Ventilation of a room with gas-using equipment: design standards + arrangement rules

Gas appliances are increasingly used not only in industrial buildings, but also in private houses or apartments.These can be both household stoves and water heaters, heating boilers installed in kitchens or boiler rooms.

Agree, properly designed ventilation of a room with gas-using equipment, creating continuous air circulation, can ensure the safety and correct operation of the equipment. But failure to comply with regulatory requirements and operating rules can result in danger to human life.

Next, we will tell you how ventilation is installed in rooms with various gas-using equipment and what is needed to install it.

The content of the article:

Regulatory requirements for air recirculation

In any premises with gas equipment, natural, continuous ventilation must be provided, providing at least three air changes in 1 hour. The speed of circulation of air masses is measured with an anemometer.

You can calculate the required amount of incoming oxygen for rooms where gas equipment is used using the formula:

L= N x V, Where

L – air flow, m3/h;

N – normalized air exchange rate (for rooms with gas equipment this indicator = 3);

V – volume of the room, m3.

Air exchange rates are regulated SP-60.13330.2016, GOST-R-EN-13779-2007, GOST-22270-2018. They apply to the design of new, reconstructed and expanded gas supply systems.

The key rules are prescribed by the following points:

- at installation of gas boilers it is important to take into account the requirements not only for the boiler room itself, but also the standards for ensuring the operation of the ventilation system;

- gas pipelines cannot cross ventilation ducts;

- all rooms into which the fireboxes of heating and cooking gas furnaces open must be equipped with an exhaust ventilation duct. An alternative is allowed - a window, window or door opening onto a non-residential premises;

- when installing a gas heater or fireplace, it is necessary to provide an exhaust ventilation device;

- if a catering establishment has a group of gas devices located close to each other, it is allowed to use one ventilation hood followed by insertion into the prefabricated chimney with exhaust fan;

- ventilation system in industrial workshops, boiler rooms, agricultural enterprises, industrial buildings of consumer services must comply with building codes and requirements for the type of production equipped inside.

There are no additional requirements for the design of ventilation in buildings of this group.

Indoor air recirculation parameters must be calculated based on the maximum permissible concentrations of NO2 and CO2 in the work area.Hoods should be placed above the burners, and supply systems should be placed outside the radiation zone.

Premises with a high degree of explosion hazard (category A) must be equipped with a mechanical supply and exhaust ventilation system. The upper levels of these premises must be equipped with natural ventilation with deflectors. During non-working hours, only natural or mixed ventilation can be used.

In premises of category A with liquefied gas circulation, forced ventilation must ensure recirculation in both the upper and lower zones. The system openings must be placed at a level of 30 cm from the floor.

The design of the emergency ventilation system must be carried out according to the standards “SP-60.13330.2016” (clause 7.6). It should be launched automatically as soon as the devices signal that the maximum permissible gas concentration indoors has been exceeded.

A dangerous gas concentration in the air is considered to be above 20% of the lower flammability limit.

Ventilation in rooms with gas equipment

Designing a ventilation system intended for small domestic premises with a boiler or gas stove will not cause difficulties. You can deal with it yourself.

Exhaust ventilation device

The action of exhaust ventilation is aimed at removing polluted air from the room.

To install it, you will need the following components: fan, air duct, ventilation grille.

When choosing a fan, it is recommended to give preference to devices with check valve. This will prevent outside air from entering the room.

Air ducts are pipes made of PVC or other materials. Its diameter must match the size of the fan.

When choosing a ventilation grill, you should pay attention to the fact that there are now many models on sale that differ in size, design, and design. Therefore, it is easy to choose an option that perfectly matches the style of the room.

Supply recirculation system

Supply equipment provides fresh oxygen supply to the room with gas-using devices. The main element of such a system is the supply unit.

Its function is to supply oxygen from outside. As the air passes through it, it is filtered, heated or cooled if the device is additionally equipped with a recuperator.

Low-power installations are suitable for domestic use. The main advantage of this type of ventilation is noiselessness and comfort in operation. The simplest example is a supply fan.

The inlets are divided into the following categories:

- Electrical device for ventilation. Provides not only filtration of incoming oxygen, but also its heating.

