Types of ventilation pipes: a detailed comparative overview of ventilation pipes

Ventilation planning is an important stage of construction. The microclimate and durability of the building depend on the efficiency of the ventilation system. It is necessary to take a particularly responsible approach to the choice of air ducts.You should understand which types of ventilation pipes are suitable for existing operating conditions.

To understand the issue, it is necessary to evaluate the properties of the materials from which they are made, as well as the operating characteristics of products of different shapes and degrees of flexibility. This is exactly what we will discuss in our article, where we will analyze in detail the characteristics of pipes made of various materials, providing the material with thematic photos.

The content of the article:

Ventilation duct requirements

Design and ventilation calculation – a responsible job that requires the performer to have knowledge of building codes and an understanding of the principles of air exchange processes. The parameters of the building itself and the climatic features of the region are of no small importance.

Regardless of the air flow circulation pattern (natural or forced), a network of ventilation ducts is installed.

Air ducts must meet a number of requirements:

- Tightness. This property is necessary to maintain draft, as well as prevent mixing of counter clean and exhaust air flows. Particular attention is paid to connecting individual elements of the ventilation line.

- Quiet operation. The level of aerodynamic noise must be within sanitary standards. Permissible system noise is 25-35 dB.

- Corrosion resistance. Air masses of varying degrees of humidity are released through the home pipeline. Water vapor can accumulate on the walls of ventilation ducts, causing the formation of rust.

- Compact and light weight. The total footage of the ventilation system lines is large enough so as not to “overload” the building and not clutter up the space; pipes with a minimum standard size are selected to ensure unhindered circulation.

- Fire safety. The material of the pipe fittings should not be easily flammable and emit harmful vapors when burned.

In addition to the basic characteristics, it is desirable that ventilation pipes comply with additional parameters: ease of installation, good thermal insulation properties and smoothness of the channels.

Types of materials and their performance properties

Most residential ventilation pipes are made of metal or plastic. The product range includes dozens of different items. Alternative options for arranging a ventilation system include products made from technical textiles and sandwich pipes.

Type #1 - plastic air ducts

The category of plastic pipes for ventilation has significantly replaced traditional galvanization and is increasingly used in the creation of air duct networks for private households.

The main arguments for ventilation from polymer pipes:

- absolutely not susceptible to corrosion, which cannot be said about galvanized counterparts;

- ease of installation and processing - plastic can be cut with a hacksaw, and individual elements can be joined by heating the ends, ensuring complete tightness of the air duct;

- light weight - in this matter polymers have no competition;

- smooth surface and absence of welds - resistance to moving air flow is reduced, which allows the use of lower power fans;

- low cost.

Treating plastic pipe products with an antistatic agent minimizes dust “sticking” and reduces the number of cleanings. Due to the physical properties of the material, the pipeline practically does not “buzz”. Dimensions: length – 3-12 m, diameter – 16-1600 mm.

The listed advantages of plastic, along with low cost, make polymer products the most popular for ventilation. However, there are also negative sides.

When giving preference to a plastic line, you should take into account the characteristics of a particular polymer.

The construction market offers the following types of ventilation pipes:

- Polyvinyl chloride. Advantages of PVC air ducts: resistance to UV rays, accessibility, operating temperature range - from -10 °C to +70 °C. A popular area of application is exhaust pipes that provide ventilation in the kitchen and bathrooms.

- Polypropylene. The material is superior to PVC in terms of technical and operational characteristics. Properties: limit heating temperature +85 °C, resistance to aggressive substances. There is a fire-resistant variety (PPS) with fire retardant additives. Polypropylene is coated with an antistatic agent, minimizing the accumulation of dust.

- Fluoroplastic. Fluorine-containing polymers are characterized by heat resistance (from -60 °C to +200 °C), resistance to UV exposure, and immunity to alkalis and acids.

- Polyethylene. Withstands negative temperatures down to -50 °C and heating up to +80 °C. The material retains its primary qualities under the influence of ultraviolet radiation.

