Restoring a cast iron bathtub at home: step-by-step instructions

It’s nice when inexpensive but neat repairs are made at home, and especially when everything is done with your own hands.Anyone who gets down to business first evaluates their capabilities, selects material, time and finances. But, it’s one thing to change the tiles in the bathroom, and another thing to change a bathtub that has turned yellow from time to time.

However, there is no need to rush to change it, since the enamel coating can be restored. You can learn how to make an inexpensive and high-quality restoration of a cast-iron bathtub at home from this article.

The content of the article:

Types of damage to a cast iron bathtub

Despite the large selection of bathtubs of different shapes, sizes and materials, cast iron all are also in demand on the market. After all, such a cast base is practically eternal and can last for several generations.

What does that require? Just periodic restoration of the enamel coating of a cast-iron bathtub is not as difficult as it might seem at first glance. To carry out restoration work correctly, you need to learn a little more about the types of damage.

Type #1 - yellowness and plaque

Roughly speaking, these are the remains of metal oxides found in water. Over the years, more and more oxides are deposited, they saturate the top layer of paint. And the moment comes when the yellowness can no longer be washed off, the top layer becomes yellow.

Type #2 - mechanical damage

Scratches or other damage to the factory enamel layer. Enamel coating is thermosetting components baked at high temperatures in several layers, which when dry become very hard, but brittle.

Any sharp blow to the surface with a hard object often leads to cracks and even chipping of part of the coating.

Type #3 - gloss damage

Gloss is a very important detail for the aesthetic appearance and technical condition of the coating. A shiny surface is an indicator of a high-quality coating. The gloss protects the enamel layer from penetration of moisture and various contaminants.

It prevents chemical elements from detergents from settling on the surface and allows the paint to remain clean for a long time. Any damage to the coating, even very minor, will reduce the service life of the entire paint layer.

Very often, wanting to quickly wash away dirt, owners use detergents based on fine abrasive powders, which very quickly turn the gloss into a matte surface.

There is an article on our website where we told you how to wash a cast iron bowl without damaging the coating. More details - go to link.

Coverage restoration options

To restore the internal surface of bathtubs, three types of restoration are common:

- applying enamel coating using a brush or spray gun;

- treating the bathtub bowl with a polymer compound - acrylic;

- installation of liner.

Dye — the service life of the enamel coating largely depends on the experience of the craftsman and the thoroughness of the preparation of the base of the bathtub/bowl. As a rule, even with careful handling of the restored coating, its service life does not exceed 1-1.5 years.

Liquid acrylic used to restore bathtubs of non-standard shape. The technology allows you to update the bowl yourself, without involving a team of craftsmen. True, you need to buy a high-quality polymer from a trusted manufacturer.

Installing the liner - this option is quite problematic, since they are cast in a certain shape and it can be very difficult to choose the right size for your bathtub. And quite often it is impossible - if you have a non-standard shaped bowl installed.

We won’t give advice on what type of restoration is better - you will figure it out on your own, assessing the condition of your bathtub and your own strengths.

Step-by-step instructions for enamel restoration

Enamel, intended for restoring the surface of a cast iron bathtub, is a material that contains a base and a hardener.

Simply put, enamel is not exactly paint in the traditional sense, but rather polymer composites that meet numerous requirements. Therefore, it is necessary to treat it as a complex chemical composition, which is manufactured and mixed using a special technology.

The main color is white, and various fillers and dyes are used to prepare colored shades.

It’s worth mentioning right away that the enameling does not in any way pretend to be of factory quality, so it should be treated as if it were a routine repair. This is just a coating with a thin layer of film that hardens in air without special ovens.

The technology of coating a bathtub with enamel is divided into four stages:

- Putty, or, as it can also be called, leveling out all irregularities, if any.

- Preparing the base for coating, which involves cleaning and removing the surface layer of existing enamel.

- Enamel preparation and application to the surface.

- Proper drying or drying.

All stages of work are very important, nothing should be missed here. Even a small inaccuracy can lead to a decrease in the service life of the coating, but let’s look at everything in order. First of all, you need to remove chips or scratches.

Step #1 - surface preparation

To properly prepare the interior surface, it is best to remove the completely damaged layer of paint. For this, the best option is if the layer is protected before priming.

Stripping can be done manually or using electrical devices: angle grinder (angle grinder), drills, grinders.

