Filters for ventilation: types, features and disadvantages of each type + how to choose the best one

Cleaning the supply air is an important function of ventilation and air conditioning systems.This task is performed by filters for ventilation - the elements trap particles of dust, dirt, allergens and other harmful impurities. The issue of air treatment is most relevant in a city, near a roadway or industrial zone.

To provide your home with clean air, you need to learn how to choose and change filter elements in a timely manner, don’t you agree? We will help you resolve these issues.

The proposed publication discusses the classification of air purifiers, outlines their purpose and application features. In addition, we have provided practical recommendations for creating a comprehensive filtration ventilation system.

The content of the article:

Why are air filters important?

If a person has installed a ventilation system in his home, office, or workplace, he expects to receive an influx of fresh, clean air, and this is impossible without an effective filtration system. Therefore, in the absence of high-quality purification of air masses, the meaning of installing expensive equipment is lost.

Even if the owner does not see the need for this procedure, it will still need to be done to protect the mechanical parts of the system itself.

Third-party particles, including small fragments of branches, insects, grains of sand and dust raised by the wind, can lead to premature wear and breakdown of expensive equipment, and repairs will be more expensive than a package of high-quality filters.

In addition, maintenance will be much more expensive. For example, the system will have to be reconfigured regularly. And since only specialists can perform this operation, each such adjustment will be expensive.

And this is not the entire list of additional work that has to be done in the absence of an effective filtration system.

Existing types of cleaners

The division into types is considered arbitrary, although it covers all sorts of features of filters. This is necessary so that consumers, manufacturers, and sellers can better navigate the design features and variety of materials.

Filtering devices are divided into types taking into account the following features:

- by design;

- purpose, effectiveness;

- operating principle.

All design features of air filters are standardized, so several types are distinguished. The same products may have different efficiencies.

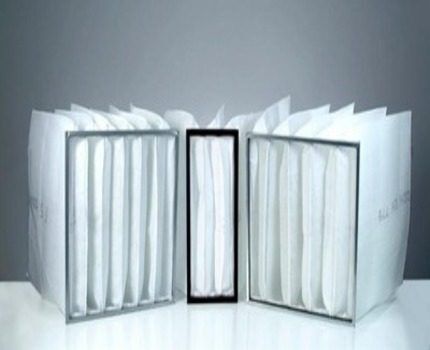

The classification of purifiers helps to easily select the models of the desired designs. For example, pocket filters used for ventilation of various rooms can be coarse and ultra-efficient.

Types of filter products by design type:

- Pocket;

- cassette;

- panel;

- filter bags.

Pocket filters They are characterized by low resistance, strength, safety, and high dust holding capacity. They are distinguished by their simplicity of design, use, disposal, and also have high fire safety.

They can be used in various fields (in production, in hospitals, in residential premises). Durable synthetic fibers are used as manufacturing material. They are sewn, welded structures, similar to pockets, which are attached to a rigid frame.

Cassette filters — used in various fields (in production, in public catering, pharmaceuticals, everyday life), they are distinguished by their strength and durability. The advantages include low initial resistance and significant dust holding capacity.

Rigid design allows you to cope with any load. The filter material is made from modern polyester fibers.

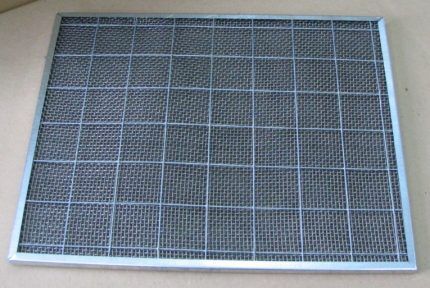

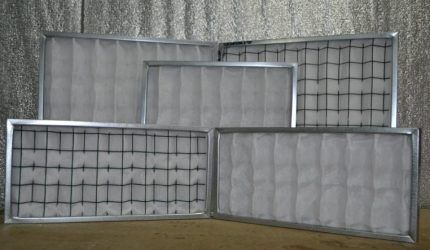

Panel filters - products for which various raw materials can be used as filter materials, including metal mesh, polyurethane foam, but most often modern polyester fibers are used.

Such devices can be part of various systems for air purification in production and at home. They are distinguished by practicality, high performance characteristics, and impressive ability to retain dust.

Filter bags are the most productive filters, therefore they are used mainly in production, including chemical plants, tobacco factories, and thermal power plants. Such products can also be used to capture various gases, for example, in the production of aluminum.

Sleeves are the most common filter elements in production, and their use is traditionally considered the most economically feasible.And all because these filters are capable of performing high-quality cleaning from a variety of gases and dust. They can be changed without stopping the technological process.

In addition, the hoses are durable and little susceptible to operating conditions - they can operate at an impressive 280°C and significant frosts.

The filter material in this case is modern polyester fibers, which are often covered with additional layers, for example, membranes to improve the quality of air treatment.