Polyurethane products have similar characteristics to PVC pipes. The difference between the latter is its high heat resistance (up to +270 °C).

We recommend that you familiarize yourself with the details selection of plastic pipes for arranging ventilation.

Type #2 - galvanized products

Galvanized pipe products are distinguished by their versatility - air ducts are used for arranging industrial, administrative buildings and residential premises.

Permissible operating environment for galvanized ventilation pipes: air temperature – up to +80 °C, humidity – up to 60%. Galvanization meets all the requirements for air exchange systems.Limitations in use – transportation of aggressive gas mixtures.

Summary of advantages of galvanized steel:

- The low weight explains the ease of assembly of the ventilation system - there is no need to build a complex supporting structure, which increases the cost of the utility network. An additional plus is the ease of transportation of pipe fittings.

- Mechanical strength – galvanized steel can withstand point pressure, mechanical impact from sharp objects and point loads. Resistance to bending pressure is higher in a pipeline with stiffeners.

- Thanks to zinc treatment, the air duct does not corrode even in conditions of consistently high humidity. Galvanized pipes are suitable for organizing ventilation outlets to the outside.

- When exposed to high temperatures, galvanizing retains its original size and shape. The fire resistance limit of pipes for multi-storey buildings is 90 minutes.

- The service life of a galvanized air duct varies from 20 to 25 years.

Additional arguments for galvanized steel: affordable price, the ability to produce pipes and fittings of various configurations.

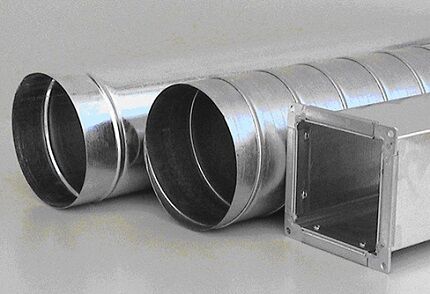

Based on the shape and manufacturing principle, galvanized pipes for ventilation are divided into the following types:

- rectangular;

- round straight-seam;

- spiral-wound.

Rectangular products are produced on tunnel assembly machines. The standard length of a pipe cut is 1.25 m, the minimum section size is 10*10 cm. Rectangular air ducts are equipped with stiffeners.

Round straight-seam steel has a simple manufacturing technology. Galvanized steel sheets are cut, rolled into a tube on rollers and fed to a seam rolling machine to join the ends.

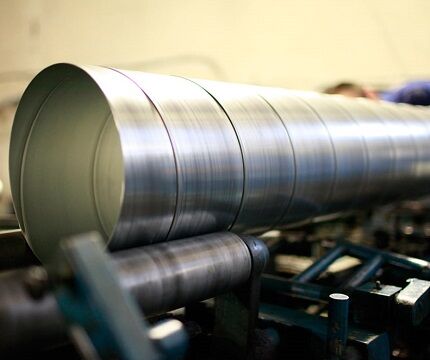

Spiral-wound products are made from galvanized strip (width - 137 mm), twisted into a spiral. Joining the edges is a locking connection with the outer seam.

The design of the pipes determines a number of positive qualities of “spiral” air ducts:

- significant rigidity;

- savings on the purchase of shaped elements;

- ease of installation;

- acceleration and low noise when transporting air - turbulence of flows intensifies in the spiral channel.

The installation of a ventilation system with spirally wound pipes will be cheaper compared to the use of rectangular products.

The wall thickness is standardized and depends on the diameter:

- 0.5 mm – for air ducts with a cross section of up to 315 mm;

- 0.7 mm – products with a diameter of 350-800 mm;

- 0.9 mm – pipes with standard size 900-1250 mm;

- 1.2 mm – air ducts with a cross-section of 1400-1600 mm.

According to the tightness class according to SNiP, galvanized pipes are divided into tight (P) and normal (N). The criterion of difference is the method of execution of the weld.

