How to choose a pump for pumping dirty water: selection rules and review of the best models

Happy owners of suburban areas know from their own experience that solving the problem of pumping out dirty water is quite problematic without the use of a garden pump.This useful device will help you empty a decorative pond in the garden in no time, and, if necessary, pump out a basement flooded with flood waters.

What types of equipment the modern market offers and how to choose a pump for dirty water will be discussed in the article.

The content of the article:

Design features of devices

The main purpose of pumps designed for pumping is to drain storage tanks and remove accumulated moisture during floods. And in case of emergencies, empty flooded basements and cellars.

Modern models of pumps for pumping dirty water can be used to solve many problems:

- clean the well shaft from silt and sand deposits;

- remove “bloomed” water from an open reservoir in the garden;

- used when constructing a drainage system.

Unlike downhole devices, such pumps are capable of passing fibers, solids and small stones. Thanks to this, they are indispensable universal assistants when performing household tasks.

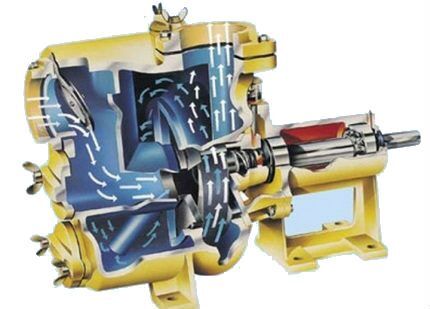

The design of any garden pump for dirty water has a similar configuration.The device consists of a metal or plastic housing, inside of which an electric motor and a pump unit are placed.

When the electric motor is turned on, a vacuum is created inside the housing. Under the influence of low pressure, the liquid is sucked into the chamber, through which it moves to the outlet hose and is forcefully pushed out.

Depending on the method of creating a vacuum inside the device chamber, pumps are divided into three groups:

- Centrifugal – they work due to the fact that under the influence of rotation of the wheel blades and the working part, the liquid is drawn into the body. Under the pressure of centrifugal force, it is pressed against the wall and then pushed out into the outlet hole.

- Vibrating – are based on the influence of the electromagnetic field created by the coil. A metal core equipped with a flexible diaphragm, retracted into the coil, creates low pressure, under the influence of which liquid is sucked into the hydraulic chamber. When the curved diaphragm returns to its original position, the pressure inside the chamber increases and water is pushed out into the outlet pipe.

- Vortex - work by rotating a metal disk with blades, called a vortex wheel. Under its action, the water twists into a vortex spiral, creating a powerful outlet pressure.

To pump contaminated liquid at the household level, site owners mainly choose vibration and centrifugal type devices.

Vortex-type models for pumping water with contaminants and inclusions are used extremely rarely, since they are very sensitive to suspended particles in water. We also recommend that you read our other material, in which we described in detail principle of operation drainage pumps and posted tips on their selection.

Types of pumps for dirty water

Depending on the method of water intake and the location of the unit body relative to the tank, garden pumps for dirty water are divided into two types: surface and submersible.

Surface models

This range of units are systems that are not immersed in water. They are placed near a reservoir, and water is collected by submerging a deformation-resistant suction hose or pipe.

The body of surface type pumps can be made of plastic or metal. Units with a plastic body operate quietly and are inexpensive. But plastic is a rather fragile material that can withstand only minor mechanical loads.

Pumps with a metal body, although they hum quite loudly during the pumping process, are not so afraid of shocks. And therefore they are famous for their longer service life.To slightly reduce the level of “growling” that occurs during vibration when pumping water, experts recommend placing the device body on a special platform equipped with a rubberized mat.

When installing the unit in non-hermetically sealed pits, it is recommended to fill the bottom of the substrate with crushed stone or gravel. Bulk materials will simultaneously perform two functions: reduce vibration of the housing and absorb excess moisture.

Among the main advantages of surface aggregates it is worth highlighting:

- Easy to use. Thanks to their compact dimensions and low weight, they are convenient to move around the territory, installing them in the right place. In case of bad weather, you can always put it indoors.

