Twin-core products have a power of 15.6 W/m at a maximum temperature of 90⁰. A single-core cable is characterized by a power of 20 - 30 W/m. Temperature limit - 120 °C.

The main difference between single- and double-core products is the connection method. The two-core wire has one end capped, and on the opposite side there is a simple electrical cord with a standard plug designed to be plugged into a 220 V outlet.

One of the cores in it is responsible for heating, and the second serves as a conductor of electric current. Single-core wires are connected at both ends, and this is somewhat inconvenient.

A feature of the first two types of resistive wire is that it cannot be cut. It simply becomes inoperable, so the purchased cable must be laid completely.

The zone thermal cable is a slightly improved structure. There are heating coils between its cores. They are located so that the cord can be cut into pieces at a certain pitch.

If a conductor burns out in some area of such a product, a cold zone will appear, but the system itself will not stop functioning.

Type #2 - self-regulating heating cable

The parallel conductors in a self-regulating cable are separated by a semiconducting matrix with a heating element in the core. It constantly emits heat, but current only passes through the conductors. The cable itself has the form of a tape. It can be cut anywhere without the risk of creating a cold spot.

Depending on the ambient temperature, the heat transfer of the cable can be adjusted, although it can adapt to the external environment independently.

It increases power when the temperature inside the pipe drops and turns off when it rises. Since the amount of heat emitted is normalized, the product never overheats. Self-regulating cable has great strength, withstands shock loads well, and is resistant to moisture and aggressive chemicals.

Due to the fact that the polymer-dielectric from which the matrix of the self-regulating cable is made contains conductive finely dispersed material, temperature adjustment is possible.

This happens as follows:

- the dimensions of the matrix decrease with decreasing temperature;

- a larger number of current-carrying circuits are formed in the conductor;

- The power used, and therefore heat dissipation, increases.

This cable lasts a long time - about 10 years. When overlapped, it does not overheat, since the power in this area becomes minimal. When cutting the cable, the total power of the segment will change, but the heating will remain the same.

The best heating cable manufacturers

Heating cables are produced by many companies, both domestic and foreign.

The most popular products among manufacturers are:

- Nelson;

- Lavita;

- Ensto;

- Devi;

- Veria;

- Raychem;

- CTK.

Let's take a closer look at the features of these companies' products.

Place #1 - NELSON LIMITRACE

The company, part of the Emerson concern (USA), specializes in the production of self-regulating thermal cables. The products are known for their high quality, because... During the production process it is subjected to multi-stage control. At the final stage, aging testing is carried out.

The service life of NELSON cable without loss of power is about 20 years.To protect water pipes from frost, a cord brand such as NELSON LIMITRACE HLT210-J is used.

It has the following characteristics:

- operating temperature limited to 120 °C;

- maximum length - up to 115 m;

- power supply - 220-240 V;

- power - 32 W/m.

NELSON LIMITRACE HLT212-J brand can also be used for heating a water pipe. It differs from the previous one with slightly greater power (37 t/m) and length - a maximum of 105 m.

The shorter the Nelson cable, the greater the power. Thus, the power of NELSON LIMITRACE HLT215-J is 46 W/m, but the length is only 95 m. NELSON LIMITRACE HLT218-J has a length of 80 m and a power of 56 W/m.

Place #2 – DEVI and Veria

The Danish company Danfoss, which produces products under the DEVI brand, supplies the market with several options for heating wires - single- and double-core, as well as self-regulating. Each type has its own purpose.

They are plastic, have a long service life, are reliable, and environmentally friendly. The products have a fixed length, so it is impossible to cut or increase their heating area. All these manipulations can only be carried out with a “cold end”. The Devi cable has reliable insulation and sufficient power for use in any conditions.

Products from Veria, a subsidiary of the Danish company Danfoss, have the same high quality characteristics as DEVI products, but their price is lower.Cable power is 20 W/m, length from 10 to 125 m. The manufacturer provides a guarantee for its heating cable for at least 12 years.

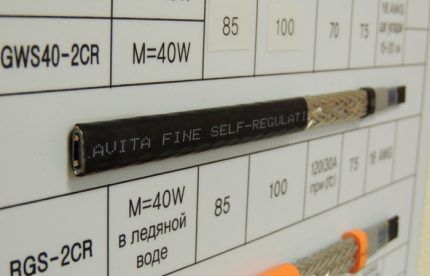

Place #3 - Lavita company

Lavita is a South Korean company. Self-regulating cables from this manufacturer are used both in everyday life and for protecting pipelines at industrial facilities. The company always fulfills its contractual obligations and strictly adheres to the quality system, so its products are in great demand on the market.

