Do-it-yourself well cleaning: a review of the best preventative and capital methods

Any tank in use needs to be cleaned. And a well filled with surface water is no exception.But, even knowing the need to regularly carry out this procedure, not all owners are ready to shell out large sums for the services of specialists.

Some people do the cleaning themselves - the work is quite labor-intensive and involves certain risks. However, by adhering to the methodology and observing safety precautions, it is quite possible to return the source of water intake to its former purity without the involvement of professionals.

We will tell you the reasons why the tank most often becomes clogged, we will describe how to carry out preventive and comprehensive cleaning of a well with your own hands, and we will also provide tips on maintaining the water intake point.

The content of the article:

When is it time to clean your well?

A properly made well can last for decades. But even a well-equipped building becomes dirty over time.

Falling leaves and dropped foreign objects cause biological processes. And metal impurities can even worsen its condition, making it potentially dangerous to human health.

A number of signs will indicate that a well at your dacha needs to be cleaned:

- The water acquired an unpleasant odor and a strange taste.

- Kolodeznaya the water has changed color, thread-like fibers began to be found in its composition.

- A clay deposit formed on the walls of the structure.

- The dynamic and static water level has dropped.

It is recommended to check the quality of drinking water annually. The procedure is best performed in the off-season. Check and well water analysis the concentration of impurities and substances in it is ordered from specialized SES laboratories.

Causes of pollution

One of the main reasons for water pollution in a well is the irregular use of the structure, as a result of which it simply silts up.

For the same reason, during breaks in the use of the structure, it is recommended to remove filters and submersible pumping equipment from it so that they do not fail prematurely. It is especially important to perform these actions in winter.

Several other problems can also cause poor water quality. Let's look at each in detail.

Poorly closing lid of the structure

The well should only be open when water is being drawn from it. The rest of the time, its neck should be tightly covered with a lid. Otherwise, dust and dirt in the air will certainly fall into the mine and “do their dirty work.”

Improperly made melt water seal

It should be a permanent waterproof “layer” around the upper casing ring.The thickness of the clay castle should be at least 50-100 cm.

If this condition is not met, perched water will penetrate into the reservoir, which along with it carries debris, waste products and eroded pieces of soil.

Seam rupture

No matter how well the seams in the well are sealed, cracks may form in them when the soil freezes every year.

Surface groundwater, which contains fertilizers and domestic wastewater, seeps into the mine through poorly sealed seams. The situation can be corrected by sealing the cracks with mortar with the addition of liquid glass.

Offset of rings of the structure

Shift of structural elements is possible for various reasons, including improper installation and natural factors.

Ring displacement options:

- At the bottom of the trunk - occurs due to the influence of quicksand. You will have to cover the tear areas with cement mortar

- Pushing out the top rings - occurs due to soil freezing. It is necessary to tighten the sheared rings with pins with thick wire.

To seal large seams, it is better to use “tension” cement grade NTs-80 or 87. The material, characterized by increased elasticity, is used in the construction of subways and underground tunnels.

In order to unconditionally get rid of contaminants and eliminate design defects, you need to decide in advance how best to clean the well and, if necessary, repair the tank.

Well cleaning technologies

There are two ways to clean a shaft-type well at your dacha: traditional manual and using a drainage pump.

Manual cleaning method pretty simple. It includes two stages: mechanical cleaning and chemical cleaning.

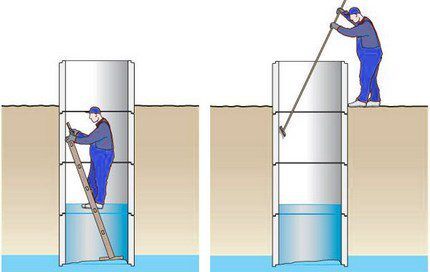

First, water is pumped out of the reservoir. Then a ladder is lowered to the bottom of the well, along which the cleaner will move during the work process. Its task is to clean the bottom and walls of the shaft from a layer of dirt and accumulated mucus with a sponge or brush.

For wells used year-round, such cleaning is recommended every 5-7 years. In the intervals between cleanings, it is only necessary to monitor the quality of the water.

If the analysis shows that the composition meets the norm, there is no need to “muddy the waters” once again. Wells built on summer cottages, the operation of which is seasonal, must be cleaned once a year.

Automated method consists of using a drainage pump that lifts sludge from the bottom and at the same time purifies the water.

The work of cleaning the hydraulic structure is performed by a pump. The desired effect is achieved due to the water circulation created by the injection unit.

