Float switch: what is it for and what to consider when choosing and installing

A reliable, practical and convenient float switch ensures correct automatic adjustment of the operation of electric pumps in sewer, drainage, drainage and water supply systems, acts as a water level sensor and protects equipment from “dry running”.

A correctly connected device monitors the functioning of the communication elements and turns the pump on or off when the permissible level of water or other liquid in the system changes. Placed in various storage tanks, containers, reservoirs, wells, etc.

The content of the article:

Structural device and capabilities of the unit

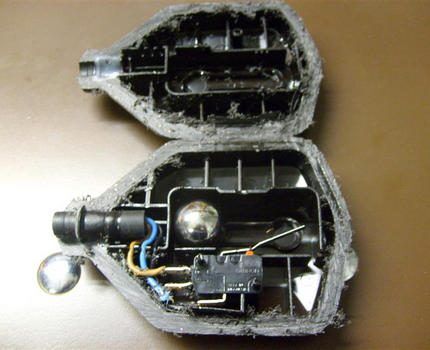

The float-type switch has a simple design. Inside the case, made of durable heat-resistant plastic, there is a working electrical switch. There is also a lever for transferring contacts in the switch and a steel ball that changes the position of the lever element when the position of the float itself changes.

Devices of this type are universal options for household equipment, because they operate equally correctly both in case of overflow and when the storage tank is empty.

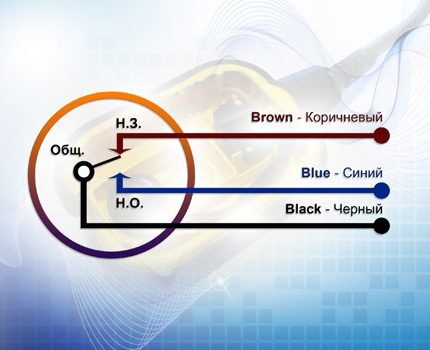

A cable consisting of three wires branches off from the switching unit - blue, brown and black. One of them (black) is common, brown comes from the normally closed, and blue comes from the normally open contacts of the switch.

The supply cable and housing box also have special requirements. The first element simply must have the highest possible level of moisture resistance, and the second element must be completely sealed and impermeable to water.

The outlet of the device is strengthened with an additional high-strength seal and is equipped with a practical device that neutralizes mechanical stress in the cable.

The insulated hollow part of the cable entry is filled with polymer resin. This prevents moisture or any other liquid in which the equipment operates from entering.

The cable housing and sheath are highly durable and heat resistant.Thanks to this, they are practically invulnerable to the effects of such elements of an aggressive environment as liquid oils, fecal water, uric and fruit acid, gasoline, etc.

The internal space of the switch housing is filled with air. Therefore, the device tends to float to the surface and occupy the highest possible position. When the liquid level in the reservoir drops, the float naturally moves down.

The length of the wire provided to move the mechanism regulates the spread between the upper and lower positions of the float. The basic starting point relative to which the movement is carried out is set by the load moving along the switch cable.

The plastic body has a smooth, non-porous surface. Pollution does not stick to it and fragments of human waste found in waste or sewer water do not stick.

Sand, paper and any other hard or dense pieces and elements slide off the unit without affecting its performance, buoyancy or functionality.

Float switches are multifunctional and are capable of solving a whole range of tasks of varying levels of complexity.

Just a few modules mounted in one tank provide:

- efficient functioning of the main pump of the communication system;

- full operation of the auxiliary pump.

In addition, they can play the role of an emergency controller, clearly recording a sharp drop in the liquid level in the tank and act as an overflow alarm sensor.

This will make it possible to reduce the load on the equipment and protect pumping system from excess wear, transition to “dry running” and other unpleasant but potentially possible incidents.

General classification of devices

Modern float switches are divided into two types. Lightweight modules are intended for pumping systems that drain or supply consumers with running water for domestic purposes. Heavy equipment is used in drainage and fecal pumping equipment.

