Choosing a pump for a well: how to choose a unit + review of the best brands

Buying a pump to service a country house will save you from a lot of problems.Relatively inexpensive compact equipment will collect water in containers for irrigation and deliver it to the bathhouse, kitchen, or pond or pool equipped on the site. Agree, doing so many things manually is too difficult, and almost impossible.

Pumping equipment will easily perform all the work listed for you if all technical and hydrogeological nuances were taken into account before purchasing it. We are happy to help you understand this difficult issue. The article presented for review contains all the characteristics and circumstances necessary for making an informed choice.

The information we offer will help you thoroughly understand what you should pay attention to before purchasing, which pump is best for a well, and what needs to be provided for connection. We have listed the leaders in the production of pumping equipment for private purposes. The information is supported by video and photo examples.

The content of the article:

Guidelines for choosing a pump for pumping out of a well

Before purchasing a well pump, you need to carefully prepare.

Without information about the source of water supply, even a brilliant salesman will not be able to accurately say which device is ideal.

For perfect pump selection, the following information is required:

- Distance from the entry point to the bottom of the well. For country prefabricated water supply systems, it is counted from the top edge of the head, because the water supply hose is usually routed through it. For permanent water pipelines, the specified distance is set aside from the entry point through the wall of the well. It can be determined with the simplest measuring device made of string and a weight tied to it.

- Static level or otherwise a mirror of water. This is the distance from the ground line to the surface of the water in the well. To determine it yourself, the above-described device must be upgraded by replacing an arbitrary weight with a heavy nut. You need to tie it to two opposite walls so that the hole in the nut that comes into contact with the surface of the water makes something similar to a pop.

- Dynamic level. It is determined in a similar way, but before it is measured, water is pumped out from the excavation. Before determining the static indicator, water cannot be pumped out.

- Full height of the well. This value can be found by adding the heights of the rings used in the construction.

- Site plan with dimensions. It is necessary to determine the distances from the water intake site to the water collection points. A hand-drawn diagram with precisely marked distances will do.

- Difference between dynamic and static level characteristic. The value gives the right to determine the flow rate of the well.

- The height of the water column. Equal to the distance between the bottom and the dynamic level.

- Degree of water pollution. Whether it is crystal clear or with a fine suspension, it belongs to the technical or drinking category.

Armed with measured and calculated data, you can safely go to a specialized store.

However, the information received is not enough for a good owner to select the perfect well pump. In order not to become a victim of banal deception, you should expand and increase your knowledge base.

Which option is needed - superficial or deep?

The design specifics of water pumps are directly related to the depth of the excavation being constructed.

According to this parameter, all types of water supply units are divided into:

