Heating of water supply: the best heating options + analysis of technical features

In winter, due to a sharp decrease in air temperature and freezing of the soil, ice plugs may form in the external branches of the water supply system. To prevent this from happening, it is necessary to organize heating of the water supply using one or more effective technologies.

The article we presented describes all the methods to prevent the formation of ice in water supply pipes. We will tell you how to properly maintain the functionality of communications in cold weather and prevent equipment breakdown. Do-it-yourselfers will find instructions on how to install thermal insulation and heating systems.

The content of the article:

Options for insulating water pipes

The problem of thermal insulation and heating of pipes arose due to seasonal changes in temperature and, as a result, the appearance of a freezing top layer of soil.

In winter, the freezing depth reaches 0.8-1.8 m on average, and in the most northern points of Russia - up to 3.5 m.

Along with digging ditches at great depths, it will be necessary to equip the head - install a caisson, where pumping equipment is usually located. These are costly and irrational measures, for the implementation of which it is necessary to attract special equipment.

To save money and make water supply maintenance easier, it is laid at a shallow depth, using various means of insulation - from thermal insulation material to the heating cable.

Often, the method of heating an underground water supply is chosen based on installation conditions and economic considerations. Sometimes it is more profitable to combine two different technologies. For example, a cable is installed along the entire length of the pipe, including the end lowered into the well, and the part located in the ground on top is insulated with a polystyrene foam sheath.

Method #1 - using insulation

The traditional and most popular method of heating pipes buried in the ground, as well as “air” water pipes, is mechanical insulation, which is produced using special materials.

The shell is selected based on the conditions of a particular region and particular features of the geological situation, for example, the aggressiveness of the soil or the presence of high groundwater.

There are a number of requirements for materials. They must have the following qualities:

- low thermal conductivity – the key to energy efficiency and savings;

- wear resistance, long service life without loss of basic qualities;

- resistance to organic and chemical substances, as well as soil microorganisms and bacteria;

- no deformation at high humidity and low temperatures.

Manufacturers usually accompany products with a list of technical characteristics that need to be taken into account when choosing alternative options. There are times when the shell is made from extruded polystyrene foam It is much more rational to use than expensive polyurethane sprayers.

Popular insulation materials:

All of the materials listed are relevant and can be easily found on sale. Preference should be given to insulation with low thermal conductivity and high strength.

It is easier to install one that does not require additional tools, is light weight and small in volume, and can be processed well.

Method #2 - air insulation

This method is used in public utilities and industry; installing a protective air cushion at the dacha is associated with difficulties. The technology consists of supplying warm air into the channel in which the water supply is located. The top of the pipe is covered with any type of thermal insulation.

This technology has variations. For example, if the diameter of the pipe is small, then it is placed in a similar product, but of a larger diameter. This arrangement prevents the water line from coming into direct contact with the ground, and therefore from cooling. In addition, a small space is created between the walls through which heated air circulates.

The disadvantage of this method is that it cannot be used for water pipes running on top of the ground. It is relevant only for communications placed in the ground, preferably below the freezing level.

Method #3 - high blood pressure

There are standards establishing the amount network pressure for various types of water supply installations. For example, for high-rise buildings the optimal parameters are 4-4.5 bar, while in private houses they can be more or less.

The maximum operating pressure for water supply systems of private houses is considered to be 6.5-7 bar, but such indicators are rare, more often they do not reach 3 bar. To protect the water supply from freezing, the pressure in the system is increased, say, from 3 to 5 bar.

The main condition is the installation of special equipment, since not everyone is able to withstand such pressure.

Increased pressure is most often used by utility workers; owners of country houses use it extremely rarely. If the strength of the system allows, the pump is turned off during the winter season and the pressure is raised to 5 bar.

Method #4 - heating using electricity

Installing a heating cable is considered the most effective method of all active ones.The principle of heating is simple: an electric current passes through a wire installed inside or outside the pipe and increases its temperature by converting electricity into heat.

TO heating cable special requirements apply. It must be protected as much as possible from external mechanical irritants and moisture. The shell must be strong, without holes or defects.

Let's consider two types of cable that are actively used for heating pipes supplying water to private homes.

Option 1 - resistive cable

The advantage of the product is a specially selected metal alloy with high resistance, which causes a large amount of heat generated. Of the two types of cable - single-core and double-core - the second option is more practical.

