Basement floor ventilation: general arrangement technology + methods of effective air exchange

Properly equipped ventilation of the basement floor, during the operation of the latter, relieves people from contact with dampness, mold, and a number of other pathogenic organisms and gases.Therefore, the presence of a hood can be ignored only in exceptional cases.

It is important to understand that creating such a system requires certain knowledge and skills, even if specialists are involved in the work.

Let's look together at the methods of ventilation and the intricacies of its arrangement.

The content of the article:

Popular ventilation methods

Relevant guidance documents and practice show that basement floors can be effectively ventilated in several ways: naturally and forcefully.

In addition, today a mixed or complex method of arranging an exhaust system is increasingly being used - which has the characteristic features of both of the above options.

And also when implementing mixed ventilation, additional equipment is used.

Based on the listed methods, all ventilation schemes in demand today have been created, so you should familiarize yourself with each of them. But first, let’s look at the general technology for arranging basement ventilation.

Technology for creating a ventilation system

Although there are several varieties of plinth ventilation systems, there is no variety of schemes and technologies. The basis of any hood is natural supply and exhaust air exchange.

The layout of any method is similar. That is, it all starts with planning and placement of products, ventilation pipes.

If the room area is large (over 50 m²), then a fan of sufficient power should be added to the design. In this case, the inlet openings must provide a supply of clean air.

If there are several rooms and it is necessary to maintain a separate microclimate in each of them, then you will need to create complex ventilation systems.

Which involve the use of natural or forced exhaust in individual rooms, and a large amount of additional equipment can be used for its implementation.

The most important point is the number of ventilation holes. If they are missing, the system will not be able to cope with the task even in a small basement room.

Since numerous stagnant zones with high humidity and other negative phenomena will form.

This indicates that there should be a lot of air ducts, and their exact parameters are indicated by the profile Code of Rules - SP 54.13330.2011. Where it is clearly noted that the total area of the ventilation openings should be 1/400 of the entire area of the basement floor.

The same document states that these elements should be located evenly around the entire perimeter. Another rule contained in the joint venture is to indicate the exact area of each duct, which should not be less than 0.05 m².

And then to determine the parameters and draw up a ventilation scheme, all that remains is to perform a simple calculation.

Why do you need:

- Divide the area of the basement by 400. The result is the total area of the holes in the basement;

- The resulting value should be divided by 2 (pairs of supply and exhaust structures) and placed evenly along the entire perimeter of the building.

It should be remembered that, according to the joint venture, you should not make a round hole with a diameter smaller than 25 cm, and the minimum size of rectangular ones should be 20x22 cm.

An exception may be situations when several smaller air ducts are placed nearby - if round air ducts are made, their diameter may be not 25 cm, but 11 cm.

You should not make the ventilation holes as large and rare as possible. For example, in a house whose ground floor area is 100 m² with a required ventilation volume of 250 cm², they should not be divided between 4 large ones, as many developers do, but divided into 10 small ones.

It’s even more practical to make two dozen minimum permissible holes, for example, round ones with a diameter of 11 cm and place them approximately every one and a half meters around the entire perimeter. And such a ventilation scheme for any basement floor will be as efficient and profitable as possible.

If the vents do not cope with the function of replacing air in the basement room, then air ducts are added to the ventilation system - pipes, which are additionally equipped with fans and other additional equipment characteristic of a forced-air system.

Features of natural air exchange

As the name indicates, this ventilation method is based on the laws of physics, so the use of any special equipment is not expected.

Air exchange occurs due to the temperature difference inside the basement and outside, as well as the pressure drop that follows this phenomenon.

The order of organization of the system

To ensure effective air exchange, a number of operations should be performed, in the following order:

- Calculate the area of air ducts. It is optimal to carry out this procedure at the design stage of the entire building. If mistakes are made, then adjustments can be made even after the facility is put into operation.