- Versatility of use. To start the device, it is enough to install it on a level surface, place the end of the suction hose in a filled tank, and at the final stage, connect it to the power supply.

- Reasonable price. The wide price range of surface pumps on sale allows you to choose a model that will satisfy the wishes and financial capabilities of any consumer.

The only “disadvantage” of surface aggregates is the limited depth. Most models can work without overload only at a depth of five to seven meters.

But it is worth considering that the further the unit is removed from the water intake, the lower its suction capacity. For this reason, the location for installing the device should be located as close as possible to the water intake.

Single-phase low-power devices are more suitable for occasional use. With frequent use, there is a high probability of their rapid failure. Since in winter, when pumping water using surface pumps, there is a high risk of the system freezing, it is better to move them indoors or wrap them up at this time of year.

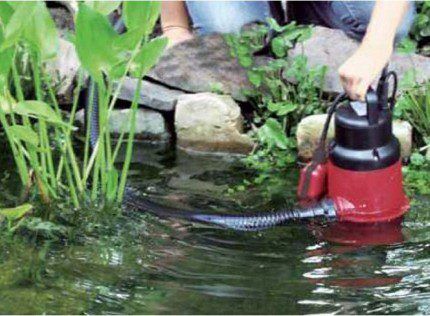

Submersible devices

Submersible models differ in that water is drawn into these devices directly through a pump without using hoses. The units are completely immersed in water and lowered to the bottom of the water intake.

Submersible models are characterized by relatively silent operation. During operation of the device, you only need to monitor the water level so that it does not fall below the critical level, and the pump does not suck in air, that is, it does not run dry. To avoid this, preference should be given to models equipped with float switch.

When working at great depths, installation in the ejector housing helps ensure suction stability. Thanks to this, the device will function normally even if there are air pockets in the system.

Submersible pumps are famous for their good resistance to temperature changes and the effects of aggressive agents, which is especially valuable when using them for arranging drainage systems. After all, dirty water can be saturated with various kinds of chemical compounds, as well as numerous alkaline and salt impurities.

Powerful three-phase devices are capable of pumping contaminated water, the diameter of solid particles in which reaches 50 mm. Such units are equipped with mesh filters with wide chambers. Through them, contaminated water, along with debris and fibers, is freely pumped without clogging the system.

Criteria for choosing wisely

When choosing a suitable model for household needs, you should focus primarily on what functions it is designed to perform and what characteristics it has.

Area of application of the unit

Planning to use the unit only for watering garden beds from a nearby reservoir or to drain a flooded cellar, you can get by with a device with a capacity of 120 l/min.

The size of solid elements that the unit can “digest” is indicated in the instructions for the specific model. On sale you can find models designed only for slightly polluted water, the structure of which may contain only a small amount of sand. There is also a wide range of units that can successfully handle even small stones.

When planning to use the unit for pumping dirty water, including fibrous structures and various-sized debris, it is worth considering the option of purchasing fecal pump.

In addition, units of this type are created from materials with increased strength and are not afraid of exposure to aggressive environments. Therefore, they have a longer service life than conventional garden pumps for dirty water.

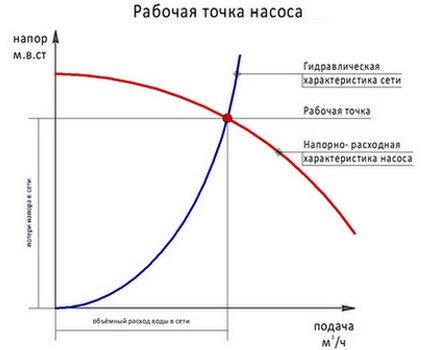

Performance and pressure

When purchasing a pump for dirty water, pay special attention to its technical characteristics:

- Performance – the amount of liquid pumped per minute.

- Pressure – the ability to push water to a certain height.

When calculating the required power of the device, it should be taken into account that the ratio of vertical and horizontal lengths will be 1:4. This means that one meter of vertical pipeline will correspond to four meters of horizontal one.

If you have doubts when performing calculations to select a device, additionally consult a specialist.

