9 best spotters: review, pros, cons, price and quality

Every time automakers reduce the thickness of the metal cladding on new car models, straightening technicians have more problems.It is much easier to straighten dented thick metal on the wings or on the roof than the thin “blown” steel lining of modern cars.

If previously the problem was solved by replacement, now metal extraction is carried out using spotters. With sufficient skill, it is possible to level the metal with virtually no traces of dents and without painting the damaged surface.

The content of the article:

What to look for when choosing a spotter?

The essence of the device is to first weld a thin metal pin (rod) in the center of the dent using a welding inverter. Next, using a special device, pull the cladding metal to its original position. After which the rod is cut, and the surface is cleaned of traces of spot welding.

If everything is done correctly, the dent will be leveled without residual stresses in the metal. If the paint on the metal is of high quality, then there will not even be traces of deformation. The point from the welded electrode will need to be cleaned and painted over. The spotter is made primarily for body repair, but it can be used to repair dents on any thin-sheet steel structures.

How does the process of metal leveling occur:

- The point for welding the electrode is determined, and the place is cleaned to white metal.

- A positioning suction cup is installed, through which the end of the electrode is welded to the damaged metal of the cladding using a gun using an inverter.

- Next, the ballast (handle) of the gun strikes in the direction opposite to the lining surface. This is the so-called reverse or inertial hammer.

During impacts, the entire structure moves by inertia from the damaged area and at the same time pulls the deformed metal to its original state.

Essentially, the device consists of a gun with a reverse hammer on a rod and an inverter. The correct choice of welding current mode, polarity and tip material determines how firmly the electrode will be welded to the lining metal. In addition, the weight and size of the reverse hammer determines whether the inertial force created is sufficient to pull out the deformed metal.

That is, when choosing, you need to pay attention to the operating voltage of the inverter for spot welding, the design and weight of the hammer, and the set of attachments.

Therefore, when choosing, look:

- weight of the device;

- supply voltage (can be 220 V or 380 V);

- connection possibilities, whether it is possible to weld electrodes from the reverse side or from both sides at the same time;

- the maximum current can reach several thousand amperes;

- is there automatic protection;

- a simple and intuitive setup system that allows you to select the optimal welding mode;

- design of the reverse hammer (weight of the ballast-breaker).

The kit includes various attachments. For example, a triangle is used to level out small dents with a diameter of several millimeters. Tip - The wavy wire provides a wider grip on metal, flapping hood trim or roof trim. There are also rings that can be welded to a deformed surface, thereby evenly distributing the pulling load.

The optimal welding output current for triangle rings will be 1000 A, for a wave - 1200 A. If you heat a lump on the metal left after drawing with an electrode with a graphite electrode, you will need at least 2200 A, for copper - 1500 A.

For your information! Many manufacturing companies, in addition to cables with clamps, add several types of attachments: “star”, “ring”, triangle, as well as electrodes made of steel, graphite and copper. They can be purchased separately, but those included in the kit are usually of better quality and are definitely suitable for the operation of a spotter of this model.

Read also: Heating systems in motorhomes. Do-it-yourself wind generator from a car generator.

Review of the best

The best spotters, as a rule, are produced by leading electrical equipment manufacturing companies in Italy and Germany. There are Russian devices. In the top of the best you can find good devices copied by Chinese companies or produced under license. Sometimes the only difference is the price.

FUBAG TS 2600

The brand is German, but the welding machine itself is produced under license in China. One of the simplest spotters. Welding power — 5.4 kW at a supply voltage of 220 V.

The device is quite light - 14 kg, although the welding current per pulse is only 2800 A. The design uses an inverter converter on keys with one output transformer. The large weight and average values of the current pulse indicate that the manufacturer did not spare the copper wire for the transformer winding. This means that the welder will definitely serve for a long time.

But when welding an electrode, FUBAG TS 2600 produces a moderately increasing current pulse.You need to press the electrode or sprocket well, otherwise the connection will be weak and can be torn off from the welding point when the metal is pulled out.

The set includes a reverse hammer, several pieces of stars and rings.

Price — RUB 30,500, guarantee — 2 years.

Great Wolf GW-60L 220

The spotter was developed in the Russian Federation and produced at industrial enterprises in China. Quite a large and heavy welder. The manufacturer positions the Great Wolf GW-60L 220 as a spotter and at the same time a spot welding machine for professional car repairs.

Characteristics:

- weight — 54 kg;

- layout — vertical stand on a single-axle wheel support;

- electrical power - 10.9 kW;

- maximum current when operating in spotter mode - 3500 A;

- there is an output for connecting a graphite electrode (heating the metal);

- The recommended thickness for working as a spotter is 0.7-1.2 mm.

Included with the welder are two reverse hammers of different lengths, a hook, a suction cup, two dozen tips of different types: “star”, ring, copper-plated bolts. The operating circuit is based on an inverter and two transformers.

