How to repair a drainage pump yourself: an overview of common breakdowns

A drainage pump in a suburban area is a kind of lifesaver in case of unforeseen situations.In design, it resembles equipment for supplying drinking water, but has the ability to move contaminated media with large inclusions.

But like any other equipment, equipment can fail. Let's try to understand the weaknesses of the unit and find out whether it is possible to repair the drainage pump with your own hands if necessary.

The content of the article:

Design of a typical drainage pump

The ability to pump water with fine gravel, large amounts of sand, and organic residues is a very useful quality when you need to pump out water after flooding or drain a pond. Drainage units are designed to work in such conditions, but exceeding the load often leads to breakdowns.

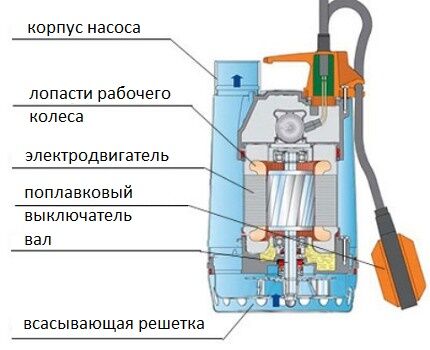

It is better to get acquainted with the internal contents of the device immediately after purchase, in order to understand which parts may fail if clogged or broken. To do this, it is not necessary to open the case or disassemble it - just study the diagram that comes with the instructions for connecting and servicing the device.

Devices for private use in summer cottages are not very powerful or have complex features. Unlike heavy industrial equipment, they are compact, relatively light (average weight - 3-7 kg), and consist of steel or plastic parts, although cast iron is still used for the production of industrial models and some household ones.

The main components of the submersible mechanism are a pump unit that pumps water and an electric motor that rotates a shaft with blades. The engine is located inside a durable housing, which is made of stainless steel or reinforced polypropylene and is double. Water circulates between the outer and inner walls, preventing cooling.

Modern models are equipped with thermal protection that is triggered when the device is overloaded. An impeller is attached to the axial shaft - a screw device that supplies liquid inside the housing. When the unit is turned on, the impeller begins to rotate, taking in water from outside and pushing it along the walls to the outlet.The first portion of water is replaced by the next one - and so on until the mechanism stops.

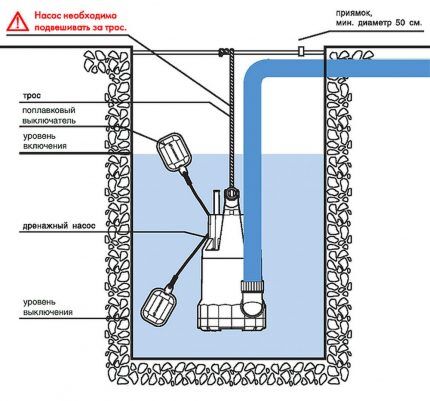

Regulates the frequency of operation float switch. It monitors the liquid level in a tank or natural body of water, and if it drops sharply, it turns off the device automatically.

As you can see, drain pump device It’s quite simple, and if you’ve ever disassembled and cleaned a submersible well pump, you can handle this category of equipment. The fecal unit is slightly different, having an additional unit for crushing particles that are too large.

Differences between submersible and surface models

The submersible apparatus is useful for cleaning deep tanks, for example, just commissioned well. The first liquid accumulated in it cannot be called drinking, since there are many large inclusions of sand and clay. Throughout the day, it is necessary to pump out the contaminated liquid so that clean, usable water comes in its place.

Unlike submersible surface pump not used for deep tanks, it is more suitable for pumping water from a pool or basement when it is flooded. A hose is placed at the bottom of the container to receive dirty water, the second hose is used to drain wastewater.

If the pump is used in an emergency, it is appropriate to use a float device that will control the critical level of water rise. The advantage is that the design of the mechanism allows you to pump liquid with large pieces of dirt - up to 5 cm (less often - 10 cm).

It is clear that the surface type aggregate differs in its structure. The working shaft and wheel are fixed inside the metal casing, and the engine can be different: for centrifugal products - single-phase with external ventilation, for self-priming – asynchronous two-pole.

Despite the contamination of the pumping environment, you should not allow the pump to operate with liquid in which gasoline, kerosene or other petroleum products and chemicals are dissolved.

