The toilet tank is leaking: what to do if a leak is detected

Any plumbing fixture should work well, and this is an axiom.If the toilet tank is leaking but no water gets on the floor, the breakdown won't cause much of a problem until it's time to pay your utility bills.

Leaks are expensive, so they should be fixed as soon as they appear. It is not necessary to call plumbers; you can do everything yourself if you understand in detail the cause of the breakdown and how to eliminate it. This is what we will do in this article by examining the design and operating principle of the cistern.

We will also analyze in detail the popular types of breakdowns that result in a leaking tank, and provide recommendations for repairs.

The content of the article:

How does a cistern work?

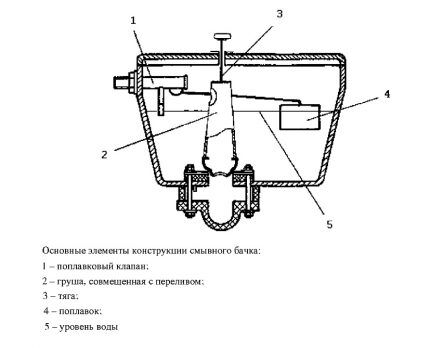

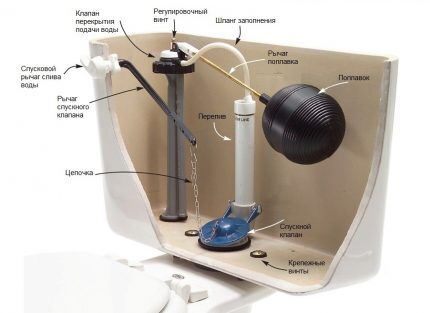

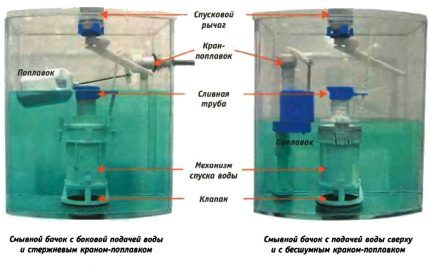

To repair a cistern, you need to understand its design and operating principle, and how to diagnose problems. It consists of several parts: body, float and drain valves, overflow, drain lever.

The float (fill) valve regulates the water level in the container. When the water leaves, the valve pulls the shut-off part down, thereby opening the fitting. Gradually, the tank fills with water, and the float valve rises and blocks its access.

The overflow function protects the container from overfilling. The part is a hollow column into which water is collected. As soon as it rises to the upper edge of the column, it begins to flow into the toilet bowl.

The drain valve closes the drain hole to allow the tank to fill with water. When the hatch opens, it flows into the toilet. The operation of the valve is controlled by the drain lever. This is a multi-part assembly that resembles a rocker arm. Pressing its free edge leads to the opening of the hatch. If you release the lever, the hatch lowers again. We looked at the device of the shut-off and inlet valve for the toilet in more detail. In this article.

The flushing mechanism can be made in the form of a button or lever, and it is located on the side or on top. Modern toilet models rarely use a lever. If there is one, then it can be activated by pulling the chain. If the drain mechanism is activated using a button, then it is placed on top - right in the center of the tank lid.

Leaks are caused by malfunctions in the operation of the tap, overflow and valve, so they should be checked first to determine the cause of the leak.

Methods for eliminating various types of leaks

There are several main types of leaks:

- Water does not stay in the tank. If the float valve does not hold water in the tank, it constantly flows into the toilet. This may be accompanied by noise. This breakdown leads to increased water consumption.

- Water flows out of the cistern onto the floor. This leak usually occurs between the tank and the bowl. A puddle forms on the toilet floor. Water accumulates and begins to flow to the neighbors below.

- Water leaks when it fills the cistern or drains into the toilet bowl. This leak is not permanent; it is detected when water is filled into the tank or drained. Most often, a leak indicates a malfunction of the drain mechanism.

The repair method depends on the type of leak. To determine which part is faulty, turn off the water, partially or completely disassemble the toilet cistern and inspect the mechanisms.

It is best to prepare in advance the tools that may be useful: gloves, wire cutters, pliers. Before inspecting the tank, you should not drain the water, because... in some cases it is needed for accurate diagnosis of a breakdown.

Option #1 - eliminating leaks from the tank into the toilet

If the toilet tank is constantly leaking and has trouble getting water into it, there is likely a problem with the flush mechanism. It is either damaged or some parts have shifted in it. Turn off the water supply and remove the lid from the tank to gain access to the mechanism.

First of all, check the location of the float: it should be level, and the part itself should move freely. It often happens that the usual displacement of the float leads to constant flow of water, because... The drain hole is not completely blocked.

In this case, it is enough to return the float to its place by bending the knitting needle or adjusting the height of the part using a gear bar, and the problem will be solved.

Make sure no water gets into the float. If you find excess liquid in it, carefully remove the part, pour out the water and find the crack through which it entered. Sometimes soldering irons are used for this, but the most convenient way to fix the leak is with plumbing sealant.

