Ventilation of clean rooms: rules for design and installation of ventilation systems

The air that people inhale inside buildings contains many impurities.The level of concentration of its pollution largely depends on various circumstances, including distance from intensive highways and industrial facilities.

There are rooms where this situation is unacceptable, since due to their specific nature, extreme cleanliness of air flow circulation is necessary. Therefore, the arrangement of cleanroom ventilation and air conditioning systems is a mandatory component to ensure an appropriate microclimate in them. Do you agree?

From our material you will learn what ventilation of clean rooms is, humidity standards, temperature conditions and other parameters that influence the maintenance of an optimal microclimate.

The content of the article:

What are clean rooms?

The definition of a clean room implies a room of a certain area in which, with the help of special equipment, the concentration of aerosol particles (dust, chemical vapors, microorganisms) in the air is maintained within specified limits.

In such a room, the amount of polluting particles on the surface of the walls, ceiling and in the air must be maintained at a minimum level.

These special rooms are equipped with the following components:

- antistatic floor;

- transfer window openings;

- transition gateways;

- solid structure with wall panels;

- ceilings with built-in lighting.

An extremely clean atmosphere in such rooms can be achieved in one way - the removal of existing air masses and the influx of fresh filtered conditioned air.

Clean rooms are necessary for such areas of human activity as medicine, pharmaceuticals, the manufacture of various electronic devices and food production.

Air exchange standards in clean rooms

With the development of new technologies, the need for clean production facilities has increased. Industry uses increasingly more expensive and complex materials.

Under these conditions, the cost of an error in the production of modern products due to the inadequacy of the industrial environment and workplace equipment is very high.

A series of standards is a generally accepted document throughout the world that establishes standards for cleanroom ventilation, design, construction, equipment and certification, as well as dividing them into special cleanliness classes ISO 14644, which has the general title “Cleanrooms and Associated Control Environments”, developed by the International Organization for Standardization (ISO).

This category of regulations includes 9 regulatory documents.

Standards ISO 14644 Clean Areas and Associated Controlled Environments.

| Document No. | Short name |

| ISO 14644-1 | Air mass purity classifier |

| ISO 14644-2 | Control and monitoring standards to confirm compliance ISO 14644-1 |

| ISO 14644-3 | Testing methods |

| ISO 14644-4 | Design, construction process, commissioning |

| ISO 14644-5 | Service |

| ISO 14644-6 | Definitions and terms |

| ISO 14644-7 | Insulating structures (boxes, shelters with purified air, etc.) |

| ISO 14644-8 | Classifier of molecular air pollutants |

| ISO 14644-9 | Classifier of surface cleanliness by particle concentration |

In Russia, an approved selection of GOST R standards is used ISO 14644, which is a translation of the international standard ISO 14644, Cleanrooms and Associated Controlled Environments.

Documentation regulating Russian standards was developed by the Technical Committee for Standardization TC 184 “Ensuring Industrial Cleanliness” and the public institution Association of Control Engineers micropollution (ASINCOM).

Depending on the cleanliness class of the industrial premises and the technical processes carried out in it, different standards apply to equipment and air exchange equipment.

There are 9 classes of premises in which a certain concentration of dust and microorganisms in the air is allowed according to GOST standards ISO 14644-1-2000.

Ventilation air preparation systems must ensure its purity in terms of the number of aerosol particles and, if necessary, the presence of microorganisms in clean areas in accordance with the requirements of GOST R 52249-2009 “Rules for the production and quality control of medicines.”

In addition, they must maintain a pressure differential relative to surrounding areas of a lower cleanliness class.

Required ventilation conditions

To carry out air exchange in clean rooms, the mobility of air flows in m/s is measured. In particularly sterile rooms in the pharmaceutical industry, a precise determination of the required ventilation is established - 0.46 m/s ± 0.1 m/s (FDA, USA).

Limit standards for the mobility of air masses in other clean rooms, as a rule, range from 0.35 to 0.52 m/s ± 20%.

Air circulation is also significantly affected by the presence of window openings:

- in a sealed room without windows, the air flow should dominate by 20% over the hood;

- in rooms with windows, the air exchange rate should be 30% higher than the hood.

Only such a ventilation system for clean areas can prevent the entry of contaminants and ensure the circulation of air masses.

When designing, increased attention is paid to technologies for supplying air flow to special-purpose objects. For example, air circulation in clean rooms with cleanliness classes from 1 to 6 is carried out by air distribution equipment from top to bottom, forming homogeneous and unidirectional air flows of low speed from 0.2 to 0.45 m/s.