The liquid passing through the filter is cleaned and then, under high pressure, is discharged back into the shaft, where it lifts silt deposits from the bottom and directs them towards the filter.

Let's look at each of these two methods in more detail.

Preventative manual method

Choosing the time for work

Craftsmen who specialize in repairing hydraulic structures recommend cleaning the well at your dacha at the end of summer. This is due to the fact that by the end of summer the water balance of underground sources has a minimum filling debit.

It is strictly forbidden to empty the mine during the spring flood. Water-saturated liquefied soil, on which, after the reservoir is empty, the water barrel ceases to exert pressure, can simply rush back into the mine.

If the well is used only in the summer, preventive cleaning should be performed more often.

Since “cleaning” activities are very labor-intensive and unsafe, it is important to observe safety measures when carrying out work. In this case, you cannot do without reliable insurance.

It is better to do the work during daylight hours. To produce it, you should attract a couple of assistants. One master will work in the mine, the other two will insure on the surface.

Keep in mind that at a depth below three meters there is a lack of oxygen. Therefore, the task of the assistants on the surface is to monitor the well-being of the cleaner and, if necessary, work together to remove him from the mine.

The cleaner must wear a safety belt to which the cable will later be attached. Before diving into a well shaft, you should make sure that there are no harmful gases at the bottom of the tank.

To do this, you first need to lower a bucket with a candle lit in it into the shaft on a rope. If everything is in order and there is no gas in the shaft, the candle will continue to burn.

Preparing the necessary materials

To carry out mechanical cleaning you will need:

- ladder;

- support rods;

- safety rope;

- platform on cables;

- wooden swing for lowering a person;

- metal brush;

- scraper or hoe;

- spatula or trowel;

- felt or fur roller.

- bucket.

All safety equipment, including lanyards and locking mechanisms, can be rented. It is necessary to prepare disinfectant compounds and concrete mortar from the materials.

It is advisable to equip the ladder on which the cleaner will work with a support platform. It will help distribute the load over a large area, minimizing the risk of “subsidence.”

Mine drainage options

You can drain the mine manually or using a pump. Hand scooping with a bucket is only effective if the source fills slowly and is shallow.However, while you pull out the filled bucket and pour it outside the site, the same amount of water has time to refill the reservoir.

There are two types of units:

- Submersible – are placed in the water column and work near the bottom of the mine. They work effectively in both clean and contaminated water.

- Superficial – the pumps are installed outside the well, and only the suction hose is lowered to the bottom. Such pumps are capable of pumping water from mines whose depth does not exceed 8-10 meters.

If the well is located on quicksand, it cannot be completely emptied. This can cause the float to move, and the water intake part of the structure will quickly silt up as a result.

The water pumped out from the tank should be discharged to a sufficient distance. Otherwise, after a short period of time, it will seep through the soil and again end up inside the walls of the mine.

Owners of wells installed on clay soils note that such pumping helps restore and even increase water flow.

Under the influence of pressure resulting from an alternate decrease and increase in the level of the water column, not only old clogged capillaries open, but also new ones appear.

Treatment of walls and bottom

Cleaning the walls of the well involves scraping off plaque from the inner surface of the concrete rings. It is more convenient to clean the upper one and a half to two meters of the shaft from the ground, and the lower areas - from a ladder installed at the bottom of the well.

After cleaning the walls, clean the bottom filter. It is usually made using three components: crushed stone, gravel and sand. This combination of materials with different structures allows for the highest quality water filtration.

To replace the natural filter, use a bucket to scoop out the old gravel and sand. It is recommended to completely remove the top layers and replace them with fresh pebbles. The thickness of the filter mound layer must be at least 40 cm.

The progress of work is demonstrated in the photo report:

Sealing and strengthening of seams

The cleaned surface must be carefully inspected. All defects will be clearly visible on it.

The easiest way to strengthen damaged seams is to cover them with concrete mortar, which contains water-repellent impregnations. They will ensure the waterproofness of the structure.

To fill large cracks, craftsmen recommend using special compounds such as "Penecritus" or "Penetron", using them to form hydroseals.

“Impregnation” with a chemical composition

After cleaning the bottom and walls of the well, the tank is disinfected. To do this, the walls of the structure are coated with a 10% bleach solution. Special compounds like "Whiteness", which can be purchased at construction stores. The remaining part of the solution should be evenly distributed along the bottom of the shaft.

Wall treatment can also be done with a solution of ordinary potassium permanganate.

Since chlorine vapor is dangerous to human health, chemical processing should be performed with safety glasses and a respirator.

Commissioning after cleaning

Having completed the work, install the pumping equipment in its original place. Equipment filters can be cleaned using strong water pressure and by washing with special products.

