How to choose a drainage pump: review of options + rating of the best equipment on the market

Drainage pumps pump out water for us from pits, low-yield wells, basements, reservoirs for irrigation and cleaning areas.In a suburban area, they have a lot of important functions that drainers can handle only with proper selection. Agree, there is little benefit from a device that is not used due to technical limitations.

We tell site readers in detail how to choose a drainage pump. Let's figure out what variety is needed to do a certain job. Here you will learn all the subtleties and technical criteria according to which the appropriate drainage pump model is determined.

The article presented for your review lists all the factors that ensure an error-free choice. Popular drainage pumps, the quality of which has been tested in practice, are given as an example and described in detail. The informative content of the text is complemented by photo and video applications.

The content of the article:

Design and principle of operation of the equipment

Initially, these devices were created to pump water out of basements flooded with water. Later area of use drainage pumps expanded.Modern models are designed for pumping lightly contaminated liquids from pits, wells, pools, pumping and cleaning wells.

In addition, they are used in production and included in the technological process. Most devices are capable of pumping liquids with impurities measuring about 10 mm.

Drainage pumps are specific equipment designed for a fairly narrow range of work. Using it for other purposes is not recommended. Despite the fact that drainers are used for cleaning shallow wells and mine wells, they are not intended for permanent work in them.

The devices cannot work as a fecal pump, although some “craftsmen” are trying to replace them.

Drainage equipment can only work with lightly contaminated liquids. The amount of solid impurities, depending on the type of apparatus, varies from 3 to 40 mm.

Whereas fecal pumps operate in aggressive liquids with a complete absence of solid inclusions. They are necessarily equipped with shredders, which, using special blades, completely eliminate large contaminants.

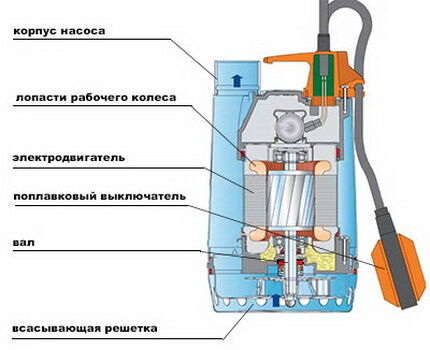

If we consider the design of the device in its most general form, it consists of several elements:

- Electrical engine.

- Impeller located on the shaft. Responsible for the movement of liquid inside the device. Can be placed directly on the engine or at some distance from it.

- Pumping unit. It is equipped with an intake pipe. Liquid enters the device through holes in the pipe.Their diameter determines the size of impurities that the device can handle.

- Sealed housing. All working elements are located inside it.

- Circuit breaker. It turns on and off depending on the liquid level. This prevents the equipment from flooding or its so-called “dry running”.

Typical pump diagram:

When the device is activated, the electric motor starts up, rotating the shaft with the impeller. A zone of rarefied air is formed around the moving blades, which reduces the pressure inside the chamber.

The liquid is drawn through pipes with holes and passes into the device. Here, under the influence of centrifugal force, it is pushed to the outlet, from where it enters the pipe or outlet hose.

For normal operation of the pump, it is important that the amount of solid impurities inside the chamber does not exceed 10% of its volume. One more nuance. Standard drains are not designed for pumping hot liquids.

They can do this for a short time as the device's motor cools, releasing heat into the pumped liquid. If you need to constantly pump hot water, you should choose a special model.

Types of drainage pumps

Depending on the installation location, there are two types of drainage equipment - surface and submersible.

Surface pumping devices

Designed for installation on the edge of a tank filled with liquid for pumping. The inlet pipe descends to the bottom of the container, where it sucks in water with impurities.

Such a device is capable of functioning without human intervention, for which it is connected to float mechanism, responding to the level of pumped liquid. When it rises, the float floats up, which is a signal to turn on the equipment and vice versa.

Surface devices are easy to maintain and portable. They are quite easy to transport and install in a new location. All equipment components are accessible, so their repair is not difficult. Surface appliances most often have medium power. Can be used in pumping stations connected to wells or wells.

Submersible drainage pumps

Pumps of this type are designed to operate directly in the pumped liquid, and therefore must be completely immersed in the reservoir. The main difference between the equipment is the absence of a suction pipe.

