Converting a gas stove to use bottled gas: how to rearrange the nozzles to run on liquefied fuel

Do you really want to see a gas stove in the kitchen, but there is no gas main near the house? This is not a problem at all; converting a gas stove to use bottled gas is quite possible, and you can do it yourself without any problems.

We will tell you in detail about the operating features of gas stoves connected to liquefied gas cylinders. Let's look at the types of injectors and the reasons why they need to be replaced. Having familiarized yourself with the material, you will be able to choose the right nozzles and easily carry out work on converting the gas stove.

The content of the article:

How to determine if a gas stove is working correctly

When igniting the burner there should be no extraneous sounds in the form of pops. The flame should burn evenly, its tongues should be bluish-white, it’s not for nothing that the gas is also called “blue fuel”.

If, during the combustion of the air-gas mixture, yellowish impurities are observed, and the flames acquire a red tint, then this clearly indicates that the jets are not working properly.

When converting the stove from mains gas to bottled gas, all of the above disadvantages manifest themselves very characteristically. And plus, due to improper pressure, soot will be released.So it is difficult to notice it immediately with the naked eye, but it will manifest itself in the form of black spots on the dishes after 1-2 days of use.

Avoiding all these troubles is quite easy. It is necessary to choose the right nozzles for a gas stove when operating conditions change and conversion to bottled gas. It should be taken into account that due to the difference in the pressure of the incoming fuel, the diameter of the holes in the injectors (nozzles) will also be different.

What is a jet (nozzle)

Almost everything gas stoves equipped in such a way that they can operate on both natural gas and propane (from a replaceable cylinder). It should be taken into account that when switching to liquefied gas, it is necessary not only to replace the nozzles, but also to install a reducer, which is responsible for equalizing the pressure of the incoming fuel.

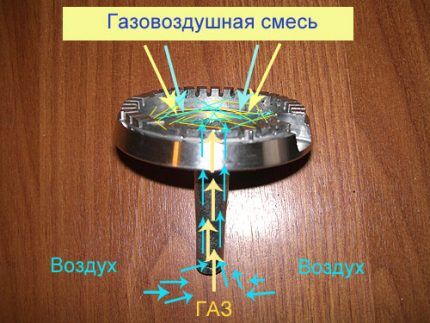

A nozzle (nozzle) is a bolt with a hole in the head for supplying gas to the burner. After entering the burner, the gas is mixed with air, and the gas-air mixture is ignited.

Depending on the fuel used, nozzles are of two types: for supplying blue fuel from the main pipeline and for supplying gas from a gas holder or cylinder.

Jets (nozzles) for natural gas in comparison with jets for liquefied fuel are characterized by:

- Shortened bolt body;

- Fewer threads;

- Increased hole diameter.

If the stove is not operating correctly, it is best to replace not just one jet, but the entire set at once, and when switching to bottled gas, this is generally a necessity.

Why and why is it necessary to change the jet?

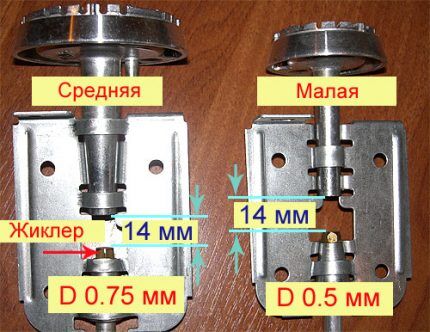

The jets for different types of gas vary significantly, so when changing the type of gas-air mixture, replacing the nozzles is simply necessary. If you pay attention to the diameter of the hole, it becomes obvious that they are not the same. In this case, the diameter of the hole depends not only on the type of gas used, but also on the size of the burner itself.

Each of the gas stove burners differs in power and size, so for stable operation it is equipped with a separate nozzle.

The more powerful the burner, the greater the volume of gas it requires to operate, therefore the diameter of the nozzle is required to be larger.

Choosing a nozzle for bottled gas

As already mentioned, the propane nozzle has a shortened body and a smaller outlet diameter. It is not recommended to try to reduce the hole yourself, since even fractions of millimeters are important here. By eye you can only improve the operation of the stove, but not achieve its ideal operation.

It is important to understand that standard jets simply do not exist. They are designed for each specific model. Modern kitchen stoves are equipped with a set of jets designed to operate on propane. Some models are even produced specifically for bottled gas.

If you do not have such a set, then the issue of purchasing them is resolved very simply. It is very easy to find the necessary product for popular models in any specialized store that sells gas equipment. As a last resort, you can always order them by visiting the manufacturer’s official website.

The procedure for performing work on replacing jets

Before converting a gas stove to use bottled gas, you should study the instructions supplied with the equipment by the manufacturer. The included manual describes in detail how to change and what injectors will be required for replacement.