1-wire requires loopback of the electrical circuit. This means that during installation, both ends must be connected to the power source. With a 2-core it is simpler: the first end is connected to a source of electricity, and the second is “shorted” by putting a contact sleeve on it.

The conductors are protected by a polymer sheath, often multilayer. In addition, they are covered on top with a grounding shield, and on the outside - with durable heat-resistant PVC insulation.

Why choose resistive cable? It has great heat transfer; in other words, it gets very hot and transfers heat to the water pipe.It can be fixed along the entire length of the line, wrapped around connecting nodes and flanges.

Additional advantages of the resistive option are affordable cost and ease of installation. All preparation and installation operations can be performed independently.

The disadvantages include the purchase of additional equipment: machines, sensors, control units. It is believed that the end sleeve must be factory-made to ensure safety and proper operation of the heater.

Option 2 – self-regulating heating wire

The operating principle and design of the cable are fundamentally different from the first option. Self-regulating systems recognized as more economical and convenient to install.

Cable structure:

From a power consumption point of view, this type of cable seems ideal. As soon as the temperature of the air or pipe decreases, it increases power consumption and generates more heat, and as the temperature increases, the conductivity drops sharply.

Efficiency is also increased by heating individual sections of the water supply. If the samreg is laid along the street and inside unheated rooms, then it will heat up the “street”, colder areas more strongly. The more vulnerable the heated area, the more heat the cable generates.

Advantages of self-regulating systems:

- energy saving;

- heating efficiency;

- distribution by “zones”;

- comfortable length.

Unlike resistive cable, which is sold ready-made and has a certain length, samreg can be cut as convenient. Typically, the cut locations are indicated on the shell, the interval between which is 20 or 50 cm.

There is also a drawback - heating extended areas costs a pretty penny. If a low-power cable can be purchased at a price of 60-75 rubles/m, then the cost of a high-quality and powerful cable reaches 300 rubles/m and more.

Recommendations and installation instructions

Covering a water pipe with thermal insulation is not as difficult as connecting heating cables, so let’s look at the technical nuances of installation that relate specifically to electrical equipment.

External installation of heating cable

Fastening along the outer surface of the pipe is often practiced when it is necessary to heat open areas of the water supply system located in the base, basement, or caisson.

There are two ways to fix the wire on the pipe:

- stretch along the surface along the entire length;

- wrap with a spiral.

The first option is more economical and practical if the cable power is enough to heat the pipe. In particularly cold areas, the second method can be used, but the wire consumption will increase.

Fastening occurs in the following order:

This is the easiest way to install a heating cable.

Recommendations for the device:

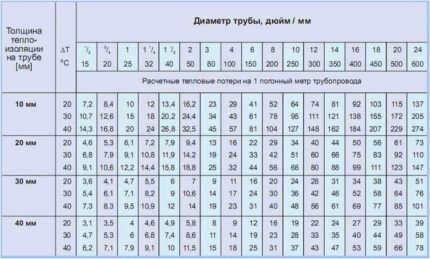

- To heat a polypropylene water pipe with a diameter of up to 32 mm, it is enough to fasten the cable along one side - which side does not matter. However, if you need to insulate the sewer, the wire is fixed exclusively from the bottom.

- If there is a choice of insulation, then you need to take a thicker one. The self-regulating cable is not in danger of overheating, but heat loss will be significantly reduced. The thicker the “coat”, the less electricity the samreg will spend, the greater the savings.

- Aluminum self-adhesive is the best material for attaching to a pipe. Acrylic adhesive does not collapse under the influence of heat, which is evenly distributed over the entire heated surface.

- The sun's rays destroy some types of insulation and fastenings, so for open areas it is better to choose black clamps and tape that do not react to UV radiation.

If the cable is fastened not in a straight line, but in a spiral, then the insulation will occur according to the same principle - putting on a “coat” and securing it with clamps. Without insulation, some of the energy will be wasted on heating the air.

The nuances of connecting a self-regulating cable

It is impractical to pull the wires to the pipe from the shield, so the samreg is connected to the power cable, which, in turn, is simply plugged into an outlet if necessary. To work, you will need a hair dryer, a knife, a set of heat-shrinkable tubes for crimping and sleeves for connecting the contacts.