- Calculate the number of exhaust openings and determine their location. This is also done at the design stage.

- Form vents. Since the efficiency of the entire system, as well as the aesthetic properties of the base, depend on this operation, this issue will be considered separately.

- Install into the holes provided deflectors or just close them protective grilles. Which prevent animals and objects from getting inside the premises.

- Test the formed system. What can you do with a burning candle?

In addition, if necessary, you can perform work on decorating the resulting air ducts.

If the performance of the ventilation holes (vents) is not enough, then the following should be done:

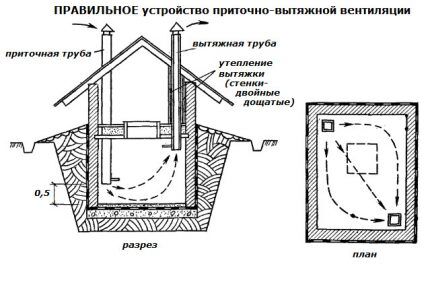

- Use exhaust pipes for air exchange.

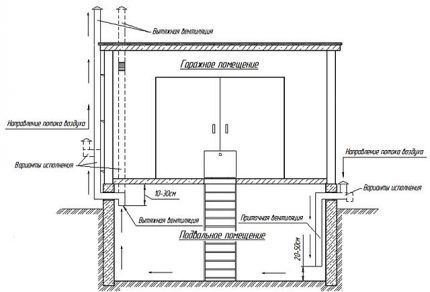

- Install the supply pipe at a level of 20-40 cm from the ground floor floor level.

- Place the exhaust pipe opposite the supply pipe, that is, in the opposite wall of the room.

The ventilation hole of the exhaust pipe should be located as close to the ceiling as possible, and if possible, directly into it. And it should come out above the roof, about 0.6 m above the roof.

Regardless of which method of placing air ducts is chosen, it should be remembered that there should be no unventilated corners. To avoid such a defect, the nearest ventilation hole should be located no further than a meter from the specified location.

But experts often recommend using the standard that is used in many European countries and placing the first vent no further from the corner than 90 cm, which is more likely to prevent negative processes from occurring on the ground floor.

How to shape holes?

There are no requirements for the configuration of the holes, that is, they can be made of any shape, even triangular, which is now becoming fashionable.

But the most popular are:

- square;

- rectangular.

They are easy to form. To perform such an operation, it is enough to use 4 planks of the required size, from which a geometric figure of the desired shape is simply built and installed in the right place, after which it is laid out with mortar or brick.

Holes of other shapes are made in a similar way, for example, triangular ones, which are increasingly popular today.

But more and more often you can find their round analogues, which are easily created using a plastic tube of the required diameter (often 110 mm) and length, which should be equal to the thickness of the base or foundation.

It is simply placed in the desired place and covered with solution. The result is perfectly straight holes.

If ventilation ducts were not made when creating the basement floor, then they are created using diamond drilling. As a result, they also turn out to be round in shape.

Important system features

The number of exhaust openings plays an important role, but when creating them, you should always remember that their location is an equally important feature that significantly affects the efficiency of the entire ventilation system.

Thus, pairs of inlet and outlet ducts should be placed strictly opposite each other.

You also need to know that:

- Exhaust openings should be located at least 40-60 cm from the ground surface. This will reduce the likelihood of them being clogged with snow, which should not be allowed, since the efficiency of removing contaminated air masses will decrease or the process will stop altogether.

- Since natural ventilation operates on the principle of temperature and pressure differences, the exhaust pipe from the base can be taken to the street by extending the main line through all floors. Which will make the system more expensive, but also as efficient as possible. It is placed 30-60 cm from the roof, as this will eliminate the possibility of snow getting into the air duct.

All input/output channels must be protected by grilles that will prevent rodents, pets, birds, and insects from getting inside.