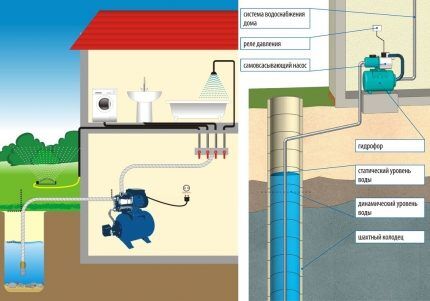

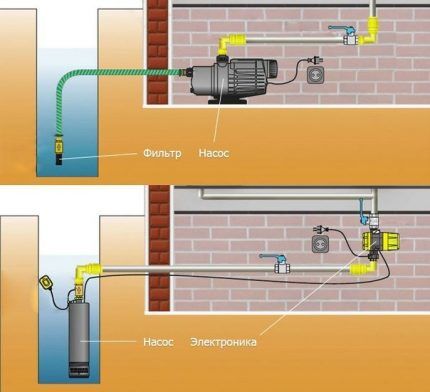

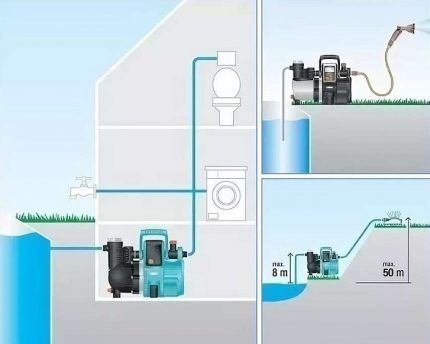

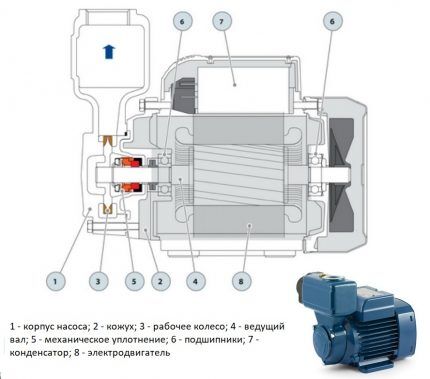

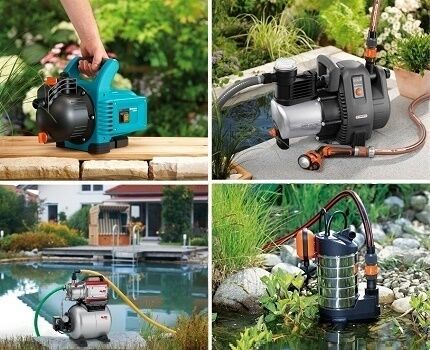

- Superficial. Installed in the house or near the well. The surface type is used to transport water from a depth of no more than 7 - 9 m. They are used mainly in the summer to provide water to temporary residences, and can be used to collect water from open sources and small wells.

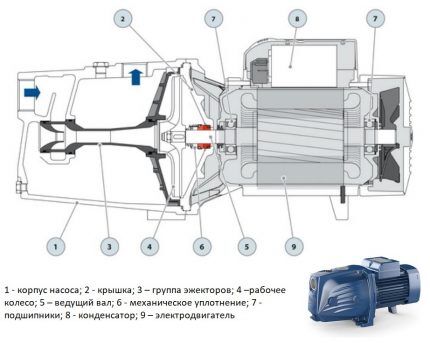

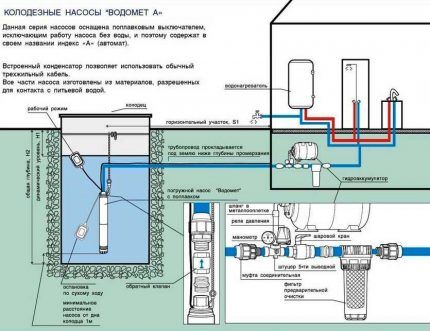

- Submersible, otherwise deep or borehole. They are lowered directly into the excavation, connected to the supply hose and to the fastening cable. Submersible pumps supply water from depths from 9 to 200 m. They are used mainly as the main working body of autonomous aquifer systems operating year-round.

Construction and installation of surface pumps significantly simpler than their deep counterparts. The suction capacity and efficiency are noticeably lower, which leads to a relatively low price.

Submersible pumps are structurally more complex and much more expensive. They are equipped with multi-stage motors, thanks to which the pumps can extract water from great depths and create noticeable pressure.

True, in the family of deep-well units you can find representatives that work excellently in “shallow” wells of 15-20 m. Note that there will be no blockages or motor breakdowns if the height of the water column is at least a meter between the bottom of the well and the submersible pump.

A similar distance should be between the top of the apparatus and the minimum water level in the well.

The range of submersible units includes well and spoken models. Both options can be used to equip a well, but a system with the appropriate name is preferable as a more adaptable type.

Both are designed to pump water without contamination.For normal operation, they need a clean water environment without grains of sand and clay suspension.

It is undesirable for deep-well equipment to be installed in an old well. In case of emergency, the walls and bottom of the excavation must be strengthened by first pumping out the water. Cracks and potholes must be sealed with concrete mortar and a new bottom filter installed.

Surface systems are less sensitive to contamination. If a well is exposed to a perched water supply intended for technical purposes, the choice should be made on one of the surface pumps.

For workings with an unstable water supply, there are models with an alarm float that automatically stops pumping when the level drops below the technical limit.

Surface type pumps can be used to extract water from wells up to 30 m deep, if equip with an ejector. The device is lowered into the excavation like a submersible unit, but water is pumped directly by a surface system.

However, with increasing depth, the performance of such a tandem decreases, and energy consumption increases. Purchasing this pair for deep mining is considered unprofitable. It's better to buy pumping station, equipped with a storage tank and automation.

Necessary and sufficient characteristics of the unit

The technical passport of the unit will familiarize the future owner with the most useful information necessary in selecting the best pump model for the well.

The following characteristics must be taken into account:

- Maximum performance. Indicates the number of liters supplied by the unit per minute. Depends on the power of the machine and the capacity of the pipe transporting water. Needed for comparison with the real need for water.

- Suction depth. Indicated in meters, it indicates from what depth the pump can pump and transport water. Needed for comparison with the dynamic level and specific depth of the well.

- Maximum pressure. Determines the distance between the point of water intake and the highest point of water collection. Needed for comparison with the required hydraulic pressure value calculated for specific conditions.