Reasons for failure of drainage pumps

Both new equipment and equipment that has been in use for more than one year can break down. A newly purchased device may fail due to a manufacturing defect during assembly: a damaged piston or an incorrectly connected valve.

Often breakdowns occur due to inept installation if:

- the unit was lowered to an insufficient depth;

- allowed air to enter the water intake compartment;

- The water intake hole is above the water and not covered with liquid.

These shortcomings can be easily corrected with a simple check, but it is better to avoid them.

Most often, problems arise during the operation of the equipment. The manufacturer sets control parameters within which it is necessary to act (they are stated in the technical data sheet of the product).If the equipment is used incorrectly, not for its intended purpose, it simply will not withstand the load.

For example, for a drainage apparatus it is normal pumping dirty water. This means that problems can arise if you start moving clean drinking water (for which borehole And well models). On the contrary, too large contaminants clog the filters, as a result of which the pump’s operation stops.

Troubles also await if the equipment is running idle, in a “dry” mode - overheating will certainly occur, which cannot always be corrected on your own. As a result of an oversight, the matter may end in expensive service repairs.

Lack of prevention and rare technical inspections can also cause breakdowns. Many troubles can be avoided by preventing them by replacing one of the parts or basic cleaning.

Malfunctions and ways to eliminate them

There are a number of opportunities to repair the equipment yourself, provided that the broken part can be replaced with a new one or a simple technical procedure can be performed (for example, cleaning). To do this, you will have to disassemble the case, perform diagnostics, identify the problem and select an identical part.

Available actions include replacing the capacitor, impeller or float, repairing the electrical cable, fixing the shock absorber, and removing large pieces of clay and sand stuck inside the housing.

If the cast iron body is cracked, the valve has failed, or the winding has stopped functioning, you should contact a service center or think about buying a new pump. Inexpensive drainage devices made in China are inexpensive, so it is not advisable to order serious professional repairs.

Failure #1 - the power cord is faulty

The flexible element - the cable - is always at risk, since due to regular twists and kinks (which often happens during transportation and reinstallation of equipment), the wires under the layer of plastic or rubberized protection are torn, resulting in the power supply to the pump being cut off.

It is necessary to find the break point and make a connection. This operation is easy to carry out if the break occurs near the plug - you just need to clean and connect the wires, finally carefully insulating the work area.

A cable break in the pump connection area requires more time to repair. First, you need to remove the equipment from the water, wipe and dry it, then disassemble it to get to the internal connection unit. Get ready for the fact that instead of hexagonal holes you will encounter triple ones, which will make it difficult to select a screwdriver.

The cover should be removed carefully, without jerking or effort. By unscrewing the bolts holding the tension element, you can examine the cable and determine the area of \u200b\u200bthe break. We remove the worn piece, mount the cable in its original place, attach the tension element, and fix the bolts.

Failure #2 - water supply stopped

The engine is running properly, but the fluid has either stopped flowing altogether or is flowing in small uneven jerks.

There may be several reasons for this strange phenomenon:

- Part of the supply line is clogged. This is an outlet pipe or supply pipe. A kind of blockage arose from tufts of algae and pieces of clay. It is necessary to disconnect the pipes and clean them. It is possible that the pipe length is longer than recommended by the manufacturer, and therefore there is not enough pressure to deliver the required power.

- The impeller is worn out. Blades are bent or damaged. You should disassemble the device, replace parts, first visually (as far as possible) determining the cause of the malfunction.

- The fluid is oversaturated with dirt and debris. Therefore, the water has a thick consistency and is difficult to pump. We solve the problem by raising the suction hole a certain distance from the bottom, where sediment accumulates.

- Engine power has noticeably decreased. What can be determined even by sound. There may be problems with the electrical supply, failure of bearings, or depressurization of the oil compartment. It is necessary to disassemble the case to determine the cause of the breakdown and replace worn parts.

The most common problem is a clogged filter. To clean the screen and suction port, you can try running some clean water through the pump. If this procedure does not help, you should disassemble the housing and clean all chambers, removing pebbles, algae and wood chips.

