How to paint a cast iron bathtub: common means and technologies

After a certain time, any plumbing equipment, even expensive and durable like a cast-iron bathtub, can become unusable.But a complete replacement is not the only option for eliminating unpleasant defects. A compromise solution is cosmetic restoration of the surface of the product.

We will tell you how to paint a cast-iron bathtub, in what sequence the work is performed, and what material is required for it. The article we presented describes in detail the technologies for applying protective and decorative coatings. Recommendations are given, compliance with which will ensure optimal results.

The content of the article:

Reasons for preferring restoration

During regular use of the bathtub, its top enamel layer becomes significantly thinner, resulting in chips, scratches, blackness, and rusty stains.

Taking water procedures in such a bath is not very pleasant or aesthetically pleasing.

An old bathtub can ruin even the most expensive interior. In addition, dirt and harmful microorganisms accumulate in microcracks and damage to the enamel, which is unsafe for health. Of course, this prompts the owners to think about replacing the old bathtub with a new one.

But in this case, a financial question arises, since the ones produced now cast iron baths, even the most inexpensive and not very high quality ones are not cheap.

In addition, when replacing a bathtub, you will need to dismantle the old plumbing fixtures, which is almost always associated with damage to the finishing elements. Therefore, not all homeowners, for various reasons, have the opportunity and desire to replace an old bathtub with a new one.

These reasons include:

- lack of financial opportunity to buy an expensive bathtub

- reluctance to spend time and money on transporting, dismantling, installing a bathtub and repairing tiles;

- the irrationality of replacing a cast iron bathtub of “Soviet” quality, since today such products are very expensive;

- savings, why throw away a reliable cast-iron bathtub that retains the heat of water for a long time.

However, skilled owners often have doubts about positive results. installing a new cast iron bathtub. Often people are afraid of the possible unpleasant smell, noise, dust, or dismantling the bathtub.

In this case, the best solution would be to paint the bathtub. Indeed, changing enamel is a fairly simple undertaking, but it requires careful and precise adherence to instructions.

If you have the time and desire to save the family budget, then you need to prepare all the necessary equipment and materials and start painting. Your bath will look fresh and perfect, just like it came from the store.

The average consumer immediately has a question: will this venture be justified from a financial point of view? Bathtub restoration in any case, it will cost several times less than buying a new one, regardless of the chosen method of work. You can not only save money, but also increase the service life of your bath several times.

Restoring outdated plumbing fixtures to their original appearance will not take much effort and time, and the results will definitely please you. The cost of the necessary materials is relatively low compared to the price of a new high-quality bathtub.

The main motivations for preferring the restoration of cast-iron bathtubs include the obvious benefits of this event, the speed and ease of execution, and the ability to give the product any chosen shade.

Today, several simple methods have been developed to return worn-out plumbing to its former, thriving appearance and continue successful operation, with a minimum of financial costs.

There are the following methods for this:

- Applying a new enamel coating to the work surface of an old bathtub.

- Filling a bathtub bowl with liquid acrylic.

- Installation of a special ready-made acrylic liner on a damaged bathtub.

The common belief that only an experienced specialist can perform such work is erroneous.

Carrying out these restoration works is quite accessible to everyone. Before you decide to take action on your own or entrust the matter to a professional, evaluate your capabilities. Painting a bathtub yourself will only cost you the purchase of materials without paying for the work.

Necessary stages of restoration

The need for restoration measures is determined if there are defects on the surface of the bathtub, such as roughness, cracks, rust, or loss of original color. A complete bathtub tank renovation consists of five stages.

List of main works

Any painting of a cast iron bathtub consists of the following procedures:

- Degreasing. Before restoration by any method, it is first necessary to thoroughly degrease the bathtub. To do this, limescale and grease deposits are removed using strong alkaline solutions and mechanical treatment.

- Removing old enamel. The process is carried out using sandpaper or grinding equipment.

- Cleaning from dust and enamel residues. Peeled enamel is removed with a vacuum cleaner and washed off with water.

- Drying the bath surface. To properly dry the bath bowl, use a regular or construction hair dryer.

- Painting process. Performed according to the chosen method.

The entire process of painting a bathtub bowl involves painting from the sides to the bottom of the entire surface. For greater efficiency, the material is applied in two stages.

The bottom of the bowl is processed at the very end of the process. After restoration, it is necessary to dry the entire new surface of the bathtub. Depending on the material used, it is better to use the bathtub after 2-6 days, so that the new coating is completely dry.