In dense structures, the joints after welding are rolled with a press and covered with sealant.This air duct can withstand pressure up to 1.5 MPa and is suitable for use in buildings with a high risk of explosion. Normal ventilation products are installed in domestic systems.

Type #3 - stainless steel pipes

Stainless steel pipes have all the listed advantages of rolled steel. Adding chromium to the alloy makes the metal resistant to rust. Adjusting the composition by introducing additional alloying elements gives the stainless steel specific qualities.

For the construction of ventilation systems, austenitic steel pipes are used, characterized by:

- corrosion resistance to many working environments;

- good manufacturability;

- strength and ductility;

- heat resistance – up to +500 °C;

- chemical inertness to toxic and radioactive substances;

- durability.

Products made from chrome-nickel stainless steel are more expensive than galvanized air ducts. Externally, the products are similar, which is sometimes taken advantage of by unscrupulous manufacturers.

There are several ways to detect a fake.

- Carrying out spectral analysis. Special instruments are required to determine the chemical composition of the metal.

- Visual inspection. It is permissible to have characteristic “stains” on galvanized surfaces – crystallization patterns.

- Electromagnetic differences. Most stainless steel alloys are not magnetic, while steel is highly attracted to magnets.

- Chemical reaction. As a result of interaction with hydrochloric acid, zinc begins to bubble (hydrogen is released), and the galvanization gradually disappears. One drop of acid is enough for the experiment.

You should also keep in mind that rolled galvanized steel pipes have a subtle bluish tint.

Type #4 - products made of black steel

Products made from “ferrous” rolled products are used in smoke removal, aspiration and ventilation systems. This is a good option for exhaust pipes for ventilation with access to the outside. Compared to stainless steel and galvanized steel, black steel has improved rigidity, fire resistance and heat resistance.

Characteristics of black steel pipe fittings:

- wall thickness – 1.2-1.5 mm;

- footage - 1.25-2.5 m;

- joining pipes using a flange method;

- Design options – rectangular, round cross-section.

The cost of “ferrous” rolled products is higher than for galvanized air ducts of the same size, but lower compared to stainless steel.

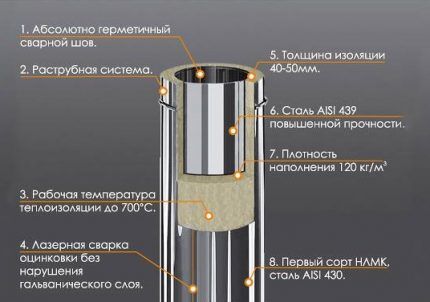

Type #5 - sandwich pipe

Insulated insulated air ducts are installed when creating ventilation for fireplaces, stoves, and heating boilers. The pipes ensure the proper level of fire safety of the system and heat retention in the room.

Basalt fiber is often used as thermal insulation filling.

Insulation characteristics:

- low thermal conductivity – up to 0.05 V*m/K;

- hydrophobicity – moisture absorption up to 2%;

- tensile strength – withstands pressure up to 10-60 kPa;

- biological resistance – the material does not rot and does not promote the growth of fungi;

- fire safety – melting point about 1100 °C;

- vapor permeability and sound insulation – partial “absorption” of vertical sound vibrations.

Basalt is chemically inert and does not react with metals - the risk of rust is reduced to zero. The choice of sandwich pipe for exhaust ventilation depends on the operating conditions.

Advantages of a ventilation system made of sandwich pipes:

- versatility of application;

- ease of assembly;

- multi-layer pipeline prevents the formation of condensate;

- thermal insulation of the air duct.

The disadvantages of insulated pipes include: high weight (2-2.5 times more than metal, several times more than polymers) and high cost.

Type #6 - technical textiles

The fabric air distribution system was proposed by Danish developers 20 years ago. The new product has partially replaced metal channels in the food, electronics, chemical industries, catering, swimming pools, concert and exhibition halls.

