Self-priming water pumps: types, operating principles, operating recommendations

Self-priming pumps are a special type of surface equipment designed to increase the working life. Their moving parts are always cool, seals are not damaged, and the motor operates flawlessly. However, due to the large assortment, it can be difficult to settle on a suitable model. Do you agree?

Everything you need to know about self-priming water pumps can be found on our website. We have described in detail the principle of the design and operation of units of this type, and the differences in design are given. The information we provide will help you make an informed purchase.

We described in detail the different options for self-priming pumps and provided recommendations for operation. Useful photo and video applications will help you deepen your knowledge.

The content of the article:

Features of self-priming units

When purchasing a unit for use in a suburban area, you should analyze a number of factors that determine the desired category.

These include:

- source depth;

- distance from source to home;

- pressure level;

- quality of supplied water;

- water consumption.

Typically, the listed data is taken into account when calculating the performance of the device, but they are also useful when choosing a pump based on the type of suction.

There are self-priming and normally priming devices.The difference lies in the design that regulates the refilling process if air gets into the system.

Normally suction pumps include submersible and semi-submersible pumps, the operation of which occurs if the liquid from the source moves into the working compartment by gravity. When air enters, automatic protection against “dry running” is triggered and the operation stops, since the device cannot operate idle. The pump has to be restarted.

Self-priming models are designed to remove air independently without human intervention. This happens due to design features: in the upper part of the working compartment there is a plunger through which air is removed. A check valve prevents him from returning.

Modern versions with built-in valves perform independent refilling, eliminating the need for constant monitoring of the equipment.

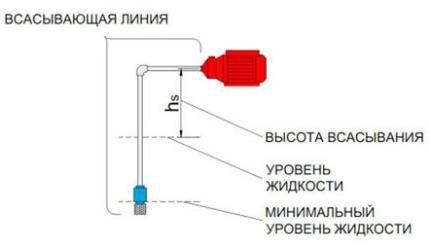

The refilling process is also associated with the low lifting height of self-priming units - up to 9 m. It is important to ensure that the working chamber is constantly filled with water, and the shorter the supply line, the faster the process of moving water occurs.

Most often, self-priming pumps are part of a pumping station with a hydraulic accumulator, a suction pipe (or ejector), shut-off valves and instrumentation.

Correct installation of the suction line

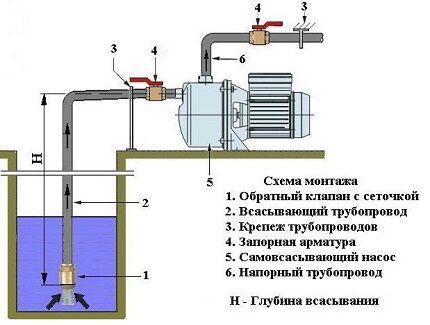

At water supply system installation It is important not only to install a self-priming pump or pumping station, but also to install a suction line.

When creating a sealed water supply system, you should check the ratio of the diameter of the pipeline to the diameter of the pipe, and also shorten (if possible) the length of the entire line as much as possible.

The longer the suction line, the higher the resistance and, accordingly, the lower the pressure. The presence of leaks can lead to equipment breakdown - this condition is relevant for centrifugal models that are not intended for pumping air-liquid media.

Pay attention to the location of the pipes.The suction line should not have kinks, kinks, or a complex prefabricated structure that rises above the level of the pump; otherwise, air pockets may form that disrupt the suction process and are difficult to remove from the system.

As additional equipment installed directly on the highway, use check valve (or a simple non-returnable analogue) and a filter. Thanks to the valve, water is retained in the pipeline and does not flow back, thereby protecting the pump owner from repeated fillings.

The filter protects the equipment from the ingress of bottom sediment with large inclusions, pieces of aquatic plants, and clay impurities.

Is it possible to replace a self-priming model with a conventional pump? If there is no other way out of the situation, then they do so - during repairs or purchase of new equipment.

However, do not forget about some nuances:

- you will have to completely fill the pump chamber and line with water before turning it on;

- it is necessary to avoid the entry of air, otherwise the equipment will fail;

- filling should be done after each “accident” caused by depressurization of the water supply system.

Practice shows that users of self-priming pumps are in no hurry to switch to conventional ones, especially since the choice of equipment is often dictated by optimal suction conditions.

Centrifugal self-priming pumps

A suitable option for autonomous use in a private suburban area is a centrifugal self-priming pump, which pumps not only clean water, but also media with small inclusions - for example, sediment from a pond.

It copes well with liquids that are a mixture of water and gas. The equipment is surface-mounted, that is, it is installed above the water surface, and the process of rising water is ensured by internal vacuum in the suction line.