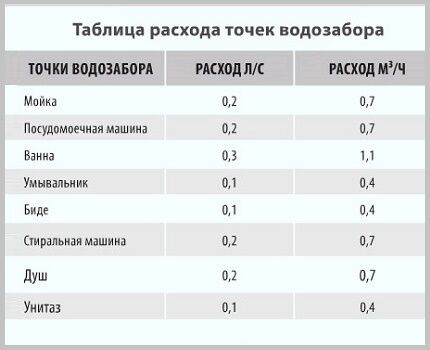

The main characteristic of the pump is performance. It should be equal to the water consumption of simultaneously operated points or the amount of water consumed in one hour.

It is unwise to buy a pumping unit with too much power. If the equipment constantly switches to “dry running”, the service life will be noticeably reduced. On the other hand, an illiterate selection of a pump will lead to a lack of pressure and a lack of water.

The choice of pump model based on performance is influenced by another very important parameter - the flow rate of the well. The amount of water in mine workings buried in a sandy aquifer is most often unstable.

Therefore, it is strongly recommended to coordinate the performance of the unit and the frequency of its operation with the flow rate of the well, and then focus on water consumption.

Example of calculations for equipment selection

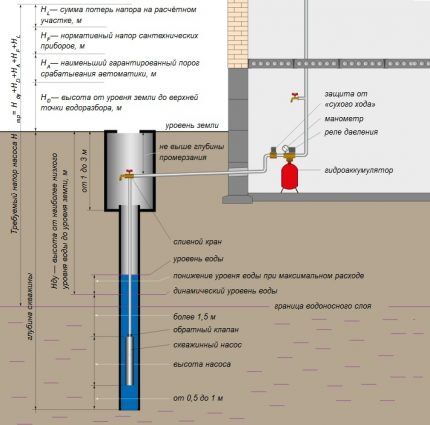

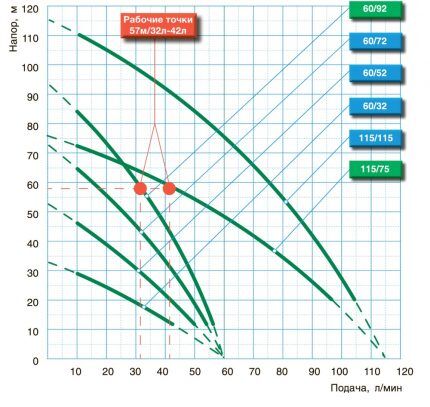

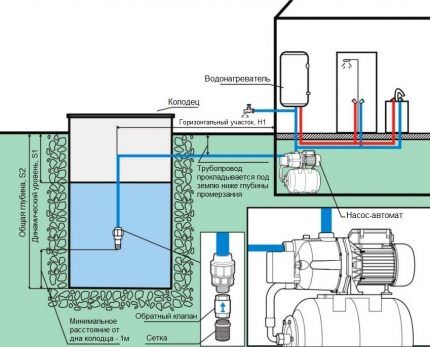

Let's assume that we are buying a submersible pump for a well 25 m deep. The dynamic level measured after pumping is established at a depth of 15 m. The distance to the house is 30 m.

Water points are located on the first and second floors of the cottage. Conditional consumers will be: shower, kitchen and watering tap. We neglect the toilet and washbasin as means of periodic use.

Let's calculate the pressure. To do this, we summarize the value of the dynamic level of 15 m, a horizontal section of the water supply system, 30 m of which is equal to 3 m of vertical supply (30/10 = 3). To these we add a gravitational indicator of 5 m, consisting of 1 m for delivery to the first floor and 4 m for delivery to the second.

Let's add 30 m required for the normal functionality of any pumping system. The following expression was obtained: 15 + 3 + 5 + 30 = 53 m or otherwise 5.3 Atm is the minimum required for supplying water to the cottage. It is customary to select equipment for performance with a small margin, taking into account some loss of power during wear.

Let's calculate water consumption. We have three permanent water points. A watering tap consumes up to 18 liters per minute, a kitchen faucet consumes 10 liters, a shower consumes 12 liters per minute. It turns out 40 liters, to which we add 5 liters for plumbing fixtures that periodically consume water.

Let's take into account that the flow rate should be less than the flow rate of the well by about 15%. If, as a result of pumping out water, the dynamic level drops, the pump will switch to “dry running,” which ultimately leads to accelerated wear of the equipment.

Let's choose a pump. We compare the performance data of the selected model with the water consumption and flow rate of the well. If a storage tank is not intended to be included in the water supply system, the pump must supply water in the volume of the total second flow rate.

If you have a conventional storage tank or hydraulic accumulator You need to focus on hourly water consumption.