The surface is processed manually using an abrasive method; for this, two types of working material are used: sandpaper and metal mesh, which is used to level the plaster during construction and repair.

When using sandpaper, you need to select the base to which it will be attached. For this, there are special graters with screw or spring clamps at the edges. You can also make the base yourself from a block of wood.

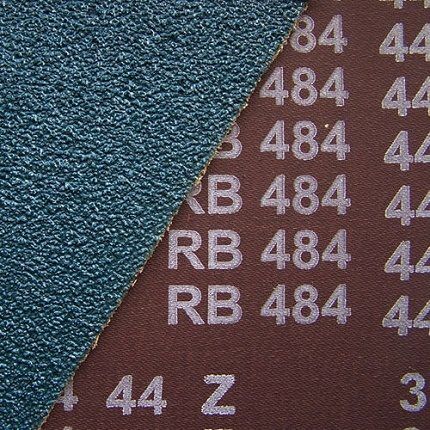

Sandpaper There are several types: paper and fabric based. Fabric ones are more durable and can be washed, paper-based ones are not. Fabric ones impregnated with a special composition are more resistant to abrasion. Suitable grain size for work P120-P180.

Metal grid more practical because it does not wear out or lose grain, and if it becomes clogged with dust, you can wash it and continue working. The mesh is attached to the holders.

A standard holder for an abrasive mesh or sandpaper should have a flat and rigid surface. Clamps for the blade can be screw or spring.

When purchasing, be sure to pay attention to the handle, which must be cast with a base. If the handle is attached with glue, then there is a chance that it will break in the midst of work. Professional meshes can be made from tungsten filaments, but they are much more expensive.

The mesh markings are the same as sandpaper.Widespread brands: R-120, R-150, R-180, R-240. For removing the surface layer of paint from a bathtub, P120 - P180 is better suited.

Surface preparation is carried out until all defects are completely removed, or until the ground layer is reached.

Step #2 - preparation and application of the composite

If the surface has unevenness, chips, or deep scratches, then it is better to use special putties to level the surface.

In order to prepare the place for repairing the chip, you need to:

- thoroughly degrease the defect with bleach, denatured alcohol or acetone;

- rinse the area with running water and dry with a hairdryer;

- clean thoroughly with sandpaper;

- rinse again with clean water and dry with a hairdryer;

- prepare the composite.

According to practicing craftsmen, putty containing fiberglass is better suited - this composition is the most durable.

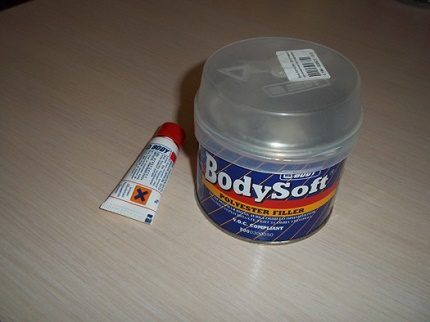

So, among suitable putties, we can recommend a polyester company Novol or Body. These materials, after hardening, have high ductility, which is important in conditions of constantly changing temperatures when using a bathroom.

Finishing putty cannot be used to seal chips in bathtubs. Since it has a large linear temperature expansion.

You must first decide on the volume of material needed. You only need a little putty, so it’s best to buy a small jar. High-quality putties are two-component, one of which is a hardener.

The ratio of mixed components is determined according to the instructions for use, but if there is none, then general standard 1:10. After combining the 2 components, you need to mix them thoroughly and quickly until smooth, the start time for hardening is 2 minutes.

After the composite is ready, all defects are repaired with a plastic spatula. Having finished sealing the unevenness, it is necessary to clean all the working tools, because after 10-15 minutes the putty will turn into “stone”.

Step #3 - painting the cast iron bowl

Painting of the accessible part of the surface is done manually using a velor roller; inaccessible areas are painted with a brush.

To apply paint with a roller, the prepared paint is poured into a special ditch. After immersing the roller in the paint, it must be rolled one or two turns along the ribbed edge of the ditch.

Then paint with intense movements from the bottom of the bathtub to the edge of the top, while the movements should be directed from bottom to top. Inaccessible places for the roller are being repainted flute with a brush.

Step #4 - drying after painting

Drying after painting occurs only under natural conditions: drying of one layer of paint should last at least 3 days. Each repeated layer adds another day. Thus, drying with a three-layer coating will be at least 6 days.