The liquid enters the pump through special holes located in the bottom of the structure. To protect the device impeller from large solid impurities, a mesh filter is mounted here.

The devices operate automatically and turn on only when a certain volume of liquid has accumulated. The equipment must be equipped with enhanced electrical insulation, which is explained by its operation in a liquid environment.The great advantage of submersible pumps is their high power and performance, noiselessness, durability, and safety in operation.

Overview of a typical submersible drainage pump using the example of the ASP 900 D INOX model:

The mechanism is used for pumping water from wells, reservoirs, basements, etc.The “weak” point of the device is the holes in the bottom, which often become silted, since the device is installed on the bottom of a reservoir or container. This drawback is less common in models in which the suction holes are located in the upper part of the body.

Criteria for the correct selection of equipment

Choosing a drainage pump is quite simple. Several important criteria must be taken into account. How to decide on the most suitable drainage model is described in great detail in one of popular articles our site.

For those who wish to briefly familiarize themselves and evaluate the selection criteria, we have given the main ones.

Characteristics of the pumped medium

Before purchasing a pump, you should determine what kind of liquid it will have to pump out. It should be relatively clean, free of rocks, high levels of dirt or sand, and free of silt deposits.

These could be flooded rooms or basements, tanks filled with rainwater, wells, ponds, etc. If the pump will be lowered into a body of water, it must stand on a solid bottom.

Therefore, it is installed in a suitable sized vat, bucket or on a special base plate. Each model is designed to work in a specific environment, that is, it specifies the maximum size of impurities dissolved in the liquid that the mechanism is able to pass through without reducing its performance.

Depending on the contamination of the liquid, all drains can be divided into groups:

- For lightly contaminated or clean liquids with impurities up to 5 mm in size.

- For medium-contaminated liquids with inclusions not exceeding 25 mm.

- For contaminated, melt or rain water. The permissible particle size of contaminants is from 25 to 38 mm.

In addition to the size of the impurities, it is also important to consider the temperature and chemical composition of the pumped liquid. Aggressive compounds can damage the pump, so you need to know exactly what its elements are made of.

Materials used in production

The service life of a drainage pump directly depends on the material used to make its elements. The device body can be made of plastic or metal.

In the first case, the cost of the device will be lower, which is more attractive to the buyer. However, the plastic case is not sufficiently resistant to mechanical damage and quite often cracks or deforms.

In this case, it can no longer be repaired. Metal casings are more durable and repairable, so pumps in this design last much longer.

Some of the best body materials are cast iron and stainless steel, which can work in almost any environment. Another important detail is the material from which the pump blades are made.

They can be made of stainless steel or a special technical polymer. In this case, the second option would be preferable. Special impurities that are present in the polymer make it more resistant to aggressive environments and mechanical stress.

A significant drawback is that they cannot be repaired. Metal blades wear out faster than plastic ones, so they are cheaper.

Circuit breaker type

Almost all modern drainage pumps are equipped with automatic switches that start the mechanism when the specified level of the pumped liquid is reached.

The device can be:

- Electronic built-in. Quite a complex and expensive unit.

- Poplavkov. A simpler, more reliable and inexpensive element.

Automatic switches of any type eliminate the possibility of the pump running dry, thereby preventing its serious damage.

Drain pump performance

Productivity refers to the amount of liquid, measured in cubic meters, that a device can pump in one hour of operation.This indicator must be indicated in the device passport. The required productivity can be determined by dividing the volume of the reservoir from which the liquid will be pumped by the expected operating time.

On average, for home use, a mechanism with a capacity of about 10 cubic meters is quite sufficient. m/hour. For professionals, models with a capacity of 100 cubic meters or more are suitable. m/hour.

Pressure of the device for pumping water

It can vary in the range from 5 to 50 m. The amount of pressure depends on the type of pump, which determines the distance to which the water is discharged or the height of the rise of the pumped liquid.

These indicators are indicated in the technical documentation. They have a ratio of 1:10 to each other. Thus, if the passport states that the pump can lift liquid to a height of 5 m, it means that it will be able to transmit it to a length of up to 50 m.