When buying a float switch for a pump, you need to have a clear understanding of the problems that need to be solved. Light elements attract customers with a low price, but can only work in clean water intended for drinking and domestic needs.

Heavy units operate effectively in environments of any level of aggressiveness, however, using them for ordinary water is considered inappropriate due to their high cost.

Conditions for making the right purchase

Before purchasing a float switch, you must identify the area and method of application of the equipment, the required electrical characteristics, module dimensions and cable length.

To avoid troubles, you should purchase a float element separately and connect it to the system yourself or by calling a professional to your home.

If you plan to equip a drainage or water intake system, it will be enough to purchase an inexpensive lightweight module. It has good swimming ability, clearly reacts to the water level in the tank and immediately sends a signal to other elements of the system if any changes suddenly occur.

For drainage and sewer systems, heavy floats without a sinker are suitable, designed to be in an aggressive high-density environment.

Nuances of electrical characteristics

The current strength and voltage of the float switch must clearly correspond to the parameters of the electric pump. The voltage level, as a rule, is 220 V. Fluctuations of this indicator within 5-10% are acceptable, both up and down.

As for the current strength, this value at the switch must exceed the parameters prescribed for the pump. The float documentation usually states the maximum permissible value for reactive and active loads. When connecting pumping equipment, the number corresponding to the reactive position is usually taken into account.

Additional selection criteria

The temperature range of float switches is quite large. Thanks to this, for drawing water from a well or borehole pumping station you can choose any unit that is most suitable for the assigned tasks in all other respects.

But you will have to pay special attention to the size of the outgoing connecting cable. Typically the length of this element ranges from 2 to 10 meters. Devices with a short cable are more suitable for shallow tanks, and parts equipped with a long cable will work successfully in wells and modern storage tanks great depth.

Features of float installation

There are several ways to install the float switch correctly. Before starting work, first of all, you should make sure that the current consumed by the pump is less than the maximum permissible current specified in the equipment operating documents.

Easy installation for one module

The simplest, fastest and not too labor-intensive installation method involves installing the float into a container using a waterproof cable and a special sinker, which is usually included in the basic kit of the unit.

Installation work is carried out in the following order:

- The sinker is threaded onto a cable rope. Then, through experiment, the length of the free-play arm of the float device is determined.

- The position of the sinker is then secured to the cable using a special, practical latch.

- The cable is attached to the outside of the tank using connecting elements.

- When the preparatory work is done, the float is connected to the pumping system. Installation and configuration of the equipment are carried out according to the diagrams contained in the documentation supplied with the device.

Upon completion of all necessary actions, the equipment must be tested for performance.To do this, the pump, under the control of the owners, is started in normal mode for 2-3 hours.

If water pumping proceeds normally and does not fail, it means that the installation and subsequent connection were made in compliance with all the rules.

Rules for installing two or more products

If, according to the design documentation, it is necessary to install several float devices, it makes sense to use the rod installation method. A fragment of a durable plastic pipe is suitable for the role of a fastening element (rod). It is clearly and securely fixed inside the container intended for filling.

Then the floats are mounted on the rod base. They are evenly distributed along the entire length of the pipe so that after fixation and adjustment there is free space around each module, allowing the devices to clearly perform their functions without interfering with each other.

The cables coming from the switches are attached to the rod using clamps. This method allows you to install almost any number of switches, thus taking control of a full-fledged complex consisting of several pumps.

If necessary, it is permissible to use two or more rods and mount on them the required number of floats corresponding to the number of pumps or control panels used.

The principle of operation of the float in different systems

The scope of application of float-type switches is very wide. The element functions correctly in standard water supply systems, effectively controls the filling and emptying of the storage tank, protects the equipment from running dry and extends its service life.

The role of the switch in water supply systems

A device placed in a container floats to the surface when the tank is filled with water and promptly turns off the operating pump, preventing it from overflowing in this way. When the water level drops, the float drops with it and immediately activates the pump to subsequently fill the container with water.

Being on the surface of the tank (when the container is full), the device will give a signal to operate automatic water supply station and turns it off when it sinks to the bottom (when the container is empty).