When disassembling the unit, be sure to use the manufacturer's diagrams or instructions. They will help you remove parts sequentially and quickly find the bolt attachment points.In some cases, worn fasteners or loose nuts cause parts to become misaligned, which also affects the performance of the machine.

Failure #3 - the engine does not start

You connect the power supply - but the pump does not work, does not make noise and does not pump water. Be prepared to have to examine all the equipment.

Here are the most common causes of engine failure:

- Power supply interruption due to broken wires. We check the cable by touch and find the break point. If the emergency area is in the area of connection to the pump, we act as described above.

- The stator winding has failed. Happens due to dry operation. If you cannot replace it yourself, contact a specialist.

- Bearing jammed. We check the part for suitability and clean or replace it based on the diagnostic results.

- The suction device is clogged with debris. We clean the blades and grille, check the integrity of the operating elements and the mesh.

- The float switch is broken. To check its functionality, you need to close the relay. The problem may be in the wire connecting the float to the pump.

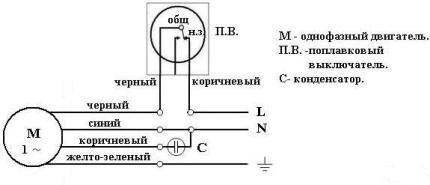

If the capacitor fails, replacement is required. Some models provide special access to it, which is a separate hole in the case.

Failure #4 - the pump turns off on its own

When the pump is turned on, it starts to work, but after some time it stops spontaneously.Most likely, the protective mechanism is triggered due to engine overheating.

The cause may be a heating cable. It is worth checking the compliance of the mains voltage and the parameters specified by the manufacturer. If the data does not match, you need to purchase a stabilizer.

Shutdowns can also occur due to the blades being clogged with debris. In this case, we recommend performing a full cleaning procedure, that is, opening the housing, cleaning the internal chambers and impeller, and checking the filter.

If blockages occur quite often, re-read the instructions for the product to clarify the size of the fractions. Perhaps the pump is not designed for pumping liquid with large particles of debris - only a fecal pump is suitable for grinding

Failure #5 - turning on the pump knocks out the electrics

When the pump is turned on, plugs fly out or wires burn out. The reason should be sought in the parts directly responsible for conducting electricity - the cable or stator winding. The serviceability of the wires can be checked using a tester; if a worn section is detected, the entire cable should be replaced or (if the break is near the end) shortened.

Winding repair is a labor-intensive task and requires special knowledge. Even with a carefully installed secondary winding, a short circuit cannot be ruled out. If you don’t have time to tinker with a burnt-out part, take the device to a service center - perhaps, after diagnostics, they will advise you to buy a new pump.

Preventive measures and regular maintenance

As you can see, the cause of wear of parts can be both inevitable wear and tear and violation of equipment operating rules. To make the device last longer, try to follow the manufacturer's recommendations. For example, position the housing so that the suction device is at a certain distance from the base of the tank and does not capture coarse particles.

At least once a year, check the serviceability of the cable and internal parts by disassembling the case as much as possible. Perform preventive cleaning, which will increase the service life of parts several times. Do not confuse the drainage device with the fecal one - it does not have a special grinder and cannot cope with the movement of large inclusions.

Conclusions and useful video on the topic

Videos from craftsmen will help you properly organize the disassembly of pumps of various brands and troubleshoot problems yourself.

Stator overheating due to violation of interval operating mode:

Features of Pedrollo pump repair:

How to fix the Vortex drain pump:

Disassembling the Praktika DNG-400 pump:

Repairing a drainage pump with your own hands is quite possible and advisable if cleaning or replacing a spare part is enough to repair it. Complex emergency cases - rupture of the housing or rotating shaft - cannot be repaired independently. Elimination of serious problems should be entrusted to specialists, and if replacement is impractical, then buy a new pump.

If after studying our material you still have questions, or you have encountered a drainage pump breakdown and know how to get out of such a situation, please leave comments. We are very interested to know your opinion.

Hello! A problem arose - I disassembled the pump, the bearing was covered. The person replaced... I didn’t disassemble the engine myself... and after all the procedures done, the engine turned in the opposite direction - what caused this?

The capacitor was most likely connected incorrectly, swap the contacts.

Good afternoon. What can happen if the float is inserted, but the water does not pump, but when the float is lifted into the air, the pump immediately starts pumping?

