Check valve for ventilation: how to arrange ventilation with a check valve for the hood

Are cooking smells coming back instead of leaving the room forever? Agree, this is an extremely unpleasant situation that you want to get rid of as quickly as possible. Most likely the problem lies in the occurrence of reverse thrust. This is a common phenomenon that has many negative consequences.

We will help you get rid of unwanted odors with a simple and inexpensive device. It will not require redevelopment of existing ventilation ducts or significant financial investments. It will be enough to install a check valve on the ventilation, which will solve the problem.

For optimal results, it is necessary to know the design options of valves, their pros and cons, as well as the rules for placement and installation in exhaust systems. All information is given in our article. It also contains useful videos with step-by-step installation instructions and photos demonstrating the essence of the material presented.

The content of the article:

Causes of reverse thrust

In order to decide whether to install a check valve, it is necessary to find out the possibility of reverse draft occurring in the home ventilation system. Understanding this process will allow you to correctly plan and implement indoor air exchange.

Operating principle supply and exhaust ventilation is based on the law that at any given time the volume of air entering and leaving the room is the same.

Thus, backdraft in the hood occurs if the total flow at the remaining air entry and exit points is directed away from the house. There are several main reasons for this effect to occur.

Often reverse thrust occurs due to a significant reduction or cessation of the flow entering the premises through supply ventilation.

This can occur as a result of gradual clogging of the holes, and in the case of a forced circuit, wear or breakdown of the mechanisms responsible for air circulation. Also, the occurrence of reverse draft can be facilitated by a sharp increase in the volume of air exiting through one of the exhaust devices.

For example, when stove heating hot air with combustion products intensively exits through the chimney. If there is insufficient supply through the supply ventilation, the direction of flow in the hoods will change.

If an air duct with several air intake points is used inside the house, it is possible to change the flow direction if forced ventilation is turned on in one of them.

So, if the boxes from the kitchen and bathroom are connected into one system, then turning on kitchen hood will lead to air pressure not only towards the street, but also towards the bathroom.

Changing environmental parameters outside an apartment or house can also cause reverse draft. During construction work associated with changes in topography, such as the construction or demolition of nearby buildings, the wind direction may change towards the exhaust.

In apartment buildings, when using common ventilation shafts to remove air, back draft into the apartment may occur due to the connection of powerful hoods by neighbors.

This problem is especially relevant for older houses, the common air ducts of which are designed without taking into account the possibility of using devices for forced ventilation.

Even if there are currently no conditions for reverse draft to occur, it is better to install a check valve when installing the air circulation system. Possible modifications, contamination of the supply ventilation or external factors can lead to a variable direction of air flow.

The cost of ready-made devices is low, and introducing a valve into already operating air ducts is a labor-intensive task. Those who want to check the functionality of the ventilation in the apartment will find detailed information in the next articleposted on our website.

Check valve types

Due to the widespread use of exhaust devices, the use of manual controls to regulate air flow is no longer relevant.

There are four fundamentally different ways to automatically prevent backdraft in a ventilation system. Each of them has its pros and cons, which must be taken into account when choosing the type of device.

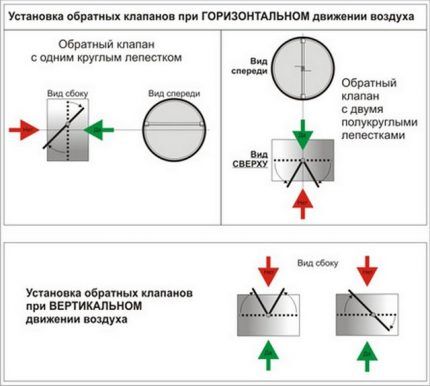

Type #1 - single-leaf gravity action

The flow directed from the room puts pressure on the valve flap and opens it to allow air to pass through. In the absence of movement or in the event of a reverse draft, there will be no pressure on the sash and it will close under the influence of gravity.

If installed correctly, a gravity check valve can be used with natural ventilation, since its resistance to opening the valve is insignificant.

There are two ways to implement this design:

- axis position offset, on which the flap is fixed, relative to the middle of the cross-section of the air duct channel;

- presence of counterweightlocated inside or outside the device.

Taking into account the fact that the principle of closing the valve is based on the action of gravity, it is necessary to place the valve, depending on the design, strictly horizontally or vertically using a level.