Clean, dry and degrease the surface of the float at the crack site, then apply sealant in a continuous line. After 5 minutes, smooth the seam either with a wet gloved finger or with a special soft spatula.

If the composition gets on other surfaces during work, it must be removed immediately. A damp cloth or napkin is suitable for this. After 20 minutes, the repaired part can be installed in place.

In some cases, it makes sense to simply replace the float valve. You can buy a new one at a hardware or hardware store. The repair is simple: unscrew the fasteners, remove the old float, install a new one in its place and secure it tightly with the old fasteners. We recommend that you read the instructions for adjusting and replacing the float.

The main thing is to choose a part of the same class as the old one. Floats can be designed for high, low or medium water pressure. If you make a mistake when choosing, it will be impossible to ensure normal operation of the float, even if it is in good order, because it will not be able to close the drain hole tightly.

Most often, repairing or replacing the float solves this type of leakage problem, but more complex breakdowns also occur. If you can't do it yourself, seek help from a professional plumber.

Option #2 - eliminating the leak between the tank and the bowl

If the design of the toilet involves a direct connection of the tank to the bowl, a leak may occur at the connection of the elements.

This happens for several reasons:

- loose tank fastenings;

- wear of gaskets;

- malfunction of the connecting cuff;

- mechanical damage to the drain tank;

- cracks or defects in the toilet shelf.

The first step is to check the strength of the tank. If the bolts are loose, they need to be tightened with an adjustable wrench. Tighten tightly, but carefully so as not to strip the threads, otherwise you will have to buy new fasteners. This is often enough to fix the leak.If not, check the cuff and gaskets.

If the connecting cuff is damaged, it is quite easy to diagnose. You need to take a dry napkin or piece of toilet paper and run it over it. The areas where wet marks will remain are damaged. As a temporary measure, they can be sealed with construction tape. To solve the problem, you should either replace the cuff or apply a special clamp.

If the cuff is heavily worn and longitudinal cracks appear on it, repair is a pointless exercise, because New leaks quickly form. The part should be replaced. If the line to the drain tank is rigid, you need to disconnect the float valve, unscrew the bolts securing the shelf, and remove the tank cover.

The cuff must be removed from the neck of the toilet. If that doesn’t work, you’ll either have to cut it off or remove the entire tank. You should only cut the cuff if you are sure that you will not use it again. Having removed the reservoir with the cuff, it should be turned upside down and the part should be replaced. You need to put the new cuff on the pipe with the side that has the smaller diameter.

Approximately a third of the length of the cuff should be located on the pipe, and two thirds - on the neck and in the space between the parts. The neck of the toilet bowl should be tightly covered with a cuff.

After replacing the part, all that remains is to put the tank in place, connect the float valve and tighten the screws. Try not to overtighten the nuts to avoid damaging the plumbing parts.

If the float valve is connected with a flexible hose, it does not have to be disconnected when replacing the cuff. It is enough to unscrew the screws and pull them out of the holes, remove the old part and carefully put on the new one. In this case, you need to lift the tank, so it is advisable to perform this operation together.

If the gaskets are worn out, they cannot be repaired and will have to be replaced. They are constantly in contact with water, withstand heavy loads, so over time they lose elasticity and cease to ensure tight connections.

First, remove the tank cap, after which the mechanisms are disassembled to get to the gasket. The old parts are removed and new ones are installed in their place, after which everything is reassembled in the reverse order. We advise you to look at the detailed instructions for selection and replacement of gaskets.

Sometimes leaks are caused by cracks and mechanical damage on the toilet shelf or in the cistern. If such defects appear, it’s time to think about buying a new plumbing fixture. As a temporary measure, you can seal the cracks with a special moisture-resistant glue for ceramic materials.

Option #3 - solving the problem of irregular leaks

It happens that leaks are not constant and appear only during certain periods. Such leaks have little effect on overall water consumption, but cause some discomfort. Let's figure out what to do if the toilet tank leaks when filling with water or when flushing.

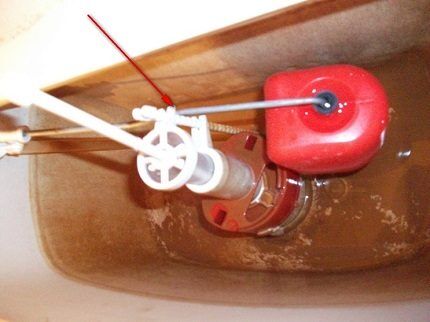

If you notice water leaking when you press the water release button, this means that the drain mechanism is faulty and needs to be repaired. First you need to check the locking valve. Remove the lid from the container and press the valve. If this stops the leak immediately, then replace the gasket and make sure it is sealed.

If the cause of the leak is not related to the gasket, check the nut that secures the tank to the pipe or shelf. Loose fasteners can simply be tightened, and if the threads are broken, replace the nut.