Swap the ends of the working winding

Hello, the pump starts, runs for 2-3 seconds and then stops.

Good time. Most often, the drainage system stalls if the impeller is blocked by something. Apparently, a pebble hit, but that's the best case scenario. It’s worse if the capacitor or motor is broken - you need to take these problems to the workshop.

The electric cable on the drain pump near the housing broke, replaced it. How to seal the connector between the cable and the housing?

Hello. Heat-shrinkable adhesive sleeves are not cheap, about 1000 rubles, but your life is also dear to us :) Good luck!

Hello! A malfunction occurred - when the float was lowered, the pump did not turn off. I replaced the float, the problem did not go away. What could be the reason?

The KLEVER 400W pump has a broken cable in the housing, I can’t take it apart to replace it.There is no fastener on top. How to get to the cable?

Unscrew from the bottom, there should be 4 more screws there.

Good evening. Please tell me, the drainage pump has stopped turning on. I disassembled the upper part where the wires and capacitor are - everything is wet. There was no closure...

Hello. Most likely, the protection worked and therefore no short circuit occurred. What to do... Disassemble, dry and look at where it has oxidized, clean, and also inspect the engine. Check the system. If you can’t figure it out yourself, contact a specialist.

I have a Patriot F400 pump. Pumps water from a fire pond to water the garden. I’ve been using it for 4 years now. During this time, I’ve already disassembled the body 2 times—the clinic’s stones and the impeller. But recently I encountered a problem - the pump does not start, but the impeller is clean and the shaft can be turned manually without resistance. I disassembled the float, but closing the contacts there did nothing.

How do I disassemble the motor housing? There are no visible screw heads. All I can do is separate the motor housing from the rotor housing. Or is this model not collapsible?

The most important thing in the topic is missing - how to properly and competently fill the grease into the oil seal so that water does not get into the pump?

Hello. A topic like this requires a separate lengthy article. We will notify the administrator that our guests are showing interest in her and I think she will appear on the portal soon.

Good evening. Tell me, the pump hums, but does not spin. It didn't jam.

Alexander, most likely the stator winding or condenser.

Hello. I ran into a problem. The septic tank rotates but does not draw water. Rotates in the right direction, completely submerged under water. Immersion depth is approximately 1000mm. The height of water rise is approximately 4000 mm. pipe diameter 50 mm. Tell me, what could it be?

Hello. Problems with windings, check valves, loose parts, napkins, rags, large pieces of toilet paper that the pump cannot pump through the diameter of the pipe (we recently encountered this). If possible, test with clean water.

Where can I buy a motor for a submersible pump?

Hello. Stores that sell pumps also often sell spare parts for them. You can ask for it to be delivered to order. Depending on the manufacturer, sometimes you can place an order from an official supplier on the company’s website. You can also use the services of an online store, but look at customer reviews.

Belamos Omega 25 drainage pump: when turned on, the shaft does not rotate, the pump hums. If you apply a small rotational force to the impeller, the pump begins to pump normally. Tell me, what can I do on my own? Or should I take it for repair?

Hello. You can inspect the impeller for damage on your own. If in doubt, take it in for repair or just ask a knowledgeable person to take a look.

Hello! The PATRIOT F400 pump hums when turned on, but does not turn the shaft; the condenser has already been replaced (it is working). If you rotate the shaft while humming, it starts working. What could be the problem?

Hello. It's difficult to guess without diagnostics. They changed the condenser too early, so if the impeller rotates easily by hand, that’s the first suspicion, but if it jerks, then there’s a different reason. In your case, it is necessary to analyze and test for a break in the starting winding.

Good afternoon. I have this problem. The Vikhr DN900 pump stopped working. The engine hums, but does not start. After opening it, I found water inside the case (where all the wires are). There was a lot of water, and water was also leaking from the engine. When you turn on the pump, the engine starts and runs only if you turn the pulley by hand. At the same time, the engine does not smoke and does not produce electric shock. Tell me how to revive the pump and where to start the repair?

Hello. The engine starts manually, and there is a hum before it starts? Disassemble the pump and inspect for oxidation, and first of all, pay attention to the impeller. Most likely, the problem is in this area.

It was the starting winding that cracked on the stator.

