Do-it-yourself well flushing after drilling: step-by-step instructions on how to carry out the work

Country property owners will definitely have to deal with drilling wells on their own property, since there is simply no other way to organize a water supply system at home. Agree, this is quite a responsible undertaking that needs to be taken seriously.

Do not forget that in order to obtain clean water from a well, it must be freed from soil particles drawn into the bottom immediately after the drilling process. Therefore, flushing the well after drilling is necessary in all cases. You can clean the mine yourself, using the necessary equipment and having some knowledge about this process.

Next, we will talk about the most common methods of flushing wells and how to do it yourself. In addition, you will learn what mistakes to avoid during the work. The material is accompanied by photo illustrations and videos that clearly demonstrate the process of cleaning wells.

The content of the article:

Why flush a well after drilling?

After graduation well drilling process requires flushing in order for the extracted water to meet sanitary and hygienic requirements.

The fact is that contaminants that make the water unusable enter the estuary in large quantities during development. Also, debris, small insects, etc. can get in from above during drilling.

If you neglect washing and immediately install filters, they will quickly become clogged and become unusable, and a layer of silt will form at the bottom, which will become a source of unpleasant taste and odor.

In addition, pathogenic microorganisms multiply very well in the muddy layer, which means that drinking water from such a well will be dangerous to health.

The silty layer will increase over time and completely block access to the aquifer. The operation of the well will become impossible. These problems can be easily avoided and the life of your source can be extended if you flush it immediately after drilling.

Reasons why it is necessary to flush the well:

- improving the quality of produced water;

- extending the service life of pumping equipment and filters;

- increasing well productivity;

- increased service life, open access to the aquifer.

Flushing the well before putting it into operation can be done with your own hands, without the involvement of specialists.

This is not a very complicated process if you know the technology and features of its implementation.

The best methods for cleaning wells

There are four ways to flush a well after drilling. Each method is carried out using various equipment and devices.

The choice of one method or another depends on many factors: the depth of the well, the type of soil, the degree of contamination, the nature of the contamination, the materials from which the well strings are made.

Four ways to flush a well:

- using a pump;

- using two pumps;

- using airlift blowing;

- manual method using a bailer.

Flushing manually - a labor-intensive and ineffective method that can be used in the presence of slight siltation in a shallow well located on clayey and loamy stable soils.

Air purging requires the use of special industrial equipment - a high-power compressor.

Few private owners have the opportunity to use such equipment. Therefore, the optimal way to clean a well before putting it into operation can be considered flushing using pumps.

Regarding washing technology, there are two methods:

- straight;

- back.

Direct flush - a method in which water is supplied inside using a flushing hose, as a result of which contaminants come out through the hole of the well.

Direct flushing is used to remove heavy sediment contaminants remaining after drilling operations.

Backwash - a method in which water enters the annulus, while the upward flow, along with contaminants, is discharged out through the pipe. This washing method is effective in removing sand and loose silt deposits.

Sometimes chemical reagents are used to flush wells; it is advisable to do this in the presence of iron-containing impurities. The cost of such reagents is quite high, so in most cases, ordinary process water is used to clean the well.

Method #1. Well flushing with one pump

This is the simplest washing method, for which you will need:

- submersible pump;

- injection hose;

- cable.

In this case, the well is flushed using pumped water, which will carry away contaminants. The duration of such pumping can range from 12 hours to several days, depending on the degree of contamination. You can stop cleaning when the water extracted from the well does not become clean.

Selecting a submersible pump

Flushing a well will only be effective if you choose the right submersible pump.

Requirements for the pump:

- optimal power;

- low price.

When flushing a well after drilling, the pump experiences heavy loads, pumping cubic meters of contaminated water. Therefore, the probability of pump failure is very high.

In other words, to flush the well, it is recommended to use a pump that is “not a pity.” It could be a very cheap model or an old, worn-out pump that has long been in need of replacement.

The best option would be to use a vibrating submersible pump. Affordable units are often used for work: "Baby" or "Stream".

Such pumps are less sensitive to silt particles and sand, unlike centrifugal pumps.

The principle of flushing with a vibration pump is as follows: after connecting the device to the power supply, a magnetic field is formed inside its body, which constantly increases and decreases.

The created reciprocating movements (vibration) lead to a change in pressure, due to which water is pumped.

The advantages of submersible vibration pumps include:

- low cost;

- ease of use;

- no heating during operation.

Disadvantages of pumps of this type:

- cannot work stably with “jumping” voltage in the electrical network;

- low power compared to centrifugal pumps.

Of course, the use of a more powerful centrifugal or screw pump will allow cleaning the well much faster.

However, the cost of even the simplest submersible pumps of these types is several times higher than that of a vibration pump. And given that, with a high degree of probability, the pump will be unsuitable for operating the well in the future, the most acceptable option would be to use vibrating submersible equipment.

Recommendations for choosing a pump for cleaning wells are given in this article.

Work production technology

Step-by-step instructions for flushing a well after drilling are as follows:

- The submersible pump is securely tied to the cable to prevent it from being sucked into the sludge. It is not recommended to use the rope or cord included in the kit, because... their strength is not always enough to pull the pump out of the sludge “trap”.