Classification of popular types of filters

For high-quality cleaning, various types of air filters are used for ventilation and air conditioning systems. To make it easy for potential consumers to understand their capabilities, such products are divided by effectiveness and purpose. The division into different groups is standardized by the state.

Groups of cleaners by effectiveness and purpose

The scope of filtration devices is regulated by domestic GOST standards (R EN R EN 1822-1-2010 and the newer R EN 779–2014). If the buyer chooses a foreign-made product, he will not feel the difference in classification, since the same standards are adopted throughout the world.

So, there are filters:

- general purpose - this type is most in demand;

- special purpose - they are used in cases where increased requirements are placed on air purity in any production, laboratory, or everyday life.

In turn, the listed types are divided into different classes, which accurately indicate their capabilities. The classification shows what part of the pollution is retained.

To check the compliance of products with requirements, instruments are used that calculate the mass concentration of foreign particles before and after cleaning.

General purpose filters are divided into the following categories:

- G-class — perform rough cleaning, used only to protect more precise parts, the ventilation equipment itself;

- M-class — refer to medium purity filters, they can be used both in the system and outside of it;

- F-class - This includes products capable of fine cleaning.

The listed devices can function in all ventilation systems. They are only dust-retaining, which will be sufficient in some cases.

If more efficient filtration is needed, then these products are used as part of the system. This is done so that inexpensive general-purpose filters protect expensive high-efficiency cleaners from the effects of large abrasive particles and debris.

Special-purpose air filters for ventilation systems are divided into the following categories:

- E and H classes - this includes all devices that are highly effective;

- U-class - Products are extremely efficient.

These filter structures are capable of solving a number of special problems, for example, capturing odors and fats. They are the most effective, but their price is significantly higher than general-purpose models. Therefore, they are used in situations where the technological process in any production or laboratory requires it.

They are also actively used in everyday life, for example, they will help people with weakened immune systems or those suffering from allergies to avoid many difficulties.

For the most accurate classification, additional digital designations are used simultaneously with letter designations, for example, G1, H9, U17. The higher the value indicated behind the letter, the more effective the product.

There are 17 digital classes in total, all of them are listed in specialized GOSTs. For example, the coarsest of the standardized filters, G1, should capture 50-65% of synthetic dust, and G4, at least 90% of the same particles.

The most accurate products, like the U17, are required to capture 99.999995% of contaminants. You can familiarize yourself with the cleaning efficiency indicators for general information, since in most cases technical documentation and passports contain alphanumeric classes.

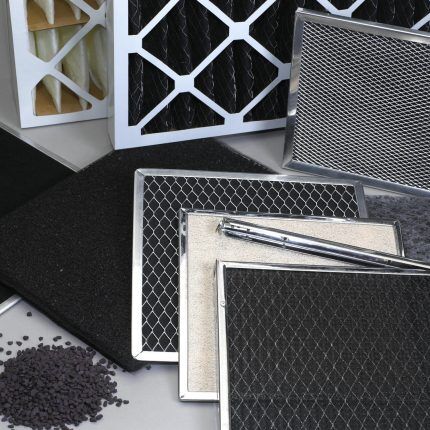

Types of filters based on operating principle

Since there are different types of air pollution, it is logical to use different types of purifiers to clean it. In fact, this is what they do, combining into the filter system products that have different operating principles, which makes it possible to more successfully capture dirt particles.

This procedure also makes cleaning more economical. The reason lies in ventilation system designs — durable and cheap devices that are pre-installed are subject to the greatest impact.

Types of filters based on operating principle:

- mechanical;

- oil;

- coal;

- spongy;

- HEPA.

Mechanical filters — designed to clean the supply air from fairly large particles, which include dust, animal hair, insects, etc. Such products are used to filter dirt measuring 5-10 microns.

The peculiarity of particles of these sizes is that they are small, but they significantly accelerate the wear and tear of the equipment of the ventilation system itself.

And also more efficient and expensive precision cleaning products quickly become unusable, which leads to disruptions in technological processes and deterioration of the microclimate in the office and home.

To prevent the listed destructive processes, mechanical filters are installed in almost any air conditioning and ventilation system and perform preliminary retention of dust and other particles. Typically, such products are made from fibrous synthetic materials with a mesh structure.

To impart strength, various modern adhesives are often used. In many cases, the used product must be disposed of, but there are models that can be cleaned by washing or using pressurized air. This makes them reusable, which is beneficial and practical.

These procedures can be performed in any workplace and even at home. The disadvantage is that a mechanical filter is not able to clean the air on its own.

Oily — purifiers, the main design element of which is the filter element. Most often it is combined and consists of durable synthetic fibers and metal mesh. But the main feature is the use of mineral oils to increase cleaning efficiency, which is achieved by adhering dirt to it.

Oil-based products are used as predisposed filters to trap large particles, which limits their functionality.

Coal models function due to adsorption - this is a physical phenomenon in which the pores of one substance absorb another. Such products effectively remove gases and odors.