A leak may occur due to the drain button being misaligned. If it gets stuck, it interferes with the valve, and the valve does not close the drain hole. In this case, the button is simply corrected, returning it to its proper place - strictly in the center.

Sometimes the problem occurs because the button breaks. It should be replaced. For installation, you can use a universal plumbing fittings, which is suitable for almost all models and is available in any hardware store.

If you have another type of breakdown that we have not covered in this article, we recommend searching among typical tank malfunctions.

Instructions for replacing filling fittings

A complete replacement of the fittings is necessary if it is discovered that the fastenings are broken or the parts are badly worn. The toilet itself can last 10-20 years, but problems arise with the fittings more often.Depending on the quality of materials and operating conditions, it must be changed approximately every 5-10 years.

To work you will need:

- new set of fittings;

- measuring instruments (tape measure or ruler);

- a pair of adjustable wrenches;

- wrenches of suitable diameter.

Don't forget about rags or wipes for cleaning in case of water leakage.

Water enters the tank either from the side or from below, and the complexity of connecting the fittings depends on this. Repairing tanks with a bottom connection is complicated by the fact that the toilet and all the plumbing elements for it are located too close to the wall. There may be some difficulties in replacing water intake fittings due to the small space. The technology itself and the sequence of work do not change.

First of all, determine the diameter of the supply pipes. It is usually 10 or 15 cm (1/2 or 3/8 inch). You can measure the inner diameter using a tape measure or ruler. Measure the pipe itself or the distance between the edges of the nut securing the flexible hose. The obtained figures are used as a guide when purchasing new fittings.

Before installing the water intake fittings, you should turn off the water supply and flush what is already in the toilet. Next, remove the cover and get to work: holding the fitting with one hand, you need to unscrew it with a wrench and remove the nut that holds it.

Sometimes it is not possible to hold the reinforcement with your hand, because... the nut is too tight.Then you can hold it using a second wrench or a convenient grip from improvised means. In some cases, you have to shorten the wrench by cutting off a part with a grinder or other suitable tool.

After checking the gasket, install the new fittings so that there is a distance between it and the walls of the cistern container. All that remains is to connect the water and make sure the installation is correct.

If you need to adjust the position of the parts, this can be done by adjusting the position of the float or tightening the diaphragm valve nut. Valves with a rod valve will have to be adjusted a little longer. Rules for setting up fittings are discussed in next article.

How and with what can you seal a crack in a tank?

Most often, toilets and bathrooms are cramped spaces where you have to place a lot of appliances and necessary items. If something heavy falls on the tank, it may break and leak. The same thing can happen if there is an impact, a sudden change in temperature, or due to improper installation.

To seal cracks in ceramic and plastic tanks, universal moisture-resistant adhesives, plumbing sealants, and even cold welding are used.

The most reliable option is two-component epoxy resin. When choosing a composition, it is important to make sure that there is a mark on the packaging indicating its moisture resistance.

Work order:

- Dry the surface thoroughly: remove drops of water with a rag, and remove remaining moisture using a fan or hair dryer. Degrease with gasoline or acetone.

- In a small container, mix the resin and hardener or prepare another adhesive composition for use.

- Apply the composition to the surface. If possible, secure the damaged area (for example, with tape on the other side of the tank). Leave until completely dry.

When working with adhesives, pay attention to the manufacturer’s recommendations regarding temperature conditions, safety measures, and curing times for the compositions.

When the adhesive composition has hardened, all that remains is to carefully sand the seam with sandpaper (M20, M40 is suitable), and then with a piece of felt.

Have you encountered a breakdown of the flush cistern of a wall-hung toilet? Analysis of breakdowns is covered in detail in our article: Toilet installation repair: possible malfunctions and ways to eliminate them.

Conclusions and useful video on the topic

There are many models of cisterns. Externally, they may differ strikingly from each other, but the internal structure is approximately the same. Watch helpful videos that will make repairs easier.

Detailed video instructions on how to eliminate water leakage from the tank into the toilet:

Step-by-step instructions for replacing gaskets:

Guidelines for replacing water intake fittings:

Almost any toilet cistern leak can be dealt with on your own.But if the breakdown is serious, and you do not have the skills to handle tools or are afraid of damaging an expensive toilet model, call a plumber. Paying for a specialist will be much cheaper than buying new equipment.

Are you trying to figure out the cause of the breakdown that caused the toilet tank to leak? Maybe you have questions that were not answered in the material above? Ask them in the block below the article - our experts will try to help you.

Or maybe you are a professional repairer of toilet cisterns and want to share practical recommendations and personal secrets? Leave your opinion and add tips in the comments.

At first glance, everything seems to be fine, but water still leaks when filling the tank. I took it apart and looked, outwardly the fittings themselves are intact, the gaskets also seem to be normal, I went through the fittings themselves several times, but still, when installing, water begins to ooze out a little. I don’t even know, maybe I should buy new fittings? Maybe there are plumbers here, tell me where to dig?