- The pump is lowered to the very bottom of the well and rises several times in a row. This is done to agitate the sediment at the bottom.

- At a certain height, the pump is suspended and connected to the electrical network. The location of the pump is determined 60-80 cm above the bottom of the source. Under no circumstances should a running pump be lowered to the very bottom!

- The pump pumps the well until the water becomes clean.

Please note that in some cases, water from the well will be released under high pressure, so measures must be taken to protect the surrounding landscape from the release of dirt.

To reduce wear on the pump, it is necessary to periodically remove it to the surface and rinse it with clean water. The frequency of washing is every 5-6 hours.

The advantages of the method of flushing a well with one pump: simplicity and high efficiency. This method is also used for well pumpingwater intake source being put into operation or already in use.

The disadvantages of this method include the fact that in most cases it takes a long time to flush, and there is also a risk of damage to the pumping equipment. This method is advisable to use on sandy and sandy loam soils.

To improve the quality and speed of washing, you can use a higher-performance submersible pump centrifugal type.

Fecal and drainage pumps, passing through itself when pumping particles with fractions up to 30-40 mm.

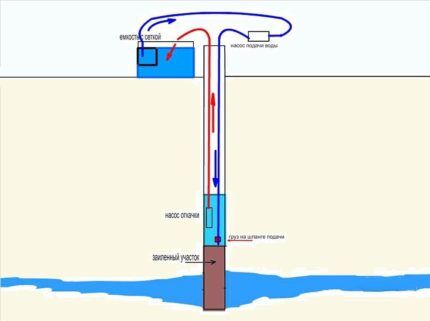

Method #2. Using two pumps

In this case, flushing is carried out using water pumped into the well by the first pump, where it “collects” contaminants and, using the second pump, lifts them to the surface into a reservoir of water.

A filter is installed in the reservoir, which cleans the incoming liquid from suspended particles and returns it back to the well for a new portion of contaminants.

To flush a well in this way you will need:

- a water tank with a volume of at least 200 l;

- submersible vibration pump (pump No. 1);

- centrifugal pump (pump No. 2);

- a bucket with drilled holes for installing a pump;

- two hoses;

- strong cable.

When implementing this method, the submersible pump experiences less load, which means the risk of its failure is reduced. This method is advisable to use in cases where further operation of the submersible pump is planned, as well as when there is a limited amount of clean (washable) water.

Flushing using two pumps is carried out as follows:

- Submersible pump No. 1 is lowered into the well using a cable and suspended 50-60 cm from the silt deposits.

- An injection hose is lowered into a water tank, and a second hose is lowered from the tank into the well.

- Centrifugal pump No. 2 is installed in the bucket and immersed in the tank.

- Both pumps are turned on, and the hose located in the well must be swung in different directions to maximize the erosion of deposits.

- Flushing continues until the water washed out of the well becomes clean.

When flushing, you should focus on a more powerful pump; it should be stopped periodically to maintain the optimal water level in the tank.

Advantages of the washing method using two pumps:

- faster and better washing;

- less load on the submersible pump;

- the area around the well is not contaminated;

- Doesn't require a lot of water.

The main disadvantage of this method is the need to constantly be present during flushing in order to monitor the smooth operation of both pumps, turning off the more powerful one from time to time.

The duration of well cleaning after drilling using this method ranges from 6 hours to 48 hours.

Method #2. Well flushing with airlift

An airlift is a special device that produces a powerful jet of compressed air, lifting water from the bottom of the well along with sand, debris and silt deposits. To flush a well with an airlift, a filter must be installed inside it, through which suspended particles are removed.

Equipment required for flushing a well after drilling using the airlift method:

- air compressor (air blower);

- technical water supply 100-200 l;

- metal pipe;

- air supply hose.

The pipe is taken to the entire depth of the well, and its diameter should be 10-15 cm less than the diameter of the casing. A narrow pipe will not work, because... will not provide effective cleaning.

The top of the pipe must have an outlet to remove contaminants.To prevent dirt from splashing onto the area adjacent to the well, a thick polyethylene sleeve or part of a rubberized fire hose must be placed on the end of the pipe.

The principle of operation of the airlift is that a volume of air is pumped through a pipe into the well, and then pushed out from there under the influence of water pressure, washing away all contaminants.

The procedure for flushing a well after drilling using an airlift:

- A metal pipe of the required diameter is placed in the well. The pipe is immersed as much as possible in the silt deposits.

- An outlet and a discharge hose are mounted at the upper end of the pipe to prevent splashing of dirt.

- The compressor turns on and compressed air enters the well under pressure.

- Air bubbles in the pipe move the water and sludge at the bottom, creating circulation.

- Under the influence of compressed air, water along with contaminants flies upward into the outlet and is removed through the outlet hose.

Flushing is considered complete when particles of silt, sand and debris stop flowing from the outlet hose. This method is quite effective and does not require the use of pumping equipment.

When performing airlift cleaning, it is necessary to take into account that too much air pressure can negatively affect the integrity of the well walls.

It is also worth considering that this method is quite energy-intensive - the compressor unit consumes a lot of electricity, and the washing time can be up to 24 hours.