Otherwise, it may either not close completely, or significant air flow forces in the ventilation system will be required to open the sash, especially if a counterweight is used.

Type #2 - double leaf using springs

The butterfly check valve is equipped with two curtains that fold when there is excess pressure on the desired side and close with the help of springs when there is no pressure. Since the closing process does not depend on the action of gravity, such a device, unlike the gravitational type, can be located at any angle.

As a rule, this option functions normally only with forced ventilation using a hood.

Before purchasing a valve, it is necessary to check the sensitivity of the curtains for opening to the air pressure characteristic of the air duct on which it will be installed. Some modern butterfly devices can be adjusted according to the force of the springs.

Type #3 - blinds on the ventilation grille

The grille that closes the exit to the street or to a ventilation shaft is often equipped with a valve that resembles window blinds in appearance. This device in detail described here. The principle of its operation is gravitational, similar to the single-leaf version.

The use of several leaves instead of one is due to the compactness of the device in the open position, which is important for external elements of the system.

The dimensions of the gratings are designed for standard parameters ventilation ducts for hoods and holes in the walls intended for air outlet.

The anti-backdraft valve can be installed on the entire grille or just on the opening for natural ventilation. There are grilles with check valves of other design solutions on sale.

However, options with a membrane or the use of springs will have serious problems with performance at low temperatures. Therefore, for a street grille it is better to choose a device with a “blind” type shutter.

Type #4 - flexible membrane

The principle of operation of a diaphragm check valve is based on the ability of the flow to change the position of the flexible plate. Its placement allows you to open the ventilation hole in one direction of air movement, and close it in the other direction, fitting tightly to the perimeter.

In cases where there is a risk that strong backdraft will deform the membrane, it is necessary to have additional stiffeners on which it will rest when closing the ventilation hole.

This fact must be taken into account when purchasing a diaphragm valve; otherwise, curvature and subsequent loose fit of the damper may occur, which will result in partial passage of reverse air flow by the device.

Features of self-production

Considering the low cost of check valves, self-manufacturing of the device is only relevant when using a ventilation grille or air duct with non-standard geometric parameters.In this case, it is often cheaper and faster to make a valve for it than to convert to a standard shape and size.

The easiest way is to make your own diaphragm or single-leaf valve. A rigid material, such as a plastic or metal plate, is used as a sash.

Particular attention should be paid to the following points:

- tight fit of the plate to the walls of the valve body or fixing protrusion to prevent the formation of a gap and the passage of air;

- eliminating plate knocking, which is especially important in the case of frequent changes in the direction of air movement.

For the diaphragm valve, you can use a sheet of thick paper or Mylar film, larger in diameter than the vent hole. In case of strong backdraft, in order to avoid deformation of the membrane material, it is necessary to install a grid on which it will rest.

Placement and installation rules

For systems of any configuration, it is necessary to plan the placement of valves in such a way that reverse draft is blocked when any combination of fans and hoods is turned on. The quality of ventilation depends on the correct installation of the devices themselves.

Valve location in the ventilation system

If exhaust system has one place for air intake, which goes through the ventilation duct into the shaft or onto the street, then to prevent reverse draft it is enough to install a single valve in the air duct.

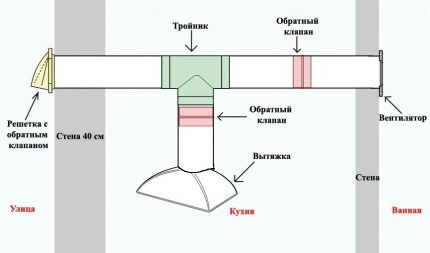

If the system topology is more complex due to the presence of several hoods or openings for natural ventilation, then the following rules for placing check valves apply:

- A check valve is installed on each branch connecting the air intake point and the main air duct. This is necessary to prevent air from being redirected towards the hood when it is not turned on.

- Typically, another device is installed at the outlet of the ventilation system. Ideally, if the channel is completely sealed, this is not necessary, but practice shows the validity of installing the valve in this location.

As a rule, a check valve is installed in places with the most convenient access to them. This is due to the fact that they must be periodically cleaned of adhering dust and grease deposits, otherwise the dampers will not close completely during reverse draft.

When modeling the ductwork, remember that the manufacturer may install a check valve on the fan or hood. In this case, there is no need to install separate backdraft protection.