- Wall inlet valve. It can operate in automatic mode and have an additional oxygen filtration option. For installation, you will need to make a through hole in the wall of the building.

- Window inlet valve. It can be either mechanical or automatic. Installed in the sash of a plastic window. The downside is the likelihood of icing at extremely low temperatures.

All of the listed types of supply ventilation are easy to assemble and operate. You can install the structure yourself.

Additional requirements regarding the supply system are put forward for rooms equipped with plastic windows that close hermetically.

The required extraction power is calculated using the following formula:

M = O x 10, Where

O is the volume of air, which is calculated as follows:

O = H x L x S.

H – height of the room, L – length, S – width.

Supply and exhaust recirculation system

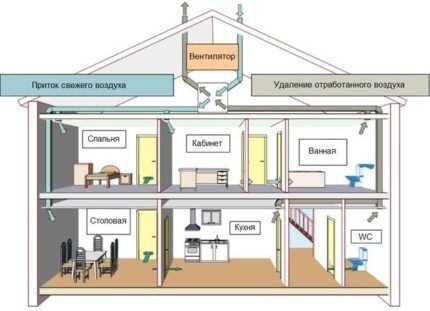

The mixed ventilation system ensures the simultaneous outflow of waste oxygen and the entry of fresh oxygen into the room. Most often used in large objects and houses with a total area exceeding 100 m2 .

Units equipped with a recuperator will reduce fuel consumption by up to 90% due to heating of the incoming air flow.

For ease of installation, combined systems can have vertical, horizontal or universal orientation. Installation is carried out after the completion of plastering and puttying of the walls, but before installing the ceiling, since the entire infrastructure will be hidden under it.

As a rule, in supply and exhaust system includes the following components: air intake valve, cleaning air filter, heater, recuperator, cooling unit, outer grille.

Ventilation of premises with gas-using equipment

Premises with gas equipment must be equipped with an exhaust ventilation duct.In addition, in the lower part of the door or wall of an adjacent room, excluding living rooms, it is necessary to make holes covered with a grill.

This will promote additional air circulation. It is allowed to use for these purposes the gaps between the floor and the door (section min 2 cm2).

Ventilation of a gas boiler room - basic requirements

Backdraft promotes the spread of combustion products, so it is not allowed in rooms equipped with a ventilation system. The oxygen circulation scheme in the boiler room is calculated based on the type and power of the installed equipment.

Basic requirements for the ventilation system in a gas boiler room:

- The ventilation system must provide three air changes per hour.

- Air supply is carried out through special holes and channels.

- Boiler room ventilation is part of the overall system of the house. Exhaust air exhaust devices must be located in the upper areas of the walls of the boiler room or on the ceiling.

- When supplying oxygen from the inside, it will be necessary to ensure inflow through a hole with a cross-section of 30 cm2 per 1 kW of equipment power. If the air draft is external, the hole with a cross-section min 8 cm2.

- Gas equipment must be installed against the wall with a gap of 10 cm.

In addition, it is worth remembering that supply and exhaust devices must be placed in the opposite part of the room.

Ventilation in a room with a gas boiler

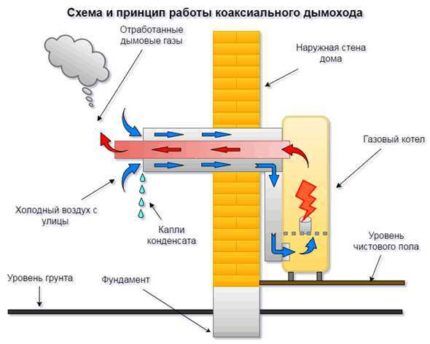

The basic requirements for ventilation systems at facilities with gas boilers or stoves are practically identical.Boilers equipped with a closed combustion chamber are equipped with a coaxial smoke duct. Through it, oxygen is simultaneously supplied from the street and combustion products are taken in.

Technological rules for installing a ventilation system for devices with a closed combustion chamber:

- The ventilation system must be sealed. Possible leaks pose high risks to human life and health.

- To ensure complete sealing, all connecting seams of the system must be treated with a sealant that is resistant to high temperatures.

- High-quality thermal insulation will prevent possible overheating and fire of system elements.

- No more than two gas devices can be connected to one chimney, regardless of their location and distance from each other.