It is clear that these are average figures that do not take into account any other parameters, for example, the diameter of the hose. Therefore, you should contact the seller for clarification. For the most general calculations, you can use such data.

For household models, it will be quite enough if the pressure indicated in the technical documentation exceeds the calculated one by 3 m. If a powerful influx of water or a lot of it is expected, the pressure “reserve” should be greater.

Diameter of outlet pipes

To ensure maximum efficiency of the pump, the dimensions of the outlet pipes must be accurately selected. If you plan to pump water, a small diameter model is suitable: from 0.5 to 1.5 inches.

In case of pumping out contaminated liquid, it is better to choose an 8-inch or even larger option. In addition, pipes for horizontal and vertical connections are available. You need to choose a model that is suitable for the type.

And a few more important points. The hose that will be connected to the outlet pipe must have a similar diameter. For household needs, you should choose portable, lightweight models. They are more mobile and easy to use.

It is worth asking about the residual level of liquid that remains after the drain pump operates. If you need to pump out water “dry,” you should choose a model that leaves no more than 2 mm of liquid.

Branded models of pumping equipment

In the rating of drainage pumps you can see both expensive devices and quite budget models. Let's talk about the pumping equipment most in demand among consumers.

#1. Italian brand Pedrollo

The company announced itself in the 70s of the last century. It quickly gained popularity for the high quality of its products, which is successfully combined with a very reasonable price.

Today Pedrollo is one of the leaders in the production of pumps of various types. The line of drainage devices of this company is quite wide. It includes the particularly popular TOP series.

These are submersible drainage units with an open centrifugal impeller. Designed to operate automatically to lift and withdraw liquids without abrasive particles. The pump housings of this series are made of glass fiber reinforced technopolymer, which gives them increased impact resistance. The impeller and suction grille are also made of technical polymer.

One of the most popular models in the series is Pedrollo TOP Vortex. Like all pumps in the TOP line, the structural elements of the device are made of “proprietary” technopolymer.

This allows it to work in various aggressive environments and pump not only water, but also chemical reagents. The device is intended for pumping dirty liquids and fecal wastewater, the size of the solid fraction in which does not exceed 20 mm.

The model is designed for continuous use, is capable of functioning in partial immersion mode, and is equipped with an emergency shutdown device. This is a fairly powerful sump pump that is extremely easy to use.

Purchased to remove water from garages, basements, and swimming pools. It can be used for watering an area and even for organizing a small fountain.

# 2. Russian pumps Gilex

The domestic manufacturer began supplying its products to the market in the 90s of the last century. Gilex brand pumps are in great demand due to their adaptation to Russian operating conditions.

For example, they are not so sensitive to frequent power surges. In addition, they are of high quality, and their cost is an order of magnitude lower than that of imported analogues.

In addition, our country has a well-developed network of Gilex service centers, which guarantees no problems with repairs and spare parts. Drainage pumps of this brand are represented by a line under the general name Drainage.

These are submersible devices of varying power, made of special plastic or stainless steel. They can operate in environments where the size of contaminants ranges from 5 to 40 mm.

The devices are economical and have an impressive service life.One of the most popular models in the line is Drainer 200/10f. This is a fairly powerful pump with a immersion depth of up to 8 m.

The device is economical, its rated power is 880 W. The device is equipped with a float switch, the operation of which can be adjusted by the user.

The drainage pump has a high-strength plastic housing and is equipped with an overheating protection system. Among the advantages of the device we can add the ability to operate for a long time in partial immersion mode. Can be used for draining wells, ponds, sewage basins, etc. The cost of such a device is quite affordable.

#3. German quality from Karcher

The time-tested German manufacturer Karcher produces reliable and durable drainage pumps. They are excellent for pumping even large volumes of liquids, as some models have a capacity of 18,000 l/h.

Easily recognizable Kärcher brand drainage pumps are distinguished by high build quality, power, performance and long service life.

The Dirt series is designed for pumping dirty water, the size of impurities in which does not exceed 30 mm. Pumps from this line are perfectly designed for work in ponds or flooded cellars and basements. Karcher offers drainage pumps with a residual liquid level of no higher than 1 mm. They pump water almost dry.

