Grease traps for sewerage: types, selection rules + installation procedure

Fatty elements contained in wastewater can block the pipe, causing a blockage. Fatty acids tend to cause metal corrosion and destroy pipelines, causing the sewer system to become unusable.

Grease traps for sewers, which are installed in the riser to the point where used water is discharged, will help solve this problem. In this material we will talk about the design features of these devices, their types and features that you need to pay attention to when choosing a grease trap for your home.

The content of the article:

- Design and principle of operation of the device

- Purpose and advantages of grease traps

- Types of grease traps by purpose

- How to choose the right grease trap?

- Performance properties of separators

- Equipment installation technology

- Review of popular grease trap manufacturers

- Conclusions and useful video on the topic

Design and principle of operation of the device

The main function of a grease trap is to filter sewage from grease, oil and solids that pollute the environment.

The equipment consists of a number of elements, these are:

- instrument compartment, in which fat and oil are collected;

- flask of 2-3 compartments, designed for settling wastewater;

- exhaust pipe, connected to the sewer system;

- inlet pipe;

- sealed removable lid, preventing the occurrence of unpleasant odors.

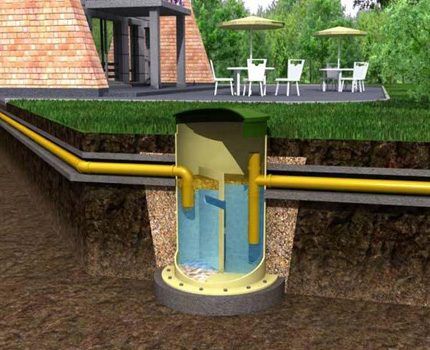

The sewer grease separator consists of a one-piece sealed housing with a lid. The removable cover allows for preventive maintenance or manual cleaning of the tank when necessary.

There are 2 pipes connected to the body - inlet and outlet. The tank is divided into 2 or 3 compartments, which communicate with each other and are designed to separate oil, fat, and solids.

From the last compartment, defatted and treated wastewater is discharged into the sewer pipeline.

Any model of grease trap for sewerage works on the principle of gravity. Particles of fat and oil accumulate on the surface of the filter, since they are much lighter than water.

Then they fall into a special settling tank, from where they are easily removed manually, using special equipment or special equipment.

Special enzymes are usually added to the device to break down accumulated fat. They allow you to significantly increase the time between cleaning the device.

Purpose and advantages of grease traps

More complex models of grease traps are used in large enterprises and are designed to effectively purify wastewater from solid particles, fat-containing and oil impurities.

According to sanitary standards in meat and dairy production and in public catering establishments, the installation of grease collection equipment in the sewer system is mandatory.

Industrial devices are installed at the outlet of a treatment structure that performs primary wastewater treatment.

Industrial devices are developed by manufacturers to ensure that clean water, purified from foreign impurities, enters the sewer system by separating and further removing the fatty component of the waste mass.

Installing a grease trap will help prevent sewerage failure due to the effects of grease deposits. It also protects the environment from the release of harmful impurities that can cause irreparable damage to the environment.

Such separators are indispensable not only in production, but also in everyday life. They reliably protect sewer pipes from the occurrence of grease valves or blockages. At the 1st stage, the device receives household water and separates fat and oil accumulations.

At the 2nd stage, the final separation of fat deposits and the removal of effectively purified water into the sewer system is observed. The device traps non-emulsified fats and removes them from wastewater.

The use of grease removal equipment has a number of advantages:

- Equipment tightness. Due to the tightness of the housing, the possibility of foreign liquid entering the filter is excluded.

- Practicality and versatility. Installation of various additional devices is possible. The sensor for the accumulation of harmful substances is in particular demand.

- No unpleasant odors. Due to the tightness of the housing, odors that usually arise during the breakdown of fats do not penetrate into the room.

- Easy to install. Installing indoor grease traps does not require any special skills and is carried out in 4 stages.

- Ease of maintenance. Cleaning most models of grease traps does not require much effort; it can be done manually using available tools.

- Acceptable cost. The devices have a low price compared to other types of filters.