Opera drainage pump. The engine is humming. The shaft tries to turn in small jerks, but does not turn. The impeller is intact. What could be the problem?

Hello. The pump was working and pumping water, then stopped and stopped pumping water. The impeller spins but does not lift water. I put it in the bucket and it barely shakes.

Hello, I have encountered a problem, the drainage pump RD-SPS-400/5 for some reason works in the opposite direction, maybe someone knows why

Well.

Submersible pump Fikalnik Prima NSF 450. The pump works but doesn’t pull water, disassembled it, cleaned it, no dirt, the engine runs, turns on and off, everything is fine, but it doesn’t push water.

The drainage pump Vortex FN110l, when it turns on, it only hums, it starts working only when you turn the impeller. Tell me how to solve the problem.

Hello.

The article briefly touches on the chafing of the electrical cable insulation and does not say a word about the best way to fix the problem in the event of a break at the entrance to the pump, including the break of the rubber band into which the cable goes. You won't be able to achieve a seal with electrical tape, is there a proven method of filling it with something sealing?

Good afternoon

The dirty water pump works, but does not gain power immediately. Accordingly, it does not pump out. What is the reason,

What thread is on the impeller of the pump Caliber NPC-400\30 - Left or right!! I can't open it!!

Good afternoon, please tell me! The pump either pumps or doesn’t pump, what should I do and what is the problem?

Hello. We have a VARIOLUX submersible pump. We needed to pump out water, but turned it on before submerging it in water (by accident). It hummed, which means the engine started and immediately fell silent. And that’s it... It doesn’t buzz anymore, even when immersed. What could have happened? Does it make sense to take it to a workshop or is it cheaper to buy a new one?

Thick rubber on the pump cables, insulation on the pipes is still intact so that water does not enter the pipe

Sergei, put on a heat-shrinkable tube of the appropriate diameter.

There is water in the WRX2-20 pump in the engine, what should I do?

Good afternoon.

If water gets into the electric motor, expect it to burn out quickly. More precisely, its winding will burn out. Here are several reasons:

1. Depressurization of the housing. This happens when the pump vibrates strongly.

2. Depressurization of the connection between the power cable and the housing. Many people lift the pump by the cable, which is wrong.

3. Water penetrates the cable if there is a defect in its sheath. This usually happens when a heavy object, for example, the pump itself, falls on the cable.

What to do in this case? First of all, the engine must be dried. There is no point in expecting a dry motor to continue working. It needs to be shown to a specialist. He must first find the reason for water getting inside. Secondly, open the motor and determine whether the winding insulation is broken. If this defect is detected, then the winding must be rewinded. True, it is not a fact that the rewound one will work for a long time.

Fecal pump “Vikhr”, DN-900. They rang, the conder is intact, the main winding is intact, but the starting winding is dead! The engine housing is not dismountable along the way, there is a groove in the center and that’s it! Is it subject to analysis? Or replace the entire pump?

Good afternoon. To troubleshoot the problem, you should contact a specialized organization.

More precisely, the engine is surrounded by a non-dismountable skirt!)

The pump Caliber NPC 550/30 NK is jammed, the engine hums, but the engine does not rotate, a Y screwdriver is needed to disassemble it, the engine itself is rusty, I could barely pull it out of the body after watering it with Vedashka, is it worth messing around with, maybe it’s better to buy a new one?

The problem is there is a drainage pump from the company Gilex 200/10. Stopped working. Plugged into the network does not buzz and does not pump, does not show any signs of life. Worked for 5 years. Tested the bend wire with zero results. What could be the cause of the breakdown. And what measures can be taken do the repairs yourself

Hello, I have this problem, the Vortex DH900 submersible pump is humming, everything seems to be spinning, but the water is not pumped out, and this happens, it stops buzzing, when you shake it, it starts working, what could be wrong? Will it get dirty?

Thank you for SUCH an article, without “water”, the very essence. The question remains whether it is possible to increase the pressure at the outlet of the GFP 370 submersible pump. Problem: the Junkers geyser does not switch to heating mode due to low water pressure from the pump connected to the inlet of the column. Is this possible or do I need a different pump?

Hello. Where in Kyiv is the repair center for the submersible pump EXPERT garden 1300 BT/