The advantages of this method include: short duration of the flushing process, pumping equipment does not deteriorate, the area around the well is not polluted, and the quality of flushing is high.

Common mistakes when flushing a well

Inexperienced well owners often make mistakes by neglecting to flush the well after completion of drilling operations. As a result, the water in the mine remains untreated, which makes its use limited.

Mistake #1. One of the most common mistakes when flushing a well with a pump is its incorrect suspension height.

The pump must not be allowed to touch the bottom; in this case, cleaning will not be effective: the pump will not be able to capture sludge particles under its body. As a result, silt will remain at the bottom of the well, blocking access to the aquifer and deteriorating water quality.

In addition, too low a pump position can lead to the equipment being “buried” in the sludge and getting it out of there will be problematic. It also happens that the pump gets stuck in the wellbore.

This can be avoided if you use a thin but strong cable for immersion, and when pulling the pump back, do not make sudden movements, but gently swing the cable to lift the pump out of the well.

Mistake #2. Improperly organized drainage. Contaminated water coming from the well should be drained as far as possible from the mouth.

Otherwise, there is a risk that it will return to the source, which will lead to an increase in the flushing period, and therefore additional financial costs.To organize drainage, it is best to use durable fire hoses.

It is important to flush the well until clean water comes out of it. Putting an unflushed well into operation is prohibited! This will lead to damage to the pumping equipment and problems well operation in future.

Conclusions and useful video on the topic

Flushing a well using a pump:

What does the process of flushing a well with one pump look like and why it is necessary to take care of organizing water disposal:

As you can see, flushing the well after completion of drilling work is a necessary activity that cannot be avoided if you want to get clean water.

Flushing can be carried out in several ways: one or two pumps or an airlift. The manual cleaning method using a bailer for primary rinsing is not practical due to its low efficiency.

Do you have anything to add or have questions on the topic? Share your experience of well cleaning with readers, please leave comments on the publication. The contact form is located in the lower block.

Please tell me, is it necessary to flush the well every day? Just before drawing water for drinking, we let the water run idle for at least 2 minutes. Or we collect it for watering seedlings, and then for drinking. Is it possible to install special filters directly into the well so that there is no doubt that the water is clean, and do the properties of water depend on the depth of the well?

The well is flushed once - after drilling.And they wash it not for 2 minutes, but for a long time, until it becomes suitable for drinking. I know people who pumped for several weeks without turning off the pump.

Water filters that are immersed in a well, of course, exist, and there are quite a large number of them. Starting from a simple gravel filter that prevents dirt from being picked up, to a bunch of different membrane filters. Normal filters are made by Honeywell and Drufi, although others can be found. In a good way, you need to conduct a laboratory analysis of the water to determine what degree of purification it needs and then decide on a filter.

What is the average amount of time it will take to pump a well? Our soil is clayey.

It would be nice if you indicated not only the type of soil, but also the depth of the well. Because, based only on data on the type of soil, it is impossible to give an answer on the specific time frames that are necessary for the full pumping of the well. In the most difficult case, it is about two days. It all depends on the thickness of the silted area that will be washed. The process may take several hours, or it may drag on for a couple of days.

I also advise you to carry out a chemical water analysis! For some reason, many people believe that it is not necessary to do this, but because of this, various unpleasant cases occur, which has a detrimental effect on health.

Good afternoon. Please tell me how to properly pump the well. From the prehistory: the drillers arrived. We drilled a well and installed a column of HDPE pipes with a diameter of 110 mm and a depth of 13 meters.The first 2 meters are peat, from 2-8 meters there is sandy loam interspersed with small pebbles, from 8 to 13 there is blue clay. Question! How to pump a well correctly and as quickly as possible??? Every other day I turn on the vibration pump, for the first 5-10 minutes the water flows relatively clear and then it begins to flow with particles of clay. I tried to stand for an hour. Transparency changes, but not much. Thank you in advance

Good afternoon, we drilled a 40 m well into limestone, drained it for 12 hours, the water was clear, but tasted of iron, after 40 minutes it became cloudy with a strong smell of hydrogen sulfide! Tell me, is it worth flushing the well again or is it already useless? (the soil is clayey) thanks in advance for your answer

If the well is 26 meters, the soil there is clayey with sand, we didn’t wash it right away, only the next day we lowered about 4 cubic meters there, started pumping and there was only sand... I’m waiting for an answer

Heh. They drained 4 cubic meters and want normal water.

You didn't even really wash out the lake.

400+ cubic meters need to be drained.

I just continuously pumped water into the raspberries for 3 weeks.

But now it’s pure - just a song.

They found drillers in Kamyshlov, they came, started drilling with an inclination, and I said: why is that? They say it’s normal, don’t strain yourself, everything is fine. They drilled, went for water several times, it took 2 days. They pumped it into the pit and it flowed from it into the well. We got together, give us the money. No flushing was discussed for a year, they promised to flush it once for free, then for money. we bought a pump, it worked for two days, the pusher rod burst. we bought a new one again, we pump the white mud, we defend it and only then use it. we cursed the very idea, the drillers and their boss. That’s how we live.