If a similar temperature has established on the ground floor and the functioning of natural exhaust has stopped, then a heater or any other heating device should be installed in the room. This will help create the necessary conditions for the resumption of air exchange as quickly as possible.

Natural exhaust exhibits its best properties when maintaining a microclimate in small rooms.Therefore, if the area of the basement floor exceeds 50 m², then you should not take risks and use a forced air exchange system or a mixed option.

Otherwise, the maximum effect may not be achieved, which will lead to negative processes.

Subtleties of the forced exhaust device

This type of ventilation system is structurally similar to the natural one described above. But what makes them different is the presence of fans and other additional equipment, which increases, and radically, the efficiency of exhaust hood in basement rooms.

Forced ventilation is considered a costly method of eliminating contaminated air masses.

And yet, such a disadvantage is offset by the lack of dependence on natural conditions, the complex configuration of the basement floor, and mistakes made when creating natural hood. That is, from everything that makes the system ineffective.

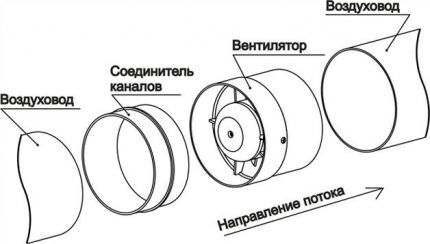

The simplest forced exhaust system is quite easy to set up - just install it in the exhaust air duct duct fan.

If the basement floor is divided into several rooms, and everything needs to be forcedly ventilated, then there will be little exhaust equipment in one room.

As a result, you will have to get out of the situation in the following ways:

- creation of air channels laid under the ceiling in all necessary rooms, which are formed from metal or plastic pipes;

- installation of exhaust and supply fans.

Supply fans will help solve the problem in particularly difficult conditions. Usually they are used exclusively in conjunction with exhaust hoods.

Since the fan is the basis for high-quality ventilation of any forced-air system, you should familiarize yourself with the technology for its selection. Since not every product will cope with the task, and many will even pose a danger to the life and health of users.

Necessary equipment to assemble the system

The following can be used to provide forced exhaust:

- fans;

- Humidity sensors, their more outdated analogues, which are hygrometers.

- thermostats;

- heaters.

Most often, fans are used to obtain the desired result. The most important characteristic of such equipment is performance and it will have to be calculated in each specific case.

But this is not difficult to do, since all you need is to use a special formula for calculation. According to which, the optimal fan power will be the derivative of the building volume of the required room and the multiplicity of the amount of air volume exchange for each hour.

ventilation is the most important performance characteristic on which efficiency depends. And if it is not enough, then forced air exchange is similar to ordinary natural one. In addition, such a product must be safe, and if the base is habitable, then silent

In addition, important performance characteristics of any exhaust fan are: safety, noiselessness, functionality. It is advisable to use a waterproof device.

Humidity sensors allow you to generate a signal to turn on/off the equipment in use. For example, the same fans. This will allow you to eliminate dampness, without overpaying for electricity. After all, ventilation devices will work in situations where this is necessary.

Thermostats are designed to keep the temperature in the basement stable. They are used to provide a command signal to turn on/off the air heater and other equipment used to heat the supply air.

This allows not only to maintain a given temperature, but also to create a pressure difference to ensure the required performance of a ventilation system without fans.

Stages of installation of a forced system

The installation of a forced ventilation system is carried out in several stages.

Which include:

- Calculation of the area of vents and their quantity. These operations are similar to those performed when designing a natural hood (listed above).

- Fan performance calculation.

- Creation of air ducts in compliance with the requirements specified for natural exhaust.

- Installation of fans and additional equipment if necessary.

- Functionality check.

All calculations are made at the design stage of the basement floor.

Mixed and complex ventilation systems

Mixed systems are among the most productive, as they take into account the specific conditions in each specific situation. They are based on the conventional natural exhaust scheme described above, with modern additional equipment adding efficiency.