In addition to these advantages, the device that collects fat also has a long service life. All equipment is made of high-quality and wear-resistant materials, which guarantees its durability.

Types of grease traps by purpose

Equipment for household purposes is installed under the sink in residential buildings, apartments and small catering establishments - bars, restaurants, cafes, confectionery shops and canteens.

There are 2 main types of fat traps:

- household appliance;

- industrial.

They are mandatory elements of the sewerage systems of restaurant-type establishments. The devices filter the grease that forms after washing dirty dishes.

Household grease traps are cleaned manually and used with a liquid flow rate of up to 1.5 cubic meters per hour. Industrial grease traps are installed in industries whose wastewater contains a significant amount of fat, oil and other foreign impurities.

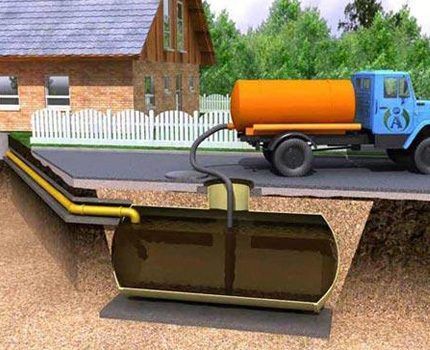

The use of an industrial device for catching grease is mandatory in large enterprises if the water flow is more than 2 cubic meters per hour. Their cleaning is carried out automatically - using special mechanisms.

How to choose the right grease trap?

Each buyer independently chooses a grease trap model depending on the requirements for the device and financial capabilities. Regardless of the model you like, it will be possible to solve the current problem of the accumulation of fat and oil impurities, which can lead to clogging of the sewer system.

Grease traps by installation type

There are several criteria for choosing a special grease trap.

According to the installation method, separators are divided into 2 types:

- installed outdoors;

- used indoors.

There are separate models for each installation method. It is rare to find “mixed” solutions that are installed both outdoors and indoors.

Grease traps of any type are installed in the sewer system.In catering establishments and in the meat, dairy and fish processing industries, the use of separators for separating fat is a prerequisite.

Household grease separators can be installed in various ways:

- in a separate room;

- under plumbing fixtures;

- in the basement.

The choice of the optimal option depends on several criteria: the dimensions of the equipment and the ease of use.

Outdoor grease traps are made from more durable materials, as they must effectively resist external soil pressure.

Installation of such a fat separator is a complex and multi-step process. At the first stage, earthworks are carried out, then the site is concreted, and only then can we proceed to installation.

Therefore, to install grease traps, they usually turn to specialized companies.

What material is the equipment made from?

The body of grease traps can be made of plastic, fiberglass or stainless steel.

Plastic grease traps are characterized by the following properties: attractive appearance and low throughput. They are mainly intended for domestic use, so they are installed indoors.

Advantages of plastic fat separators:

- Environmental friendliness of the material. Plastic is considered safe for the environment and people.

- Practicality. The material allows manufacturers to produce devices of standard sizes and tailored to individual customer requirements.

- Ease of maintenance. Equipment can be cleaned manually using available tools.

- Durability. Plastic has a long service life; the device can last up to 30 years.

For the correct operation of grease traps, it is recommended to use a fat and oil deposit level sensor or other additional devices

Fiberglass is made from glass fiber and a polymer binder. Fiberglass grease traps have excellent strength characteristics. Due to this, they can be installed both indoors and outdoors.

The main advantages of a fat separator made of reliable fiberglass:

- Resistance to aggressive environments. The devices are resistant to extreme weather conditions and harmful chemicals.

- Increased strength. Grease traps made of fiberglass have proven themselves to be durable and reliable equipment.

- Light weight and easy to care for. Fiberglass grease separators are easy to clean.

The design of fiberglass grease traps can be horizontal or vertical

Fat separation equipment made of durable stainless steel is the most expensive among different models. It can be installed outdoors and indoors.

Some manufacturers make separators for fat impurities from galvanized steel. The quality characteristics of such devices are lower than those of stainless steel devices.