At the final stage, they wait for the well to naturally fill with water and leave it for two/three days. Then the liquid is pumped out again and the tank is refilled, assessing the condition.

The water should have a transparent color, be free of all kinds of impurities and unpleasant odors. Before using water for its intended purpose, let it settle. This may take another day or two.

Drainage cleaning

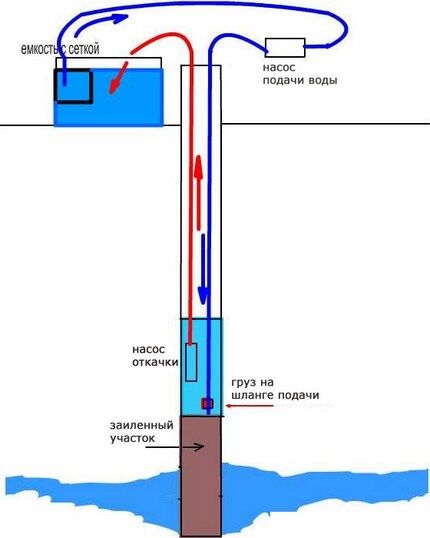

Most cleaning operations in a well shaft can be performed using machinery. It is only necessary to organize the circulation of liquid.For cleaning, a well is installed at the bottom of the shaft pump equipment. It will pump water to the surface.

The unit is installed on a stand 10-12 cm wide. This is necessary in order to prevent the device from being pulled into the silt. The pressure hose of the unit is lowered to the bottom of a storage tank installed nearby. For this purpose, you can use an old bathtub or a three-hundred-liter barrel.

A pumping unit is mounted to the top of the shaft, which will pump water back into the well.

The well is cleaned by turning on both units alternately:

- drainage pump will free the well from dirty water;

- pressure pump, generating a dense flow, will clean the walls and bottom of the tank.

You can manipulate the hydraulic nozzle, removing deposits from the walls of the shaft, both from the ground and from the stairs. Dirt settled during the pumping process is removed manually, using a sprayer and special chemical compounds for this purpose.

During the procedures, it is necessary to lift the pump from time to time and clean the filter elements. The procedure is carried out until deposits no longer form on the filters.

Major cleaning of a hydraulic structure is carried out using more powerful pumps equipped with large filters that are capable of passing through contaminated water with inclusions of silt fibers. The procedure is performed in several stages, which may take up to 2-3 days.

After completion of major cleaning, to maintain cleanliness in the mine, you should run the drainage pump. The frequency of the procedure depends on the characteristics of the soil.

For more information on choosing well cleaning tools, see this article.

Conclusions and useful video on the topic

One example of how to clean a mine well on your own using a drainage pump:

When planning to clean the system manually, to simplify the task, experts recommend using a grader. With this small bucket, equipped with two interlocking blades, you can quickly and effectively clean the bottom of the tank.

How to use the tool is clearly described in the video:

Regular implementation of simple well shaft cleaning procedures will improve the flow of water and improve its quality characteristics.

Do you have personal experience with cleaning a well? Do you want to share effective methods or ask questions on the topic? Please leave comments and participate in discussions - the feedback form is located below.

The contamination of a particular well depends on the owners themselves. If they did not take measures to protect against external threats during the construction stage, then that is their problem. In our village, even the most dilapidated buildings are still standing, but in most of them, the contents are no longer suitable for drinking. The wood is rotten and all that remains is to redo everything. The work is not easy, and there is no point in rebuilding it, since the water supply has been in place for a long time.

Even a well made well needs to be cleaned every 2-3 years. You can clean small wells yourself; to clean a deep well, it is better to call a specialist. Earth gases, floaters, collapse of a log house - the savings are not worth the risks.

There is nothing difficult in cleaning a well, but still, it is better for inexperienced owners to call the experts for the first time and carefully observe their actions. So I was an attentive spectator and after their work I even successfully cleaned the well on my own for my sister, who had a crack in the wall of the shaft. The technique corresponds to what is written, but you always need to pay special attention to insurance and involve at least 2-3 people!

By the way, regarding the running water - yes, it’s really convenient, but the taste of water from a well is much more pleasant.

Undoubtedly, it is cheaper to clean the well yourself. But if the problem is serious, then it is better to contact specialists. For example, I really liked the guys from the “Well Expert” company. They work conscientiously and charge inexpensively. My well is over forty years old, and the water has always smelled like mud. And after cleaning and disinfection by Karcher, the water became clean and tasty, the smell disappeared. We couldn't do this on our own.