The float will command to close the valve or lower the valve with a servo drive when it appears on the surface of the container filled with liquid. Having dropped to the bottom (when the tank is empty), the device will again open the valve or gate, reactivating the filling of the tank with water.

The float will send a signal to the control center or directly to the operator when it reaches the surface of the filled container. The device will report the absence of water in the tank when it sinks to the bottom of the working container.

Contact with drainage or sewer system

For drainage, fecal and sewage pumps It is recommended to use a heavy float switch.It is adapted to work in high-density liquids and easily copes with the assigned tasks.

The device clearly monitors the operation of the pumping complex and, having floated to the surface when the container is full, immediately activates the equipment. The shutdown occurs at the moment when the device sinks to the bottom as a result of emptying the tank.

The functionality allows connecting two pumps to one float switch. In this case, the pumping units will work in turn. One will begin to fill the container when the float is in the lower position, and the second will start working when the switch is at the top.

However, experts point to the low efficiency of the system and draw attention to potential differences in the supply of household water while filling the tank.

Equipment maintenance and repair

A float-type switch is a structurally simple and affordable device. It functions reliably and efficiently even in an aggressive environment and is not afraid of intense loads. Subject to compliance with the operating rules stated by the manufacturer, it fulfills the entire warranty period and after it also continues to fulfill its duties with high quality.

If the module is used only in a complex of structures involved in drainage or water supply, it does not require regular maintenance. The aquatic environment is considered the least problematic and does not have any negative impact on the equipment.

If the field of activity of the float is located in more aggressive, difficult conditions, for example, in sewer or fecal pits, the device requires more serious attention.

Plumbers recommend thoroughly rinsing the float with a hose at least once a month to prevent it from sticking to the pressure pipe or pump walls during daily operation. If the equipment is regularly rinsed with a stream of water, it will last much longer and will not lose its functionality even over time.

The most common breakdowns of the unit include burnout of contacts in the electrical cable, damage to the insulating layer, violation of the seal of the housing and penetration of moisture into it. If such problems occur, all faulty elements must be replaced immediately, since they cannot be repaired.

If the electronic module itself fails, the owners will have to throw it away and install a new one in the tank as quickly as possible. It’s not worth buying the first float element you come across, even if its price is attractive.

It is better to contact a specialized service center and purchase a branded certified part with documents that fully meets all the requirements for equipment of this type.

Conclusions and useful video on the topic

Rules for installing a mechanical float valve-switch to protect the storage tank from overfilling. Interesting aspects of the work that should definitely be taken into account.

How to install a float switch with a water level control option in a tank and connect it to an alarm circuit. All the subtleties of installing and connecting equipment with your own hands at home.

The head of one of the largest service centers talks about the features and nuances of the functioning of float switches and their scope of application.

In order for pumping equipment to serve for a long time, efficiently and fully, it is necessary to equip it with one or more float switches. These small, structurally simple units will take over the basic control parameters of the communication system and protect the equipment from excessive loads and “dry running”.

Installing the floats is not too difficult, and even an inexperienced home craftsman, with step-by-step installation instructions at hand, can handle the job without any problems. If you are not 100% confident in your abilities, it is quite appropriate to turn to plumbers. They will equip the communication complex with the necessary number of control parts.

Please write comments in the block below, ask questions, post photos on the topic of the article. Tell us about how you chose the float switch, how you connected the device and how it serves now. Share useful information that may be useful to site visitors.

A simple and reliable thing. I have never encountered a float switch failure before. Although it is clear that the microphone inside may fail, it is clear that the products are of high quality.

I need a float switch that would turn on and off at a depth difference of 30 cm. Are they available with such precision?

Good afternoon, Roman, now everything can be purchased.

For example, the PDU-P501 float sensor, judging by the diagram in the passport, allows regulation of less than 30 centimeters (attached a screenshot of part of the passport). If you are not satisfied with plastic products, you can look at the two-level sensor-switch PDS-03 (screenshot attached).