The carbon filter used for ventilation can only be used in conjunction with an additional trap for small dust and grease particles installed in front of it. The reason is that larger grains clog the pores of the coal and make the adsorption process ineffective.

The advantage of this type is a sufficient degree of purification at a moderate cost. It is often used in everyday life - it is common carbon filter for hoods. It has found application in medicine, pharmaceuticals, and small industries. The disadvantage of such products is the need for regular replacement.

Sponge filters — clean the air from fairly fine dust and other solid elements. The name comes from filter materials (sponge rubber, polyurethane foam), which, to increase efficiency, first undergo special treatment to increase the pore area.

They are reusable because they can be washed. They are used in everyday life, in production, and in medicine. The disadvantage is that these collectors are only suitable for removing dust from the air, although they do it efficiently.

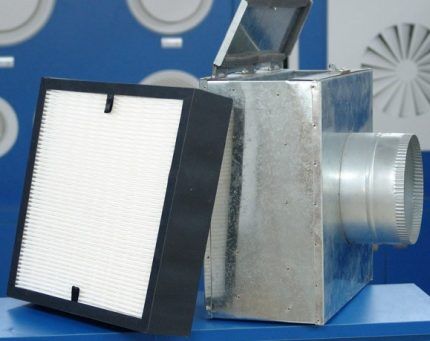

HEPA filters designed for highly efficient collection of small dust particles.They are often the main component, although they should always be used with pre-installed filters that will clean the air of large dirt elements.

The surface of such products is coated with chemical solutions to inhibit various types of bacteria.

They are used wherever there are increased requirements for air quality. Since they successfully get rid of allergens (spores, pollen, wool, house dust, etc.), they are often used in everyday life. Cleaners are made from special paper or synthetic fibers.

HEPA filters are often installed in household air purifiers.

If you need maximum cleaning efficiency, you should choose ULPA filters, which have the same operating principle as HEPA, but are capable of capturing a slightly larger amount of dust. All high-performance products are quite expensive, in addition, they have a fragile design.

Innovations in ventilation systems

In addition to the cleaners listed above, new high-tech methods are increasingly being used. For example, photocatalytic filters have recently begun to be used for ventilation systems, but they are quickly becoming in demand.

The reason for its growing popularity lies in the ability to equally effectively fight various viruses, bacteria, and toxins that decompose into safe products, such as water. Cleaning is carried out under ultraviolet light in a photocatalytic chamber.

Electrostatic filters, which with the help of air ionization and the effects of electrical forces are capable of removing the smallest particles of pollution from waste masses.

How to choose an air purifier

The design of the ventilation system itself must be tested for resistance to possible mechanical stress to which it will be subjected during use. This procedure is extremely important.

In this way, it is determined whether the conditions for effective functioning will be created for the filters. This must be done before starting operation and after making significant design changes.

All filters used must meet a number of conditions. Thus, during operation, these products should not emit fibers or dust, which can cause damage to people and equipment. That is, any cleaner must be guaranteed to be safe.

An important quality is tightness, which prevents the leakage of contaminated air between the body of the product and its mounting frame. Aerodynamic characteristics must comply with the standards for its class.

Each filter must be tested for efficiency and compliance with other characteristics, which is necessarily indicated in the product passport or in a separate act.

Manufacturers and installation organizations must form a complex filtration system and initially select individual components for its composition, since an outsider will not be able to take into account all the important nuances, which will lead to low efficiency.

Conclusions and useful video on the topic

Information about the design of the popular pocket filter will help you understand what these products are:

A review of the carbon filter will give you the opportunity to understand its features:

Filters are capable of removing any contaminants from the air, but for this it is necessary to select products taking into account the appropriate technical characteristics. You must understand that only filtration systems assembled from several types of purifiers can cope with the assigned tasks.

To select them, you need to have certain skills, knowledge, or seek help from specialists who will competently perform the work.

Do you have anything to add or have questions about choosing different filters for ventilation? You can leave comments on the publication, participate in discussions and share your own experience of using air purifiers. The contact form is located in the lower block.

At our enterprise, the director installed good filters in the ventilation system. I purchased it myself and chose HEPA filters designed for complete cleaning. In summer, dust and poplar fluff do not fly. The only inconvenience of using such filters is that they become clogged with debris very quickly. Then it becomes clearly visible what kind of air we breathe, and the filters themselves have to be changed regularly.

HEPA filters clean microparticles, and cheap filters can handle dust and poplar fluff. But, unfortunately, HEPA filters are too expensive to use for ventilation.

Which filter to choose to install in front of an electric heat gun. Because dust burns when it hits the heater and oxygen in the room is consumed???

It is best to install a panel filter with minimal resistance in front of the heat gun so as not to ruin the gun itself. I made individual ones, fine mesh-foam rubber-Zauber G4 - mesh 25*25 mm, filter from Zauber 40 mm. In the absence of time and funds, mesh and padding polyester were used.

What kind of filter should be installed at the inlet of the supply ventilation of a common pool? It was true that delayed me.