Standards for mounting distances for air ducts: calculation of geometric data of the ventilation route

A residential building must maintain all conditions for normal human life. This is an undeniable truth, isn't it? To ensure a comfortable stay in any room, complex engineering communications are laid.

You can’t do without a ventilation system. When creating it, it is necessary to comply with the standards for air duct fastening distances developed and approved by government departments. This requirement is relevant not only for legal entities, but also for private developers.

We will talk about how to correctly plan and lay air duct routes. We'll show you the best way to secure them. From the article we presented you will learn at what distance from other communications ventilation ducts can be installed.

The content of the article:

Ventilation system in a private house

The design and installation of a ventilation system in a single-apartment residential building is carried out taking into account the requirements for operational characteristics prescribed in SNiP 31-02-2001 and SP 55.13330.2016.

Ventilation in a private house can be with either natural or mechanical stimulation of air exchange, with the removal and influx of air masses through air ducts. The main thing is to maintain clean air in the premises.

Exhaust air with an unpleasant odor or containing harmful substances, such as fuel combustion products, is discharged directly outside. That is, they should not penetrate into other rooms in any way.

Be sure to ensure the removal and flow of air in the kitchen, bathroom, and boiler room. The minimum performance of the ventilation system with full or partial air exchange in a given period of time is regulated.

When organizing a ventilation system that meets established requirements and is capable of providing a comfortable microclimate, it is important to correctly determine the configuration of air ducts, take care of sealing ventilation openings, places where pipes pass through walls and ceilings in order to prevent the occurrence of cold bridges and prevent rodents and insects from entering the house.

Air duct installation rules

Air ducts are metal or plastic pipes that remove and supply air to rooms. They can have both round and rectangular cross-sections.

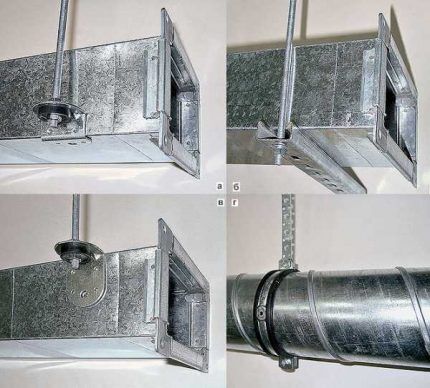

Works on installation of a ventilation system include one of the most critical stages - attaching air ducts to load-bearing building structures. Fixation can be carried out using various fastening elements - clamps, consoles, profiles, brackets, staples, punched tape. The choice of fastening type depends on the size of the air channel and the shape of its cross-section.

The finished air duct system must be reliable and resistant to external and internal loads, as well as maintainable.

It is important that it meets safety requirements, that the equipment does not pose a threat to humans and does not affect the safety of the house itself, that the noise and vibration created by air flows do not exceed the maximum permissible level, and that the weight of the air ducts is not transferred to the fans.

Air duct mounting methods

The duct can be attached directly to the ceiling, wall, or to load-bearing elements attached to them, for example, to a T-beam or I-beam. Such beams are widely used in construction.

The orientation of the air duct is predominantly vertical or horizontal; in some cases, if there is a technical need, the air ducts are installed at a slight angle.

The main fasteners used are:

- brackets;

- traverses;

- clamps;

- perforated tape.

L- or Z-shaped brackets and studs are used to secure rectangular ducts. The brackets are attached to the body of the air duct using self-tapping screws that form holes in the metal.

The studs are threaded galvanized rods. To attach the stud to the ceiling, use a metal hammer-in anchor with a spacer.

Pre-drill a hole and hammer in the anchor with a chisel. The process is similar to installing a plastic dowel into a wall. When the pin is screwed into the anchor, its spacer part opens like the petals of a flower, forming a structure that is securely held in the ceiling.

Instead of anchors, you can use other fasteners, but they will not provide the same reliability.Under heavy loads, the connection between the stud and the ceiling will weaken. As a result, the duct may move and become deformed.

If the duct is massive, it is better to choose a reinforced Z-shaped bracket. Thanks to the additional corner that will support the air duct, the structure will acquire the necessary rigidity and less load will be placed on the stud. To prevent noise from oscillating the air duct, the fasteners are supplemented with rubber seals.

If one of the sides of a rectangular duct exceeds 60 cm, not brackets are used, but traverses, also complete with studs. The traverse is a horizontal beam that can either be suspended or rest on a vertical support.

When using a traverse, no self-tapping screws are required and the air duct maintains its integrity. Placed on a support, it does not move laterally thanks to the studs that keep it in a stable position. To ensure that the air duct fits tightly to the traverse, a rubber seal is installed that dampens noise and vibration.

Air ducts of round cross-section are attached to the load-bearing surface using studs and clamps of the appropriate diameter. In this case, the clamp should tightly cover the air duct.

It can also be worn over thermal insulation. Fasteners are available in a wide range of sizes to fit standard duct sizes. Due to ease of use, installation time is saved.

It is not necessary to mount the duct directly to the ceiling. You can do it differently. If there is a metal beam (T-beam, I-beam, corner) in the area through which the ventilation main runs, place a clamp on it and attach a pin to the clamp.

In private homes, round air ducts of small diameter are often used. If the diameter does not exceed 20 cm, punched paper tape can be used as fasteners. The manufacturing material for it is galvanized steel, which meets the requirements specified in GOST 14918-80. The thickness of the tape varies from 0.5 mm to 1.0 mm. There are mounting holes for fixing air ducts using self-tapping screws.

A loop is formed from the tape and put on a pipe like a clamp. Another way is to secure the punched tape to the mounting bolt at the junction of the pipes. It can also be used in conjunction with clamps.