There are two types of textile pipes:

- airtight;

- breathable.

The purpose of airtight systems is to transport and remove air masses. Manufacturing material – polyamide.

Fabric systems do not have the disadvantages of metal air ducts. The significant advantages of textiles include:

- No drafts. There is often a draft in the air supply area from the metal/plastic duct. A “dispersed” supply of air jets is carried out through textile pipes.

- Noise-absorbing qualities. The fabric dampens the aerodynamic noise of the fan and air flows.

- Easy to clean. The textile acts as a barrier, partially filtering the supplied air. The material accumulates dust, but is easy to clean – it can be washed (50 cycles) and disinfected.

- Protection from condensationA. Due to vapor permeability, condensation does not form on the surface of the fabric pipeline. Microorganisms do not develop in dry canals.

The optimal air flow speed for a textile pipe is 5-8 m/s; for other types of pipes there are also air flow speed standards, which should be taken into account when designing ventilation and choosing air duct material.

As the pressure decreases, the shape of the “sleeve” is maintained by thin sewn-in rings. The service life of the air duct is 10 years. Fire hazardous rooms are equipped with textile pipes with additional glass fiber - limit temperature +300 °C.

Features of rigid and flexible ventilation ducts

Depending on the degree of flexibility, a distinction is made between rigid and flexible air ducts. The choice between the two positions depends on the complexity of the system being constructed and operating conditions. When installing a rigid network, turns and transitions are formed using connecting corner elements.

We recommend that you familiarize yourself with the main types of fittings for steel pipes and technology for performing various connection options.

Flexible air ducts are made from various materials.But, regardless of the material of manufacture, corrugated air ducts, compared to rigid channels, have some disadvantages: low sound insulation, reduced air flow speed due to corrugated walls.

It is the composition of the pipe that determines its technical and operational properties:

- Aluminum corrugation: corrosion resistance, resistance to temperature fluctuations (-30 °C/+270 °C), tightness, bending radius - 0.76 d, chemical inertness, fire resistance.

- Polyester reinforced with steel frame. Characteristics: low cost, moisture resistance, low flammability, temperature range -20 °C/+65 °C, light weight. The disadvantage is the accumulation of static electricity.

- Polyester film with aluminum foil It is characterized by high strength (permissible pressure - up to 2400 Pa), good aerodynamic properties.

- Thermal insulation corrugation provides a reduction in heat loss and prevents condensation.

Regardless of the type of ventilation pipe you choose, it is important to know how to install it correctly. We provide installation diagrams and detailed instructions for installing flexible and rigid air ducts reviewed here.

Comparison of round and rectangular sections

Many people wonder what shape of pipe to choose: round or rectangular? If you evaluate the throughput, round products win - the air masses encounter less resistance, which means circulation is faster.

In rectangular pipes, the corners remain unused, so fittings with an increased cross-sectional area are selected. However, such a highway takes up less space - wide and flat models are easier to hide behind a suspended ceiling or above cabinets.

Also, the cross section is an important parameter that is used when calculation of air duct areanecessary for the installation of a ventilation system. Correctly performed calculations will allow you to purchase the required amount of material without overpaying for extra pipes.

Conclusions and useful video on the topic

Characteristic features of plastic, asbestos-cement, corrugated aluminum and galvanized steel pipes for ventilation of basements and cellars:

The organization of a ventilation system requires a competent approach to the selection of the main structural elements - ventilation pipes. Most of the requirements for air ducts of private houses are met by products made of galvanized steel, stainless steel and plastic..

The form is not of fundamental importance. Its choice depends on the characteristics of the ventilation network trajectory.

Are you selecting the appropriate type of pipes for installing a ventilation system, but still haven’t found the answers to all your questions? Ask them in the comments below this article - our experts will try to help you.

Or do you have knowledge/practical experience in installing ventilation pipes and want to supplement our material with useful clarifications and comments? Write your opinion, add tips supported by practical experience.