Suction valve location

The suction openings may be located in the bottom of the device or in the upper part above the engine compartment. Devices whose suction valves are located at the bottom of the housing demonstrate much greater efficiency. They are able to pump water out of the tank practically without any residue.

To drain ponds and filled tanks, it is worth choosing units whose suction valves are located on the body in the upper part. “Upper” pumps are more durable due to the fact that placing the suction pipe above the engine compartment reduces the risk of damage to the working chamber when large particles enter to a minimum.

When working with pumps whose suction holes are located in the bottom of the device, experienced owners recommend placing the units on special stands.

Auto shut off float

Although automation increases the cost of equipment, it helps prevent engine overheating.

The float is a device in the form of a plastic floating box. An electrical cable and a steel ball are placed inside it. It reacts to changes in water level and closes/opens the switch contacts.

The main advantage of the device is that it simultaneously performs two functions: it acts as a water level sensor and serves as an actuator for controlling the pump.

By spending a little more money on a device equipped with an automation system, you don’t have to worry that after pumping out the water it will run dry. The only thing is that once every few months it is recommended to wash the float switch with a stream of water under pressure to remove dirt. Preventative cleaning will prevent the float from sticking to the outlet pipe.

Comparative review of the best manufacturers

The company is rightfully considered the market leaderGrundfos". The Danish company is the oldest manufacturer of pumping equipment.The developments introduced by the leading company's technologists were subsequently adopted by other manufacturers.

The range of manufactured products is represented by pumps of all varieties and types. And they all have one thing in common - the highest quality, confirmed by an effective manufacturer’s guarantee.

Another imported brand that has earned a positive reputation among buyers from different parts of the world is the brand "Pedpollo".

“Pedrollo pumps work everywhere” is the main slogan of the world famous brand. And if you study the characteristics of the equipment he produces, it is worth highlighting the versatility of its application. The pumps are capable of operating in contaminated water, aggressive environments and at high temperatures.

Among domestically produced pumping equipment, the most well-proven products are those manufactured under the following brands:

- "Gilex" — pumping equipment from a domestic manufacturer is focused on the conditions of the Russian outback with its abundance of “difficult” soils and wetlands, as well as possible fluctuations in power grids.

- "Vortex" — pumps from this manufacturer are famous for their high power and low noise. The certified equipment produced by the company undergoes numerous tests for performance and endurance.

- "Foreman" — powerful and easy-to-maintain pumps of this brand are manufactured using advanced technologies. This allows the company to keep the quality level at a high level.

Among the brands of pumps for dirty water, brands that have also proven themselves to be "DAB", "Karcher" And "Belamos". The equipment produced under these brands is famous for its optimal price-quality ratio.

When purchasing a suitable model, you have to set priorities: pay more and choose an unquestionable European brand, or purchase an inexpensive domestic product, but risk receiving low-quality warranty support.

In order not to doubt your choice, we suggest that you familiarize yourself with rating of drainage pumps.

Conclusions and useful video on the topic

What are the differences between a dirty water pump and drainage equipment:

If there is no electricity in your area, the only solution to the problem is to purchase a manual pump pump. Pumping liquid through such units is carried out due to the movement of the piston, which increases the pressure in one chamber and decreases it in the other.

The price of the products ranges from 150 USD. But, as when choosing similar electrical models, key attention should be paid to the size of solid inclusions they are designed for.

Are you looking for a pump to pump out dirty water? Or do you already have experience using similar equipment and can you give practical advice to our readers? Please write comments in the block below.

This spring, the basement at the dacha was flooded several times with flood waters.We bought an inexpensive surface pump especially for pumping them out. The unit burned out on the third use. Warranty repairs were refused because we violated the operating conditions, since the pump was idling for some time. Now we have purchased a pump with a built-in grinder to draw water from the pond at the end of the site. I hope it will last a long time.

At our dacha, the Malysh submersible pump has been working properly for about 10 years now. The design is very simple, one might even say primitive, but it never failed. I can’t say for sure the depth of the well, thirty meters, I think. The pressure is good. We use water for irrigation. In the spring, you understand what kind of dirt accumulates, but it pulls everything out perfectly. Here is the simplest pump.