The advantages of this method: punched paper tape is cheaper than hardware, and installation is easier with its help. But there are also significant drawbacks. Since punched paper tape is not able to provide the necessary rigidity, vibrations and lateral movements increase.

Difficulties arise when aligning the punched paper tape in height, which is why the air duct begins to make noise during operation, and the risk of depressurization of the line increases.

Distance between fastenings

SP 60.13330 and SP 73.13330.2012 indicate how to calculate the fastening of square and round air ducts. The recommendations of equipment manufacturers specified in the instructions are also taken into account. To get the correct result, you need to know the length of the air ducts and the permissible distance between the fasteners.

Fastenings for horizontal non-insulated metal wafer-free air ducts are installed at a distance of no more than 4 meters from each other. This requirement equally applies to supports, hangers, and clamps.

The rule applies to rectangular and round air ducts whose diameter or largest side does not exceed 40 cm. For air ducts with a rectangular cross-section or a diameter of more than 40 cm, the distance between fasteners is reduced to 3 meters.

Horizontal metal non-insulated air ducts on a flange connection with a diameter or larger side of up to 2 meters are mounted with a step of no more than 6 meters between fasteners. Attachment to flanges is not permitted. The maximum distance between fastenings of vertical metal air ducts is 4.5 meters.

To connect main sections of air ducts, they can be used as shaped elements. flexible air ductsmade from polymer film. In some cases, they serve as the main elements for constructing a ventilation line.

Rings made of steel wire are used to secure flexible polymer air ducts.The diameter of the wire should be within 3-4 mm, and the diameter of the ring itself should be 10 percent larger than the diameter of the air duct. The step between the rings is no more than 2 meters.

With this type of installation, a support cable is pulled along the air duct, to which the rings are attached. The cable itself is attached to building structures in increments of 20 to 30 meters. The flexible air duct must be tensioned so that sagging does not form between the rings, reducing the pressure in the system.

Distance to other structures

The standards determine not only the distance between fasteners, but also the distance from the air ducts to the surrounding building structures. Round air ducts are placed at a distance of at least 10 cm from the ceiling, and at least 5 cm from the ceiling.

There must be a distance of at least 25 cm between the round air duct and the elements of the water and gas supply systems. The air ducts are also located at a distance of 25 cm relative to each other.

The distance between rectangular ducts and building structures depends on the width of the duct.

In the list below, the first value is the width of the duct, the second is the distance to the ceiling:

- up to 40 cm – from 10 cm;

- 40-80 cm – from 20 cm;

- 80-150 cm – from 40 cm.

Regardless of the cross-sectional shape, the air ducts must be located at a distance of at least 30 cm from electrical wires.

The connections between the air ducts must be located at a distance of at least 1 meter from the point of passage through the wall or ceiling.

The fastening is carried out in such a way that the axis of the air duct is parallel to the plane of the wall or ceiling.In order to remove condensate, the air duct can be positioned at a slope of 0.015 in the direction of the condensate collector.

Fasteners perform an important function - holding the air ducts in the designed position. The service life of the ventilation system largely depends on them. Therefore, they must have high mechanical strength to provide the necessary structural rigidity.

Made from galvanized or stainless steel, they are not subject to corrosion, are resistant to aggressive environments, temperature changes and allow you to quickly install a ventilation system without drilling or welding.

How many fasteners are required?

The type of fasteners and their quantity are determined at the design stage, taking into account the weight, dimensions, location different types of air ducts, materials of manufacture, type of ventilation system, etc. If you plan to tackle these issues yourself, you will need to do the calculations and use reference data.

The consumption rates for fastenings are calculated based on the surface area of the air ducts. Before you begin calculating the surface area, you need to determine the length of the duct. It is measured between two points where the center lines of the highways intersect.

If the duct has a round cross-section, its diameter is multiplied by the previously obtained length. The surface area of a rectangular duct is equal to the product of its height, width and length.

Next, you can use reference data, for example, standard indicators of material consumption (NPRM, collection 20) approved by the Ministry of Construction of the Russian Federation. Today this document has an inactive status, but the data contained in it for the most part remains relevant and is used by builders.

The consumption of fastenings in the directory is indicated in kg per 100 sq. m. m. surface area. For example, for round seam air ducts of class H, made of sheet steel, 0.5 mm thick and having a diameter of up to 20 cm, 60.6 kg of fasteners per 100 sq. m. will be required. m.

At installation of air ducts straight sections of air ducts together with bends, tees and other shaped elements are assembled into blocks up to 30 meters long. Next, fastenings are installed in accordance with the standards. The prepared air duct blocks are installed in the places designated for them.

Will familiarize you with the regulatory requirements for organizing ventilation in a private home next article, which is worth reading for all owners of country property.

Conclusions and useful video on the topic

Attaching air ducts to ceiling tiles:

Making clamps for round air ducts with your own hands:

What does the assembled ventilation line look like:

Installation of a ventilation system in a private house does not require the use of cranes and other special equipment, but when developing the project it is necessary to take into account the specific layout of the house and the location of building structures along the path of the ventilation main.

Approximately, “by eye” it is impossible to determine the length of the air duct links and the distance between the fasteners. To do this, you need to know the standards and, based on them, perform calculations based on specific conditions. As a result of properly performed work, your home will be equipped with an effective and durable ventilation system for a comfortable life.

Would you like to tell us about how you assembled the ventilation system in your house/apartment/office? Do you have useful information on the topic of the article that is worth sharing with site visitors? Please write comments in the form below, post photos and ask questions.