Particular attention must be paid to installing the valve near the entrance to the shaft of apartment buildings.

The general ventilation system is a cavity protected from direct sunlight with a positive temperature, into which moist air periodically enters, which is an ideal environment for the reproduction of various types of microorganisms. Insects, birds and rodents also often live there.

The air in such mines rarely meets the sanitary and epidemiological requirements for residential premises. Therefore, even in the case of regular sanitization of ventilation shafts, it is necessary to prevent the possibility of reverse draft and air from entering the apartment.

Nuances of installation and maintenance

To create household ventilation, round or rectangular air ducts of standard sizes are used. For them, there are ready-made solutions containing a check valve that can be installed anywhere in the system. In this case, the installation process will be similar to connecting any other ventilation element.

If it is necessary to alternate the operation of natural and forced ventilation, there are two standard solutions for installing a check valve to make this possible:

- installation of a tee near the ventilation grille, with installation of a valve on a branch for natural ventilation;

- purchasing a specially designed grille with two holes for both types of ventilation.

Installation of such a grille can be done using self-tapping screws or liquid nails.

The first method is preferable, since disassembling the ventilation system for carrying out cleaning, repairing or changing its configuration is easiest to do by first removing the grille.If you decide to install a grille on the inside of the room, you must carefully seal the joint between the grille and the wall.

One of the problems with outdoor grilles equipped with blinds is freezing and icing of the shutters in cold weather. The air coming out of the bathroom, toilet or kitchen is saturated with moisture, which freezes at subzero temperatures.

In this case, two problems arise:

- the flaps no longer close the ventilation hole tightly, as a result of which, in the case of reverse draft, air penetrates into the room, albeit in a smaller volume than in the complete absence of protection;

- there is a significant reduction in the cross-section of the hole, resulting in reduced system capacity, which reduces air circulation and increases the load on fans and kitchen hoods.

In this regard, it is necessary to periodically check for ice on the grill and remove it. The easiest way to perform this procedure is mechanically, but there is a risk of damage to the body and curtains if they are made of plastic. Therefore, it is better to install a rigid grille made of metal outside.

Conclusions and useful video on the topic

Installation of the valve in a ventilation grille of standard sizes:

Method of installing the valve for alternating operation of forced and natural ventilation:

Diaphragm valve manufacturing:

Installing a check valve in the exhaust air exhaust system will ensure normal ventilation functionality, eliminate reverse air flow, and eliminate unpleasant odors and toxic volatile compounds..

You can install this device yourself if you purchase a ready-made structure that matches the cross-section of the ventilation duct in the house.

Those wishing to share their opinions on the information presented or ask questions on points of interest are invited to leave comments. Please write in the block located under the text of the article. Share useful information, post photos on the topic.

I was faced with the problem of poor-quality exhaust: from the bathroom to the restroom there is a standard hole in the wall as an exhaust, but this is not enough to completely eliminate condensation. Because of this, I encountered corrosion on the washing machine and mold on one of the walls. I plan to improve the exhaust system based on what I think is clearly presented material.

Oh yes, we had this problem in our bathroom. In general, such situations are typical for rooms with high humidity. The ventilation we had in the old apartment, of course, worked disgustingly. On the washing machine, mold began to grow on the rubber bands. I had to redo everything because the condensation was tormenting me.

There is a rectangular box with a check valve in the kitchen, it works fine.

Alexander, in your case, a check valve is unlikely to help. You need to install a duct fan and think about the automation to turn it on.Usually the fan is paralleled with the light bulb so that they turn on simultaneously. But if it is very damp, you can additionally switch it on via a time relay. For example, every hour for five minutes. Then you will always have normal humidity in the bathroom.

Alexey gives the right advice; with the help of a fan I solved all the problems in the bathroom back in 2010. The hood works great today.

Didn't understand. Is the check valve, that is, the second one, located in the vent hole? So that when the fume hood is not working, odors from the ventilation duct do not come into the apartment.

I understand that you are interested in a butterfly valve using springs (type 2 in the article). Yes, it really is located inside the ventilation duct. Only you must understand that the normal functioning of this type of valve is possible with forced exhaust. You will also need to pre-adjust the springs to set the required level of resistance.

When the hood or hood is not working, the duct is automatically blocked, which prevents smell from the kitchen from reaching another part of the ventilation. The springs will have to be adjusted every few years.

Alexey, hello.

I need your advice.