The control is based on a microprocessor. This is not the best solution for welders. The model is full of electronics, there is a screen and several adjustment knobs. Controlling the spotter is quite complicated; many functions would simply be superfluous in a home workshop.

The model can be recommended for a small auto repair shop for a couple of workers. Price - 39 thousand rubles, warranty - 12 months.

KraftWell 220 V

Despite the sonorous name, this is a completely Chinese brand. The KraftWell 220 V spotter, included in the rating, is designed and manufactured using an inverter circuit.Thanks to this, the size and weight of the spotter allow the welder to be easily carried by one person. We can note the good build quality and well-thought-out placement of buttons on the control panel.

Characteristics:

- spotter power — 10 kW;

- limiting current value in a pulse — 3500 A;

- There is built-in protection against overheating of the element base.

Supply voltage — 220 V, output from 1 V to 10 V. The control system is equipped with a current hold timer when welding the electrode to the metal. Therefore, it is possible to adjust the spotter’s response parameters to the working thickness of the metal (0.8-1.5 mm).

The kit includes a set of tips, a suction cup, and a reverse hammer. According to reviews, the spotter is capable of operating even with a slight heating overload. But it’s better to let the device cool down every 2-7 minutes of operation.

Price — 42 thousand rubles, guarantee — 12 months Most users consider KraftWell 220 V a worthy competitor for most German licensed spotters.

GYS GYSPOT 2700

Spotter 2700 is from the famous French company GYS, but production is located in China. In fact, this is not only a spotter, but a universal device for performing body repairs. Unlike most Chinese licensed welders, GYSPOT 2700 is distinguished by its durability, ability to work at low and high air temperatures in spot welding and spotter mode with irregular overload. First of all, due to the special cooling system.

Main characteristics of GYSPOT 2700:

- weight - 14 kg;

- power - 6.2 kW;

- welding current - 2700 A;

- supply voltage - 220 V;

- output - 1-5.6 V.

The discharge occurs due to the accumulation of energy in supercapacitors.Therefore, the design turned out to be much more reliable and durable than traditional transformer spotters.

Most users praise GYSPOT for fine-tuning the characteristics. If you correctly configure the welding parameters, the spotter will produce exactly the required current value. Moreover, during operation, even with strong heating, the settings do not change and do not require correction.

Price for GYSPOT 2700 — 29 thousand rubles, guarantee — 12 months

If you need a more powerful device for a body shop, then instead of the 2700 model, the GYSPOT 3904 is better suited. This is a professional-class device, 380 V power supply, weight — 34 kg. This spotter is designed for almost round-the-clock load with short breaks.

Price — 54 thousand rubles, guarantee — 1 year.

RedHotDot HAMMER T-34

Made in China using tracing papers from the German brand RedHotDot. One of the heaviest devices in the 5.2 kW power class. Even when compared with the Chinese-German FUBAG, which weighs only 14 kg, while the HAMMER T-34 — 25.5 kg. This means that the developers tried to make the welder high-quality, easy to maintain and, if possible, indestructible. For this purpose, they even made protection according to class IP21.

They partially succeeded, since the RedHotDot HAMMER T-34 spotter enjoys well-deserved attention from all bodybuilders.

The maximum welding current is 3.8 kA. This is enough to grab any stars, crosses, pins to the dented metal. And most importantly — do not burn the damaged area.

The set includes the spotter:

- a pair of reverse hammers (one of them is 1.1 kg);

- gun with welding hose and “ground” with a cross-section of 70 mm2;

- a large set of attachments, pins and sprockets.

The SINERGIC assistant system is used to control the spotter. It will help you select the current parameters for the first metal drawing. Then all this will be stored in memory and can be used in other areas.

Price — 55 thousand rubles, warranty for RedHotDot HAMMER T-3 - 2 years.

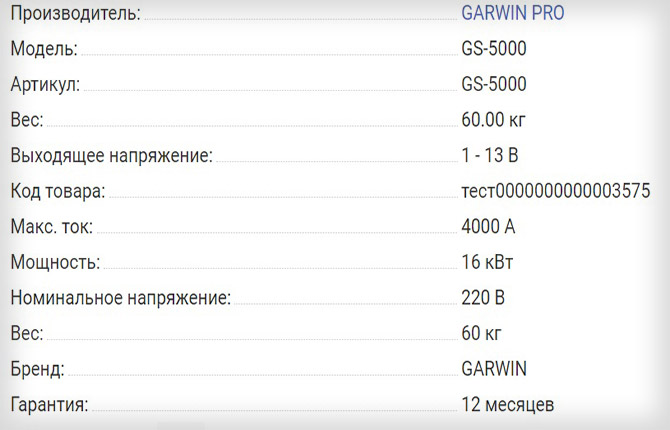

Garwin GS 5000

The spotter is of a professional level, so the design is aimed at constant use at service stations and in small auto repair shops. Unlike most light spotters (14-20 kg), this model weighs as much as 60 kg.