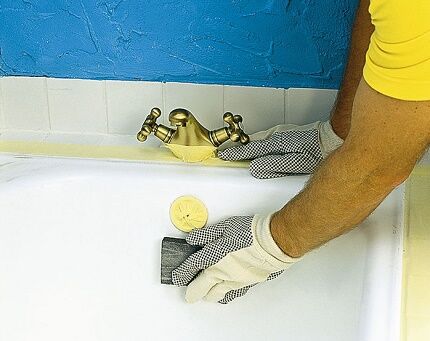

During work and during drying, it is necessary to prevent water, dust, and any contaminants from getting onto the surface of the bath. To do this, the taps and shower are carefully insulated, and the door is tightly closed. The work is carried out in special clothing and gloves.

Types of degreasing and rules for their implementation

To obtain a durable and reliable new coating, high-quality degreasing of the bathtub bowl before painting is of great importance. Degreasing can be done in two ways. The first method uses baking soda, a metal dish scraper and coarse sandpaper.

Baking soda is applied to the scraper and the entire bathtub bowl is processed in a circular motion, removing grease deposits. Areas of chips and cracks are treated most carefully.The tiles bordering the sides of the bathtub are also washed. Painting tape is applied to it before painting.

The same procedure is repeated using sandpaper. If the contamination is not severe, degreasing is carried out only with soda without using an abrasive. This method is considered the most economical and is used in the restoration of all types of bathtubs.

The entire degreasing process takes about 30 minutes. It is not recommended to use grinding wheels or a grinder, as unwanted black marks may form on the surface. Finally, the bath bowl is thoroughly washed to remove soda. This technology is most suitable for restoring bathtubs with a previously applied acrylic coating.

The second degreasing method is more used when processing enameled cast iron bathtubs. Here we use: a bristle brush, sandpaper, degreasing agent, car putty. After thorough cleaning sandpaper, apply a degreaser with a brush to the entire area of the bathtub bowl for 5 minutes.

The largest defects must be repaired with quick-drying putty. Drain and overflow areas are thoroughly degreased. It is necessary to remove all applied materials from the surface to the factory base.

To check the quality of degreasing, water is poured onto the surface of the bath. If drops of water flow quickly without lingering or accumulating, it means the procedure was carried out correctly.

It is very important to choose the correct technology of work that is most suitable for the condition of your bathtub, otherwise the restoration will not give the desired result.

Bathtub restoration with enamel

Bathtubs that were installed in the old days are of enviable quality. But, as time has shown, their weak point is the enamel coating. Over time, during long-term use, the enamel layer is depleted, red rust spots and a network of small cracks appear on the surface of the bathtub, and the whiteness and perfection of the coating are lost.

In this case, thrifty owners will help correct the situation bathtub restoration with enamel, evenly applied to the inner surface of the bowl. Even the oldest bathtub will acquire its original appearance after a high-quality new coating is installed.

Features of enameling

Let’s say right away that this method of restoration is not suitable for every bathtub.

Painting with enamel will be the optimal solution if its surface:

- darkened, yellowed or dark spots are visible;

- became rough and covered with a network of small cracks;

- lime deposits and mold on the face;

- the shine of the enamel is partially or completely absent.

Such defects will easily disappear under a new enamel layer. But if there is more significant damage to the surface layer, such as voluminous chips, deep cracks or the enamel falls off in pieces, then it is necessary to use other restoration technologies, since this will not give the desired effect.

The positive result of the renovation also largely depends on the correct choice of the method of applying enamel and on the purchase of a quality product for the job.

Saving on paint may subsequently lead to the need for repeated restoration. Professionals recommend selecting products from well-known, trusted manufacturers, despite the slightly higher cost, because they fully meet all quality standards. Only a high-quality product will guarantee that you restore the surface enamel layer of your bathtub to a snow-white state.

Enamel has excellent characteristics epoxy or two-component polyurethane enamel. The painting itself must be done in two or even three layers to obtain a guaranteed restoration result.

To apply each new enamel layer, a portion of the coloring composition is prepared anew. The components of the prepared enamel, after thorough mixing, begin to gradually harden and after 2-3 hours the mixture will be unusable. Therefore, the enamel is prepared in portions in the required amount.

Before applying a new layer, the previous one is thoroughly dried and degreased, according to the manufacturer's instructions. For better adhesion and fluidity of the composition, the enamel is kept in a container with heated water before mixing with the hardener.