Differences in pumps based on operating principle

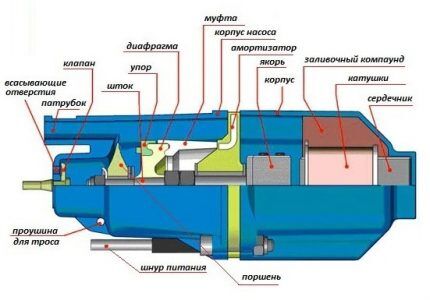

The operation of all types of water pumps is to suck in water and then push it out into the water inlet pipe and further along the pipeline. A vacuum is created inside the unit, due to which suction occurs.

A portion of water pumped into a vacuum chamber is displaced by the next portion. This continues until the desired liquid flows into the tap intended for its passage.

According to the methods of vacuum formation, household pumping equipment is divided into the following types:

- Centrifugal. They work by generating centrifugal force by the blades of a centrifugal wheel. These include a significant portion of surface aggregates. The least sensitive to the presence of grains of sand in water is centrifugal pumps, but there are still restrictions on the degree of pollution.

- Vortex. A vacuum is created by rotating a vortex wheel. This is a disk with small blades placed around a circle, forming a vortex cavity inside the device. Additional acceleration is imparted to the water particles that fall into it, due to which the vortex units produce a higher pressure than centrifugal ones. The disadvantage of vortex devices is their vulnerability to dirty water.

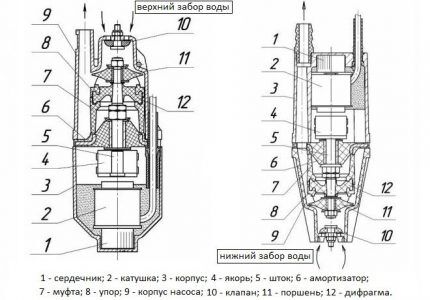

- Electromagnetic, aka vibration. They function by drawing in water by a diaphragm located inside, which in turn activates the reciprocating movements of the electromagnetic field. They belong to submersible pumps, unlike their vortex counterparts, they are more adapted to somewhat contaminated water.

Self-priming pumps were invented to extract and transport water with a significant air content. These are surface systems, in the model range of which you can find options with and without an ejector. Various companies produce self-priming pumping equipment for pumping clean or contaminated water.

All of the listed types of pumps are used in the construction of autonomous water supply systems and supply water for household needs, drinking purposes and site irrigation.

Review of pumps from trusted manufacturers

The buyer who owns an estate with a well is offered an extensive range of reliable pumping equipment supplied by domestic and foreign manufacturing companies.

Decent offers from foreign brands

Let us list the popular foreign brands of pumps that are in demand among summer residents and lovers of country life:

- ESPA, Spain. The products of the manufacturer Espa Group are distinguished by stable operation, endurance, and maximum adaptability to operation in difficult Russian conditions. The company's activities started with the production of centrifugal pumping systems more than half a century ago. Now the company offers a series of submersible well pumps and surface stations for domestic use. Price tag from 9 thousand rubles.

- PEDROLLO, Italy. For more than 20 years, it has been supplying deep well pumps and self-priming surface units to the domestic market. The company's products are attractive due to their lightness, which is successfully combined with the strength of the parts and housing; anti-corrosion materials that meet high environmental requirements are used in production. Price from 14 thousand rubles.

- KARCHER or KG for short, Germany. It has been producing pumps for over 80 years; the line of pumping equipment for wells includes submersible pumps and water supply stations with automation and a hydraulic tank. KG pump technology is characterized by perfect assembly precision and long service life. Price from 9 thousand rubles.

- GARDENA, Germany. The company specializes in the production of garden tools and equipment. It produces garden pumps for collecting water from shallow excavations and open reservoirs, borehole pumping equipment and automatic pressure stations. The price of the units depends on the design complexity, starts from 6 thousand rubles, the average price tag is 13 – 23 thousand rubles.

- GRUNDFOS, Denmark. The largest manufacturer of pumping equipment, whose products are respected for their wear resistance and high degree of corrosion protection. Submersible and surface Danish pumping machines are justifiably popular, the average price is 27 thousand rubles.

- ZDS, Italy. It produces premium pumping equipment; the company is famous for its unique system of protecting engines from overheating, dry running, and power surges. The product line for wells includes high-performance items capable of pumping water with some sand content. Average price tag from 32 thousand rubles.

The wide foreign selection is somewhat overshadowed by the impressive cost of serious models. Moreover, pumps for collecting perched water can be purchased at a very reasonable price.