For internal heating of pipelinesfor transporting drinking water, Lavita HPI 13-2 CT food cable is used. It is highly flexible, which guarantees easy installation. The fluoropolymer from which the external insulation is made is completely environmentally safe.

Laser marking is also harmless; it does not dissolve in water. Long service life and economical energy consumption ensure flexible power changes.

Rated cable power is 13 W/m, maximum temperature 65 °C. The length of the heating circuit depends on the switching temperature and is 51 - 108 m maximum.

Place #4 - manufacturer Ensto

Ensto heating wires, produced by the international concern Ensto, created in Finland, are distinguished by their high quality.

They provide safety and energy efficiency, guarantee protection of water pipes from freezing. The products are easy to install, convenient to use, durable, because... High quality components are used in production.

For domestic use, the Ensto Plug’n Heat cable set is most often used. This is a self-regulating cable with a power of 90 W, a length of 10 m. The maximum operating temperature is 65 ° C. Installation is possible both inside and outside the pipe.

Place #5 - Raychem company

To protect a water pipe of a relatively small cross-section from freezing, the most suitable option is the Raychem ETL cable. It is equipped with a Teflon shell, suitable for both external and internal installation.

The cable regulates heat transfer based on the ambient temperature. In water at 5 °C it has a power of 20 W/m; when installed on top of a metal pipe at the same temperature, the power is halved. The cable is certified for use in drinking water supply systems.

Raychem FroStop Blask cable is suitable for outdoor use. In this case it has a power of 18 W/m at 0 °C. When installed in cold water, its power increases to 28 W/m.

Self-regulating FroStop Green with a rated power of 10 W/m, GM-2X (18 W/m) is also used to protect water pipes.

Place #6 - domestic manufacturers

Chuvashteplokabel is a domestic company created 18 years ago. Produces thermal products under the brand name CTK. Heating cables are created taking into account all the advanced developments of European companies. Their quality is not inferior to foreign ones, and their price is lower.

Ekkotec company, supplying products under the brand H.B.S., also produces a large range of heating cables.

"Thermal systems" - an association of companies producing heating cables under the trademark TS-HEAT.

The company has installed the latest equipment, allowing it to produce a wide range of high-quality heating cables. The basis of self-regulating products is a high-tech semiconductor matrix.

Heating cable marking

Knowing how to decipher the designation of a heating cable, you can accurately choose the appropriate option for yourself.

Thus, the markings applied to the Raychem self-regulating cable 10BTV2-CR can be read like this:

- 10 — power in W/m;

- BTV2 - brand of cable intended for voltage 220 - 240 W;

- CR - indicates that the cable design includes tinned copper braiding and outer polyolefin insulation.

The presence of a copper screen and an outer insulating layer in the cable design is also indicated by the letters ST, CF. If these symbols are not in the labeling, then it is a semi-finished product.

On cables supplied by Thermal Systems, the type of sheath can be identified from the designation. Abbreviation TSA...P indicates the presence of a weather-resistant polyolefin shell.

And here TSA...F - indicates that the cable sheath is made of corrosion-resistant fluoropolymer.

If a self-regulating cable does not have a screen, its protection class is 0 (zero). It can only be used in conditions without moisture, conductive dust and in accordance with clause 1.1.13 PUE.

Unbraided cable markings may look like this: SRL 30-2. In this case, it is an SRL brand cable with a power of 30 W/m, planned for a voltage of 220 V.

The HS-FSM2 also lacks CR symbols on its markings, indicating that this cable does not have a shield.

Cable selection criteria

Selecting a heating cable according to all the rules involves taking into account several criteria:

- design features;

- type of external insulation;

- temperature class;

- water pipe cross-section;

- power;

- manufacturer.

Externally, this type of product differs little from each other, but different brands of cable have their own individual characteristics. They are different, which can be clearly seen by examining each criterion in detail.

Criterion #1 - cable design features

First of all, when choosing, you should pay attention to the design features of the heating cord. Thus, a self-regulating cable, in addition to two copper conductors and a matrix, can have insulation, braiding, and an outer sheath.

Braiding increases the mechanical strength of the product. If it is not on the thermal cable, it is an economy class product.

The presence on the market of a self-regulating cable that is not equipped with copper braiding or external insulation is not uncommon. This reduces product safety, reliability and is contrary to generally accepted standards.In fact, this is not a cable, but only a blank.