Types of structures and their features

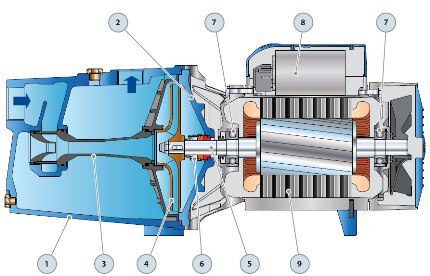

It is necessary to familiarize yourself with the design of a self-priming centrifugal pump in order to be able to troubleshoot and perform regular maintenance. The unit is a simple mechanism, enclosed in a durable spiral-shaped case with a lid; the case material is stainless steel, cast iron, plastic.

Inside there is an impeller (steel or polymer), equipped with blades turned in the opposite direction. In addition to the impeller, important parts are the diffuser and the ejector (Venturi tube).

Thus, almost all parts are static, and movement is determined by the only dynamic element - the impeller disk(s).

The design of the pump means easy access to the main part for routine inspection or minor repairs (for example, cleaning or turning). Since the device is located outside, unlike its submersible counterpart, it is always possible to inspect it and replace parts.

Centrifugal models are more massive than vortex models, but they are much quieter and are capable of pumping dirty water with inclusions of the middle fraction. For heavily polluted environments, special drainage pumps are designed, and if additional grinding is necessary, fecal pumps are used.

When choosing a unit from a supplier, inquire about the possible configuration: in addition to an electric motor, a gasoline or diesel engine is used, but for dacha use, electric equipment is more optimal. With regular preventive inspections and maintenance, the service life of a centrifugal pump reaches 20 years.

Model specifications vary, but averages may look like this:

- temperature inside the system – up to +35ºС;

- outside air temperature (at the pump installation site) – up to +35ºС;

- lifting height of the suction line – up to 8 m;

- the highest pressure in the system is 6 bar;

- motor – two-pole asynchronous (protection class not lower than IP 44).

Most of the parts are made of stainless steel; graphite or ceramics are used as the material for the mechanical seal.

Thus, the self-priming unit is very similar in structure to a conventional one. centrifugal pump, with one difference: the process of liquid recirculation occurs inside the housing, and not in the remote line.

The water fill and drain plugs, the stand for mounting to the engine, the location of the pipes connecting the device to the pressure and suction pipelines are the same as for simple equipment.

Features and principle of operation

Through the pipe, water flows from the suction pipe into the housing and fills the entire space, after which the impeller is automatically activated.Under the influence of centrifugal force, the liquid is displaced from the center to the peripheral areas and moves under pressure into the pressure line, also connected through a pipe.

As the pressure in the central part decreases, water is again sucked into the housing from the suction pipeline. The frequency of suction and ejection is the basis for the continuous supply of water by centrifugal equipment.

The number of impellers in pumps can be different, from one to several (single-stage and multi-stage), but this does not change the principle of pumping liquid into the housing and further along the main line.

Scope of application of centrifugal units

Centrifugal self-priming devices are capable of pumping liquids that vortex-type models cannot handle:

- viscous media;

- liquids with solid particles;

- abrasive liquids.

In this regard, this category of pumping equipment is often used in production, for example, for pumping petroleum products. In private use, the unit will not stagnate if the owners use a country pond or other body of water to water the garden or vegetable garden, the water of which is not clean and transparent.

The device is capable of moving liquid with thick bottom sediment, pieces of mud and other aquatic plants.

Household pumps also do an excellent job of pumping clean water, so they are also good for creating an autonomous water supply for a building and adjacent buildings (bathhouse, summer kitchen).The powerful pump is suitable for equipping a rational watering system not only for beds, but also for lawns, greenhouses, flower beds and gardens.

When starting up, the water supply system self-priming process occurs, which saves money on maintenance and guarantees stable operation.

Vortex impeller pumps

Among the self-priming modifications there is a group of vortex pumps, however, unlike centrifugal analogues, they are not suitable for pumping viscous media.

The presence of solid inclusions in the water must be excluded, otherwise the performance of the equipment will be impaired. Vortex-type pumps are simple to design and maintain, but have lower performance and low efficiency.

Device diagram and operating principle

The internal parts of a vortex pump differ little from analogues of centrifugal equipment.The main dynamic part is the impeller disk, equipped with blades arranged in a circle.

The blades rotate inside a kind of channel connected to the inlet and outlet pipes. The liquid enters through the suction pipe, under the influence of rotation of the wheel it twists and moves along a helical path towards the outlet.