In areas of a lower cleanliness class, the formation of a non-unidirectional flow is allowed using several ceiling diffusers.

Air purification methods

There are two types of cleanrooms. As a rule, they differ from each other in the method of purifying air masses:

- rooms with turbulent ventilation;

- rooms with laminar, one-way flow.

The latter variety allows you to maintain the highest degree of cleanliness, due to the fact that the flow directed in one direction pushes polluted air out of the desired room faster and with better quality.

Through air intake grilles located at the bottom of the walls, part of the displaced air is discharged outside. During a day of operation, ventilation installed according to this principle can displace exhaust air up to 20 times.

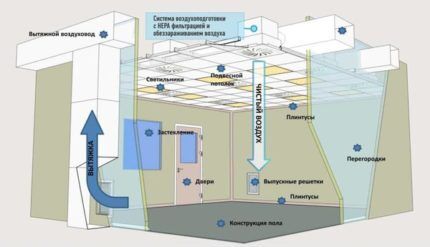

If it is necessary to make the air in a clean room even more purified, a type with a flow directed in one direction is selected. The meaning of laminar ventilation is to equip effectively filtering components to supply air flow.

Fresh air entering the room moves through it in one direction (from top to bottom), while dust microparticles are retained and removed through holes in the floor. Typically this process takes place at an air flow speed of up to 0.4 m/s.

Ventilation equipment

In order to choose effective ventilation equipment in a clean room, it is worth understanding the problems that it will solve.

Air exchange in clean rooms is not aimed at removing contaminating bacteria and particles, but at preventing their entry.

The required equipment will be as follows:

- Filter ventilation modules. Components of systems whose main function is to clean the air from contaminated particles and impurities. Supplied with filters HEPA And ULPA to achieve the required degree of purity according to the classifier.

- Air distributors. This is a group of climate control equipment for removing impurities, ventilation and air conditioning in clean areas.

- Ventilation systems and conditioning. Installation with a full cycle of air flow preparation in clean rooms. Its functions include: cleaning, maintaining temperature, humidity and air pressure. Typically, such installations are characterized by uninterrupted, silent operation and can adjust the indicators automatically.

- Filters of various cleaning classes. They are often selected according to the requirements for a specific type of room cleanliness. The most effective scheme for removing foreign particles from the supply air by passing it through 4 types of filters - coarse, fine, high efficiency (HEPA) and ultrafine (ULPA) cleaning.

The main objective for the continued functioning of this equipment is high-quality initial design and installation.

Otherwise, the staff and owners do not experience any operational difficulties.

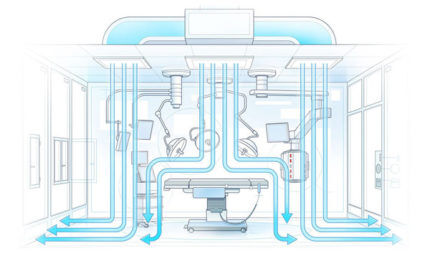

How the system works

Ventilation of clean rooms operates properly and makes it possible to ensure standard indicators through the smooth operation of all system components.

Before entering the room, the air goes through four levels of filtration at four filters, which clean the air flow from certain types of contaminants.

A laminar air flow is supplied, allowing for the formation of a directed movement of purified air masses, and it, in turn, pushes out aerosol particles from the existing air.

The main component of the entire ventilation installation is the system central air conditioning, equipped in accordance with the specifics of clean rooms. Most of the air preparation and purification processes take place here.

And ease of management and maintaining constant indicators of cleanliness in the room is ensured by equipment for automation and dispatching of the entire system, which contains a large number of sensors for monitoring indicators, a device for remote command transmission, etc.

After putting the system into operation, the operating status of all elements is monitored by personnel working in the room, and if any malfunctions or emergency situations are detected, the software will quickly inform you about this automatically.

Features of designing ventilation systems

The design and installation of ventilation and air conditioning systems for clean rooms requires the necessary experience in working with special equipment, as well as knowledge of the requirements and standards for these rooms.