Grease traps made of stainless steel are distinguished by high hygienic properties, excellent performance characteristics, and a long service life. It is also worth noting the high anti-corrosion qualities of stainless steel separators.

Performance properties of separators

Grease traps vary significantly in power and performance. Devices with a capacity of 0.1 to 2 l/s are considered household equipment.

All devices with a capacity of more than 2 l/s belong to industrial devices. Fat separators provide effective wastewater treatment from fats up to 20 mg/l.

The performance of the equipment must correspond to the amount of sewage entering the device or be higher than this value.

Grease traps also differ in how they are cleaned. There is equipment:

- manual cleaning;

- mechanized cleaning.

In most cases, grease separators are manually cleaned with low throughput, intended by the manufacturer for indoor installation.

They are under constant control; filters are cleaned manually using available means.

Grease traps for mechanized cleaning are, most often, industrial fat separators, characterized by high productivity. Typically, devices are equipped with sensors that signal the need for cleaning.

The cleaning procedure is carried out using pumps or specialized vehicles.

Equipment installation technology

The installation process of a fat separator can be carried out in various ways. It is necessary to choose the optimal type of installation depending on the type and characteristics of the grease trap. Let's consider several options for installing separators.

Installation of an outdoor grease trap

The installation procedure for an industrial grease trap is complex and time-consuming. Therefore, most trap buyers prefer to entrust the installation of equipment to specialists.

In order to carry out the installation yourself, it is necessary to carry out a number of preparatory work:

- Selecting a location for installation. When choosing, you should take into account the layout of the site, as well as the possibility of performing landscaping work in the future.

- Determining the size of the pit for mounting the device – its depth should be such that the grease trap lid is approximately 4 cm higher than the surface of the ground.

- Digging a hole. At the very bottom we will equip a solid formwork into which we will pour a mixture of sand and cement. For sandy soils and loams, a solution prepared in a ratio of 1:5 is optimal.

- We wait until the solution hardens, the minimum is 14 days.

When the preparation of the base for installation is completed, you can proceed directly to the installation of the equipment. To do this, we install the grease trap body on a concrete base and securely fasten the device to the hinges embedded in a homemade concrete slab during the pouring period. If you forgot to install the hinges, they can be secured with anchor bolts.

Now we are constructing unique plywood walls around the equipment installed in the pit. This process is necessary to prevent soil shedding. If you plan to operate the separator in a cold climate, then it must be covered with heat-insulating material. Mineral wool or polystyrene foam is suitable for this.

All that remains is to connect the grease trap to the communication networks. To do this, the output pipe of the equipment must be connected to drainage system. The joints must be treated with sealant. And we connect the inlet pipe of the device to the sewer pipe. Coat the joints of the elements with sealant.

We fill all the free space created between around the grease trap body with soil.Usually backfilling is used, during which the soil dug out from this place during the hole digging stage must be filled into the opening.

We must not forget about the need installation of a fan riser. It is required to remove excess gases accumulated in the sewer system. If there is a large load on the wastewater disposal system, it is better to install several risers at once. The fat accumulation sensor, which is installed inside the equipment, will warn you about the need for a cleaning procedure.

It is recommended that the installation and installation of industrial grease traps be carried out with the assistance of professional installers. They must have permits to carry out the full range of work.

Also, professional specialists have the necessary construction equipment for installation, so they can perform the necessary procedures for stable and long-term operation of the equipment.

Installing a grease trap indoors

Installing a household separator under a sink is a simpler process than installing equipment outside. To do this, you first need to choose the optimal location for installing the equipment.

It should be located on an easily accessible, hard and as level surface as possible, close to plumbing equipment.

It remains to perform a number of sequential actions:

- We bring the outlet pipe of the equipment into the sewerage system. At the connection point you need to install a rubber gasket, which comes with the device.

- We connect the inlet pipe of the trap to the outlet pipe of the sanitary equipment or to the pipeline (at the junction of the sink and washing equipment), not forgetting to install a special gasket.

- We fill the grease trap with the required amount of water to check the device for leaks.

If the test is successful, you can install the lid on the grease trap. Once the cover is installed, the installation of the equipment can be considered complete.