It should be remembered that electrical equipment becomes more dangerous in a humid environment, so special attention must be paid to tightness.

Photo instructions for connection:

As you can see, there are difficulties in internal cable installation no, you just need to perform all manipulations very carefully and consistently.

When choosing a power cable, you must consider the location of the outlet. If it is located next to a pipe, you can buy the shortest product, but more often you have to purchase a 4-5 meter cord.

All that remains is to compress the end of the samreg:

With a sealed end, the cable is completely ready for use.To prevent the water pipe from freezing, all that remains is to secure the samreg along the entire length of the pipeline, insulate it and insert the plug into the socket.

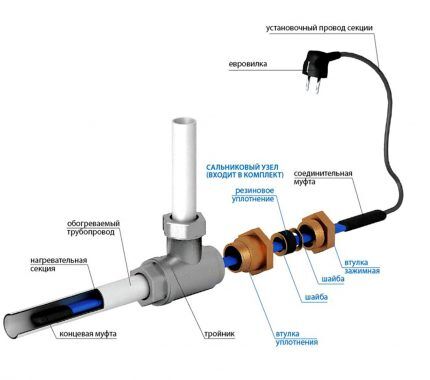

In some cases, the installation of an external cable is considered unsuccessful, for example, if it passes through floor slabs or concrete blocks of a well. Then internal installation is used.

If for external heating it is better to use a flat type product, then for internal heating a special cable with a round cross-section and especially reliable waterproofing is suitable.

Internal installation heating cable requires special care and compliance with certain rules. For example, you cannot pass the cord through nodes where threaded connections protrude from the inside - sharp edges can damage the protective sheath.

Conclusions and useful video on the topic

Video #1. Outdoor installation instructions:

Video #2. Detailed description of internal installation:

Video #1. Practical application in dacha conditions:

If you choose the right method for insulating the water supply and carry out installation work in compliance with the rules, then there will be no problems with the pipes in the winter. The insulation of the main line laid in the ground should be taken care of in advance, and open areas can be thermally insulated at any convenient time.

Would you like to tell us how you insulated the water supply line on your own country property? Is there information on the choice of material and technology for its installation that is worth sharing with site visitors? Please write comments in the block below, ask questions, post photos on the topic of the article.

Regarding the self-regulating cable, an explanation must be made: it is regulated not by the outside air temperature, but by the temperature of the cable itself. For most brands, this is 35-45 degrees (there are also high-temperature ones - 75-80). So you shouldn’t count on it not consuming electricity in warm weather. At a minimum, the water in the pipe is always below the specified temperatures.

Two years ago I installed home plumbing. And due to the low professionalism of the workers, in the coldest months I was left without water, since they did not insulate the pipe, assuring me that it was deep underground and was not afraid of frost. In the spring, I called other specialists who insulated the pipe using a “shell” of water-repellent material, but last winter there were no problems with the water supply. The material used for insulation, although expensive, fully fulfills its purpose.

My water supply goes into the cold basement of the house, and in severe frosts it sometimes catches water, although the entire pipe is insulated using Energoflex pipe insulation. I heard about heating cables that they can be used for heating. I want to use your installation technology; I prefer a self-regulating cable to save energy and nerves.

Delirium - increased pressure cannot protect against freezing. At least look at the signs...

Didn't you study physics at school? 🙂 At least repeat the basic laws...

gentlemen and others, physics has nothing to do with who has the depth of freezing -!!! That's how to lay the water pipeline! At minus 30, freezing of mixed soil reaches 2.5 meters, I laid 2.6 meters under the bottom of the foundation and there was no problem, but the supply to the bathhouse is a whole science, I laid a metafloor with an external water heater - it broke in one area, the reason: poor-quality metafloor, the wrong temperature interval was selected on the temperature controller and the temperature sensor was installed incorrectly - corrected: metal was laid, a cable with a power of 17 W/m was selected, a Chinese controller was supplied with an on-off temperature interval (+5-20 degrees), places couplings, the cable goes around a spiral with a ring (for possible replacement, including tees and valves), plus it is wrapped in self-adhesive foil, the tests were successful at min. 36 degrees, I did not try internal heating, since the system has 6 atmospheres and a pipe of 12 mm is enough for the supply to be wonderful……………