The entire electrical part is made on a single power transformer with several copper windings. The power of the spotter is 16 kW, but in terms of the level of protection and resistance to shock loads, the device turned out to be much more reliable than the more common capacitor and inverter models.

In this case, the settings of current and output voltage parameters are controlled using a microprocessor. There is a function to automatically turn on the blower, the board with keys and the transformer winding.

The spotter is equipped with a full set of welding accessories: a reverse hammer, a pair of cables, a switchable power cord, several types of nozzles and electrodes.

Important! Garwin GS5000 — one of the few spotters whose electrical characteristics of the welding transformer allow working with thin sheet stainless steel. Therefore, it is often used to repair tuned cars with a large number of chrome and nickel plated parts in the car lining.

TELWIN DIGITAL PULLER 5500 400V

One of the best spotters available to the amateur welder or small auto repair shop. Made in Italy.It has earned a reputation as a reliable and very accurate tool for straightening and pulling out dents. Unlike Chinese spotters, there are practically no defects when working with TELWIN. The price of the model is 59 thousand rubles. This is the most affordable model. More powerful spotters of this brand cost three to four times more.

Characteristics:

- weight — 21 kg without trolley;

- power — 11 kW;

- the maximum welding current in the electrode sticking mode on the dent surface is 3800 A. It is possible to weld thin sheet metal up to 1.5 mm thick;

- idling — 6 V, in spot welding mode — 1 V;

- power supply — 380 V.

The spotter uses a combined electrical circuit based on inverter switches with one power transformer. The use of a three-phase network to power the spotter made it possible to reduce the weight and dimensions of the welder.

The system provides effective protection of wiring and electronics from overheating. Even if you use the spotter constantly, then when the critical temperature reaches 80OAutomatic airflow will turn on. In extreme cases, the electronics will block operation until the device has completely cooled down.

Guarantee — 12 months

WIEDERKRAFT WDK-9BN

Produced in China, but developed by a famous German brand. Price — 38 thousand rubles. For the same money you can buy a good spotter with a stabilizer from the same manufacturer. But WDK-9BN has certain advantages. Firstly, there is a built-in spot welding module. Secondly, the electrical circuit is different:

- well-thought-out protection against overheating or emergency operation;

- automatic control system and mode settings. There are several standard settings in the memory that can be used for welding electrodes;

- the ability to create your own spotter operating modes and remember them in the memory of the settings block.

Despite the fact that the spotter belongs to the class of a professional tool, the device turned out to be relatively light — 19 kg with a power of 14.3 kg. The maximum current that can be obtained for spot welding is — 3.8 kA. The spotter is easy to set up and maintain. If necessary, you can simply plug it into a power outlet.

The welding kit includes an inertial hammer, cables, a set of washers and nozzles.

Warranty - 1 year.

Nordberg WS4

The device is made in China, the circuit was developed by German engineers within the Nordberg brand. It is positioned as an inexpensive (33 thousand rubles) welder for household use, available for use even by untrained workers. In addition to the functions of a spotter, the device can be used for spot welding, soldering, and thermal local softening of metal. Powered by regular network — 220 V, the housing is made according to protection class IP21.

Characteristics:

- weight - 19 kg;

- transformer power — 10 kW;

- maximum current - 3500 A;

- You can weld sheets with a thickness of 0.8 mm to a base of 1.2 mm.

The output voltage in spotter and spot welding mode is 1-6 V, there are 10 V pins for heating metal (usually springs) with a graphite rod, butt welding metal 13 V. The response time of the spotter can be adjusted within 0-99 milliseconds.

The welder turned out to be simple, without any complex settings. A simplified membrane keyboard on the front panel allows you to switch modes even with gloved hands.

According to the manufacturer, the spotter has a microprocessor control system.In fact, the electronics only work when a mode is selected; all other functions are at the level of a simple welding transformer. According to user reviews, the device operated without any problems, even in severe frost and did not turn off even with slight overheating.

You can buy a good spotter, but without the spot welding function, or a more expensive combined type device. For a large auto repair shop, it is more profitable to purchase spot welders and spotters separately. For one master, perhaps a combined device will be optimal.

Tell us about your experience working with spotters of various brands. Which of them, in your opinion, turned out to be the most successful and deserve attention? Also bookmark the article and share it on social networks.

Transformer ones are very heavy, but they are best suited for a workshop. If you do individual body repairs, it is best to take a French 2700 or a Gispot 3904 if the garage has three phases.

What's the point of buying this spotter for the garage? Any tinsmith can level it faster and better. Unless there is a lot of ice, when there is a queue to repair bumpers and bodies.