Significant disadvantages include the high cost of repairs and the difficulty of delivering original spare parts to replace worn-out ones that have not withstood the hardships of local operation.

Details about domestically produced pumps

The disadvantages of foreign units spontaneously turn into advantages of domestic products. The buyer of a pump with a Russian brand will not be intimidated by the price, nor will they be bothered by the difficulties of repair.A pleasant bonus will be a convincing one-year warranty, as well as the ability to quickly exchange your purchase for a more suitable model.

Kid: small and smart!

With hard work and unpretentiousness household pump Kid familiar to many generations of summer residents. The products are manufactured by JSC HMS Livgidromash, located in the Vladimir region. Over more than 70 years of development, the only representative gave rise to numerous modifications.

The product line includes models with variations in pressure and intake depth; there are options with a suction pipe located at the bottom or at the top.

Purchase with a lower connection if you are transporting impeccably clean water. They are purchased with an upper pipe if there is a risk of clogging with silt and other suspended impurities.

The universal unit is suitable for extracting water from wells, open reservoirs, and boreholes. This is not the most suitable type for equipping a constantly functioning water supply system.

However, among equally compact machines, it leads in performance parameters. Resistant to power surges, tolerant of shortcomings in the electrical network, and protected from dry running.

The vibration unit Malysh attracts with its simplicity of design and attractive price. On average, the cost of miniature equipment ranges from 1.5 to just over 2 thousand rubles. Analogue – pump Brook, practically no different from the Malysh in technical and price aspects.

Well pumps from the company Gilex

JEELEX - a pioneer in the production of pumps in the post-Soviet space. Founded in Klimovsk near Moscow, the company has been producing pumps for household and industrial use for almost a quarter of a century. The manufacturer has the latest equipment, innovative technologies and its own engineering developments.

Gilex offers owners of country plots with a well a wide range of pumping equipment and issues instructions for installation and operation. The company publishes recommendations on how to correctly select the optimal pump for a well and other water supply sources.

To collect water from shallow wells, surface self-priming installations are produced "Jumbo" and automatic pumps.

Automatically functioning equipment supplies clean water from excavations, main networks, open reservoirs, turns on/off independently, and maintains a stable pressure in the water supply system.

If the automatic station is equipped with an ejector, then the requirements for the purity of the pumped water can be reduced. The price for the simplest products is from 6.5 thousand rubles.

pump and automatic pump, the latter operates in automatic mode, maintaining the required pressure in the system, turning on and off as needed (+)

The marking of Gilex submersible pumps indicates the volume of maximum water flow and the pressure value in the form of a fraction.

Index A denotes automatic pumps, the operation of which is controlled by the level of water taken. The letter CH denotes models with a frequency converter, the index DOM denotes automatic machines that maintain constant pressure in the water supply network. Price from 7 to 25 thousand rubles. depending on the design complexity.

Conclusions and useful video on the topic

Tips for selecting the optimal pumping equipment from sales specialists:

Personal experience of a summer resident who chose a pump for a deep well:

Review of pumping equipment from Gilex to help customers:

The detailed information we offer with the criteria for choosing the optimal well pump will help you purchase the ideal unit with the required technical characteristics.

We introduced production leaders in the pump production segment and introduced them to approximate price tags. Now you can carry out your planned pump purchase with confidence.

Are you looking for an efficient well pump? Or do you have experience using such installations? Please leave comments on the article and share your impressions of using pumping equipment.

If you take a submersible pump, then choose between the production of pumps by Livgidromash and Gileks, and from the western ones GRUNDFOS. All others are pampering or overpaying for a brand. Brook and Baby from Liven are stable, reliable, but outdated. If you need a pump with a selection of characteristics, take “Dzhileks” from Klimovsk, they will put all the listed Western companies in their belts in terms of price, reliability, quality, characteristics and power. GRUNDFOS, although manufactured in China and Russia, still has a high-quality assembly, and is also unpretentious in operation.

All the pumps that I have listed are repairable, interchangeable, easy to operate and forgiving of user errors.

I completely agree with the opinion from the previous comment about the reliability of the “Malysh” pump. The fact that it is outdated is not a reason to abandon it. These pumps work for many years. I wanted to share one useful “life hack” on my own behalf. To prevent the pump from becoming clogged with sand and silt when using it in a well, pull a regular women's stocking over it. It will act as a filter and the pump will not be overloaded.

What a "Baby"! What do you recommend!!! Any vortex, centrifugal, but not vibration! All seams and water seals will fly out! Please pump something out of the pit and into the well just to kill the well. Read the recommendations of drilling and well companies, they don’t even recommend doing primary pumping.