Criterion #2 - external wire insulation

The type of external insulation is also of great importance. To protect your home water supply, an insulating layer made of polyolefin is quite suitable.

For industrial environments, fluoropolymer is more suitable as external insulation. To lay the cable in a pipe, fluoroplastic insulation is required.

There are also recommendations regarding the thickness of insulation depending on the diameter of the pipe. With its value of 15 or 20 mm, the optimal thickness of the insulating layer is 20 mm. For cross-sections of 25 and 32 mm, the optimal insulation thickness is 30 mm. For water pipes with a cross-section of 40, 50, 65 mm, the thickness of the insulation must be equal to the diameter of the product.

Criterion #3 - cable temperature class

Temperature class is the next most important evaluation indicator when choosing a heating cable. A low-temperature product can warm up to 65 °C with a specific heating power of a maximum of 15 W/m. This product is more suitable for a pipeline with a small cross-section.

The thermal cable, heating up to 120 °C, with a maximum power of 33 W/m is classified as medium temperature. It is used for medium diameter pipes.

It is better not to use a cable that heats up to 190 °C, with a power of 15 to 95 W/m, for home plumbing at all. It is used in industrial environments where large diameter water pipes are installed.

Criterion #4 - choice by power

It is important when choosing a thermal cable to proceed from the cross-sectional area of the water pipe and select the appropriate power according to it.

Experts recommend focusing on the following parameters:

- pipeline diameter 1.5-2.5 cm - power 10 W/m;

- 2.5-4 cm - 16 W/m;

- 4-6 cm - 24 W/m;

- 6-8 cm - 30 W/m;

- More than 8 cm - 40 W/m.

The choice of power is impossible without taking into account the pipe material. If it is made of polymers, then the power of the cable should not exceed 17 W/m. Otherwise, the water supply may fail due to overheating.

The last criterion is the cable manufacturer. It’s better to pay a little more, but the system will work like a clock.

You can learn how to choose a heating cable to protect sewer pipelines from next article, which we strongly recommend reading.

Conclusions and useful video on the topic

Video #1. About the features of choice:

Video #2. About the design and advantages of a self-regulating cable:

When deciding on purchasing a heating cable for your water main, you need to proceed from specific conditions, based on technical and operational characteristics.

If you approach the choice from the financial side, the self-regulating option will cost more. This choice is justified by high reliability and considerable energy savings.

Would you like to talk about how you selected and installed a heating cable with your own hands? Do you have useful information on the topic of the article that is worth sharing with site visitors? Please write comments in the block below, ask questions and post photos.

I believe that sometimes such cables are simply necessary, especially for those houses built in areas with an extremely harsh climate. After all, if water freezes in winter, then due to expansion it can simply rupture the pipe.Personally, we played it safe and also decided to install such a cable at the initial stage of construction. We bought a two-core cable, I don’t remember the manufacturer, since everything was done by a team, but for two years there were no problems.

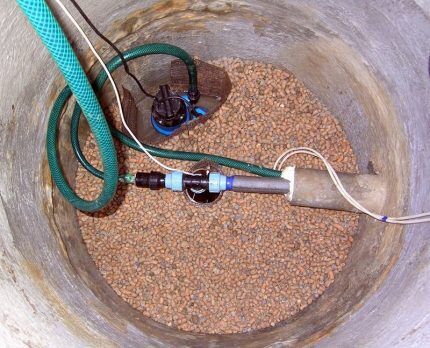

I plan to use water from a well at my dacha in the winter. The distance from the well to the house is about 20 meters. The HDPE pipe with a blue stripe is buried 30-40 centimeters deep; there is no way to dig it deeper. I plan to use it on weekends, New Year holidays, etc., that is, not all the time. After use I will drain the water. Which heating cable would be best for my situation?

It’s very bad that you can’t dig the pipe deeper, at least 1 m. But self-regulating cables were invented to help out precisely in such situations. For your case, I would recommend the EASTEC SRL-16 cable. The cost of the cable is about 100 rubles. per linear meter, it’s not difficult to guess from the article number that the power is 16 W/linear meter.

This is a manufacturer from South Korea; a semiconductor matrix with temperature class T6 is used as a heating element. This self-regulating heating cable is specifically designed for heating drains and pipes from the outside. In your case, you need to wind the cable in a spiral, with an average step, there will be about 30 m of cable per 20 m pipe, a total power of approximately 480 W. For a clear example, I am attaching a diagram of the spiral laying of the heating cable.