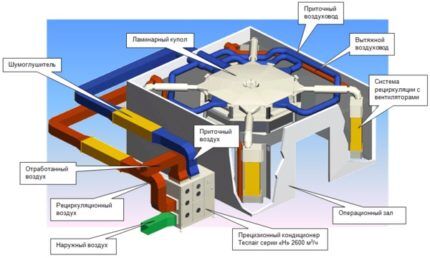

There are three main schemes for systematizing air exchange in clean areas:

- direction of air flows parallel to each other;

- random direction - fresh air is supplied in different directions;

- mixed supply - can be seen in large rooms, when in one part the air masses move in parallel, and in the other - randomly.

Depending on the dimensions of the room and the location of the work area, the most appropriate ventilation system design is selected.The most optimal solution is ventilation with a flow of fresh air directed in one direction.

Often used for clean rooms supply and exhaust ventilation system. Its meaning is as follows: a stream of fresh air is supplied from above at a certain speed under pressure, which pushes the polluted air masses in the room down to the supply opening.

Cooled air is supplied at low speed to the top of the facility through the ceiling panels. It envelops the area of the room, lowering dust particles down to the hood, creating a minimal degree of irritation.

With this ventilation system, drafts and dust swirls do not form on the floor. Moreover, the delivered fresh stream is first prepared and supplied to the room with the required humidity and temperature.

Popular ventilation schemes

When designing a ventilation system, one of the primary tasks is the accurate and proven organization of air flow distribution.

At the moment, designers use several common solutions for the location of air distribution equipment, the choice of which depends on the purpose.

Let's consider the most popular, proven schemes for organizing ventilation of the operating room:

- air flow in one direction through an inclined ventilation grille;

- through the use of ceiling diffusers, a non-unidirectional air flow is organized;

- air enters the operating room through a perforated ceiling panel with the organization of a vertical unidirectional flow of the air mixture;

- the supply air mass is supplied through an air distributor in the ceiling, creating a laminar air flow directed to the work area;

- The air mixture is not unidirectional and is supplied through an air ring hose.

The exhaust ventilation system in operating rooms is carried out by installing exhaust fans and wall ventilation grilles with the valve in the opposite direction.

In accordance with practice, the best device for organizing laminar air flow directed in one direction in operating rooms is ceiling mesh air distributors.

For example, on a laminar ceiling measuring 1.8 by 2.4 m in an operating room with an area of 40 m², it makes it possible to create a 25-fold air exchange with an air flow exit speed of 0.2 m/s from the installation.

These data are considered sufficient to absorb excess heat on the number of personnel and equipment operation in the operating room.

Installation of ventilation systems

The peculiarity of installing ventilation in clean rooms is associated with high requirements for various types of zones, the classification of which depends on the characteristics of the technological processes carried out in them, as well as their purpose, microclimate standards and routing of engineering structures.

Installers need to understand that air ducts for installation in clean rooms, preparatory procedures are required even before installation, without which subsequent installation cannot be carried out.

Let's consider the main stages:

- At the preparatory stage, the air duct parts are placed in a specially designated cleaning area. Before installation, parts and fittings undergo initial dry mechanical cleaning to remove liquid and solid contaminants from the surfaces formed during production and transportation.

- Next, you should carry out a primary wash of all internal surfaces with tap water and organize drying until completely dry. dust-free zone. After visual inspection, ventilation system components, depending on the degree of contamination, are subjected to secondary washing and drying or are immediately sent for antiseptic treatment.

- After final treatment, it is recommended to minimize contact with the cleaned elements of the internal surfaces of the air ducts and the room air. This can be achieved by wrapping the end parts with polymer films. After this, the components are sent to a warehouse with controlled cleanliness parameters.

- The cleaned batch of parts and air ducts arrives at the installation site right before installation. The protective film is removed immediately before connecting parts of air ducts and shaped elements, while contact with tools, fasteners, and open skin of extremities with the inside is unacceptable. When stopping installation or taking a break, temporarily seal the end parts, joints and inserts.

At all stages of installation work, it is necessary to control and reduce the number of possible contaminations of internal surfaces.

Conclusions and useful video on the topic

The video will talk about how ventilation is arranged in clean rooms for industrial purposes:

Video about how ventilation is set up in the clean rooms of the operating room:

Design and installation of ventilation and air conditioning systems in clean rooms is a labor-intensive process that requires certain knowledge, norms and rules of air exchange and air supply, as well as skills and experience in the use of air distribution equipment.

That is why it is recommended to contact only specialists for the design and installation of a ventilation system at such facilities.

If you have questions about the topic of the article or can supplement our material with valuable information on arranging ventilation in clean rooms. Please leave your comments and share your experience - the communication block is located under the article.