It is not recommended to speed up this process with artificial ventilation, because uneven drying is possible, which will lead to internal tension of the film, and as a consequence, its subsequent peeling.

Nuances and tips for independent work

Deciding to go independent coating restoration, it is important to adhere to a number of rules and perform all actions consistently. Only in this case can a positive result be guaranteed.

Firstly, before starting work, it is recommended to wipe all the walls, ceiling, in general, do a wet cleaning in the room where the bath is located, since any speck on the surface fresh enamel will noticeably worsen its condition.

If the shower is not dismantled, it must be removed to eliminate even the theoretical possibility of water drops falling while the paint is drying.

Secondly, degrease the prepared surface. The best solution for degreasing is denatured alcohol, solvent 646, or, in extreme cases, acetone.

Solvents are good for processing, but do not remove residual corundum particles or debris, so after cleaning it is best to rinse and vacuum the surface.

Third, you should prepare the paint correctly. It must be mixed according to the attached instructions. It is worth remembering that the time for painting after mixing the components is 15-20 minutes.

The viscosity of the paint should not be too thick, otherwise it will be very difficult to apply, but not liquid, so that drips do not form.

Almost all paints are diluted with 646 solvent or acetone. The acrylic-based composition is incompatible with domestic solvents.

Fourth, you need to take time to prepare the brush flutes. Which consists of combing out loose hairs with a fine comb so that they do not fall out during the coloring process.

Then you need to run it over coarse sandpaper several times to give the bristles a pointed appearance.

FifthlyTo speed up the surface preparation process, you can use a power tool. If you don’t find what you need, you can borrow it from a good-natured neighbor or friend.

A home handyman who does his own repairs must have electrical appliances in his arsenal: a drill, screwdriver or angle machine (angle grinder). If you use special attachments, they are suitable for initial surface treatment before painting.

You can also use it to prepare the surface. screwdriver, clamping a backing material for abrasive material into the chuck instead of a drill. Or use special attachments for angle grinder typewriter

When using electrical appliances to paint surfaces, you should pay attention to some of their features:

- Not all power tools have dust protection in the ventilation holes; to prevent paint particles from getting inside the device, you can cover the ventilation holes with several layers of gauze.

- Electrical appliances with commutator motors create a spark between electric brush and collector plates. If they are used continuously, paint will accumulate inside, which can cause a fire.

When using power tools, it is better to give preference to devices with rechargeable batteries - they are more mobile and safer.

Conclusions and useful video on the topic

This is how you putty a chipped bathroom:

The most common mistakes when restoring coverage:

Detailed instructions for restoring the bathtub cover:

As you can see, produce enamel restoration at home is not so difficult, the main thing is to clearly understand the sequence of operations and do everything without errors. But if you doubt your own abilities, entrust this work to professionals.

Have you ever renovated a bathtub yourself? Please tell visitors to our site which method you used and why you chose it. Leave your comments in the block below. There you can ask questions about the topic of the article.

I restore it with paint. Yes, it doesn’t last long, for 2 years, but it requires minimal effort compared to acrylic. I don’t have the opportunity to take my family out for a week while they make a bath, so I paint it myself, it takes a couple of days at most, which can be survived. Only the first time I didn’t think and didn’t clean the shower, as a result the coating was ruined. I don't make these mistakes anymore.

It would be as simple as it is written... I couldn’t cope, I did about the same thing, and in the end: leveling and sanding it myself is hellish work. Puttying requires experience and dexterity, and applying enamel is actually something fabulous, because the enamel has slipped off the walls and the bottom has become thick. The miser pays twice (that's me to myself). I had to call the master and listen to a lot of interesting words from the bathroom about my golden little hands and my smart little head. Recommendation from me: if you don’t know how, don’t try it.

Can these methods be applied to a shower tray? Or are these just bathroom tips?

In principle, the advice can be applied to the restoration of shower trays, only taking into account the design features of the product. Here you also need to understand what your shower tray is made of. If it is acrylic, then it cannot be enameled; it must be coated with acrylic.

Whereas you can cover a metal tray with enamel or liquid acrylic at your discretion. The rules for surface treatment and preparation are the same as for bathrooms.

I would also like to note that sometimes a limescale deposit forms on the pallet, which many people mistake for a peeling enamel coating. In this case, it is enough to simply use cleaning products, for example Domestos, which is sold in almost any store.