For more information on how to choose and install a grease trap under a sink, read this material.

Review of popular grease trap manufacturers

The modern market offers a wide range of fat separators made by foreign and domestic manufacturers. It should be noted that there are no significant differences in the equipment of different companies.

Devices of any brand work on the same principle - they function due to the force of gravity. Many manufacturers offer additional equipment in addition to traps, such as a stand.

When choosing the optimal model, you should focus on the purpose of the grease trap, as well as the prestige and reputation of the manufacturer.

Grease traps from the following companies are in particular demand:

- Helyx;

- Wavin Labko;

- Evo Stock;

- flotenk;

- UE "Polymerkonstruktsiya"

Helyx is a popular manufacturer that produces mainly industrial vertical and horizontal grease traps. The separator is used as the initial treatment system.

It is installed at the site of industrial sewage discharge, which contains contaminated and greasy wastewater.

Wavin Labko is a Finnish developer and manufacturer of innovative electronic fat accumulation meters and traps made of fiberglass and polyethylene.

Wavin-Labko's EuroREK grease traps are used in restaurants, cafes, canteens, gas stations, meat processing plants and slaughterhouses.

Russian manufacturer Evo Stock manufactures equipment for various purposes from heat-resistant reinforced plastic that is resistant to corrosion.

The devices are equipped with hermetic seals that effectively prevent unpleasant odors from entering the room.

Company Flotenk produces industrial and household devices from durable reinforced fiberglass

The advantages of grease traps from Flotenk are aesthetics, the presence of a level alarm, a degree of purification of up to 50 mg/l, and durability. The manufacturer produces vertical and horizontal grease traps.

The grease catcher from Polymerkonstruktsiya Unitary Enterprise is a container made of a spiral pipe, with inlet and outlet pipes.

The outlet pipe is located at a considerable depth, which prevents fat from leaking through.

Conclusions and useful video on the topic

The useful qualities of grease traps are described in the video:

You can clean the grease trap yourself. The video will show you how to do this:

The operating principles of grease removal equipment for production needs are described in the video:

A grease trap can significantly reduce the risk of corrosion on pipes and clogging of the sewer system. The equipment does not require special care; it is only necessary to clean the filter in a timely manner.

A properly selected and properly installed grease trap will effectively purify water and protect the wastewater disposal system from global pollution.

Already have personal experience using grease traps for sewerage? Tell us which device you preferred, are you satisfied with its performance? Perhaps there are some features of using this device? Leave your comments and ask questions in the block below.

I live in a private house, and the drains here quickly become clogged due to grease, even if you just wash the dishes. I found out about the existence of grease traps by accident and immediately decided to try it out. For now I put the simplest one under the sink. It's small and installation was easy. We've been using it for less than six months now, but we've already noticed a difference: the drains don't clog as quickly as before.

But it’s definitely a good idea, as I myself hadn’t thought of using the difference in densities of these liquids before.But I’m just thinking about buying a special container directly; there’s no particular point in it, since the design is quite simple: a plastic box with a partition, and holes of the required diameter for pipes. I think I’ll make one for my dacha, otherwise after a holiday there is an eternal problem with clogged pipes.

I did the same for myself.

Grease traps are very important for household use. They should probably be used by many people for the reason that they do not pollute the environment with harmful substances that may remain after food, scale, etc. Plus, such a system will prevent drainpipes from becoming clogged quickly.

First of all, grease traps are installed so that this “good” does not accumulate in the ventilation! Am I wrong? Another thing is how often should ventilation ducts in apartments be cleaned and who should do this?

I am concerned about the organization of drainage from the kitchen/bathhouse in a summer cottage where there is no toilet, but there is a washing machine, dishwasher, shower and sink. That is, I don’t need an expensive septic tank, but apparently I need some kind of grease trap, but so that it also purifies the water from washing powder. I still don’t understand which trap to choose, whether there are traps with additional filters, etc. The article does not say anything about my option.

It is better to install a metal grease trap; from experience, it passes all fire inspection tests! And metal does not absorb odors, unlike plastic. Plastic ones are bad, it’s better to use steel ones.