Methods for painting a bathtub with enamel

The most important and crucial step in restoring a bathtub is applying enamel to the prepared surface. Without using the services of hired specialists, paint the bath at home you can do it yourself using two methods - painting with a flute brush or a spray gun with a compressor.

To carry out restoration work using this method, you will need the following:

- high-quality enamel;

- quick-drying primer for filling larger cracks;

- a degreaser such as acetone;

- detergent;

- rough sandpaper or other abrasive;

- napkins or rags of natural composition;

- construction tape, plastic film;

- rubber gloves and overalls.

Before work, it is better to divide the prepared coloring agent into two parts - for the starting and finishing coating. The base layer of enamel is applied with a wide brush in a thin layer. Work begins from the edges of the bathtub tank towards the bottom. It is necessary to cover the entire surface of the old layer with new enamel, spreading the paint with a brush thoroughly and evenly.

If lint from the brush gets onto the enamel, remove it with a knife or tweezers, never touching the paint with your hands.Without waiting for the base layer to dry and preventing dustiness Once the enamel has already been applied, finishing work is done after about 20 minutes.

The second part of the enamel is applied with the same brush, moving from the middle to the top. After painting, you need to give about 15-20 minutes for the enamel to straighten spontaneously. Then, with a brush, the enamel stains that have not been straightened out are carefully removed using movements from the middle to the edges.

This must be done while the enamel is still mobile and has not lost its fluidity. Now leave the bath alone until the enamel layer is completely distributed and dry. You cannot use the plumbing fixtures for another 3-6 days, depending on the manufacturer’s recommendations.

Applying enamel with a spray gun has a number of advantages. We easily obtain a smooth and even surface with little material consumption and without much effort. But for this purpose you need to work with a professional tool.

Aerosol cans will not give the desired result. Practice has shown that it is most rational to solve the issue comprehensively. Namely, do the starting coating with a brush, and the finishing coat with a spray gun. This way you are guaranteed a perfect new bath cover.

Restoring an old bathtub with acrylic

Ten years ago restoring an old bathtub It was only possible by painting with enamel. Today, another alternative method has emerged for restoring the damaged surface layer of a bathtub bowl using modern material - liquid acrylic.

With this material, you can easily transform your outdated plumbing fixtures yourself in literally a matter of hours and increase its service life by another ten years.

Advantages of acrylic in painting

Acrylic is a unique material. Thanks to its properties, an old, worn-out plumbing product is transformed before our eyes into a brand new one, as if from a store. The material has excellent mechanical, chemical and decorative qualities. Excellent quality for bathtub surfaces is its good anti-slip properties.

To carry out reconstruction with acrylic, there is no need to dismantle the facing tiles and bathtub tank, which greatly simplifies and speeds up the process. Most often, for work in this category, a liquid or bulk type of acrylic called Stakryl, etc. is used.

The advantages of these funds include:

- good fluidity for ease and uniformity of layer application;

- ideal smoothness of the resulting surface, without flaws, bubbles and roughness;

- low thermal conductivity, maintains water temperature for a long time, no foreign odor;

- easy to use and maintain, just wash occasionally with soapy water;

- high strength and wear resistance of the acrylic layer;

- whiteness and excellent gloss last for a very long time.

The material consists of two components - acrylic itself and a special hardener, which, when combined, form a very dense, reliable film with a thickness of 3 to 7 cm.

Before applying a new acrylic surface layer to the bathtub, similar preparatory procedures are carried out as when painting with enamel. The old surface is well treated with emery, the dirt is washed off, degreased with solvent or soda, if necessary, treated with auto putty and proceed directly to processing.

Carrying out the “fill bath” technology

This restoration technology is suitable for acrylic and enamel cast iron bathtubs.To carry out the work on your own, you need to prepare the appropriate acrylic composition, a plastic container with a volume of up to 1 liter, a small metal spatula and a flashlight for easy quality control.

All technology self-filling bath consists of the following points:

- The mixture is prepared according to the instructions from two components. Part of the solution is poured into a prepared plastic container for direct pouring of acrylic.

- Liquid acrylic is poured from a glass in a small, neat stream around the perimeter of the upper contour of the bathtub. Using a spatula, apply the composition under the edge of the facing tile.

- The poured coating should drain down to half the walls of the bath.

- There is no need to use brushes or rollers when working.