The repeated presence of liquid in the space between the blades generates additional energy and pressure, which raises the water to the required level, and this is the basis of the operating principle of a self-priming vortex pump.

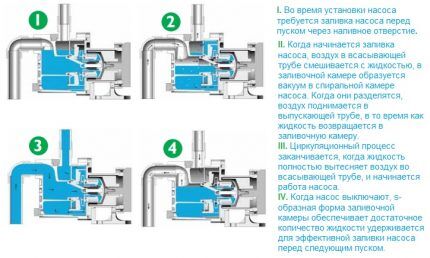

The sucked air is mixed with the liquid, then the mixture is again divided into two components: the air is discharged outside, and the liquid continues to circulate in the working chamber. After all the air has been removed, the chamber is completely filled with water and put into operation using the principle of centrifugal equipment.

A mandatory element, like centrifugal equipment, is a check valve that performs two functions:

- prevents backflow of air;

- ensures that the working chamber is filled with water.

The maximum height of water rise, which is provided by vortex self-priming equipment, is 8 meters. Vortex pumps differ from centrifugal pumps in two fundamental qualities: they do not pump dirty media, but do an excellent job of moving a mixture of air and liquid.

The low efficiency (from 25% to 45%) is explained by the fact that a lot of energy is spent on the fluid injection process.For this reason, owners of suburban areas prefer centrifugal units. Vortex equipment is usually thought of when it is not possible to install a more productive analogue.

Benefits of domestic use

The advantage of this category of self-priming pumps is their compact size and increased pressure (5-7 times more than that of centrifugal devices). Thus, it is rational to use them when servicing a water source located at a far distance from water points, provided that greater performance is not needed.

An example would be pumping water from a well, the lifting height of which does not exceed 7-8 m, into the so-called “working area”, where garden plantings, beds, and greenhouses are usually located. Considering the unevenness of the terrain and the curve around country houses, you should count on a pipeline up to 100 m long, which means that a lot of pressure will be required.

In addition to the use of vortex modifications in autonomous private water supply systems, they are used for extinguishing fires, ventilation devices, and in thermal installations.

Ejector - a device for deep sources

Self-priming pumps with a built-in ejector are designed for open natural reservoirs, wells and wells, the depth of water intake in which does not exceed 7 m or 8 m.

Typically, the technical characteristics of this category of equipment are reduced to the following parameters:

- productivity – 4-5 m³/h;

- pressure – 4-6 bar;

- pressure – 50-60 m.

Together with a hydraulic accumulator, pressure switch and a set of automation, such modifications form efficiently operating pumping stations. At some distance from the building, where the main water collection points are located, there is little surface self-priming equipment; an additional mechanism is required.

You can increase the suction power by using remote ejector, which copes with the rise of water located at a depth of 35-40 m. Industrial models of ejectors are able to work effectively if the water surface is at a depth of 19-20 m. The long distance to the source is also not an obstacle for the ejector device.

When using a remote ejector, the efficiency of the pumping station drops sharply - up to 30-35%, but the noise level characteristic of built-in ejectors is reduced.

Conclusions and useful video on the topic

The presented video materials will help you understand the design and operating principle of self-priming equipment.

Video #1. Pump assembly from the Asterion company (UP series):

Video #2. Operating principle of a centrifugal self-priming pump:

Video #3. Professional review of Aquario pumps (AJC series):

Centrifugal and vortex self-priming pumps are the most suitable equipment for private use in suburban areas. With their help, you can create a water supply or irrigation system.

But remember that maximum efficiency can be achieved only by carefully analyzing the conditions of use of the pumping station and studying the technical characteristics of the selected model.

We are waiting for your stories about your personal experience of pumping water with a self-priming pump. Please leave comments in the block below. Here you can ask questions on points of interest and share useful facts.

We chose a pump to build a pond and waterfall. It was necessary that the pump could be turned on/off automatically, be unpretentious, not stuck, could start on its own, and not become clogged by sand and stones from the bottom of the reservoir. We chose a simple centrifugal one, the cheapest one we found, since we needed a small flow of water, and not an imitation of a mountain river. The pump worked flawlessly in the summer, but did not survive the winter; it was torn apart by frost due to unaccumulated water, which stagnated due to improper installation. They replaced it, and the new one has been in service for 5 years without any complaints.

About four years ago, when they decided to organize normal water supply in a rural house, I had to carefully study this issue. Moreover, during the process we were forced to test several different types of pumps. Well depth: 8 meters to water plus a water column of 6 meters. The vortex pump has proven itself best (our model is not the same as here). True, over the years it has become worn out and will soon have to be either revived or replaced with a new one. Maybe I'll have to re-read it again.