In the living room I want to drill a hole in the front wall to connect the hood. The diameter of the hole for the corrugation is 125 mm.

The hood is a box in which a duct fan is installed and from which the corrugation will be connected to the hole in the wall.

The hood is needed for small airbrush work for painting small objects (hobbies).

The hood will be connected periodically 2-3 times a week for 30-40 minutes.

Please tell me what options there may be for finishing the hole in the wall. I mean that air from the street does not enter the room and, accordingly, cold does not enter in the winter.

I understand that the hole needs to be insulated and a check valve installed.

But maybe you, as an expert, can advise the best option for my situation.

I will be grateful to you in advance for your answer.

Sincerely, Alexander.

Hello.

Please tell me...how long does it take to wait for a comment to be verified???)))

I already wrote to your email... and silence)))

Is the site crap???

Everything is in theory. How to put it practically? For example, check valve TU U V. 2.5-25-.2-30037114-004-2003? It itself is flat 14 mm, it has three plastic hooks in the shape of round teeth.

Are you sure you carefully read the article and looked at all the attached materials? I think not. In the “Conclusion and useful information on the topic” section, the first video clearly shows how to install a similar check valve.

But I would strongly recommend using a different type of check valve. The fact is that the option you are considering is the simplest, but it can hardly be called a full-fledged check valve. Essentially, this is a membrane that bends when the hood is turned on; moreover, this membrane can become detached. See for yourself video example. It is better to use a single-leaf gravity valve.

The point is not in valves and fans, but in ensuring inflow into the apartment, if you have PVC windows installed, if there is no inflow, then, accordingly, the hood will not work well.

Good afternoon How to install the valve correctly: vertically or axially? We have the 5th last floor, there is no technical floor. The pull is tipping over, and if it pulls, it’s very weak.

Satellite ventilation duct. When it throws in, there is a stench, there’s no other way to describe it! Maybe you can recommend something?

I set it along the axis: it seems to be pulling (the sash is about 45 degrees), but it also manages to throw it. Placed horizontally: closed almost all the time, i.e. about 5 degrees ajar. I have no idea what to do.

Hello. Your article mentions automatic models. Share the link or manufacturer

The new apartment had stupid ventilation for the bathrooms, where the only exit to the ventilation duct was in the toilet, and between the bathroom and the toilet there was a hole in the wall with bars. I immediately fixed the hole in the wall, laid the wires, and hung two lamps there on both sides so that it would look decent. I was tormented (there is very little space), but I made a separate 125 mm channel to the bathroom, through a plumbing box (although this is not supposed to be, theoretically). I stuck a gravity check valve into the bathroom; there wasn’t enough space on the toilet for a check valve of this design; you’ll have to install a membrane or spring one. So far I have installed industrial fans on ball bearings, 120 mm - they will work for 20 years (the price, by the way, is at the level of conventional hoods, only more difficult to install); a time relay for the toilet so that after the lights go out it will work for a few more minutes.I plan to convert it to computer low-voltage fans, also on ball bearings, the speed on which can be adjusted. I want to install a Chinese PLC to control lights, fans and a bactericidal lamp (from mold) based on signals from humidity and motion sensors; I laid a bunch of wires on the ceiling in advance. I installed decorative grilles with hinged doors, which are absolutely fantastic - neat and very easy to maintain. Now the mirror in the bathroom does not fog up, and the toilet is quite fresh.

Gravity valves do not have to be installed exactly like this - in the photos and pictures the axis is strictly horizontal/vertical, you can place the damper rotation axis at an angle and adjust the opening force by tilting the axis, the main thing is to make sure it works. It is better to install the valves at a distance from the fan blades (from 5-10 cm), otherwise additional noise will occur; Some diaphragm valves have curved thrust baffles to straighten the swirling flow from the fan, maybe they don’t make noise when installed close, I’d like to check. The entrance grille must also be at a distance from the blades. The faster the fan spins, the more noise it makes, this is a general law; To reduce noise, low-speed, large-diameter fans are used and/or they are moved away from the room (placed far back in the ventilation duct). By the way, all the valves slightly interfere with the air flow, you need to keep this in mind. I’m not a ventilation specialist, the article didn’t give me anything special, but I read it to check; It's nice to see that all the problems were immediately solved in the right way.

Hello. The valve does not work on the car. opening after turning off the hood. What solution can you recommend?