Any scheme of a mixed or complex ventilation system implies the presence of a large number of structural elements and equipment.

In this case, standard solutions are not the way out. Since it is necessary to perform large volumes of calculations in each specific case.

Such systems are useful when the ventilation system needs to create different conditions in individual rooms of the basement.

For example, if a pantry, gym and wine cellar are located underground. Then, in the place where something is stored, you can take advantage of natural ventilation; for effective air exchange in the training room, an exhaust fan should be installed instead of a vent.

And where wine is stored, which requires a special regime, in addition to all of the above, it is necessary to use a number of additional equipment.Which will help maintain the microclimate stable.

In a room with wine racks you will need check valves, which exclude the entry of external air into the room, air conditioners, control systems, etc.

The exact layout of mixed or complex systems is created in each individual case, taking into account the needs. When arranging, you should use the same technologies and schemes as when creating other types of hoods.

For example, if the basement floor is divided into several rooms, then you should remember that adjacent walls are an obstacle to the movement of air masses. As a result, the creation of vents, air ducts, and channels is required.

There are several more articles on our website where we talked in detail about the arrangement of ventilation in various rooms. Recommended reading:

- Ventilation in the garage.

- Organization of cellar ventilation.

- Arrangement of ventilation for the steam room.

- Pool ventilation.

- Installation of a basement ventilation system.

Conclusions and useful video on the topic

The video will allow you to deepen your knowledge of arranging basement ventilation and creating holes with diamond cutting, which will help you avoid mistakes that lead to financial losses.

An example of working ventilation in the basement of a private house:

Although there are several types of hoods, the basis for ventilating basement spaces is the natural way. Which ensures efficient exchange of air masses for a plinth with an area of up to 50 m2.

If the dimensions of the basement floor are larger than the specified value or the area is divided into several rooms, then the effectiveness of natural exhaust will not be enough.

In such situations, modern equipment will be needed to organize a forced ventilation system with the arrangement of ventilation ducts equipped with fans to speed up the process of supplying fresh air to replace the remote air for each of the rooms on the ground floor.

Do you have personal experience in installing a basement floor ventilation system? You can share your own experience or ask questions about the topic of the article in the block below.

Last summer, I built a garage with a full basement on my plot of land. Apparently the builders incorrectly designed the ventilation system, and now that the snowmelt period has begun, a persistent smell of dampness has appeared in the basement. I carefully inspected all the walls and floors, but found no moisture or mold. I think the problem is the insufficient number of exhaust vents (only one). Now I don’t know what to do? Drill additional holes, install a forced ventilation system in an existing vent, or make several air hatches in the floor of the first floor?

Is it really a ventilation issue? If this is the case, then it will not be difficult to make additional vents. Ideally, of course, it is better to involve those specialists who were involved in this work for you, so that they correct their own mistakes.

But it may be that there are problems with waterproofing. This is actually why there is a damp smell in the basement.Then you will have to try to eliminate this more serious problem. Could you take a few photos or at least post a rough floor plan of the room so that the dimensions and location of the vents can be seen.

Also, have you checked the vents yourself? They could simply become clogged, which is why the ventilation system in the room was disrupted.

Think about forced ventilation as a last resort if there are no problems with waterproofing and there are no blockages in the existing vents.

The drawing with supply and exhaust natural ventilation is incorrect; if we place any long pipe vertically, a natural draft will form in it because at the bottom of the pipe the air pressure is greater than at the top of the pipe, so the air will flow upward. If we lower the lower end of the pipe into the cellar, then the natural draft will be for a limited time - until the pressure equalizes due to the vacuum in the cellar, that is, a second pipe is needed for supply. This second pipe must be much shorter in size than the first, otherwise there will be no circulation; in general, the first pipe must pull over the second. In the figure, the inlet is slightly longer than the hood. If it were twice as long, natural ventilation would go backwards to the front, the inlet would become a hood and the hood would become an inlet