- Combustion products must be discharged into the chimney at a distance min 50 cm at different levels.

- If the oxygen supply is from one level, the chimney must be equipped with a special cut, the height of which must be more than 50 cm.

The standard calculation of the required volume of circulation of air masses should be made according to the following standards: outflow in the volume of three times air exchange in a room with gas-using equipment, and supply is the sum of the outflow volume and the volume of oxygen required for combustion.

When designing a ventilation system, it is necessary to take into account the power of the equipment. The oxygen supply must ensure the combustion process is maintained.Otherwise, the performance of gas equipment is disrupted and soot is formed.

A constant flow of air prevents the atmosphere inside the room from becoming thinner and reducing draft. When calculating the required volume of oxygen supplied, it is important to take into account the volume of the room.

Technological rules for installing a ventilation system for devices with an open combustion chamber:

- The room must be equipped chimneyensuring constant circulation.

- From the room with gas boiler A general exhaust ventilation system is being installed.

If a gas boiler is placed in a boiler room, it must be equipped with a permanently functioning supply ventilation supplying oxygen from the street.

Ventilation of rooms with geysers

The main requirement when designing a ventilation infrastructure in a room equipped with a gas water heater is the presence of an exhaust pipe. It can be made from coaxial, steel or metal pipe.

The coaxial option is recognized as the most reliable, which leads to its wide distribution. Design features vary depending on the power of the speaker itself.

The exhaust pipe mechanism consists of the following elements:

- pipe (it is recommended to provide thermal insulation);

- feedthrough pipe;

- special fasteners, brackets;

- clamps (attached to pipe joints);

- adapter connecting the column to the pipe;

- special window for revisions;

- container collecting condensate;

- protective umbrella - installed outside to protect against liquids, debris, etc.

The diameter of the pipe must be absolutely the same along its entire length. Its total length must be at least 4 m. When choosing a design, climatic conditions should be taken into account. For cold regions, insulation is recommended. The end point should rise to min 1 m from the roof.

Ventilation system for rooms with a gas stove

Below are the standards "SP-402.1325800.2018"regulating the basic requirements for sufficient air exchange in rooms with gas stoves:

- the minimum ceiling height must exceed 2.2 m;

- presence of a ventilation duct. As an alternative, windows and vents located in the upper part of the room can be used;

- doors to the room must have an open window with an area of 0.25 m;

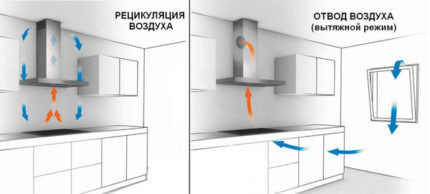

The most popular method of ventilation in the kitchen remains the installation of a hood. A fan placed inside will remove carbon monoxide and odors generated during the cooking process. In this way, forced ventilation will be provided in the room.

The wide umbrella design will ensure precise direction of air directly into the air duct. There is a wide range of hoods on the market, the prices of which vary depending on the brand, power and additional options.

All hoods are divided into 2 categories:

- Ensuring the removal of combustion products to the outside.Such hoods provide complete removal of waste oxygen to the outside and ensure the supply of fresh oxygen from outside.

- Working on the principle of air filtration and recirculation. This type does not participate in the air exchange process in the room with gas-using equipment. Air masses circulate exclusively inside.

Regulatory documents regulating air conditioning and ventilation allow the use of mechanical ventilation of the supply-exhaust type for rooms with a gas boiler, if this does not disrupt the overall ventilation system of the building.

This point implies that the hood air duct cannot cut into the shaft, blocking the ventilation grille, otherwise when the hood is turned on, the room with the boiler will not be ventilated.

This problem can be solved by installing a special ventilation grille equipped with an outlet for a round air duct.

Conclusions and useful video on the topic

To learn how to combine a ventilation system and a hood, watch the following video:

Main mistakes in installing natural ventilation:

The most difficult stage in installing ventilation is its design. The design of the system must be developed taking into account all the listed standards and requirements determined by gas services. This will ensure safety for human life and high-performance operation of equipment.

Do you have any questions, find any shortcomings, or can you add valuable information to our material? Please leave your comments, share your experience, and ask questions in the block below.