- The lower part of the walls of the bath and its bottom are poured while passing through the second circle of the spiral, maintaining a layer of 5 mm.

- Excess mixture flows through the drain into a tray.

If sagging forms during operation, there is no need to correct them; after drying, everything will straighten out on its own. When restoring with acrylic, one trick is observed - the working surface must be warm. To do this, first fill the bath with hot water for 5-10 minutes.

After draining, carefully dried cotton cloth and dry with a hairdryer. Before painting and during the process, moisture on the surface is unacceptable, since acrylic does not stick well to wet surfaces. The adhesion of acrylic is carried out mainly due to the roughness of the base and the structural integrity of the material itself.

If the acrylic coating becomes leaky, water will quickly destroy it from the inside.Such consequences can be prevented by using an additional layer of acrylic. The thickened surface acquires good operational strength. It is advisable to carry out the entire pouring procedure carefully but quickly, since the acrylic sets and loses its fluidity.

The acrylic pouring technology should ideally take about 2-3 hours, no more. After complete polymerization of the finished layer, after 1-6 days, the sewerage system is connected and the bathroom can be used. As can be seen from the above, such renovation of an old bathtub is not difficult and is accessible to almost everyone, even a person far from construction.

Alternative to painting the bathtub

This is what people call restoring the surface of an old bathtub by installing an acrylic liner. The essence of the method is to install a ready-made acrylic liner that fully matches the configuration of your bathtub. From an execution point of view, this method is the simplest. There is no need to prepare the surface by degreasing, sanding or drying.

But there are some nuances here:

- the liner is adjusted around the perimeter;

- The surface of the bowl is treated with emery, because it is necessary to increase the roughness of the base;

- special adhesive polyurethane is applied from the sides and down the bathtub;

- The sides and body of the liner are pressed tightly together to prevent the formation of voids between the surfaces.

You can use the plumbing and connect the siphon within 5-6 hours. Pay special attention to matching the profiles of the bathtub and the liner, otherwise repairs are impossible.Advantages with disadvantages liner and filling bath you will find out by reading the article we recommend.

This method of restoration, although the simplest, is also the most expensive of those listed. To guarantee a good result, weigh your options and choose the most affordable method for restoring your old bathtub.

In order for the enamel restoration procedure to occur as rarely as possible, a cast iron bathtub must be properly cared for. Dedicated to methods and care products next article, the contents of which we advise you to familiarize yourself with.

Conclusions and useful video on the topic

Video with a visual representation of the stages of staining:

Method of using liquid acrylic:

Remember that you can restore every bathtub to almost perfect condition with your own hands, regardless of its condition. The main thing is to be patient, follow the instructions and use only high-quality materials. In any case, you are unlikely to spoil your old bathtub, but turning it into a new and shining one is easy!

Tell us about how you restored the protective and decorative coating of your own cast iron bathtub. You may have valuable information that will be useful to site visitors. Please write comments, ask questions, post photos on the topic in the block located below the text of the article.

I have a steel bathtub that was inherited from builders with a defect - a chip on the bottom, which over time began to rust. They changed it to acrylic, in which after seven years the yellow base began to show through.Now we need to paint both bathtubs, one to sell, the other to use. It’s easier to cover both with acrylic. How will acrylic adhere to the smooth enamel of a metal bathtub?

You can’t just take and apply acrylic to a cast iron bathtub! Yes, this can be done, but such a restoration will be of exactly zero use.

You will need:

1. Waterproof sandpaper;

2. Baking soda;

3. Pliers;

4. Screwdriver;

5. Several spatulas;

6. Putty (automotive fiberglass is best);

7. Gloves;

8. Construction hair dryer;

9. Drill (mix liquid acrylic);

10. PlastAll self-leveling acrylic.

In order not to talk for a long time about each point and the sequence itself, here are links to videos that you can use as a guide:

1. Surface preparation - https://www.youtube.com/watch?v=Q-l2qVjxHOM

2. Application of acrylic - https://www.youtube.com/watch?v=FRkqVv7yNqw

For clarity, I also attach a photo of the bathtub before and after restoration with acrylic.

The apartment we bought had a cast iron bathtub installed, but it was not in very good condition. Getting it out of the laid tiles and lowering it from the 5th floor (without an elevator) is a tedious job. So we decided to just cover it with acrylic. We are very pleased with the result - the bathtub is like new. We called specialists to do the work, everything was done quickly, and most importantly - without noise and dirt!