For pumping clean or slightly contaminated liquids, the manufacturer offers the Flat series. These devices can be installed in swimming pools or drainage wells. The peculiarity of the line is that the devices leave a layer of water no higher than 1 mm, that is, they pump out the liquid almost dry.Karcher pumps are equipped with an intelligent level sensor with an adaptive algorithm.

This allows the device to react almost instantly to contact with liquid and adapt to operating conditions that change over time. The SP 3 Dirt model earned high praise from consumers.

This is a fairly powerful device for pumping dirty liquid with inclusions no larger than 20 mm in size. Equipped with a float switch and a ceramic-granite oil seal, which significantly increases the service life of the device.

#4. Inexpensive drainage pumps from PATRIOT

Garden equipment of the American brand Patriot appeared on the domestic market in 1999. The company sells equipment and tools under its own brand.

The products have an attractive balance between cost and quality. There are four samples in the line of drainage pumps. One of the most popular models is the PATRIOT F 300, characterized by its low price and good performance characteristics.

Pumps for pumping out dirty water from the Patriot brand are distinguished by an attractive ratio of affordable cost and high quality.

The device works with dirty water with inclusions no larger than 5 mm in diameter, and is equipped with a float switch. The pump can be lowered into the pumped-out medium to a depth of no more than 5 m. The throughput capacity of the device is 3.5 m.3/h.

At the same time, it has fairly modest dimensions and relatively low power consumption. The drainage pump is easy to maintain and can be used in a pond or well, weighing only 3 kg.

#5. GNOM brand dirty water pumps

Produced by the Moscow Pump Plant. The line of drainage devices includes household and professional models.The devices are equipped with a built-in hermetically sealed electric motor.

Designed to work with liquids with a density of up to 1100 kg/m³. The permissible size of impurities is 5 mm. Devices designed to operate in a liquid medium with temperatures from 35 to 60C are marked “T”.

In the line of drainage pump equipment, one of the most popular varieties is the 16-16 model. This is a submersible pump with a 1.1 kW electric motor. The head of the device is 16 m, the liquid supply is up to 18 m. Such characteristics allow the device to be used for pumping sandy or clayey waters from deep trenches and pits, flooded basements of large areas.

The drainage pump GNOM 16-16D can be used to lower the level of continuously existing groundwater. In addition, the equipment is used for watering greenhouses, greenhouses and vegetable gardens. Capacity is 16 m3/h.

The device has an air release button, which speeds up its startup and ensures stable operation of the device. It must be said that many owners of private estates and summer cottages consider this model to be one of the best.

Conclusions and useful video on the topic

Video #1. Types of drainage pumps:

Video #2. Important criteria for choosing a drainage pump:

Video #3. How to choose a drainage pump:

A drainage pump is a must-have for a country house or cottage. Its functionality is quite wide. The device will successfully cope with pumping water from a flooded basement or well, and will also help the owner in watering the area.

When choosing drainage equipment, it is important to clearly understand how it will be used. This is the only way to choose a model that is optimally suited for specific conditions.It must be remembered that its service life directly depends on the quality of installation and operating conditions.

You can ask a question or talk about your own experience in selecting and using a drainage pump in the block below. Please comment on the article. We or site visitors will be happy to answer.

In the spring, when the basement flooded as the snow melted, we had to urgently buy a drainage pump. I chose carefully, but was limited by budget. I took a model of a submersible pump, in which the holes often became clogged. I had to additionally install a fine mesh in 2 layers (there was a piece of mosquito net left). Partially solved the problem. Still, it’s better not to save on such purchases.

You need a budget automatic sump pump to pump water out of your garage subfloor. The depth is approximately two meters. Any advice?

The most budget-friendly option we have tested is the Malysh 10M; it also copes well with dirty water. If you absolutely need a drainage pump, then pay attention to JILEX Drainage 200/25, a good model for very reasonable money.

What I don’t recommend are Chinese drainers, which are sold, for example, in Leroy Merlin or other chain stores. They break down very quickly, just waste your money.

The pump specifications indicate: Lifting height: 10.8 m. Immersion depth: 10 m.

In this regard, the question is: what height of water rise can you expect if the immersion depth is 2 m?