It should be taken into account that at all stages of work on rearrangement of jets must be done very carefully. The use of force here is not at all acceptable, since unnecessary careless movement can lead to breakdown, followed by a major overhaul of the equipment.

The key to a successful replacement is compliance with safety standards and the availability of a simple set of tools:

- The required number of nozzles, depending on the design of the burner;

- A set of open-end or spanner wrenches;

- Several Phillips screwdrivers of the appropriate size;

- Flexible hose for connecting the cylinder

The work begins with turning off the gas supply valve and preparing the surface for storing removed parts and supports. Next, you should lift the metal grate, remove the dividers from the burners and remove the burners from their sockets.

Removing the hotplate

To gain access to the jets, you need to remove the burner table cover, which is usually secured with screws. The number of mounting screws may vary between models.

In any case, you just need to remove the screws, after which the cover can be easily removed. In most modern models, the nozzles are screwed directly into the body; in this case, dismantling the table is not required. Let's consider a more complex option, where it is impossible to get to the injectors without removing the cover.

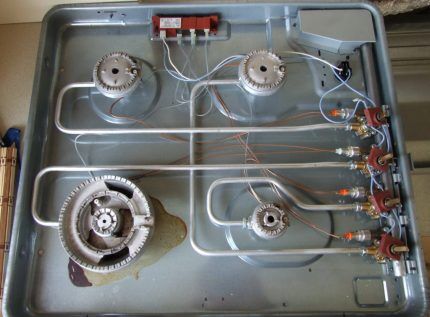

Internal structure of a gas stove

The burner bodies are attached to traverses, which are metal strips. The design of all burners is the same, the only difference is the length of the aluminum pipeline through which the fuel is supplied.

The outlet from the tube is called a nozzle, from which gas enters the nozzle, then enters the burner leg, mixes with air and enters the divider.

The latter must be carefully inspected during operation - uneven dissection of the flame indicates that the divider is clogged, which is why gas burner doesn't burn well. It needs to be blown out or cleaned.

Methods for replacing jets

The easiest way to replace it is to simply unscrew the jet using a wrench and install a new one in its place. But this method is not always suitable, since the tips very often stick to the nozzle, and excessive force can lead to damage.

It is best to first release the tips of each of the jets. To do this, you need to find a latch, which is a plate with a slot. If you gently squeeze the latch with your fingers, you can easily remove it from the socket, after which, by simply pressing the tube, the nozzle with the tip is lowered down from the fastening ring.

Trying to remove a nozzle that is stuck to the tip, you can simply break the tip itself. If the nozzle does not turn out without force, then the freed tip must be clamped in a vice or try to use an adjustable wrench.

If you pull off the tip, the O-ring will remain inside. When installing a new jet, it must be put back on the pipe. No ring lubrication is required, nor is nozzle thread sealing. After installing the nozzle in place, all that remains is to assemble the burner table, if it was dismantled.

Replacing nozzles in the oven

When solving the problem of how to correctly convert a gas stove to bottled gas, do not forget about the oven, because with changes in pressure and fuel composition, it may also not work correctly. Usually the nozzle is located in a special housing behind the oven wall on the left side. An arc-curved burner is connected to a nozzle.

In order to gain access to the burner, you need to remove the floor.A specially cut hole is provided for this; just pull it towards you and the floor will come out. After this, you need to unscrew the bolts securing the burner, remove it and gain access to the hole where the gas comes from. This is where the nozzle is located.

During operation, the nozzle could become very stuck to the nozzle body. In this case, you should not try to unscrew it using excessive force. Since if the thread is torn, the entire body will need to be replaced. It is better, as in the case of burners, to remove the nozzle along with the nozzle.

To easily unscrew the nozzle from the nozzle to replace it, you can treat it with special means. All that remains is to screw the new nozzle into the nozzle and perform the assembly work in the reverse order.

Conclusions and useful video on the topic

Comparison of the operation of a gas stove before replacing nozzles when switching to bottled gas and after. Carrying out work to replace injectors:

Replacing nozzles in a gas stove oven:

Nozzles or jets are an important component of any gas stove. Only strict compliance with the diameter of the outlet hole can guarantee high-quality and stable operation of the equipment.

It is not at all difficult to purchase and replace injectors with your own hands. The main thing is to take into account that all work must be carried out carefully without using unnecessary effort. Each of the jets has its own marking; if you look closely, it is impossible to confuse them, both when purchasing and when replacing.

Please leave comments in the block form below, ask questions, post photos on the topic of the article. Share useful information that will be useful to site visitors. It is possible that your advice will provide effective help.

Everything is written correctly, but you didn’t say anything about the VMR (low flow screw), and the manufacturer, in particular Hephaestus, recommends changing it too. This is written in the technical documentation of the PGE 3110-04 model.